Mild steel is one of the most common materials used in various industries across the globe because of its inexpensiveness and versatility. Its unique combination of mechanical properties, together with its cost efficiency, makes it an invaluable asset in construction, automotive, and machinery production. In this article, we aim to provide an insightful exposition of mild steel, which includes its grades, important characteristics, and diversified applications. Understanding these details would enable professionals and metalworking hobbyists to make the right choice with respect to using mild steel in different projects. Let’s delve into the details of this remarkable material and understand why it continues to be an engineering and manufacturing favorite.

What is Mild Steel and How is it Different from Other Steel Types?

Mild steel or low carbon steel is a classification of steel with around 0.05–0.25% carbon content by weight. When compared to high-carbon or alloy steels, its low carbon content makes it more ductile, malleable, and easier to weld. Unlike stainless steel, mild steel does not contain significant amounts of chromium, which means it lacks corrosion resistance. Protective coatings are needed in corrosive environments. Its strength, along with low cost and easy fabrication, makes mild steel highly sought after in construction and automotive parts manufacturing.

Defining Mild Steel

Mild steel, also known as low-carbon steel, is a type of carbon steel with a carbon content typically between 0.05% and 0.25%, making it ductile, weldable, and machinable, but less strong and resistant to corrosion compared to higher-carbon steels.

Comparison with Carbon Steel and Other Steel Types

Carbon steel is compared with mild steel, stainless steel, alloy steel, and tool steel based on properties like carbon content, strength, ductility, corrosion resistance, and applications.

| Parameter | Carbon Steel | Mild Steel | Stainless Steel | Alloy Steel | Tool Steel |

|---|---|---|---|---|---|

|

Carbon Content |

0.05-2.1% |

0.05-0.25% |

<1.2% |

Varies |

High |

|

Strength |

High |

Moderate |

Moderate |

High |

Very High |

|

Ductility |

Low-Moderate |

High |

Moderate |

Moderate |

Low |

|

Corrosion Resist. |

Low |

Low |

High |

Moderate |

Low |

|

Applications |

Structural, Tools |

Construction |

Medical, Food |

Industrial |

Cutting Tools |

Applications and Benefits of Mild Steel

Applications

- The construction industry for structural frameworks, such as beams and columns.

- The automotive industry for body panels and chassis components.

- Manufacturing machinery and equipment.

- Fabrication of pipelines and storage tanks.

- Production of household appliances, such as refrigerators and washing machines.

- Agricultural equipment, like plows and tractors.

- Shipbuilding for hull construction.

Benefits

- Excellent weldability allows for easy fabrication and joining.

- High ductility enables it to withstand considerable deformation before failure.

- Affordability makes it cost-effective for large-scale applications.

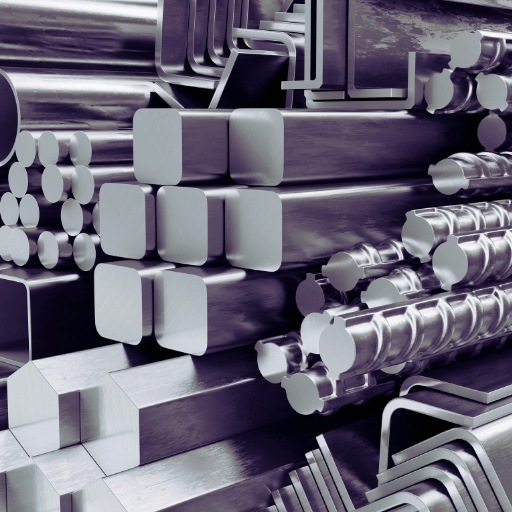

- Readily available in various shapes and sizes to meet diverse needs.

- Sufficient tensile strength suitable for handling considerable loads.

- Easily recyclable, contributing to environmental sustainability.

Exploring the Properties of Mild Steel

Understanding Mechanical Properties

Mild steel’s mechanical properties include tensile strength, yield strength, ductility, malleability, machinability, weldability, impact resistance, and moderate hardness.

| Property | Description |

|---|---|

|

Tensile |

Moderate (400-550 MPa) |

|

Yield |

Low (250-350 MPa) |

|

Ductility |

High stretchability |

|

Malleability |

Easily shaped |

|

Machinability |

Easy to cut/shape |

|

Weldability |

Excellent |

|

Impact |

Good resistance |

|

Hardness |

Moderate (120-160 Brinell) |

Key Chemical Composition

Mild steel primarily consists of iron with carbon (0.05%-0.25%), manganese, phosphorus, sulfur, and sometimes trace elements like silicon and copper.

