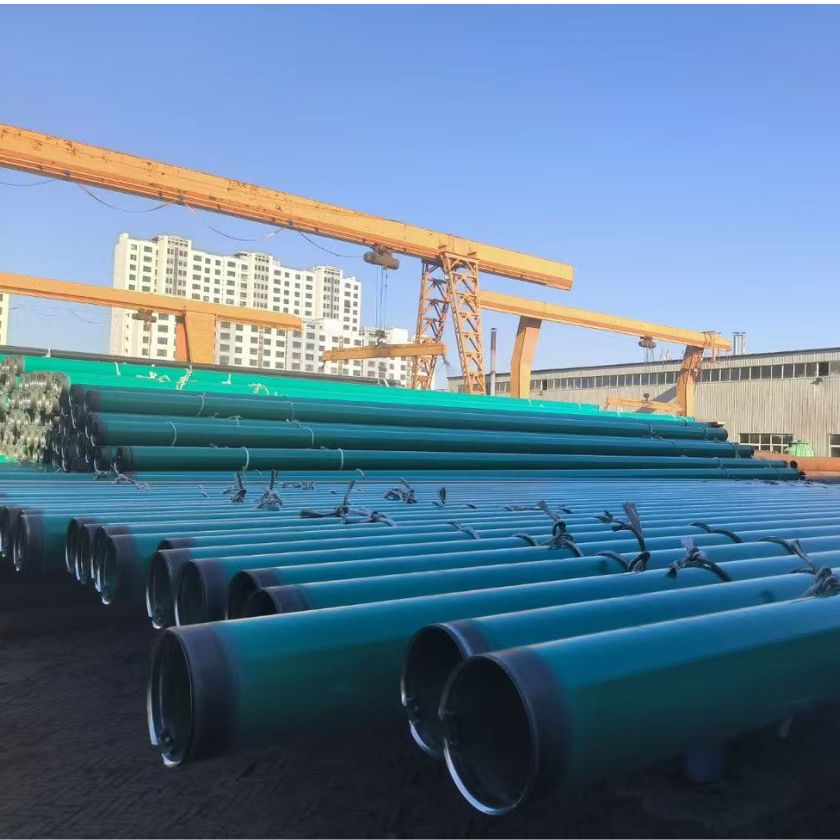

FBE Coated Pipe

FBE Coating Consists Of Epoxy Powder Coating, Solid Solution Additives And Various Adhesives.

It Can Be Used Flexibly On The Surface And Inner Wall Of Steel Pipe To Extend The Service Life Of Steel Pipe, And Has More Stable Anti-Corrosion Protection Performance.

We Can Produce FBE Coated Steel Pipe With Different Thickness According To Customer’s Requirements, Our FBE Coated Steel Pipe Is Strictly In Accordance With ASTM A934 / A934M, ISO 21809-1, EN 10290, NACE SP0394, AWWA C222.

Recommended Products By Balingsteel

-

300 Microns FBE Coating Pipe

300 Microns FBE Coating Pipe

Advantages of FBE Pipe

Balingsteel Provides You with High-Quality FBE Pipe, Which Has the Following Advantages:

- Strong Adaptability to Construction Environment, Not Easy to Corrode and Rust.

- Strong Bonding and Adhesion Strength, Permanent Anti-Corrosion on the Surface of Steel Pipe, Increasing the Service Life of Steel Pipe.

Contact Us to Get Your Quality FBE Pipes!

Wide Application

FBE Anticorrosive Piping Can Be Used in a Variety of Industries:

- External Anti-Corrosion FBE Pipeline: Usually Used in Oil and Gas Transportation Line Pipeline.

- Internal Anti-Corrosion FBE Pipeline: Usually Used in Drinking Water Transportation Pipeline.

If You’re Struggling with What to Do if You Use FBE Piping, Contact Us!

What Should We Consider When Choosing FBE Coated Pipe?

Surface Treatment

Before FBE Anti-Corrosion, We Need to Make Sure That the Steel Pipe Is Glossy and Free of Impurities,

And Has Good Adhesion and Bonding Conditions.

Application Environment

Usually FBE Anti-Corrosion Pipe Is Suitable for Temperatures from -40°c to 120°c. If the Ambient Temperature Exceeds the Normal Requirements, We Need to Adjust the Anti-Corrosion Formula.

Thickness of Coating

Before Choosing FBE Anti-Corrosion, We Need to Confirm the Thickness and Standard of Coating in Advance. The Commonly Used Thickness Is 250um, If You Have Other Thickness Requirements, Please Feel Free to Contact Us.

