When considering well-rounded and recognized materials in various fields of industry, 4130 chromoly steel is frequently cited as a leading example. This alloy is ever popular because of its strength, light weight, and weldability, making it suitable for everything from aerospace parts to performance automotive components. But what exactly does 4130 chromoly steel offer that allows it to thrive in such harsh environments? In this guide, we will cover everything there is to know about 4130 chromoly steel: its distinguishing features, major benefits, frequent uses, and much more. Engineers and manufacturers will find practical ư information in this article, but so will anyone interested in sophisticated materials, as it explains in what ways 4130 chromoly steel plays a crucial role in contemporary construction and manufacturing around the globe.

What is 4130 Chromoly Steel?

4130 chromoly steel is a type of low-alloy steel because it contains chromium and molybdenum as alloying elements. It has a high strength-to-weight ratio, very good toughness, and welds well. The designation 4130 is based on its standardized chemical makeup, particularly the 0.30% carbon content, which offers a good balance between strength and workability. This steel chromoly alloy is widely used in the aerospace, automotive, and construction industries due to its dependable performance under stressful conditions.

Understanding Chromoly and Its Composition

Chromoly, or 4130 steel, is a low-alloy steel with chromium and molybdenum as the primary alloying elements. The alloying elements of chromoly include about 0.30% of carbon, which improves the strength of the steel without compromising the workability. This composition also provides chromoly with good durability, low weight, and weldability, which make it suitable for more demanding applications such as automotive parts, aircraft components, and bicycles.

How Does 4130 Chromoly Compare to Other Steel Grades?

When weighed against other categories of steel, 4130 Chromoly has an unrivaled combination of strength, weight, and flexibility. It surpasses 1018 carbon steel in boasting greater tensile strength—4130 having a tensile strength of 97,000 to 110,000 PSI while 1018 is approximately 64,000 PSI. This range makes 4130 alloys optimum for bearing loads and enduring high-stress conditions.

Moreover, his 4130’s lower carbon content renders it more weldable and machinable than numerous other high-strength Chromoly steels. Elements like Chromium and Molybdenum do, however, increase its wear, fatigue, and corrosion resistance, facilitating its widespread use in motorsport and aerospace industries.

Stainless steels like 304 are unrivaled in corrosion resistance owing to their higher chromium content. However, they tend to be denser and do not match 4130’s exceptional strength-to-weight ratio. Wrought tool steels, such as D2, have increased hardness but are too brittle to accommodate dynamic versatility. Structural alloy steels also exhibit some of 4130’s features, such as 4140, but are much harder and therefore less ductile, weldable, and more difficult to work with, making 4130 a more versatile option for multi-faceted applications.

The unique combination of strength, toughness, and versatility makes 4130 Chromoly an asset in applications where saving weight and having optimal mechanical performance are critical. Its profile sets it apart in an industry where enhancing durability while minimizing design and operational efficiency is key.

Why is 4130 Chromoly Popular in Various Industries?

4130 Chromoly is renowned in many fields because of its low cost, mechanical properties, and versatility. It contains Chromium and Molybdenum, two low alloy elements. With added alloys, it has better strength-to-weight ratios with increased toughness, fatigue resistance, and overall performance. These benefits make it very desirable where every ounce matters, especially for high-performance activities.

Aerospace is one of the major industries that employs 4130 Chromoly. Its unparalleled ability to withstand stress and fatigue over long periods is extremely useful for planes because providing high stress and fatigue is the last thing you want. For instance, 4130 is widely used in aircraft fuselages and in parts like the landing gear. It provides great reliability under extremely demanding load conditions, supporting its wide adoption. 4130’s tensile strength is also very appealing, often cited around 90-100 ksi in normalized conditions.

The automotive and motorsport industries have also adopted 4130 Chromoly. It is now used as the base material for roll cages, chassis, and suspension systems. The pliable nature of the material, coupled with its high yield strength, also make it a perfect candidate for being impact resistant while being able to be formed into complex shapes. Many racers have come to appreciate the light weight of the material as it increases vehicle performance and speed.

