Introduction

Steel, the “skeleton” of modern industry, derives its performance from a delicate balance of chemical composition, controlled metallographic structure, and advanced heat-treatment processes. Baling Steel, a leading supplier of premium steel products, is dedicated to providing customized solutions that meet the most rigorous industrial conditions through precise elemental regulation. This report provides an in-depth analysis of how chemical elements influence steel properties and includes a verified cross-reference of common steel grades and ASTM standards under Baling Steel’s strict quality control.

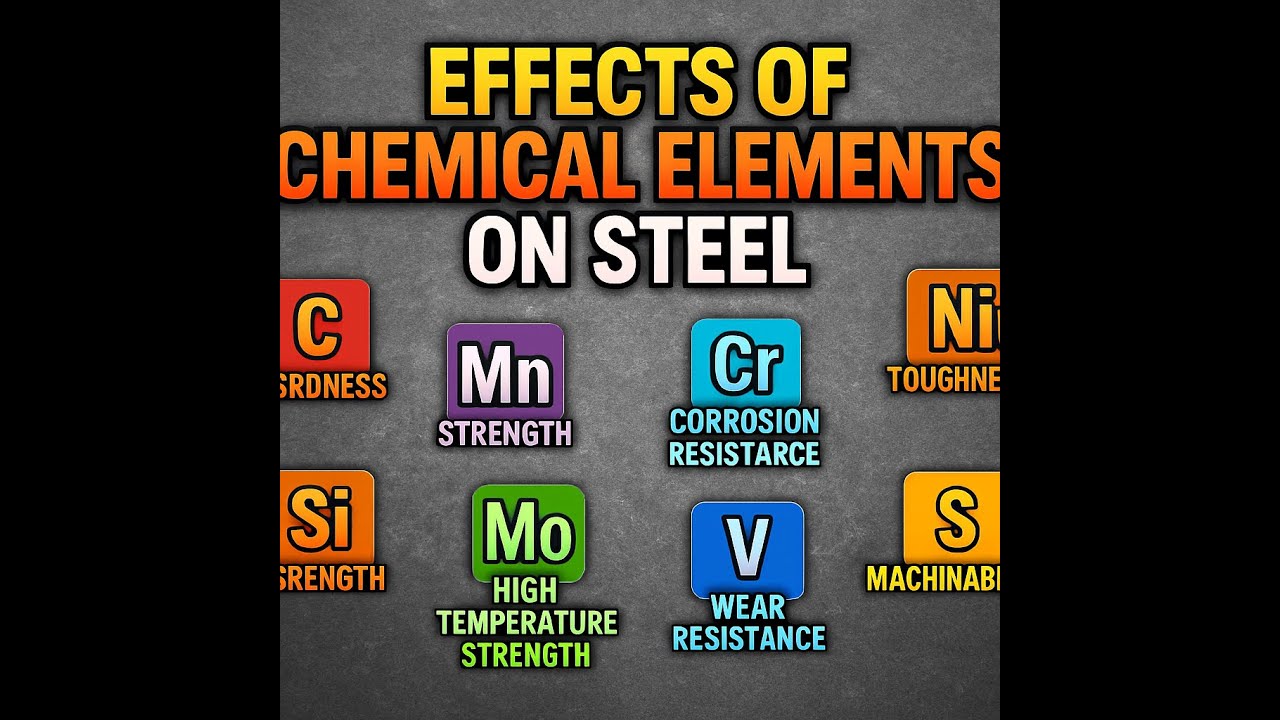

Influence Mechanisms of Chemical Elements on Steel

Core Alloying Elements: The Balance of Strength and Toughness

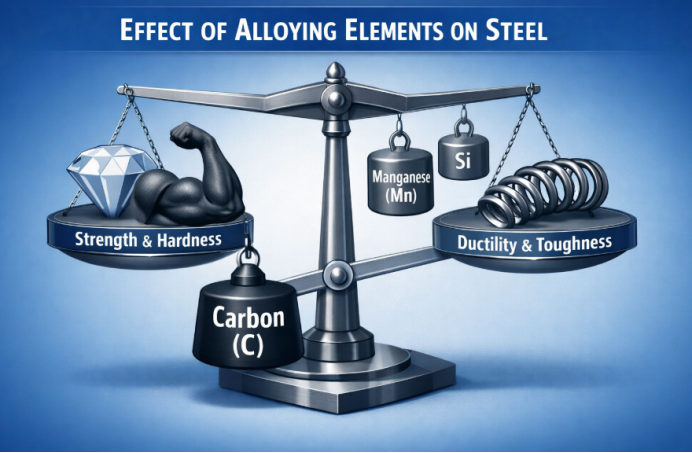

Core elements such as Carbon (C), Manganese (Mn), and Silicon (Si) form the foundation of steel performance. Baling Steel excels in controlling these elements to ensure every batch of product possesses superior base properties.

Carbon (C):

The king of reinforcement. As carbon content increases, strength and hardness rise significantly, but ductility and toughness decrease accordingly . Baling Steel precisely controls carbon levels to achieve the optimal balance for specific applications.

Manganese (Mn):

