In structural projects, the outcome can dramatically vary depending on the quality and dependability of the materials used. Among the essential materials for construction and the like, large diameter steel pipes have been there for a very long time and have been valued for their strengths, durability, and adaptability. But then again, not all steel pipes are the same, and picking the right supplier turns out to be as important as choosing the right material. The blog post delves into the reasons for large diameter steel pipes being indispensable to structural applications, emphasizes their main advantages, and gives useful tips on what a reliable supplier should possess. So, whether you’re a planner of a massive infrastructure project or a sealer of high-performing materials for special applications, this write-up will measure up your decision-making process to the point of erecting your project successfully.

Understanding Large Diameter Steel Pipes

Large diameter steel pipes are crucial in transportation of heavy loads and offering support in construction, industrial and infrastructural projects. The pipes are built to endure not only high pressure but also have exceptional strength-to-weight ratios thus ideal for demanding uses like pipelines, foundations and bridges. Moreover, their longevity, resistance to factors in the environment and customization to specific project needs make them even more advantageous. In choosing these pipes, give priority to certifications, material quality and supplier’s reputation to guarantee reliability and long-term performance.

What are Large Diameter Steel Pipes?

Large diameter steel pipes are indeed strong, flexible, and multifunctional tubes that are utilized in different sectors for transporting liquids, supporting constructions, and lots of other building purposes. One of the most common features of these pipes is their large diameter that not only allows but also provides high flow and good support. The making of these pipes is done mainly through the spiraling or longitudinal welding methods, and they are meant to endure the toughest of conditions by maintaining their pressure resistance, corrosion resistance, and the overall strength required for the extreme situations which are the utmost need for Oil and Gas company pipelines, heavy industrial areas, and even large-scale public works projects.

Common Applications of Large Diameter Pipe

Water and wastewater systems, oil and gas pipelines, and industrial processing plants often employ large diameter pipes. These pipes are essential for the movement of large quantities of fluids or gases over long distances. Most importantly, their superb strength and durability make them suitable for use in structural applications like bridge building and placement of deep foundations through piling.

Benefits of Using Steel Pipes in Construction

Steel tubes are strong, long-lasting, and adaptable materials, and therefore, they have many pros in building works. Their tensile strength has a quality of maintaining the strength of the structure even during very heavy load, which makes them perfect for deep building practices below ground. Moreover, they can withstand very high or low temperatures, will not get rusted (if coated), and can bear the outside pressure which will all together add to their longevity. The good thing is that steel piping does not need much cumbersome processing and installation; hence the use of them in different construction sites becomes easy. The combination of these features makes steel pipes the go-to material for the demands of contemporary construction in terms of reliability and efficiency.

Specifications and Sizing of Steel Pipes

To accommodate the diverse construction and industrial applications, steel pipes are produced with an extensive selection of diameters and thicknesses. The diameter is indicated by the nominal pipe size (NPS) while the wall thickness by schedule numbers. Standard diameters are commonly from 4 inches to over 120 inches for big projects. The wall thickness usually ranges from Schedule 10 (light) to Schedule 160 (extra heavy), thus making the pipe suitable for different pressure and structural applications.

The materials used must comply with the specified industry standards, such as ASTM, ASME, or API, which means that the pipes will have quality and performance that can withstand different operating conditions. It is advisable to refer to the project specifications for accurate sizing and also check the compliance with the relevant standards based on the application needs.