Furthermore, the material’s weldability advantageouly impacts fabrication processes. Engineers can impose intricate designs onto components without considerable detriment to the useful material properties after wedded treatment. Moreover, 4130 Chromoly is used by high-end bicycle manufacturers for the frames of expensive bicycles because it can absorb and withstand substantial forces while offering a smooth and durable ride, making it quite popular in the cycling and mountain biking industries.

For all these reasons, 4130 Chromoly has become widely adopted across numerous industrial sectors. This is made possible due to unmatched performance, ease of machining, and advanced fabrication adaptability. It is also easy to see why these attributes open the door for modern engineering challenges that involve strict requirements for safety, design, and durability.

What are the Characteristics of Chromoly?

Exploring the Mechanical Properties of 4130 Chromoly

4130 Chromoly is known for its remarkable strength in both ductility and tensile strength. Its normalized form has a tensile strength of about 90,000 psi, which provides chromoly excellent durability for applications that put it under great stress. The material exhibits a good elongation percentage, which provides good flexibility and resistance against cracking during deformation. It is also tough, which means 4130 can absorb impact energy without fracturing. Along with being weldable and easy machining, 4130 is versatile for many structural and performance-based applications.

The Role of Chromium and Molybdenum in Chromoly

Chromium and molybdenum are key alloying elements in 4130 Chromoly steel, each providing essential charactoristics that improve the performance and applications chromoly steel is used for. For example, the addition of chromium (Cr) improves the hardness and strength as well as the alloy’s ability to resist corrosion. Chromium also plays a major role in wear resistance, which is critical for any material that is eroded by abrasive forces during usage. Moreover, chromium adds to the steel’s capability to resist oxidation at elevated temperatures so that it can function in extreme environments for long periods.

On the other hand, molybdenum (Mo) is very important to improve the alloy’s strength, creep resistance, and toughness and is even greater at high temperatures with dynamically applied loads. Refined grain structure is also the result of molybdenum, which provides better consistency and mechanical strength of the steel. In addition, molybdenum greatly decreases the susceptibility to hydrogen embrittlement and ensures uniform hardenability to the material. The combination of properties from chromium and molybdenum guarantees that Chromoly is strong and can endure significant structural and dynamic impact-focused demands with remarkable resilience.

New developments in material science have measured the value of these constituents. Molybdenum has a lesser presence, constituting roughly 0.15-0.25% of the alloy. It is also known that Chromium usually constitutes 0.8-1.1% of the alloy. While percent composition amounts may appear trivial, the structural and performance impacts an alloy’s microstructure undergoes is profound, thus making Chromoly critical to the automotive, aerospace, and high-performance engineering industries.

Corrosion Resistance and Toughness Factors

The alloying elements synergistically contribute to the corrosion resistance of chromoly steel. It also enhances it to some degree, with Chromium being critical in the formation of a passive oxidation layer on the surface that mitigates oxidative damage even amid extreme environmental deterioration. Molybdenum adds to this by improving the resistance to localized corrosion, for example, pitting and crevice corrosion, which is especially advantageous in chloride-rich areas.

Chromoly exhibits enhanced impact toughness in combination with Molybdenum at approximately 70-100 Joules at room temperature, attributing this to the microstructure, which is crafted specifically for strength and ductility. Molybdenum charpy v-notch COR alloys sustain moderate load fragments without fracturing; chromoly’s yield strength is enhanced on top of this due to heat treatment, which uniformly withstands a wide temperature range, rendering it valuable for use in aerospace and motorsport applications where thermal shock, loading, and rapid temperature shifts are frequent.

Chromoly steel stands out as an adaptable and trustworthy material because of its unparalleled durability while enduring harsh conditions and extreme corrosive environments.

How is 4130 Chromoly Tubing Used in Applications?