Summary Table of Key Chemical Composition Parameters

| Parameter | Details |

|---|---|

|

Iron (Fe) |

Base element |

|

Carbon (C) |

0.05%-0.25% |

|

Manganese |

0.3%-1.6% |

|

Phosphorus |

≤0.04% |

|

Sulfur (S) |

≤0.05% |

|

Silicon (Si) |

≤0.6% |

|

Copper (Cu) |

≤0.55% |

Role of Low Carbon Content and Its Impact

The low carbon content in mild steel significantly influences its mechanical properties and overall performance, making it a versatile material for numerous industrial applications. Carbon, as a key alloying element, determines the hardness and ductility of steel. With a carbon content ranging between 0.05% and 0.25%, mild steel maintains a balance between strength and malleability. This makes it more ductile and easier to weld, cut, and form compared to higher-carbon steels.

From the latest data on material engineering properties, low carbon levels in mild steel result in enhanced machinability and reduced brittleness, ideal for construction applications such as beams, plates, and reinforcing bars. Furthermore, low carbon inhibits crack propagation during mechanical stresses, ensuring reliability and safety in structural designs. However, the trade-off is that mild steel exhibits lower tensile strength than higher-carbon counterparts, often necessitating surface treatments or alloying with elements like manganese to enhance strength while retaining its ductility.

What Are the Different Grades of Mild Steel?

Overview of Popular Steel Grades: EN8, EN1A, EN3B

EN8, EN1A, and EN3B are popular steel grades known for their specific properties and applications: EN8 is a medium carbon steel with good tensile strength, EN1A is a free-cutting mild steel ideal for machining, and EN3B is a general-purpose mild steel suitable for welding and machining.

Here’s a concise table summarizing their key points:

| Grade | Type | Carbon | Strength | Machining | Welding | Uses |

|---|---|---|---|---|---|---|

|

EN8 |

Medium |

0.4% |

High |

Moderate |

Limited |

Shafts, studs |

|

EN1A |

Mild |

Low |

Low |

Excellent |

Limited |

CNC parts |

|

EN3B |

Mild |

Low |

Moderate |

Good |

Excellent |

General use |

Characteristics and Uses of Each Mild Steel Grade

Mild steel grades vary in carbon content and properties, offering diverse uses such as construction, automotive, machinery, and household applications.

Summary Table of Mild Steel Grades

| Grade | Carbon (%) | Key Property | Typical Use |

|---|---|---|---|

|

1008 |

<0.1 |

Formability |

Auto bodies |

|

1010 |

0.08-0.13 |

Magnet cores |

Electrical |

|

1015 |

0.13-0.18 |

Wear-resistant |

Machinery |

|

1018 |

0.14-0.2 |

Carburizing |

Gears |

|

1020 |

0.17-0.23 |

Strength/Ductile |

Shafts |

|

S275JR |

0.25 |

Structural |

Frames |

|

S355JR |

0.23 |

Toughness |

Heavy machinery |

|

C22 |

0.18-0.23 |

Machinability |

Camshafts |

|

C45 |

0.42-0.50 |

High strength |

Axles |

|

EN1A |

0.15 |

Free machining |

Bolts |

|

EN3B |

0.16-0.24 |

Precision |

Machine parts |

How to Choose the Right Grade of Steel for Your Project

When selecting the right grade of mild steel for your project, I consider a few critical factors. First, I assess the mechanical requirements, such as the need for strength, ductility, or machinability. For applications requiring precise machining or threading, I often opt for grades like EN1A due to their excellent machinability. Alternatively, for components subjected to higher stress or requiring durability, EN8 is a strong choice because of its improved tensile strength. I also evaluate environmental conditions, such as exposure to moisture or corrosive agents, and look into whether additional surface treatments or alloying will be necessary for the grade I choose. Ultimately, ensuring the steel grade aligns with the functional demands and operating conditions of the project is key to achieving a reliable and cost-effective outcome.

How Does Weldability and Machinability Affect Mild Steel Usage?

Examining Weldability and Its Importance

Weldability is a critical property when considering the application of mild steel in various construction and manufacturing projects. It refers to the ease with which the material can be welded without compromising its structural integrity or performance characteristics. According to the latest data, mild steel exhibits excellent weldability due to its low carbon content, typically around 0.05% to 0.25%. This low carbon concentration minimizes the risk of hardening during welding, reducing the possibility of cracking or distortion in the heat-affected zones. Additionally, mild steel’s relatively uniform microstructure allows for consistent welding results across a variety of techniques, including shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and submerged arc welding (SAW).

