Understanding Steel Box Sections: The Benefits of Mild Steel Hollow Sections

Steel box sections, especially mild steel hollow sections, have forged themselves into an indispensable aspect of modern engineering and construction. Celebrated for their strength and flexibility coupled with cost-effectiveness, these sections and steel square profiles constitute the backbone of innumerable structural and architectural applications.

Introduction to Steel Box Sections

Steel box sections, or hollow structural sections, are very versatile and durable structural members generally employed in engineering and construction. These sections have a hollow, rectangular, square, or circular cross-section, providing a high strength-to-weight ratio and uniform load distribution.

Key Characteristics

- Made from mild steel to maintain its ductility and allow welding

- Economic elements in construction

- To be loaded in tension or compression

- Maintain structural stability under full weight loads

- Conform to industry standards for easy integration

What is a Steel Box Section?

A steel box section is a metal profile having a hollow, empty section created with square, rectangular, or circular configurations. Normally, these sections are made of mild steel or stainless steel to achieve a greater strength-to-weight ratio. Steel box sections are formed by a cold-forming process or welding and find many uses in construction, engineering development, and industrial applications for their versatility and durability.

Why Steel Box Sections Are Preferred

- Ability to distribute the load evenly

- Provide resistance against buckling

- Ensure structural integrity in frameworks, beams, and columns

- Conform to standardized specifications

- Treated against corrosion for an extended lifespan

Importance of Mild Steel in Construction

Mild steel, because of its many applications and cost-effectiveness in construction, is of utmost importance. It draws attention for its strength-to-weight ratio, ductility, and weldability, to name a few; these qualities render mild steel usable in construction applications such as structural work, reinforcement, or support systems. It can be subject to heavy stress without deformation or strain, so construction must, in turn, be rated `safe and durable.`

Applications of Hollow Sections in Industry

Civil Engineering and Construction

Railings that find applications in buildings, bridges, and infrastructure for their strength-to-weight ratio and beauty.

Automobile Industry

Frames and components of vehicles are manufactured to maintain design integrity while ensuring lightweight construction for better performance and fuel economy.

Manufacturing and Equipment

Used in machinery and equipment as key constituent elements in framing systems, providing for the best design and durability.

Transportation and Logistics

Trailers, containers, and structures that require strength and versatility.

Renewable Energy Sector

It is a must for cases like securing wind turbines, solar panel mounts, and renewable energy equipment requiring solid stability against all manner of environmental changes.

Agriculture and Fencing

Agricultural machinery and fencing constructions are due to toughness and durability.

Types of Steel Box Sections

Rectangular Hollow Section (RHS)

Rectangular Hollow Sections are steel profiles having a rectangular cross-section, widely used in construction and engineering due to their strength, durability, and even weight distribution. They find application in frameworks, load-bearing structures, and furniture manufacture, providing excellent resistance to bending and torsion.

Square Steel Box Sections

Steel square box sections are hollow steel profiles with a square cross-section, widely utilized in building engineering. The symmetrical shape allows equal distribution of strength in all directions, making them ideal for load-bearing works, columns, supports, and structural frameworks.

Comparison of ERW and Other Types

Mechanical Properties of Mild Steel Box Sections

Strength and Durability

Mild steel box sections represent a definite unity of strength and flexibility. They carry great loads and are suitable for structural applications. They can resist deformation during normal working conditions through their toughness. Proper finishing or treatment provides corrosion resistance and prolongs their service life in different environments.

Weldability of Mild Steel Hollow Sections

Mild steel hollow sections show excellent weldability due to their low-carbon nature, significantly reducing cracking hazards during or after welding. They are conducive to various welding methods, such as MIG, TIG, and arc welding.

Welding Best Practices

- Maintain proper heat input and cooling rates

- Use appropriate welding techniques and equipment

- Pre-heating is usually not required

- Perform post-weld inspection for structural integrity

Bending and Forming Capabilities

Steel alloys demonstrate excellent bending and forming ability for a wide range of industrial applications. These materials contain adequate ductility and toughness to be shaped into complex configurations while maintaining their structural integrity. Modern metallurgical techniques maximize these qualities, decreasing the possibility of cracks or wrinkling during forming.

