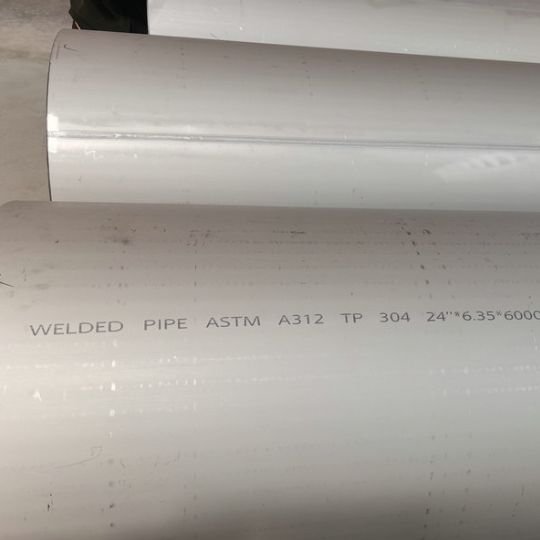

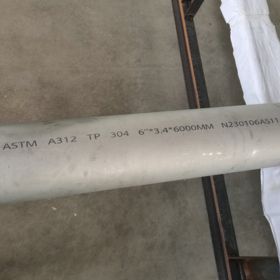

Stainless Steel Welded Pipe

Welded Stainless Steel Pipe Is The Most Common Petrochemical Product, With Welded Pipe And Stainless Steel Properties.

Because It Is Welded, The Price Is Relatively Low, The Base Material Is Stainless Steel Coil. It Has The Properties Of Stainless Steel To Resist High Temperature And Corrosion.

Balingsteel Can Supply Welded Stainless Steel Pipe In ASTM A312 / A312M, ASTM A249 / A249M, ASTM A554, and ASTM A270.

Recommended Products By Balingsteel

-

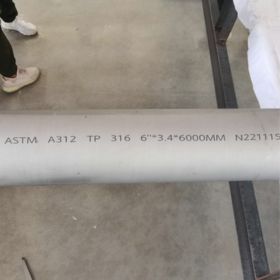

ASTM A312 Pipe

ASTM A312 Pipe

H-Q Stainless Steel Welded Pipe

Balingsteel Has a High-Quality Inventory of Stainless Steel Welded Steel Pipe for You to Choose From, Our Stainless Steel Welded Steel Pipe Has the Following Advantages:

Excellent Weldability, Moldability, Standardization, ABS, CSC, ISO, ASTM Standards and Certifications.

Reliable Corrosion Resistance in Accordance with NACE MR0175 / ISO 15156.

Wide Application

Balingsteel’s Stainless Steel Welded Pipes Are Used in a Variety of Industries, Such As Chemical Industry, Oil & Gas Industry, Power Generation Projects, Renewable Energy Industry, Pipeline System Projects, Medical Industry, Food Safety Industry, Resource Recovery Industry, Drinking Water & Wastewater Industry, Aviation Industry.

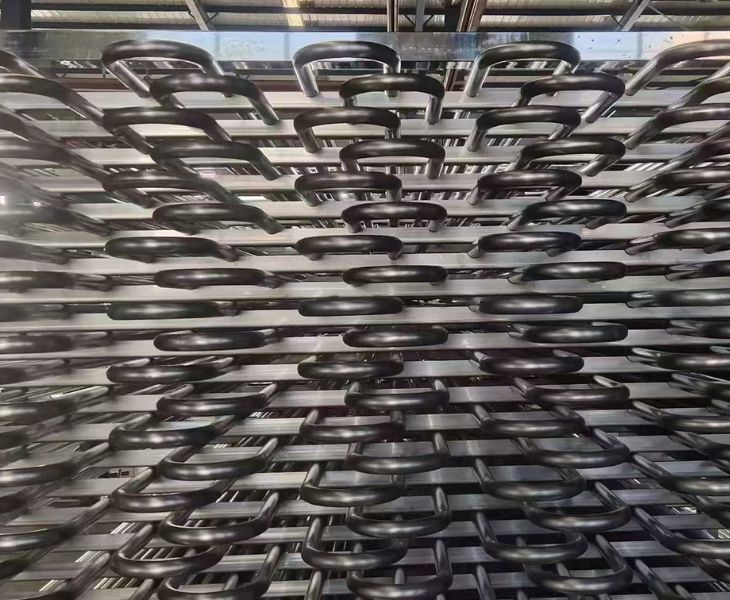

Customized Your Welded Stainless Steel Pipe

Balingsteel Can Customize Your Welded Stainless Steel Tubing:

- Bent Welded Stainless Steel Tubes for Boiler Condenser Equipment

- Cut Welded Stainless Steel Tubes to Meet the Different Lengths of Your Piping System.

