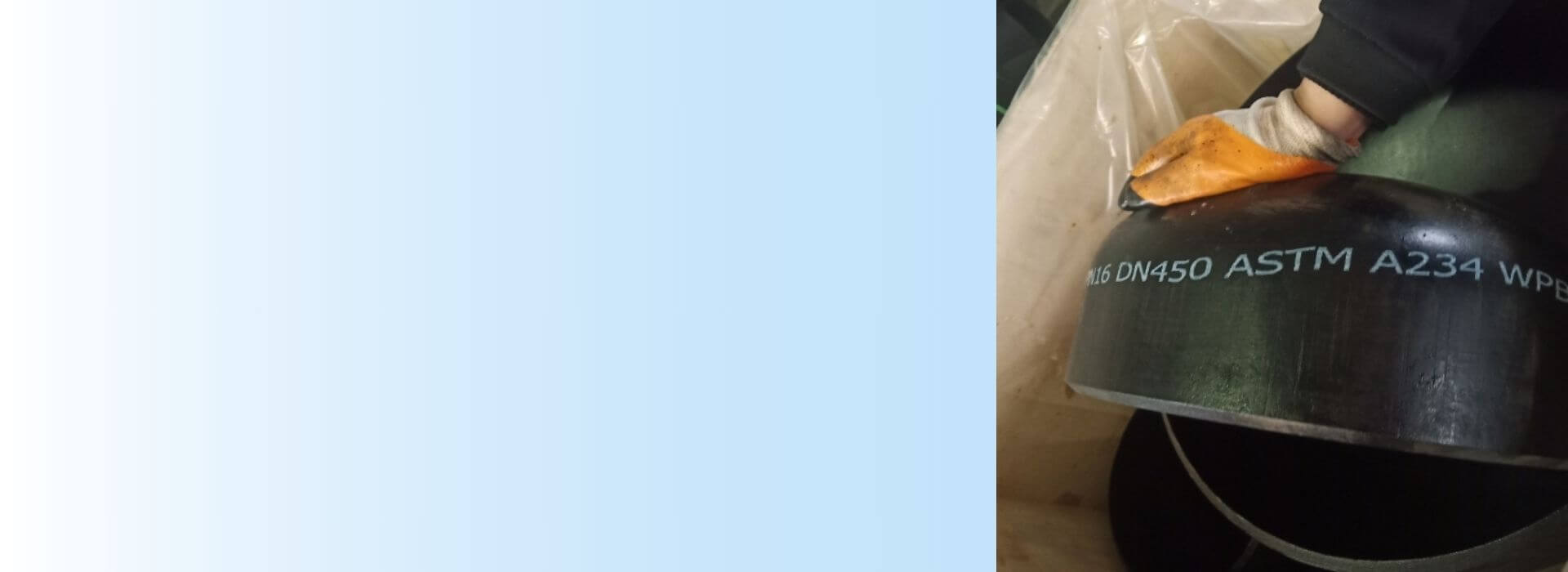

Steel End Caps

Steel End Caps Is Used At The End Of A Pipe System For Termination And Closure. It Is Available In Welded And Threaded Caps.

Standard Sizes Are Up To 48 Inches In Diameter, And If This Is Exceeded, A Custom Finish Is Required.

Balingsteel Can Provide Caps In Carbon Steel, Alloy Steel, Stainless Steel, And Duplex Stainless Steel. Please contact us to Get a Free Quota!

Recommended Products By Balingsteel

Customized Your Steel End Caps

Balingsteel Can Customize Various Sizes and Materials of Pipe Caps to Pipes According to Your Requirements.

- Size:1/2”-48”Or Customized Size.

- Material:Carbon Steel End Caps,Stainless Steel End Caps,Alloy Steel End Cap,Nickel Alloy End Caps,Duplex Stainless Steel End Caps.

- Standards:ANSI/ASME B16.9,API 6A,DIN EN,JIS,BS.

- Functionality:Flanged End Cap,Threaded End Cap,Welded End Cap,Slip-On End Cap.

If You Have Any Questions About Pipe Caps or Designs, Please Feel Free to Contact Us!

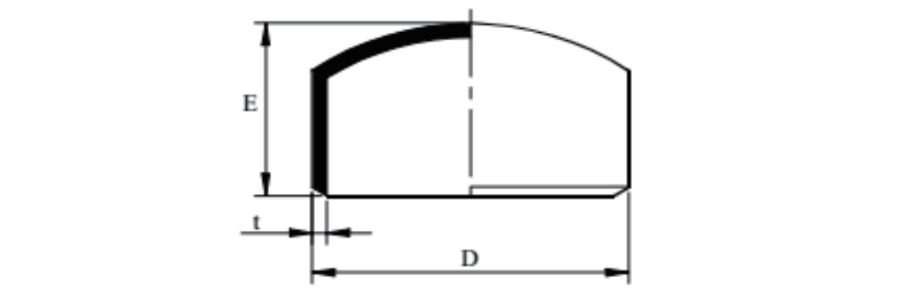

Data Sheet

- Weights of Steel Pipe Cap

- Dimension For Carbon and Alloy Steel Pipe Cap

- Dimension For Austenitic and Austenitic-Ferritic (Duplex) Stainless Steel Pipe Cap