Common Uses: From Bicycle Frames to Roll Cages

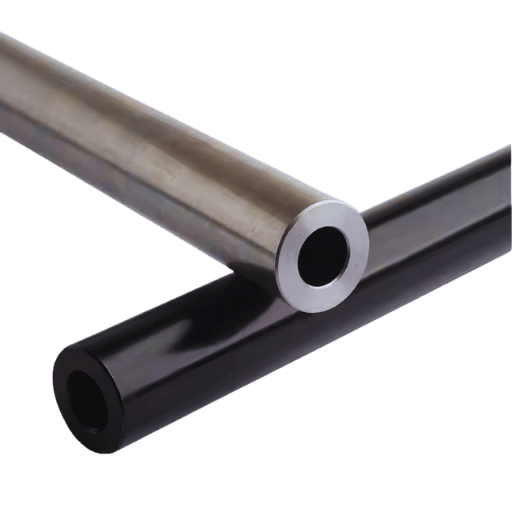

Utilized across various industries for its strength, lightweight properties, and durability, 4130 Chromoly tubing is commonly found in high-performance bicycle frames and used as material for roll cages in motorsports. Bicycle frames benefit from the strength-to-weight ratio that enhances performance and reliability, whereas roll cages require the material’s ability to withstand high-impact forces while maintaining structural integrity. These applications further demonstrate the versatility of 4130 chrome moly tubing alongside its safety-critical and performance-focused design capabilities.

Benefits of 4130 Chromoly Tubing in Automotive and Aerospace

4130 Chromoly Tubing is prized in the automotive and aerospace sectors because of the mechanical properties it possesses alongside its lightweight and reliable structure. It is also efficient, having a useful tensile strength of 90,000 to 110,000 psi. This provides proper performance under stress, which is helpful in automotive applications like chassis and suspension parts, providing safety and performance while withstanding impact.

The aerospace industry also benefits from the lightweight 4130 Chromoly along with other elements assembled in the tubing as it also helps to fuel aviation and augment payload while remaining strong. The structural integrity maintains with the unique composition of the tubing, comprising chromium and molybdenum which grants better resistance to fatigue and corrosion making it useful for the aircraft fuselage and legs.

Moreover, 4130 Chromoly Tubing is very easy to weld, providing practicality in assembly and servicing. This is essential for complex design creations like performance vehicle roll cages and aircraft high-load components. The recent technology developed for heat treatment further improves the strength and toughness of the material, ensuring reliability in harsh operational conditions. Its seamless integration into demanding industrial applications proves it is engineered to precise standards offe critical safety and performance.

Choosing the Right Chromoly Tubing Distributor

In choosing a chromoly tubing distributor, the following considerations will determine the quality and efficiency of your supply chain.

Compliance with Industry Standards

Distributors should offer chromoly tubing that meets iso-documented structural industry standards like ASTM A519 or AISI 4130. Certifications ensure that materials are compliant with the engineering and safety standards of specific applications for aviation, motorsports and industrial manufacturing.

Business Sustainability and Operational Risks

Ideal distributors implement strict quality control policies including non-destructive testing along with retention of material batch numbers. These measures not only help to ensure positive product outcome but also aid in early detection of failures ensuring lower spend during production.

Comprehensive Product Offering and Modification Flexibility

Find those that provide polyhedral catalogs and those offering specialized services that help minimize execution timelines through advanced project-specific machining that can be completed before order fulfillment, simplifying rare assembly.

Material Availability and Consistent Transit Times

Accuracy within set timelines is paramount while completing projects. A potential distributor needs to be evaluated based on how fast an order can be put together and how dependable transportation systems are with meeting expected dispatch dates. Global suppliers actively seek out trustable vendors with reliable networks to prevent delays due to a lack of resources or scheduling complications with shipping.

Competing Pricing Transparency

Analyze the market quotation of multiple distributors to account for the cost vs quality ratio. Pricing policies that include custom services such as cutting or heat treatment are easier for budgeting because they limit chances for hidden costs.