If You Need Customization, We Are Your First Choice!

Types of Stainless Steel Welded Pipe

According to the Material Stainless Steel Welded Steel Pipe Can Be Divided into Austenitic Stainless Steel, Ferritic Stainless Steel, Martensitic Stainless Steel, and Duplex Stainless Steel, Please See the Following Classification Material:

304&304L Stainless Steel Welded Pipe

Widely Used in the Chemical, Petroleum, and Medical Industries, It Is the Most Common Material with a High Cost Performance.

310&310H&310S Stainless Steel Welded Pipe

It Is a Commonly Used Ferritic Stainless Steel and Is Generally the Most Cost-Effective Choice with High Durability.

316&316L Stainless Steel Welded Pipe

The Most Commonly Used Material, Can Be Used in Medical Aviation, Compared to 304 Performance Is More Superior, But the Price Is Relatively High.

317L&321&321H&347&347H Stainless Steel Welded Pipe

High-End Stainless Steel, Mainly Used in Aerospace, Chemical and Petroleum Fields, With Excellent Acid and Alkali Resistance and Durability.

Duplex 2205&31803 Stainless Steel Welded Pipe

It Has High Corrosion Resistance and Toughness and Is Widely Used in Petrochemical and Natural Gas Pipeline Projects.

Data Sheet

- 304/304L

- 310/310H/310S

- 316/316L

- 317

- 321/321H

- 347/347H

- 2205

304 Chemical Element Content (%) |

||||||||

| Constituent | C | Si | Mn | P | S | Cr | Ni | Mo |

| Min | – | – | – | – | – | 18 | 8 | – |

| Max | 0.08 | 1 | 2 | 0.045 | 0.03 | 20 | 10 | – |

304L Chemical Element Content (%) |

||||||||

| Constituent | C | Si | Mn | P | S | Cr | Ni | Mo |

| Min | – | – | – | – | – | 18 | 8 | – |

| Max | 0.035 | 1 | 2 | 0.045 | 0.03 | 20 | 12 | – |

304/304L Mechanical properties |

|||

| Condition | Tensile Strength | Yield stress | Elongation |

| σb | σs | δ | |

| Mpa | Mpa | % | |

| 304 | ≥515 | ≥205 | ≥40 |

| 304L | ≥485 | ≥170 | ≥40 |

310 Chemical Element Content (%) |

|||||||

| Constituent | C | Si | Mn | P | S | Cr | Ni |

| Min | – | – | – | – | – | 24 | 19 |