The importance of weldability lies in its direct impact on productivity and material performance. Materials with high weldability, such as mild steel, can be processed efficiently with less need for pre-treatment or post-weld heat treatment, contributing to cost and time savings. Furthermore, the superior weldability of mild steel ensures strong and durable joints, which are essential for applications ranging from automotive manufacturing to large-scale infrastructure projects. This combination of versatility, cost-effectiveness, and reliability makes mild steel one of the most popular materials in modern engineering and construction industries.

Factors Influencing Machinability of Mild Steel

- Material Composition: Variations in the carbon content and alloying elements such as manganese, sulfur, and phosphorus can significantly affect the machinability of mild steel. Higher sulfur content, for example, can improve machinability due to the formation of manganese sulfide inclusions.

- Microstructure: The grain size and phase distribution within the steel influence cutting performance. Fine-grained microstructures generally improve machinability by reducing tool wear and producing smoother surfaces.

- Heat Treatment: The presence or absence of heat treatment alters the hardness and ductility of the material, which in turn impacts machinability. Annealed mild steel, for instance, is typically easier to machine.

- Surface Finish: The condition of the raw material’s surface, such as whether it is hot-rolled or cold-rolled, affects tool performance and cutting efficiency.

- Cutting Speed and Feed Rate: The parameters of the machining operation, including the speed at which the cutting tool operates and the feed rate, directly influence material removal rates, surface quality, and tool life.

- Tool Material and Coating: The type of tool material (e.g., high-speed steel, carbide) and any special coatings (e.g., titanium nitride) significantly impact the tool’s ability to cut through mild steel efficiently and resist wear.

- Coolant and Lubrication: The use of appropriate cutting fluids enhances heat dissipation, reduces friction, and improves surface finish, thus promoting better machinability.

- Workpiece Hardness: Variations in hardness across the mild steel workpiece, often caused by prior processing, can lead to inconsistent cutting performance.

- Machining Environment: Vibrations, machine rigidity, and alignment of the workpiece directly affect precision and overall machinability.

Techniques for Improved Machining and Fabrication

Mild steel’s excellent weldability and machinability make it versatile for various applications, while techniques like heat treatment, surface coating, and precision machining enhance its fabrication and performance.

Advantages of Using Low-Carbon Steel in Construction

Benefits of Low Carbon Content in Structural Steel

- Enhanced Ductility: Low carbon content improves the ductility of structural steel, allowing it to deform under stress without cracking or failing.

- Ease of Welding: Low-carbon steel has excellent weldability, reducing the risk of brittleness or cracking at welded joints.

- Improved Machinability: Materials with lower carbon content are easier to cut, drill, and machine, making fabrication processes more efficient.

- Resistance to Brittle Fracture: Structural steel with low carbon content is less prone to brittle fractures, even in low-temperature environments, enhancing safety in diverse applications.

- Corrosion Resistance (with Proper Treatment): Though inherently corrosion-resistant properties depend on additional alloying elements, low-carbon content allows for better compatibility with protective coatings.

- Cost-Effectiveness: The reduced carbon percentage simplifies production processes, resulting in a cost-effective material for large-scale projects.

- Consistency and Predictability: Low carbon content ensures a more uniform microstructure, providing reliable performance and simplifying quality control during construction.

Exploring Corrosion Resistance and Ductility

Low-carbon steel is advantageous in construction due to its enhanced corrosion resistance, high ductility, ease of welding, and affordability.

Comparative Analysis with Higher Carbon Steels

Low-carbon steel offers advantages like enhanced workability, corrosion resistance, durability, sustainability, and cost-effectiveness compared to higher-carbon steels.

Here’s a concise table summarizing the key points:

| Parameter | Low-Carbon Steel | High-Carbon Steel |

|---|---|---|

|

Workability |

High |

Low |

|

Durability |

Moderate |

High |

|

Corrosion |

Resistant |

Less resistant |

|

Cost |

Low |

High |

|

Sustainability |

High |

Moderate |

|

Brittleness |

Low |

High |

|

Weldability |

Easy |

Difficult |

|

Strength |

Moderate |

High |

Frequently Asked Questions (FAQs)

Q: What are the physical properties of mild steel?

A: Mild steel and low carbon steel share ductility, toughness, and weldability. Physically, mild steel possesses moderate tensile strength, superior formability, and good impact resistance. It can be easily machined, hot rolled, or cold drawn, which adds to its usefulness.

Q: What are the chemical properties of mild steel?

A: The composition of mild steel contains mostly iron and carbon, approximately 0.25% carbon, which is low. Additionally, mild steel contains small amounts of manganese that increase strength and hardness. These chemical characteristics make it ductile, weldable, and adaptable in many fields.

Q: How does mild steel differ from other types of steel?

A: Unlike low carbon, medium, and high carbon steel, mild steel contains around 0.25% carbon, which makes it classified as low carbon. While mild steels are preferred for high ductility and easy weldability, it does not possess as high tensile strength and wear resistance when compared to other steels.