Client Support and Technological Knowledge

Select a distributor that offers prompt answering of client inquiries and technical support. Distributors with a staff of qualified engineers and other specialists are ideal for consulting about the choice of the materials, how to maximize their use, and whether they meet the industry standards.

Practices of Sustainable Development

With greening of this industry, the sustainable sourcing and supply chain management practices of distributors becomes increasingly important. Analyze also their policies concerning material recovery, energy consumption, and waste management as part of business operations.

Example Data for Chromoly Tubing Specifications

|

Specification |

Value Range |

Application Use Case |

|---|---|---|

|

Size Range |

OD 0.25in – 6in |

Roll cages, space frames, and structural builds |

|

Wall Thickness |

0.028in – 0.500in |

High-performance components, load-bearing parts |

|

Typical Yield Strength |

~70,000 psi |

Lightweight yet strong material applications |

|

Tensile Strength |

~90,000 psi |

Withstands high-stress environments |

By evaluating these factors, engineers and manufacturers can confidently select a chromoly tubing distributor that aligns with their operational needs, ensuring quality and performance across critical applications.

What are the Weldability and Fabrication Techniques for 4130 Chromoly?

Best Practices for Welding Chromoly Steel

When conducting the weld for 4130 chromoly steel, following certain outlined steps will help preserve the integrity and the overall functionality of the material:

- Clear The Area: For sections thicker than .12 inches, pre-heating needs to be done to about 300 degrees Fahrenheit. This will help reduce crack risks. Preheating is not required for thinner sections.

- Put in Place A Suitable Filler Material: To ensure ductility and weld brittleness, use ER70S-2 or any other recommended filler material that has a lower tensile strength than the base metal.

- Excessive Heat: Surrounding metal can become weaker due to excessive heating and should be avoided. Shorter weld passes should be utilized to achieve better control over the HAZ.

- Mild Cooling: Stress concentrations should be avoided for the welded area, meaning rapid cooling methods should not be employed.

- Post Weld Heat Treatment: After completing the weld, any critical application need to undergo a stress relief heat treatment to get rid of the residual flaws and enhance the overall toughness.

Implementing these steps will assist in achieving dependable and robust welds while preserving the 4130 chromoly steel’s structural properties.

Tips for Maintaining Structural Integrity During Fabrication

- Select Relevant Materials: Check that all materials satisfy the requirements as to their specifications, and that all are free of defects or imperfections.

- Observe Required Design Criteria: Follow preset design limits to ensure that components will not exceed the predetermined operational loads and stresses.

- Employ Proper Measuring Instruments: Use measuring and aligning tools that are precision calibrated for all stages of fabrication to ensure exact alignment.

- Conduct Routine Checks: Check at various stages both during and after assembly to check for form and other possible errors.

- Regulate the Conditions of Work: Control various conditions, such as temperature and humidity, that might adversely affect the properties of the material.

- Exercise Good Welding Practices: Apply correct welding methods; check the welds to ensure uniformity and strength, and to guard against weak areas.

- Check for Stress and Strain: Look at potential weak points for stress concentration and make additions as required.

Following general ‘best practices’ will enable the preservation of structural integrity during fabrication.

How Does 4130 Chromoly Fit into the Range of Steel Products?

Comparing Chromoly with Mild Steel and Stainless Steel

While assessing 4130 C romoly in terms of Weldability and strength, corrosion resistance, and weight. The first two factors, strength and weight, will be discussed in this section.

Strength-to-Weight Ratio

To begin with, Chromoly is an alloy steel composed of Chromium, Molybdenum, and some other elements. Mild Steel centers around 50,000 – 70,000 psi while Chromoly boasts a tensile strength of about 97,000 psi. So we could state that the latter is more resistant and durable. ranging from 70,000 to 220,000 psi for some grades of Stainless Steel, offers a diverse strength spectrum. Serverally notes that Mild Steel is weakest against abrasion, while chromoly pure steel performs best. This is crucial for its consideration in manufacturing purposes for needed components in motorsport or airplanes due to the reduced quality alongside an asserted strength.