| Max | 0.25 | 1.5 | 2 | 0.045 | 0.03 | 26 | 22 |

310H Chemical Element Content (%) |

|||||||

| Constituent | C | Si | Mn | P | S | Cr | Ni |

| Min | 0.04 | – | – | – | – | 24 | 19 |

| Max | 0.1 | 0.75 | 2 | 0.045 | 0.03 | 26 | 22 |

310S Chemical Element Content (%) |

|||||||

| Constituent | C | Si | Mn | P | S | Cr | Ni |

| Min | – | – | – | – | – | 24 | 19 |

| Max | 0.08 | 1.5 | 2 | 0.045 | 0.03 | 26 | 22 |

310/310H/310S Mechanical properties |

|||

| Condition | Tensile Strength | Yield stress | Elongation |

| σb | σs | δ | |

| Mpa | Mpa | % | |

| 310 | ≥515 | ≥205 | ≥40 |

| 310H | ≥515 | ≥205 | ≥40 |

| 310S | ≥515 | ≥205 | ≥40 |

316 Chemical Element Content (%) |

|||||||||

| Constituent | C | Si | Mn | P | S | Cr | Ni | Mo | N |

| Min | – | – | – | – | – | 16 | 10 | 2 | – |

| Max | 0.08 | 0.75 | 2 | 0.045 | 0.03 | 18 | 14 | 3 | 0.01 |

316L Chemical Element Content (%) |

|||||||||

| Constituent | C | Si | Mn | P | S | Cr | Ni | Mo | N |

| Min | – | – | – | – | – | 16 | 10 | 2 | – |

| Max | 0.03 | 0.75 | 2 | 0.045 | 0.03 | 18 | 14 | 3 | 0.01 |

316/316L Mechanical properties |

|||

| Condition | Tensile Strength | Yield stress | Elongation |

| σb | σs | δ | |

| Mpa | Mpa | % | |

| 316 | ≥515 | ≥205 | ≥40 |

| 316L | ≥485 | ≥170 | ≥40 |

317 Chemical Element Content (%) |

|||||||||

| Constituent | C | Si | Mn | P | S | Cr | Ni | Mo | N |

| Min | – | – | – | – | – | 18 | 11 | 3 | – |

| Max | 0.08 | 0.75 | 2 | 0.045 | 0.03 | 20 | 15 | 4 | 0.1 |

317 Mechanical properties |

|||

| Condition | Tensile Strength | Yield stress | Elongation |

| σb | σs | δ | |

| Mpa | Mpa | % | |

| 317 | ≥515 | ≥205 | ≥35 |

321 Chemical Element Content (%) |

More | ||||||||

| Constituent | C | Si | Mn | P | S | Cr | Ni | N | Ti:5(C+N)~0.70 |

| Min | – | – | – | – | – | 17 | 9 | – | |

| Max | 0.08 | 0.75 | 2 | 0.045 | 0.03 | 19 | 12 | 0.01 | |

321H Chemical Element Content (%) |

More | ||||||||

| Constituent | C | Si | Mn | P | S | Cr | Ni | N | Ti:4(C+N)~0.70 |

