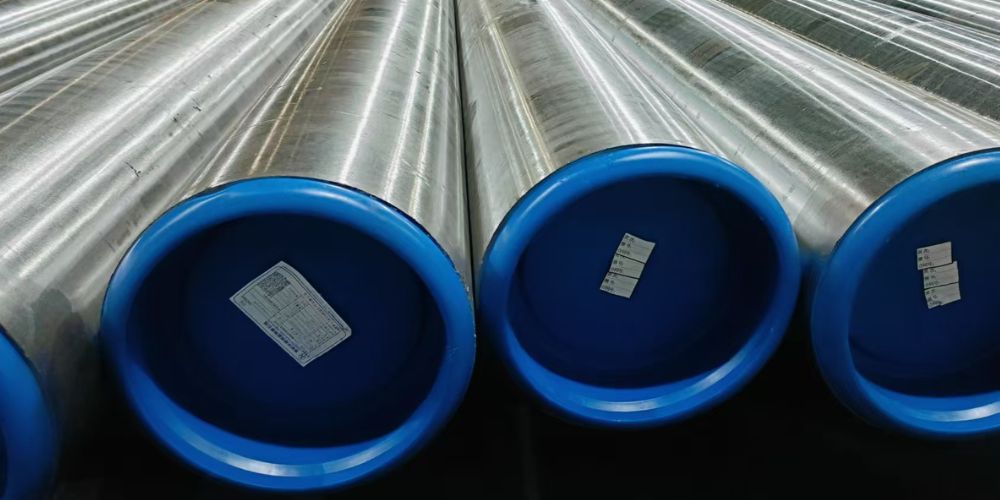

A335 P22 Material Pipe

Your A335 P22 Pipe Supplier

Balingsteel Is Your Professional Chinese A335 P22 Pipe Supplier. Following Specifications According To ASTM, ASME/SA Standards:

Size: 1/8”~48”

Wall Thickness: Sch5, Sch40, Sch80, Sch160, XXS Or Customized Size

Length: 0.1m~24m.

Surface: Varnish Coating, Black Paint Coating, Woven Bag Packaging, Wooden Box Packaging, Steel Strapping

Production Type: Hot Rolled Or Cold Drawn,Normalizing Or Tempering

High-Quality A335 P22 Pipe

BalingSteel Has The World’s Most Advanced Production Technology And Data Management Process To Produce Your P22 Seamless Pipe. We Can Evenly Control The Wall Thickness Of Your Steel Pipe To Ensure That The Average Wall Thickness Deviation Does Not Exceed 1%. By Accurately Controlling The Wall Thickness Of The Alloy Pipe P22, You Can Save Your Costs And Help Your Project. Please Contact Us ASAP.

Fast Delivery

As An Automated Steel Company, BalingSteel Uses 5G Data And Big Data Analysis To Formulate Production Plans. We Can Ensure That Your Urgent Projects Can Be Delivered In Time And Alleviate Your Urgent Delivery Requirements. Usually Our Fastest Delivery Time For Large Quantities Is 20 Days. If There Are Other Special Circumstances, Please Contact Us As Soon As Possible To Get The Latest Delivery Plan.

A335 P22 Material Composition

A335 P22 Chemical Composition |

|

| Element | Content Range |

| Carbon (C) | 0.05-0.15% |

| Manganese (Mn) | 0.30-0.60% |

| Phosphorus (P) | ≤0.025% |

| Sulfur (S) | ≤0.025% |

| Silicon (Si) | ≤0.50% |

| Chromium (Cr) | 1.90-2.60% |

| Molybdenum (Mo) | 0.87-1.13% |

A335 P22 Mechanical Property |

|

| Property Parameter | Standard Requirement |

| Tensile Strength | ≥415 MPa (≥60 ksi) |

| Yield Strength | ≥205 MPa (≥30 ksi) |

| Elongation (50mm gauge length) | ≥30% |

A335 P22 Tolerance Requirements |

|

| Outside Diameter Tolerance | According to ASTM A999/A999M |

| Wall Thickness Tolerance | According to ASTM A999/A999M, typically ±12.5% |

Heat Treatment Requirements |

|

| Normalizing Temperature | 900-950°C |

| Tempering Temperature | 650-750°C |

Other Test |

|

| Ultrasonic Testing | ASTM A388 or ASTM E213 |

| Radiographic Testing | ASTM E94 |

| Magnetic Particle Testing | ASTM E709 |

| Liquid Penetrant Testing | ASTM E165 |

| Hydrostatic Test Requirements | P = 2ST/D P = Test pressure (MPa) S = Allowable stress (MPa) T = Nominal wall thickness (mm) D = Outside diameter (mm) |

Get Your A335 P22 Pipe

Please Feel Free To Ask Us About The Price Of P22 Alloy Steel Pipes. BalingSteel Will Provide You With The Best Service.