Data Sheet

- Coating Thickness

- Coated Pipes Specification

- Coating Specification

- Coating Processing

Coating Thickness

| ISO 21809-1-THICKNESS OF FBE COATING | |||||||||

| M kg/m |

Coating thickness mm |

||||||||

| Class A1 |

Class A2 |

Class A3 |

Class B1 |

Class B2 |

Class B3 |

Class C1 |

Class C2 |

Class C3 |

|

| M ≤ 15 | 1,8 | 2,1 | 2,6 | 1,3 | 1,8 | 2,3 | 1,3 | 1,7 | 2,1 |

| 15 < M ≤ 50 | 2,0 | 2,4 | 3,0 | 1,5 | 2,1 | 2,7 | 1,5 | 1,9 | 2,4 |

| 50 < M ≤ 130 | 2,4 | 2,8 | 3,5 | 1,8 | 2,5 | 3,1 | 1,8 | 2,3 | 2,8 |

| 130 < M ≤ 300 | 2,6 | 3,2 | 3,9 | 2,2 | 2,8 | 3,5 | 2,2 | 2,5 | 3,2 |

| 300 < M | 3,2 | 3,8 | 4,7 | 2,5 | 3,3 | 4,2 | 2,5 | 3,0 | 3,8 |

| DIN 30670-THICKNESS OF FBE COATING | ||||

| DN (mm) | Epoxy Powder (μm) |

Adhesive Layer (μm) |

Min. Thickness on The Coating (mm) | |

| Common Level (G) | Strengthen Level (S) | |||

| DN ≤ 100 | ≥120 | ≥170 | 1.8 | 2.5 |

| 100 < DN ≤250 | 2.0 | 2.7 | ||

| 250 < DN < 500 | 2.2 | 2.9 | ||

| 500 ≤DN < 800 | 2.5 | 3.2 | ||

| DN ≥ 800 | 3.0 | 3.7 | ||

Coated Pipes Specification

| Suitable Size for FBE Coated pipe | Small diameter pipes: 1/2 inch to 12 inches (DN 15 to DN 300) |

| Medium diameter pipes: 12 inches to 24 inches (DN 300 to DN 600) | |

| Large diameter pipes: 24 inches to 48 inches (DN 600 to DN 1200) | |

| Very large diameter pipes: Over 48 inches (DN 1200+) | |

| Suitable Grade for FBE Coated pipe | API 5L (Grade B, X42, X46, X52, X56, X60, X65, X70, X80) |

| ASTM A53 (Grades A, B),ASTM A106 (Grades A, B, C),ASTM A252 (Grades 1, 2, 3) | |

| ASTM A335 (Grades P1, P5, P9, P11, P22, P91),ASTM A387 (Grades 11, 22, 5, 9) | |

| UNS S30400,UNS S31600,UNS S41000 | |

| Suitable Pipe Type for FBE Coated pipe | SMLS-Seamless Steel Pipe |

| ERW-Welded Steel Pipe | |

| LASW&SAWL-Longitudinal Submerged Arc-Welding Pipe | |

| SSAW-Submerged Arc Welded Pipe |

Usual Standards and Applications of FBE Corrosion Protection

| Coating Type | Coating Standard | Application |

| External FBE Coating/Internal FBE Coating | DIN 30670 | External Coatings of Steel Pipes for the Transport of Water, Oil, and Gas |

| SSPC-PA 1 | Steel Structures Painting Council | |

| AWWA C210 | Fusion-Bonded Epoxy Coatings for the Interior and Exterior of Steel Water Pipelines | |

| AWWA C213 | Fusion-Bonded Epoxy Coatings for the Interior and Exterior of Steel Water Pipelines | |

| AASHTO M 232 | Epoxy Coating for Steel Reinforcing Bars | |

| External FBE Coating/Internal FBE Coating | ISO 21809-1 | External coatings for pipes transporting petroleum and natural gas |

| ISO 21809-3 | External coatings of pipelines | |

| ISO 11124-3 | Specification for metallic blast-cleaning abrasives | |

| ISO 12944-5 | Protective paint systems | |

| External FBE Coating/Internal FBE Coating | ASTM D3227 | Standard Guide for Fusion-Bonded Epoxy Coatings for Steel Pipelines |

| ASTM F1542 | Standard Specification for Fusion Bonded Epoxy Coatings for Steel and Concrete Reinforcement | |

| ASTM D543 | Standard Practices for Determining the Resistance of Plastics to Chemical Reagents | |

| ASTM A775/A775M | Standard Specification for Epoxy-Coated Reinforcing Steel Bars | |

| ASTM G8 | Standard Practice for Performing Accelerated Tests of Coatings on Steel Exposed to a Humid Atmosphere | |

| External FBE Coating/Internal FBE Coating | NACE SP0178 | Standard Practice for the Application of Coating Systems for the External Protection of Steel Pipelines |

| NACE SP0394 | Standard Practice for Fusion-Bonded Epoxy Coating Systems for the Interior of Steel Pipes | |

| External FBE Coating/Internal FBE Coating | API RP 5L1 | Recommended Practice for the External Coating of Line Pipe |

| API RP 5L2 | Recommended Practice for the Application of Protective Coatings for Line Pipe | |

| External FBE Coating/Internal FBE Coating | BS 7209 | Fusion-Bonded Epoxy Coatings for Steel Pipes for the Transport of Petroleum and Natural Gas |