Understanding Pipe Diameter and Size

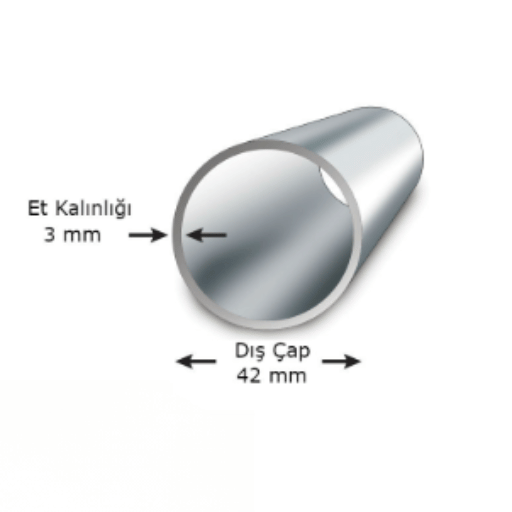

The diameter and size of the pipes are the major considerations in choosing the right pipe for any application. The two principal measurements are Nominal Pipe Size (NPS), which denotes the approximate internal diameter, and Outer Diameter (OD), which specifies the external measurement. Moreover, the wall thickness, denoted by the pipe schedule, influences the internal diameter, and pressure-handling capacity as well. For the determination of the right size, it is crucial to refer to the distinct industry standards and project requirements, which will of course guarantee the best performance and safety for the intended application.

Length and Inventory Considerations

Project specifications, storage facilities, and transport methods should all be taken into account when assessing length and inventory issues. Usually, standard pipe lengths are sold pre-cut into standard sizes, but in some cases, lengths tailored to the applications may be required. Having the right stock of materials will help not only to cut down on waste and costs but also to keep the supply chain running smoothly without interruption. Careful organizing will make it possible to have the right get the right pipe lengths and correctly deal with delivering limitations at the same time.

Mechanical Properties of Large Diameter Pipe

Big pipes have great mechanical properties such as high tensile strength, great durability, and resistance to external pressures, which make them very useful. These features are of great importance for the water and gas industries as well as for the construction of various structures. One of the main factors that determine the material’s performance is the type of steel or the quality of concrete, which also provide excellent resistance to deformation and cracking during heavy loading. Besides, the wall thickness and the manufacturing processes are also factors that help the pipes to withstand the difficult environmental conditions and at the same time keep their integrity for a long time.

Manufacturing Process of Large Diameter Steel Pipes

The whole process of large diameter steel pipes manufacturing includes many steps, each of them forming the strength and durability of the pipe:

1.Preparation of Steel Plates

The conversion of the steel plates starts with only the industry highest quality steel plates or coils, which undergo a thorough examination for material integrity and compliance with the existing industry standards.

2.Forming

The forming stage is where the steel plates are shaped into a cylindrical form by either the UOE (U-ing, O-ing, Expanding) or the spiral welding method. This later on sets the pipe’s diameter and overall shape.

3.Welding

Application of welds is the way of joining the two edges of the steel plates. The most common methods are submerged arc welding (SAW), which provides strong and consistent welds for large pipes.

4.Heat Treatment

Pipes might go through heat treatment in one form or another, to, on the one hand, increase their mechanical properties like toughness and strength, while on the other hand, getting to be a critical step in gaining the hammering of performance when the operating conditions are concerned.

5.Inspection and Quality Control

Pipes are subjected to a variety of rigorous inspections including non-destructive testing (NDT), hydrostatic testing, and dimensional checks, which help to rule out the possibility of any non-compliance with regulatory and project specifications.

6.Coating and Final Finishing

The application of protective coatings is the last-man standing, as in they shield the pipes from corrosion and do help them to last longer. Finally, the pipes are cut, beveled, or made according to specifications.

This entire procedure does not compromise on quality nor do the standards. Consequently, the end products are capable of serving the most demanding applications in the oil and gas or water distribution industries.

How are Large Diameter Pipes Manufactured?

Large diameter pipes are produced via a sequence of highly accurate and tightly controlled actions. To begin with, first-class steel plates or coils are chosen and made into tubes by means of spiral or longitudinal welding. The welded parts are subjected to very strict tests, including ultrasonic and radiographic testing, to check the strength of the material. After that, the pipes are subjected to heat treatment in order to increase their strength and durability, then the hydrostatic test is carried out to verify that they can bear high pressures. To complete the process, protective coatings are applied to prevent corrosion, and the pipes are tailored to the particular demands of the project and the applicable regulations. This careful and thorough method guarantees that the pipes are trustworthy and suitable for critical uses in industries such as petroleum, gas, and water distribution.

Quality Control in Steel Pipe Production

The procedure for producing steel pipes includes quality control that guarantees the pipes produced are not only up to the mark of the industry but also in accordance with the specifications of the project. The entire process of pipe-making is subjected to strict inspections, and these include material testing, dimensional checks, non-destructive testing, and hydrostatic pressure testing. Apart from the use of advanced quality management systems and compliance with international certifications, these techniques also assist in the identification and reduction of defects. Thus, the final products that go to the market are pipes that are safe, durable, and reliable for the applications they are intended for.