Acts as both a deoxidizer and an alloying agent. It significantly improves hardenability, strength, and hardness while enhancing hot working properties. Proper manganese levels refine grain size and improve toughness, though excessive amounts can impair weldability .

Silicon (Si):

A primary deoxidizer. Silicon improves the elastic limit and oxidation resistance, but excessive amounts can make steel brittle and reduce ductility .

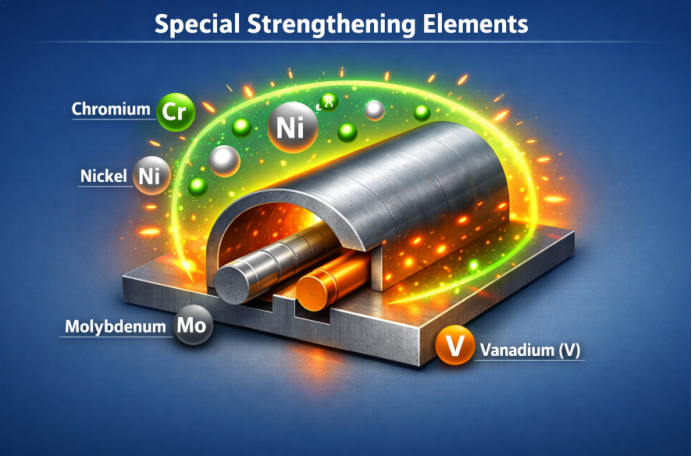

Special Strengthening Elements: The Shield of Defense and Endurance

By adding elements like Chromium, Nickel, Molybdenum, and Vanadium, steel gains special “skills” such as corrosion and high-temperature resistance. Baling Steel’s advanced smelting technology enables precise addition of these elements for high-performance specialty steels.

Chromium (Cr):

The core of rust prevention. When content exceeds 12%, it forms stainless steel, providing excellent corrosion resistance . Baling Steel’s chromium-containing steels perform exceptionally well in extreme corrosive environments.

Nickel (Ni):

The guardian of toughness. Particularly in low-temperature environments, nickel significantly prevents brittle fracture. Baling Steel’s low-temperature steels are trusted for their precise nickel content.

Molybdenum (Mo) & Vanadium (V):

The “steel bones” at high temperatures. Molybdenum improves creep resistance, while vanadium significantly enhances wear resistance by refining grain size .