Weights of Steel Pipe Cap According ASME B16.9:

| ASME B16.9 | Dimensions in mm | |||||||

| Nominal Pipe Size | Dimensions | Wall Thickness | Approx. Weight | |||||

| Outside Diameter at Bevel: D | Length: E | t | ||||||

| inch | inch mm | mm | Sch No. | mm | kg | |||

| 1/2 | 21.3 | 25 | Std/40 | 2.77 | 0.03 | |||

| XS/80 | 3.73 | 0.04 | ||||||

| 3/4 | 26.7 | 25 | Std/40 | 2.87 | 0.04 | |||

| XS/80 | 3.91 | 0.05 | ||||||

| 1 | 33.4 | 38 | Std/40 | 3.38 | 0.08 | |||

| XS/80 | 4.55 | 0.11 | ||||||

| 1-1/4 | 42.2 | 38 | Std/40 | 3.56 | 0.12 | |||

| XS/80 | 4.85 | 0.16 | ||||||

| 1-1/2 | 48.3 | 38 | Std/40 | 3.68 | 0.15 | |||

| XS/80 | 5.08 | 0.20 | ||||||

| 2 | 60.3 | 38 | Std/40 | 3.91 | 0.22 | |||

| XS/80 | 5.54 | 0.30 | ||||||

| 2-1/2 | 73.0 | 38 | Std/40 | 5.16 | 0.37 | |||

| XS/80 | 7.01 | 0.50 | ||||||

| 3 | 88.9 | 51 | Std/40 | 5.49 | 0.62 | |||

| XS/80 | 7.62 | 0.85 | ||||||

| 3-1/2 | 101.6 | 64 | Std/40 | 5.74 | 0.90 | |||

| XS/80 | 8.08 | 1.25 | ||||||

| 4 | 114.3 | 64 | Std/40 | 6.02 | 1.12 | |||

| XS/80 | 8.56 | 1.57 | ||||||

| 5 | 141.3 | 76 | Std/40 | 6.55 | 1.83 | |||

| XS/80 | 9.53 | 2.63 | ||||||

| 6 | 168.3 | 89 | Std/40 | 7.11 | 2.80 | |||

| XS/80 | 10.97 | 4.26 | ||||||

| 8 | 219.1 | 102 | Std/40 | 8.18 | 5.1 | |||

| XS/80 | 12.70 | 7.8 | ||||||

| 10 | 273.0 | 127 | Std/40 | 9.27 | 9.0 | |||

| XS/60 | 12.70 | 12.2 | ||||||

| 12 | 323.9 | 152 | Std | 9.53 | 13.1 | |||

| 40 | 10.31 | 14.2 | ||||||

| XS | 12.70 | 17.4 | ||||||

| 14 | 355.6 | 165 | Std | 9.53 | 15.7 | |||

| 40 | 11.13 | 18.3 | ||||||

| XS | 12.70 | 20.9 | ||||||

| 16 | 406.4 | 178 | Std | 9.53 | 20.0 | |||

| XS/40 | 12.70 | 26.5 | ||||||

| 18 | 457.0 | 203 | Std | 9.53 | 25.5 | |||

| XS | 12.70 | 33.8 | ||||||

| 20 | 508.0 | 229 | Std | 9.53 | 31.7 | |||

| XS | 12.70 | 42.2 | ||||||

| 22 | 559.0 | 254 | Std | 9.53 | 38.6 | |||

| XS | 12.70 | 51.3 | ||||||

| 24 | 610.0 | 267 | Std | 9.53 | 45.1 | |||

| XS | 12.70 | 60.0 | ||||||

| 26 | 660.0 | 267 | Std | 9.53 | 50.8 | |||

| XS | 12.70 | 67.6 | ||||||

| 28 | 711.0 | 267 | Std | 9.53 | 56.9 | |||

| XS | 12.70 | 75.7 | ||||||

| 30 | 762.0 | 267 | Std | 9.53 | 63.3 | |||

| XS | 12.70 | 84.2 | ||||||

| 32 | 813.0 | 267 | Std | 9.53 | 70.0 | |||

| XS | 12.70 | 93.1 | ||||||

| 34 | 864.0 | 267 | Std | 9.53 | 77.0 | |||

| XS | 12.70 | 102.4 | ||||||

| 36 | 914.0 | 267 | Std | 9.53 | 84.2 | |||

| XS | 12.70 | 112.0 | ||||||

| 38 | 965.0 | 305 | Std | 9.53 | 97.0 | |||

| XS | 12.70 | 129.1 | ||||||

| 40 | 1016.0 | 305 | Std | 9.53 | 105.2 | |||

| XS | 12.70 | 140.1 | ||||||

| 42 | 1067.0 | 305 | Std | 9.53 | 113.7 | |||

| XS | 12.70 | 151.4 | ||||||

| 44 | 1118.0 | 343 | Std | 9.53 | 128.7 | |||