A: EN8 steel or EN 1.1121 is classified as medium carbon steel, which differs from mild steel due to its greater carbon content. It is more tensile and harder, making it possible to manufacture components that need to be strong and wear-resistant. EN8 steel differs from mild steel in that it can be heat-treated to improve its mechanical properties even further.

Q: How is galvanised mild steel different from regular mild steel?

A: Galvanized mild steel is coated with a layer of zinc, which protects it from corrosion. This makes the steel galvanised, which can be used safely outdoors and in industrial places where water and other corrosive substances may attack the steel structure.

Q: What applications is mild steel commonly used for?

A: Due to mild steel’s versatility and low price, it can be used in construction and the automotive industries. Mild steel is a product that is offered as round bars and free-cutting steel, too. Its good weldability and formability broaden its use in structural engineering.

Q: Is it true that mild steel can be welded easily?

A: Mild steel can be welded easily. Since mild steel contains a low level of carbon, it can be welded without the risk of cracking. This type of steel is used for welding in the construction and automotive industries.

Q: What are the benefits of using mild steel in construction?

A: In terms of construction, mild steel has the benefits of a high strength-to-weight ratio, good weldability, ductility, and versatility. This type of steel can be fabricated into different shapes and sizes, such as beams and round bars, and is used in the construction of buildings, bridges, and other structures.

Q: For what application is a round bar made from mild steel applied?

A: A Round bar made from mild steel is widely used in the manufacturing and construction industries. It can be used as a raw material by CNC machining and laser cutting to make parts of different components used in various industries. Round bars are needed in many sectors for accurate measurements and strength.

Q: What role do alloying elements play in mild steel?

A: With alloying elements such as manganese, moderate steel can have its mechanical properties, like tensile strength and hardness, further developed. These elements aid in performing better in mild steel for some engineering uses, without altering essential properties like ductility and weldability.

Reference Sources

1. Title: The Inhibitory Properties of Lemon Balm (Melissa officinalis) Boiling Extract on the Corrosion of Mild Steel in Sulphuric Acid Medium

- Authors: P.A. Nikolaychuk et al.

- Publication Date: March 1, 2024

Key Findings:

- This study assesses the potential of lemon balm extract as a corrosion inhibitor for mild steel in 0.5 M sulfuric acid solution.

- It was demonstrated that the addition of extract in the concentration of 100 mg/L decreased the corrosion rate by 15%, and with a concentration of 10 g/L/, this increased to 75% reduction.

- The adsorption isotherm of the extract components on the steel surface fits the Langmuir model, which suggests a mechanism of physical adsorption.

- The Gibbs energy of adsorption was calculated and was less than -20 kJ/mol, thus affirming the physical nature of this adsorption.

Methodology:

- Corrosion inhibition effectiveness was assessed using some electrochemical techniques and electrochemical impedance spectroscopy EIS (Nikolaychuk et al., 2024).

2. Corrosive Inhibition of Mild Steel in Eriobotrya Japonica Lindl. Sulfuric Acid Solutions

- Authors: Zheng Xingwen et al.

- Published On: 14TH June 2018

Main Results:

- The extract of the loquat leaves demonstrates the behavior of a mild cathodic inhibitor and reaches maximum inhibition efficiency of 96 % at 100% V/V concentration.

- Higher temperatures resulted in lower efficiency of inhibition.

- The adsorption of the extract is consistent with the Langmuir adsorption isotherm for corrosion of mild steel.

Approach:

- The authors made SEM observations of the surfaces of the specimens, evaluated their electrochemical behavior, and recorded their weight loss, classifying them into groups with varying concentrations of plant extracts (Zheng et al., 2018).

3. Corrosion Inhibition of Mild Steel in 1M HCl by D-Glucose Derivatives of Dihydropyrido [2,3-d:6,5-d′] Dipyrimidine-2, 4, 6, 8(1H,3H, 5H,7H)-tetraone

- Authors: C. Verma et al.

- Publication Date: 03/20/2017

Main Considerations:

- The examination of these compounds revealed a mixed kind of inhibition, predominantly cathodic.

- The inhibitory compounds adsorbed onto mild steel surfaces per the Langmuir adsorption isotherm.

Approach:

- This study utilized gravimetric, electrochemical, surface analysis, and quantum chemical calculations within the overarching framework of the corrosion inhibition degr……..(Verma et al., 2017).

4. Material Overview • ANSI – This document contains material standards for EN classifications, among other things.

5. A new corrosion inhibitor and its development tested on mild steel – An investigation on industrial uses of mild steel and mild steel corrosion inhibitors.

6. Carbon steel