Design Benefits of Using Steel Box Sections

Structural Integrity of Hollow Tubes

Hollow tubes provide superior structural integrity with their high strength-to-weight ratio. Their closed shape offers excellent resistance to torsion, bending, and compression, making them preferred in load-bearing applications. The even stress distribution minimizes deformation chances, ensuring long-term stability in various conditions.

Aesthetic Advantages of Rectangular Steel Sections

Clean and Modern Look

Sleek and streamlined appearance in keeping with contemporary architectural trends.

Versatile Design Applications

Even shape and sharp edges integrate into any architectural style.

Smooth Surface Finish

Fine finish aesthetic glued on with paints, coatings, and natural finishing.

Symmetry and Proportionality

We balance aesthetic considerations with structures well proportioned to please the eye.

Space-Efficient Design

Narrow profiles integrate well without imposing heavily on visual space.

Glazing Compatibility

Excellent compatibility with glass panels for facade or framing applications.

Weight-to-Strength Ratio in Construction

The weight-to-strength ratio is an important selection of construction materials as it affects the efficiency and performance of the structure. Materials having a good strength-to-weight ratio, such as rectangular sections of steel, will offer maximum strength to the structure with minimum load being imposed on the foundation. This act precludes excessive use of materials and helps save on transportation costs. Such factors provide the scenes whereby modern construction goes by the motto “green and cheap.”

Installation Tips for Steel Box Sections

Preparation and Cutting Techniques

- Measuring: Use a steel tape or laser measurer to mark the line. Double-check the measurements to ensure they are accurate.

- Marking the Cutting Line: Mark the cutting line clearly with a marker or scriber by using a straightedge or square.

- Cutting Process: Choose the appropriate tool as per the thickness and work-hacksaw, angle grinder, power saw, or plasma cutter.

- Clamp the Steel Section: Clamp well with a bench vise or heavy-duty clamps so that it does not move around.

- Use Protective Equipment: Use PPE such as safety goggles, cut-proof gloves, a face shield, ear protection, and a dust mask.

- Coolant or Lubricant: This is recommended for thick sections to prevent heat buildup and enhance final finishing.

- Cutting: Maintain an even and steady cutting pressure. Do not rush to avoid inaccuracies.

- De-burr Edges: Use a file or grinder to clean burrs and sharp edges away to make handling safer.

- Inspecting and After-Cut Work: See if it is cut accurately before installation.

Welding Best Practices

Safety

- It must be provided with a proper ventilation system.

- Wear the appropriate safety attire.

- Use a welding helmet of the correct shade.

- Wear flame-resistant clothing.

Preparation

- Keep all surfaces clean and free from contamination.

- Use an electrode or filler material that is compatible with the workpiece.

- Check your equipment settings to make sure that they correspond with the type of material.

- Set voltage and amperage correctly.

Technique

- Correct positioning of the torch.

- Keep a consistent angle and distance.

- The application of the weld should be smooth.

- Inspect the weld for uniformity and penetration.

Safety Considerations During Installation

Necessary Safety Measures

- Protection: Wear gloves, eye protection, and flame-resistant clothing

- Ventilation: Choose well-ventilated spaces to moderate toxic fumes occurring as a result of the operation

- Equipment: Check for damage to the tools and equipment to be used

- Workplace: Keep the workplace tidy and avoid combustible materials

- Instructions: Follow the specifications given by the manufacturer for safe operation

Future Trends and Innovations

![Resistance values with different imperfection models—in [kN].](https://baling-steel.com/wp-content/uploads/2025/09/1.1-36.png)

Summary of Key Benefits

Workplace safety in steel box section installation requires a comprehensive approach emphasizing tool inspection, organized work environments, and strict adherence to manufacturer specifications. Proper safety policies minimize hazards and ensure operations meet working standards.

Future Innovations in Steel Hollow Sections

Oblations to improve the steel hollow sections are oriented toward material efficiency, longevity, and ecological impact. High tensile strength lightweight alloys have been developed to optimize structural performance with minimum material use. New processes have been introduced to automate laser welding, and 3D printing brings advantages in accuracy, time, and cost in manufacturing.