| XS | 12.70 | 171.2 | ||||||

| 46 | 1168.0 | 343 | Std | 9.53 | 137.9 | |||

| XS | 12.70 | 183.5 | ||||||

| 48 | 1219.0 | 343 | Std | 9.53 | 147.6 | |||

| XS | 12.70 | 196.4 | ||||||

| NOTE: (1) Length E applies for thickness not exceeding that given in column |

||||||||

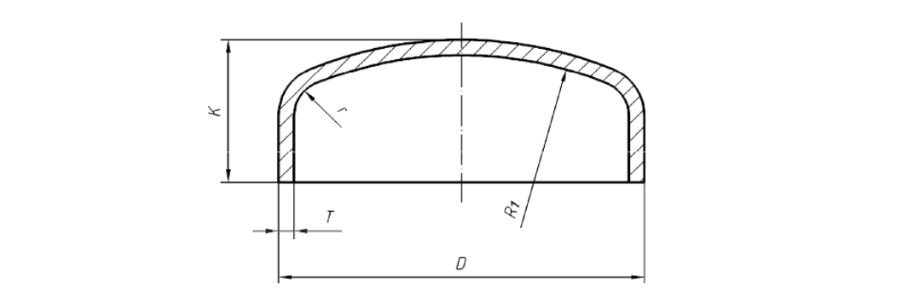

Dimension Requirements of Steel Pipe Cap According EN 10253-2: For Carbon and Alloy Steel:

| EN 10253-2: For Carbon and Alloy Steel | Dimensions in mm | |||||

| DN | D | K | DN | D | K | |

| 15 | 21.3 | 25 | 650 | 660 | 267 | |

| 20 | 26.9 | 25 | 700 | 711 | 267 for T ≤ 25 | |

| 25 | 33.7 | 25 | 290 | |||

| 32 | 42.4 | 38 | 750 | 762 | 267 for T ≤ 20 | |

| 40 | 48.3 | 38 | 310 | |||

| 50 | 60.3 | 38 | 800 | 813 | 267 for T ≤ 17,5 | |

| 65 | 76.1 | 38 | 330 | |||

| 80 | 88.9 | 51 | 850 | 864 | 267 for T ≤ 14 | |

| 90 | 101.6 | 64 | 350 | |||

| 100 | 114.3 | 64 | 900 | 914 | 267 for T ≤ 10 | |

| 125 | 139.7 | 76 | 370 | |||

| 150 | 168.3 | 89 | 1000 | 1016 | 305 for T ≤ 14,2 | |

| 200 | 219.1 | 102 | 420 | |||

| 250 | 273.1 | 127 | 1050 | 1067 | 305 for T ≤ 13 | |

| 300 | 323.9 | 152 | 405 | |||

| 350 | 355.6 | 165 | 1100 | 1118 | 343 for T ≤ 12 | |

| 400 | 406 | 178 | 390 | |||

| 450 | 457 | 203 | 1150 | 1166 | 343 for T ≤ 11 | |

| 500 | 508 | 229 | 375 | |||

| 550 | 559 | 254 | 1200 | 1219 | 343 for T ≤ 10 | |

| 600 | 610 | 267 | 360 | |||

Dimension Requirements of Steel Pipe Cap According EN 10253-4: For Austenitic and Austenitic-ferritic (Duplex) Stainless Steel:

| EN 10253-4: For Austenitic and Austenitic-ferritic (Duplex) Stainless Steel Dimensions in mm |

||

| DN | D mm |

K mm |

| 15 | 21.30 | 25 |

| 20 | 26.90 | 25 |

| 25 | 33.70 | 38 |

| 32 | 42.40 | 38 |

| 40 | 48.30 | 38 |

| 50 | 60.30 | 38 |

| 65 | 76.10 | 38 |

| 80 | 88.90 | 51 |

| 100 | 114.30 | 64 |

| 125 | 139.70 | 76 |

| 150 | 60.30 | 89 |

| 200 | 219.10 | 102 |

| 250 | 273.00 | 127 |

| 300 | 323.90 | 152 |

| 350 | 355.60 | 165 |

| 400 | 406.40 | 178 |

| 450 | 457.00 | 203 |

| 500 | 508.00 | 229 |

| 600 | 610.00 | 267 |

| 700 | 711.00 | 267 |

| 800 | 813.00 | 267 |

| 900 | 914.00 | 267 |

| 1000 | 1016.00 | 305 |

- By Installation: Welded Pipe End Caps, Clamp-on Pipe End Caps, Screw-on Pipe End Caps, Bolt-on Pipe End Caps, Push-fit Pipe End Caps, etc.

- By Design: Flanged Pipe End Caps, Threaded Pipe End Caps, Slip-on Pipe End Caps, Pop-in Pipe End Caps, etc.

End Caps for Steel Pipeline, The Main Purpose of the End Caps Is to Seal Piping Systems or to Make Oil and Gas Storage Tanks.

Yes, Balingsteel Can Customize Special Shaped Caps for Other Applications Such as Hollow Tubes, Pipe Fittings and Welded Designs.