| Min | 0.04 | – | – | – | – | 17 | 9 | – | |

| Max | 0.01 | 0.75 | 2 | 0.045 | 0.03 | 19 | 12 | 0.01 | |

321/321H Mechanical properties |

|||

| Condition | Tensile Strength | Yield stress | Elongation |

| σb | σs | δ | |

| Mpa | Mpa | % | |

| 321 | ≥515 | ≥205 | ≥40 |

| 321H | ≥515 | ≥205 | ≥40 |

347 Chemical Element Content (%) |

More | ||||||||

| Constituent | C | Si | Mn | P | S | Cr | Ni | N | Nb:10C~1.00 |

| Min | – | – | – | – | – | 17 | 9 | – | |

| Max | 0.08 | 0.75 | 2 | 0.045 | 0.03 | 19 | 13 | 0.01 | |

347H Chemical Element Content (%) |

More | ||||||||

| Constituent | C | Si | Mn | P | S | Cr | Ni | N | Nb:8C~1.00 |

| Min | 0.04 | – | – | – | – | 17 | 9 | – | |

| Max | 0.01 | 0.75 | 2 | 0.045 | 0.03 | 19 | 13 | 0.01 | |

347/347H Mechanical properties |

|||

| Condition | Tensile Strength | Yield stress | Elongation |

| σb | σs | δ | |

| Mpa | Mpa | % | |

| 347 | ≥515 | ≥205 | ≥40 |

| 347H | ≥515 | ≥205 | ≥40 |

2205 Chemical Element Content (%) |

|||||||||

| Constituent | C | Si | Mn | P | S | Cr | Ni | Mo | N |

| Min | – | – | – | – | – | 22 | 4.5 | 3 | 0.14 |

| Max | 0.03 | 1 | 2 | 0.03 | 0.02 | 23 | 6.5 | 3.5 | 0.2 |

2205 Mechanical properties |

|||

| Condition | Tensile Strength | Yield stress | Elongation |

| σb | σs | δ | |

| Mpa | Mpa | % | |

| 2205 | ≥655 | ≥450 | ≥25 |

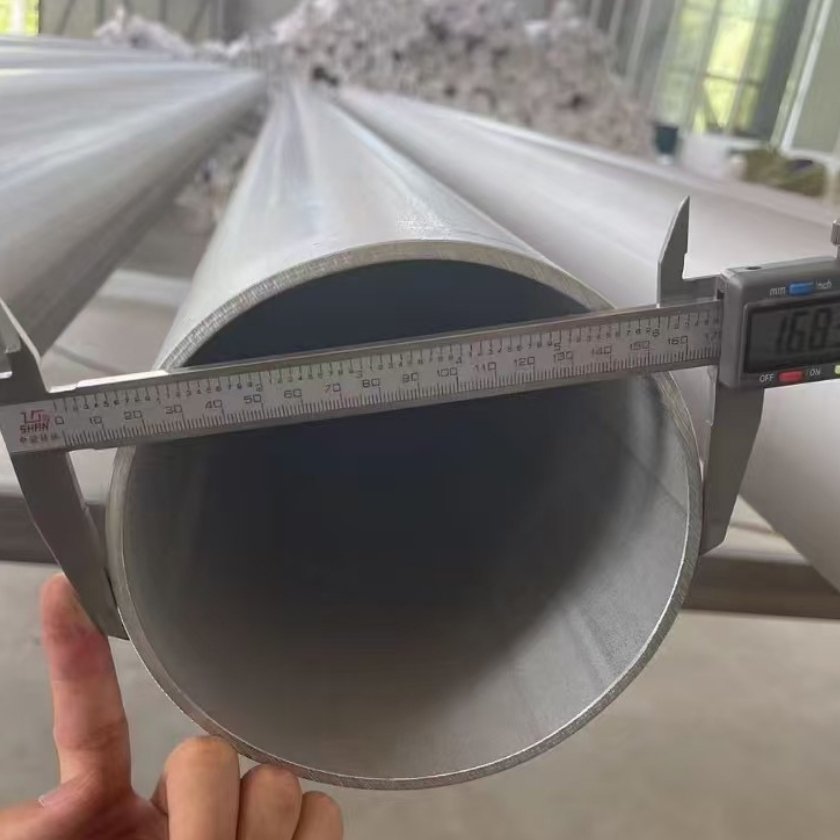

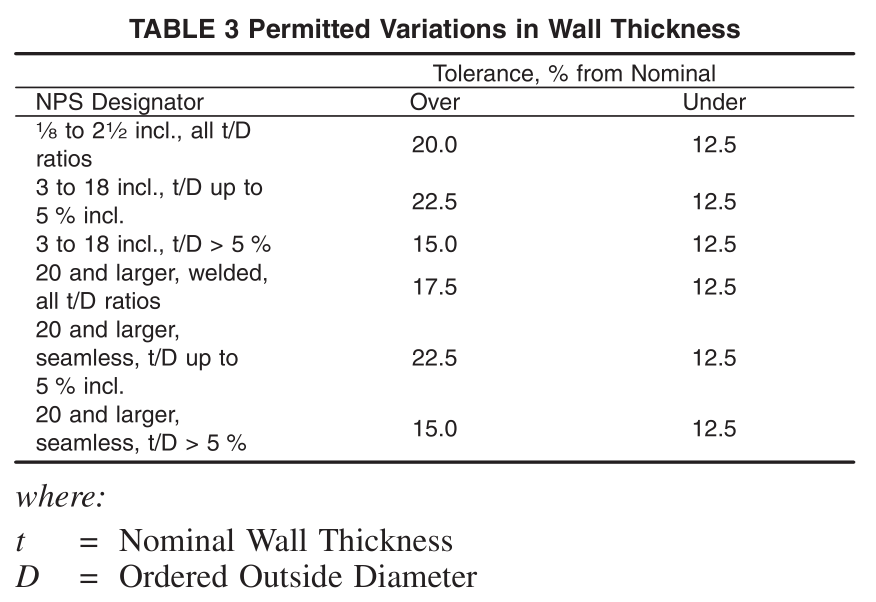

Stainless Steel Welded Pipes Under Different Standards Have Different Tolerance Requirements, Such as ASTM A312 Allowable Range as Shown in the Table Below:

For Further Information on Wall Thickness Caliber Tolerances, Please Contact Us!

Its Customs Code Is 7306, If There Are Different Usage Scenarios, We Can Discuss with You to Choose the Customs Code Accordingly.

The Smaller of OD and the Thicker of WT Stainless Steel Welded Pipe, The Greater Its Hydraulic Pressure Value, We Will According to the Customer and the Standard Requirements of the Hydraulic Pressure Test.