Sustainability Focus

Ramped up utilization of recycled materials and carbon-neutral production processes target global sustainability demands alongside meeting the modern construction requirements.

Why Choose Steel Box Sections?

Steel box sections provide unparalleled construction and engineering versatility. Maintaining excellent strength-to-weight ratios while holding the integrity of the structure and resisting bending and torsion, they do best in load-bearing frameworks, bridges, and the new-age architectural domain. They can be recycled, which supports sustainable construction practices, which, in turn, reduces material wastage. The uniformity of sections affords ease in fabrication that increases design and installation efficiency.

Frequently Asked Questions (FAQs)

Reference Sources

Research Studies and Publications

1. FEM-Based Resistance Models for Local Buckling of Welded Steel Box Section Columns: An Overview

- Authors: Irvin Quillupangui, B. Somodi, B. Kövesdi

- Published in: Applied Sciences, February 29, 2024

Key Findings:

- Investigations focus on the local buckling behavior of welded square box-section columns under pure compression.

- Being buckled locally is of the utmost importance for thin-wall structures as it impairs their stability and load-bearing capacity.

- A new numerical model for the determination of ultimate buckling capacity is developed, validated against both experimental records and existing analytical design approaches.

Methodology:

- Two calculation methods are used: one with equivalent geometric imperfection to account for residual stresses and out-of-straightness, and another with realistic geometric imperfections combined with an experimental residual stress pattern.

- From the outset, all results of the numerical model must come with the trade-off of accuracy measured against test results from international literature(Quillupangui et al., 2024).

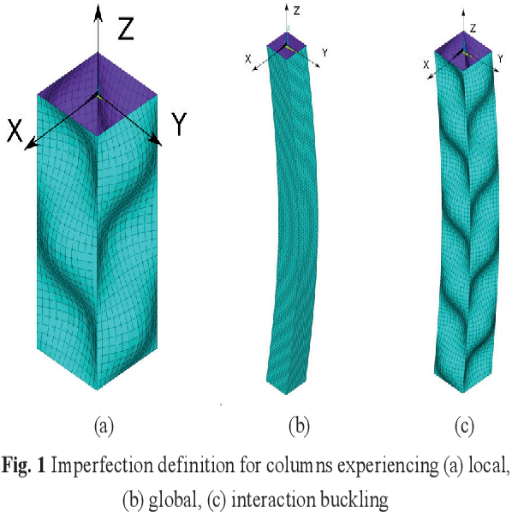

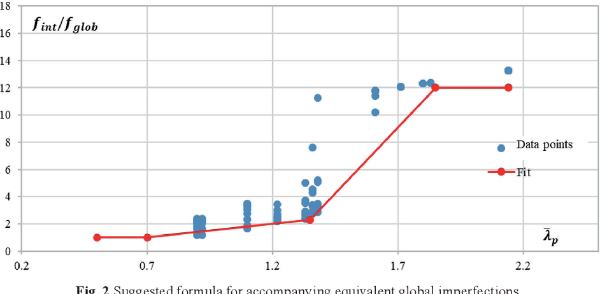

2. The Imperfections for Local and Global Interaction Buckling of Welded Square High Strength Steel Box-section Columns

- Authors: M. Radwan, B. Kövesdi

- Published in: Periodica Polytechnica. Civil Engineering, July 17, 2023

Key Findings:

- The research highlights the interaction issues between local and global buckling modes in high-strength steel box-section columns, which have so far enjoyed little attention from researchers.

- It provides an approach to identifying equivalent geometric imperfections for use in nonlinear plastic analysis in estimating the interaction buckling resistance.

Methodologies:

- A validated numerical model for parametric studies to determine accurate buckling capacities is developed with the intention of calibrating equivalent local and global imperfection combinations for FEM-based design(Radwan & Kövesdi, 2023).

Conclusion

In essence, they serve as something that absolutely must be present to effect any sort of construction, beginning from the mere framework all the way up to the high complexity of an architectural design. Knowing the properties, applications, and installation techniques offers fragrance into going for the best solution for the work, respecting both safety and structural integrity.