Certifications and Standards for Structural Pipe

The manufacturing and testing of structural pipes normally follow strict international standards that guarantee quality, safety, and durability. The most common certifications are ASTM (American Society for Testing and Materials) standards, including ASTM A500 for cold-formed welded pipe and ASTM A53 for steel pipe used in different applications. API (American Petroleum Institute) specifications are also considered as the main standard for some specific applications while ISO (International Organization for Standardization) certification is acknowledged for quality management systems worldwide. In other words, compliance with these standards makes it possible for pipes to have the required mechanical properties, performance characteristics, and health and safety assurance for the various industries that use them.

Choosing the Right Supplier for Large Diameter Steel Pipes

Choosing the right supplier for the large diameter steel pipes is very important for the quality, reliability, and compliance of the whole project. The first step in the process is to check the supplier’s reputation through industry reviews, testimonials, and case studies. Supplier who has global standard certifications, for instance, ISO or API, would be the right one as he guarantees the quality and safety protocols will be followed.

On top of that, consider their production capacity and how they are able to provide customized solutions, as this might influence the timelines and how suitable they are for your project. Definitely, Suppliers which implement strict quality control procedures and use materials whose source is known are the ones who will probably deliver products that can withstand high-performance demands. Make sure they have a strong customer support service that will not only take care of your inquiries but also provide you with the technical insights and help you through the entire lifecycle of the project.

Factors to Consider When Selecting a Supplier

Supplier selection should be based on the supplier’s reliability, quality assurance, and efficiency. Look into their history in terms of punctuality and quality of output. Confirm that they are following the regulations of the industry and that they are open about their practices, including the origin of the materials they use. Communication and customer service are to a great extent the backbone of the relationship and that would be the way to go to make sure that all the difficulties are dealt with successfully. Besides, check whether they can increase the production if required by the project, without reducing quality and efficiency.

Evaluating Product Quality and Customer Service

When assessing quality of products, take into consideration aspects such as how long the product would last, its usefulness and whether it meets the specifications. Analyze what other customers think about the product and if possible, ask for samples and draw your conclusions based on that. In case of customer service, put the following as main criteria: quickness, clear communication, and efficiency in solving problems. A trustworthy partner will always show that they are dedicated to fulfilling the expectations and will provide the concerns promptly with clear communication during the whole process.

Understanding Pricing and Delivery Timelines

While considering the prices and delivery dates, make sure that there is transparency and that the project requirements are met. Contact several suppliers to obtain quotes and by doing so, you will not only find the best price but also take into account some other factors like quality and extra services. In terms of delivery dates, think if the supplier is able to not only keep the deadlines but also to reroute the schedule if necessary. Good communication about possible delays or changes to the plan is essential for smooth workflow. Also, always put these conditions in the contract to avoid future disagreements.

Reference Sources

1.IndustrySelect – Key Facts on the Steel Tube and Pipe Industry

Gives a complete picture of the steel pipe and tube industry, like their sales and marketing tactics.

2.Quora – How to Get Customers for the Steel Market

Describes the marketing of steel products, including large steel pipes, by online campaigns and trade fairs besides metal market.

3.Research and Markets – Large Diameter Steel Pipes Market Report

Provides in-depth analysis of the market including forecasts and trends for large diameter steel pipes.

Frequently Asked Questions (FAQs)

1.What are large steel pipes used for?

Construction, oil and gas pipelines, water and sewage systems, and industry are just some of the uses for them.

2.What sizes are available for large steel pipes?

The range of sizes is extensive, with diameters from a few inches to several feet depending on the application.

3.What materials are large steel pipes made of?

Carbon steel, stainless steel, and alloy steel are the usual materials, with the final choice depending on the required strength and corrosion resistance.

4.Are large steel pipes customizable?

Absolutely, they can be tailored in terms of dimensions, wall thickness, and coatings to fit the specific needs of the project.

5.What is the cost of large steel pipes?

Prices are influenced by factors such as size, material, and quantity, plus the prevailing market conditions.