Corrosion Resistance

Mild Steel ranges around No Protection whereas Stainless Steel offers portions of pseudoprotection like rust and oxidation shielding alongside claiming Chromoly as stronger than Mild Steel but weaker when it comes to protecting against abrasion while Mild Steel becomes weaker still.

Weldability and Fabrication

Due to its alloying elements, Chromoly possesses moderate weldability. Its proper techniques of welding, such as pre-heating and post-heating treatment, are done to minimize cracking risks. Mild Steel has a high degree of weldability and gives much more leeway during welding, so it lends itself to fabrication quite easily, especially for less demanding applications. Weldable Stainless Steel often bridges gaps with specific filler components but may require precise heat control to prevent warping and loss of corrosion resistance.

Applications and Cost

Some examples of Chromoly applications include aircraft components, bicycle frames, and racing car roll cages. Its usage spans nearly all domains that require high-strength structures. These projects require significant Mild Steel raw material at a lower price, so it is more often utilized in construction and general-purpose work for weaker applications. Weldable Stainless Steel regions include medical, food, and even marine industries due to its outstanding resistance towards rust. While priced much higher than Mild Steel, Chromoly, boasting high strength and low weight, still serves as a viable option in comparison to high-end Stainless Steel.

Evaluating these relevant points allows professionals to achieve performance, durability, and budget requirements concurrently by selecting materials tailored to their needs.

Understanding the Strength-to-Weight Ratio of 4130 Chromoly

4130 Chromoly’s strength-to-weight ratio is one of its most distinctive properties, as well as being highly sought after in areas where durability and weight are critical. 4130 Chromoly also has around 90,000 psi tensile strength in a normalized state, while its density is lower than many other high-strength steels. Because of this, it performs exceptionally well in harsh conditions such as the airframe of an aircraft, racing cars, and bicycles, which all require a fine balance between weight and structural soundness, bolstered by its unrivaled tensile strength of 90,000 psi.

Exploring Alloying Elements and Their Role in Chromoly

The alloying elements that procure Chromoly’s enhanced properties, it is also known as 4130 steel, are molybdenum and chromium. Chromoly derives its enhanced properties from the key alloying elements, primarily chromium and molybdenum. Chromoly is renowned for its remarkable combination of strength, toughness, and low weight, all of which enable it to excel in precision applications in demanding industries. This is achieved thanks to molybdenum, which increases the material’s strength by improving its hardenability and corrosion wear resistance. In turn, chromium increases the alloy’s resistance to corrosion and wear, especially in tough conditions.

Frequently Asked Questions (FAQs)

Q: What is 4130 Chromoly Steel?

A: 4130 Chromoly Steel is classified as low alloy steel because it contains chromium and molybdenum as the primary strengthening elements. This alloy possesses remarkable strength, an exceptional ratio of strength to weight, and is quite adaptable across numerous fields of use.

Q: How does 4130 Chrome Moly differ from standard steel?

A: 4130 Chrome Moly is different from standard steel because of its alloy composition. Unlike standard carbon steel, 4130 Chrome Moly includes chromium and molybdenum, which improve the mechanical properties of the alloy, including the strength, hardenability, and corrosion resistance.

Q: What are the common applications of 4130 Chromoly Round Tube?

A: The 4130 Chromoly Round Tube is used in numerous tubing applications such as automotive roll cages, light weight bicycle frames, components of aircraft fuselage structures, and other frameworks that require high tensile strength and low mass.

Q: Why is 4130 Chromoly Steel considered easy to weld?

A: 4130 Chromoly Steel is easy to weld because of the low carbon content along with its excellent weldability. It can be welded with TIG or other methods while maintaining structural integrity as long as proper preheat and post-weld thermal treatment are done.