Available Sizes and Weight

We Can Apply the Following Formula to Calculate the Meter Weight——[Outer Diameter – Wall Thickness] X Wall Thickness X 0.02466 = Weight per Meter (Kg), Such as OD:168.3MM, WT:7.11M M, Its Meter Weight Is (168.3-7.11)*7.11*0.02466=28.26KG/M.

| Available Sizes | |||

| OD | WT | OD | WT |

| Φ33.7 | 1.8-2.0 | Φ139.7 | 2.5-2.75 |

| 2.1-2.4 | 3.0-4.5 | ||

| 2.5-3.25 | 4.75-5.75 | ||

| 3.5-3.75 | 6.0-7.75 | ||

| 4.0-4.25 | 8.0-10.0 | ||

| Φ42.3 | 1.8-2.0 | Φ146 | 2.5-3.0 |

| 2.1-2.4 | 3.25-5.75 | ||

| 2.5-3.5 | 6.0-8.75 | ||

| 3.75 | 9.0-10.0 | ||

| 4.0-4.25 | Φ159 | 2.5-2.75 | |

| Φ48.3 | 1.8-2.0 | 3.0 | |

| 2.1-2.4 | 3.25-6.75 | ||

| 2.5-3.25 | 6.8-8.5 | ||

| 3.5 | 8.6-10.0 | ||

| 3.75 | 10.25-11.75 | ||

| 4.0-4.25 | Φ165 | 2.5-2.75 | |

| 4.5-4.75 | 3.0-3.2 | ||

| Φ60.3 | 1.8-2.0 | 3.25-4.5 | |

| 2.1-2.4 | 4.75-5.25 | ||

| 2.5-3.5 | 5.5-6.75 | ||

| 3.75-4.0 | 7.0-10.0 | ||

| 4.25-4.75 | Φ168.3 | 2.75 | |

| 5.0-7.0 | 3.0-3.25 | ||

| Φ76.1 | 2.5-2.75 | 3.5-6.0 | |

| 3.0-4.0 | 6.25-8.0 | ||

| 4.1-4.75 | 8.25-9.75 | ||

| 4.8-5.25 | 10-11.75 | ||

| 5.5-6.0 | Φ177.8 | 2.75 | |

| 6.25-7.0 | 3 | ||

| Φ88.9 | 2.5-2.75 | 3.25-3.5 | |

| 3.0-4.0 | 3.75-6.00 | ||

| 4.25-4.75 | 6.25-8.75 | ||

| 5.0-5.25 | 9.0-9.75 | ||

| 5.5-6.5 | 10.0-11.75 | ||

| 6.75-7.75 | Φ194~Φ203 | 2.75 | |

| 8-9.5 | 3.0 | ||

| Φ102 | 2.2-2.4 | 3.25-3.75 | |

| 2.5-3.0 | 4.0-6.75 | ||

| 3.25-4.50 | 6.8-9.75 | ||

| 4.75-5.75 | 10-11.75 | ||

| 5.8-6.25 | Φ190.7~Φ216.3 | 2.75 | |

| 6.5-7.5 | 3.0 | ||

| 7.75-9.75 | 3.25-3.75 | ||

| Φ108 | 2.3-3.0 | 4.0-6.75 | |

| 3.25-4.50 | 6.8-10.0 | ||

| 4.75-5.75 | 10.25-12.0 | ||

| 5.8-6.25 | Φ219 | 5.0-11.98 | |

| 6.5-7.5 | |||

| 7.75-11.75 | |||

| Φ114.3 | 2.2-2.5 | Φ273 | 4.78-11.98 |

| 2.75-4.0 | 12-13.98 | ||

| 4.25-4.75 | Φ299 | 5.5-11.98 | |

| 5.0-6.25 | 12.0-13.98 | ||

| 6.5-8.0 | Φ325 | 5.08-11.98 | |

| 8.25-11.75 | 12.5-13.98 | ||

| Φ121 | 2.5-2.75 | Φ355 | 5.5-11.98 |

| 3.0-4.75 | 12.0-13.98 | ||

| 5.0-5.75 | Φ377 | 5.5-11.98 | |

| 6.0-7.25 | 12.0-13.98 | ||

| 7.5-11.0 | Φ406 | 5.5-11.98 | |

| Φ133 | 2.5-2.75 | 12-13.98 | |

| 3.0-5.0 | Φ426 | 5.5-11.98 | |

| 5.25-6.75 | 12-13.98 | ||

| 7.0-9.75 | Φ457 | 5.75-11.98 | |

| If You Don’t Find the Size You Need or You Need a Customized Size, Please Contact Us Today! | 12-13.98 | ||

| Φ508 | 5.75-11.98 | ||

| 12-13.98 | |||

| Φ610 | 6-11.98 | ||

| 12-13.98 | |||