| BS EN 10290 | Steel tubes for the external coating of steel pipes |

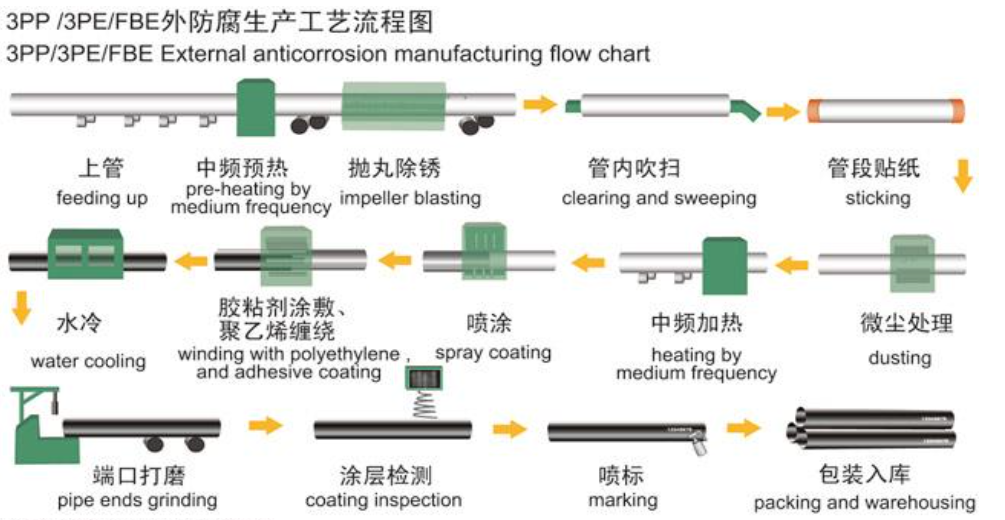

Flow Chart of External Anti-Corrosion FBE

Feeding Up——Pre-Heating by Medium Frequency——Impeller Blasting——Clearing and Sweeping——Sticking——Dusting

——Heating by Medium Frequency——Spray Coating——Winding with Polyethylene and Adhesive Coating——Water Cooling

——Pipe Ends Grinding——Coating Inspection——Marking——Packing and Warehousing

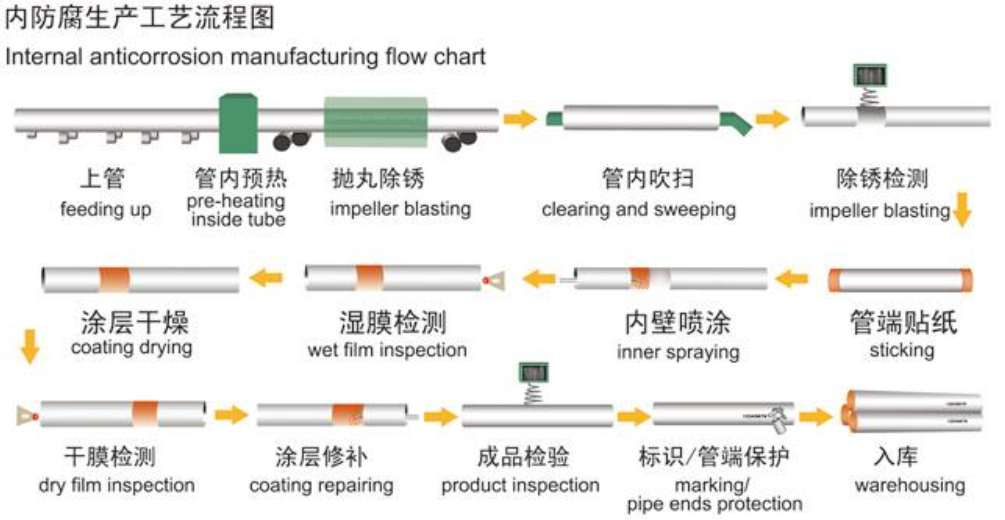

Flow Chart of Internal Anti-Corrosion FBE

Feeding Up——Pre-Heating Inside Tube——Impeller Blasting——Clearing And Sweeping——Impeller Blasting——Sticking

——Inner Spraying——Wet Film Inspection——Coating Drying——Dry Film Inspection——Coating Repairing

——Product Inspection——Marking/Pipe Ends Protection——Warehousing

The Price of FBE Corrosion Protection Is Calculated According to the Surface Area of the Steel Pipe and the Thickness of the Corrosion Protection, Which Is Usually 3.8~5usd/㎡. Please Contact Us for an Accurate Quotation.

When You Need to Extend the Life of Your Pipes, For Example, Or When You Need to Transport Drinking Water.

- FBE Coating: It Is a Single-Layer Fusion Bonded Epoxy Coating Directly Covering the Inner Wall or Surface of the Steel Pipe.

- 3LPE Coating: A Three-Layer Coating Structure Consisting of an Epoxy Powder Coating, A Bonding Layer, and a Polyethylene Coating. Covering the Surface of the Pipe Through a Layer-by-Layer Process.