Q: What is the advantage of using 4130 Chromoly Steel in the automotive industry?

A: In the automotive sector, 4130 Chromoly Steel is respected for its high tensile strength and superlative strength-to-weight ratio, which makes it useful in crankshafts and clutches where performance and durability are needed, as 4130 withstands extreme heat and pressure.

Q: In what way does the chromium content impact 4130 Chromoly Steel?

A: The chromium content in 4130 Chromoly Steel aids in the prevention of oxidation and corrosion, which increases the steel’s life and allows use in needed environments.

Q: Mention any two differences between 4130 and 4140 Alloy Steel.

A: Between 4130 and 4140 Alloy Steel, the most notable difference is the amount of carbon they both contain. 4140 has a higher amount of carbon which increases the alloy’s hardenability amd overall strength. 4130, on the other hand, is easier to weld and has a better strength-to-weight ratio.

Q: Is it possible for 4130 Chromoly Steel to be work-hardened?

A: It is possible for 4130 Chromoly Steel to undergo work hardening processes. It can be further enhanced by mechanical processes like cold working, which increases its hardness, as well as its tensile and yield strength.

Q: What factors should be taken into account when buying Chromoly Steel Products from a dealer?

A: While buying Chromoly Steel Products, take into account the dealer’s track record, professional history, claim to quality certifications, available alloy steel grades, and if they can supply tailored material matching project needs for fabricated components in terms of weight, strength, and resistance to oxidation and corrosion.

Reference Sources

1. Effects of Heat Treatment on Wear Properties of Chromoly Steel

- Authors: S. Meddah et. al.

- Published: 2023

- Journal: The Eurasia Proceedings of Science Technology Engineering and Mathematics

Summary of Findings:

- The research examined the effect of heat treatment (quenching and tempering) on the hardness, microstructure, and wear resistance of chromoly steel.

“The best result was achieved by quenching followed by tempering at 700ºC for 15 minutes which produced a microstructure of globular pearlite and a hardness value of 226HB.” - “Moreover, the sample tempered at 600ºC exhibited a 49% reduction in wear rate compared to the sample treated at 550ºC.”

- Also noted were several different wear mechanisms: abrasive wear in the untreated samples and adhesive wear in the heat treated samples.

Research Approach:

- Hands-on testing included processes to heat treat the samples and measure the samples’ hardness and resistance to wear as well as conduct a microstructural analysis. (Meddah et al., 2023)

2. WASPAS – Sunflower Optimization Algorithm Hybrid for Parameter Appraisal of Electrochemical Machining of AISI 4140 Chromoly Steel

- Authors: A. Barua et al.

- Published: 2023

- Journal: E3S Web of Conferences

Main Contributions:

- The focus of this study was the optimization of the ECM (electrochemical machining) process including surface roughness and MRR (material removal rate) for AISI 4140 chromoly steel.

- Critical factors have surfaced that show feed rate greatly influences surface roughness and MRR.

- Optimization techniques were able to provide sufficient accuracy in alignment with prior ECM research.

Methods Explained:

- Research incorporated hybrid methods with Taguchi, WASPAS, and Sunflower algorithms, completed with ANOVA for factor scrutiny (Barua et al., 2023).

3. Mechanical properties of Quenched Hardened Chromoly Steel using Taguchi Coupled WASPAS Technique

- Authors: Bibhu Prasad Kandi et. Al

- Published: Year 2021

- Journal: Materials for Today: Proceedings

Key Findings:

- The study focused primarily on the mechanical characteristics of Chromoly Steel that is quenched and hardened.

- This study reinforces the impact of performance optimization on primary mechanical features using Taguchi coupled with the WASPAS technique.

Methodology:

- An experimental evaluation of mechanical features was carried out, and results were optimized using the Taguchi method (Kandi et al., 2021).

4. Steel

5. Alloy

6. Corrosion