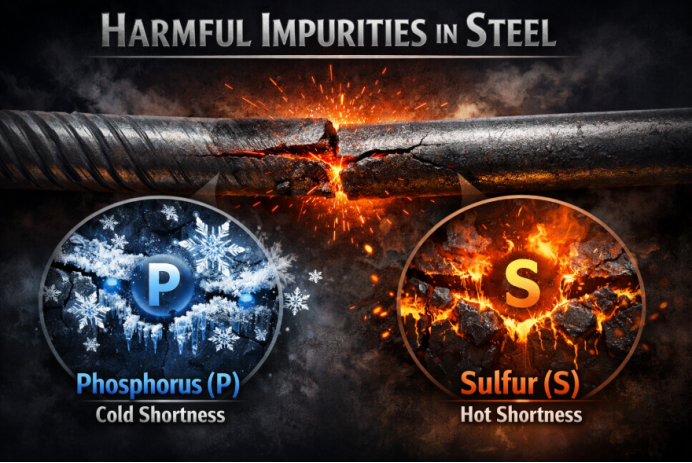

Harmful Elements: The Invisible Crack Promoters

Phosphorus and Sulfur are the “health killers” in steel and must be strictly controlled. Baling Steel uses international advanced refining technologies to reduce phosphorus and sulfur to the lowest industry levels.

Phosphorus (P)

Cold Shortness: In low-temperature environments, phosphorus makes steel as fragile as glass, leading to sudden fracture . Baling Steel’s strict quality control effectively avoids cold shortness.

Sulfur (S)

Hot Shortness: During high-temperature processing (such as forging or welding), sulfur causes cracking along grain boundaries. Baling Steel’s low-sulfur products guarantee excellent processing and welding quality.

Common Boiler Pipe Materials

The following table summarizes the detailed chemical composition data for common steel grades produced under Baling Steel’s strict supervision, along with suggested ASTM/ASME equivalents.

| Steel Grade | ASTM Equivalent/Alternative | C (%) | Si (%) | Mn (%) | Cr (%) | Mo (%) | V (%) | Description |

| 10# | ASTM A179 / A192 | 0.07-0.13 | 0.17-0.37 | 0.35-0.65 | ≤0.25 | – | – | High-quality carbon steel, excellent ductility |

| 20# | ASTM A106 Gr.B | 0.17-0.23 | 0.17-0.37 | 0.35-0.65 | ≤0.25 | – | – | Common medium/low pressure pipe material |

| 20G | ASTM SA210C | 0.17-0.24 | 0.17-0.37 | 0.35-0.65 | – | – | – | Boiler specific, stable high-temp performance |

| 15CrMoG | ASTM A335 P11 | 0.12-0.18 | 0.17-0.37 | 0.40-0.70 | 0.80-1.10 | 0.40-0.55 | – | Low-alloy heat-resistant steel |

| 12Cr1MoVG | ASTM A335 P11/P12 (Similar) | 0.08-0.15 | 0.17-0.37 | 0.40-0.70 | 0.90-1.20 | 0.25-0.35 | 0.15-0.30 | Excellent high-temp oxidation resistance |

| T91 | ASTM A335 P91 / A213 T91 | 0.07-0.14 | 0.20-0.50 | 0.30-0.60 | 8.00-9.50 | 0.85-1.05 | 0.18-0.25 | High-strength heat-resistant steel for supercritical boilers |

| 2Cr13 | ASTM 420 | 0.16-0.25 | ≤1.00 | ≤1.00 | 12.0-14.0 | – | – | Martensitic stainless steel, high hardness |

| SA210C | GB 25MnG (Equivalent) | ≤0.35 | ≥0.10 | 0.29-1.06 | – | – | – | Medium carbon manganese steel for high-pressure boilers |

Note: The above data has been verified against GB 5310 and ASTM standards. Baling Steel guarantees that all products come with detailed Quality Certificates.

Conclusion: Choose Baling Steel for Excellence

Understanding the precise balance of chemical elements is key to selecting the right steel for your project. From strengthening carbon to protective chromium and nickel, every element plays a vital role.

Baling Steel ensures that every inch of steel possesses the exact chemical composition and superior performance required. We provide not only international-standard products but also professional material consultation to help you choose the best solution.

When you need high-performance, high-reliability steel, choose Baling Steel. Our products are widely used in construction, energy, transportation, and machinery manufacturing worldwide. Contact Baling Steel today and let’s build excellence together!

References

[1] Zhihu. Effect of Various Chemical Elements on Steel Properties.

[2] Corrdata. Impact of Different Elements on Stainless Steel Performance.

[3] Diehl Steel. Effects of Common Alloying Elements in Steel.

[4] ASTM Steel. 21 Chemical Elements and Effects on Steel Mechanical Properties.