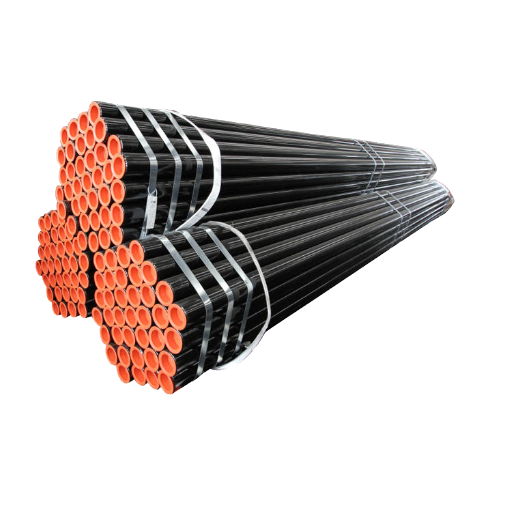

Black steel and similar black metallic gas pipes are traditional and widely applied for gas lines in residential, commercial, and industrial applications. Being a robust and durable pipe with less cost, these pipes are responsible for safely transferring natural gas or propane to appliances and systems.

Introduction to Black Metal Gas Pipes

Besides being strong, impermeable to corrosion, and cost-effective, black metal pipe systems are used in gas distribution. These pipes are of plain steel and are least susceptible to cracking and leakage when subjected to high gas pressures. They are also heat-resistant and are suitable for conveying combustible gases, such as natural gas and propane.

Key Benefits:

- Can be fabricated and installed with ease

- Practical choice for residential, commercial, and industrial installations

- Must be correctly installed and should undergo periodic inspection to ensure safety

- A must for preventing corrosion and sustaining the life of the pipes

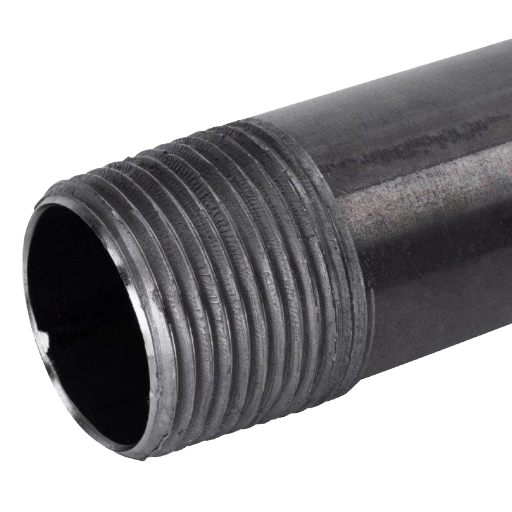

What is Black Steel Pipe?

Black steel pipe is a steel pipe commonly used for the transportation of gas and water in residential as well as industrial applications. It is manufactured without a galvanized zinc coating and hence the dark matte look. Lack of protection against corrosion from moisture, however, means that the pipe gains greater strength and pressure-holding capacity.

Common Applications

- Fire sprinkler systems

- Oil and gas lines

- HVAC applications

- Structural applications

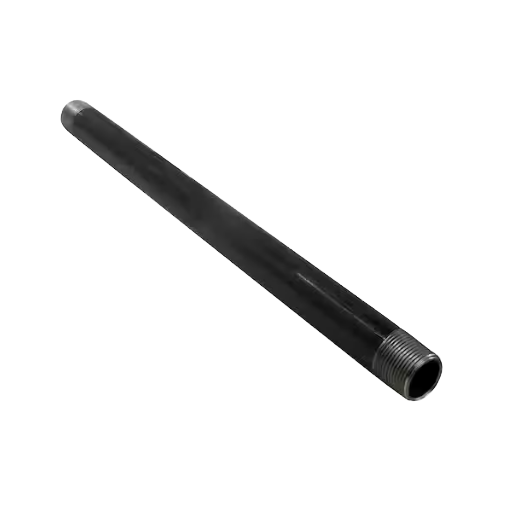

Common Uses of Black Iron in Gas Lines

Key Properties of Schedule 40 Black Pipe

Installation Tips for Black Pipe

Essential Tools and Materials for Installation

Required Tools & Materials:

For gripping and turning the pipe

Tape or paste for leak-proof connections

Pipe cutter or saw for accurate length

For accurate pipe measurements

To smooth edges after cutting

For creating precise threads

Step-by-Step Installation Guide

-

1

Planning Layout: Designed as per the building code requirements

-

2

Shut off the Gas Supply: Prevent leakages during installation.

-

3

Measure Pipe Length: To mark appropriately for natural gas installations.

-

4

Cut Pipes: Cuts must be neat and precise.

-

5

Deburr Edges: Smooth to hold tight joints

⚠️ Common Installation Mistakes to Avoid

Systems not aligned as a result

Causes leakages and feeble joints

Causes sagging and hence failures

Causes faults to not be detected

Safety Measures When Using Black Gas Pipes

Understanding the Risks

🔧 Corrosion Risk

Prone to rust in humid environments, compromising structural integrity

⚠️ Gas Leaks

Improper installation can lead to dangerous gas leaks

🏗️ Weight Concerns

Requires proper support to avoid sagging or stress

🔗 Thread Issues

Poor threading results in weak connections

Emergency Procedures for Gas Leaks

🚨 IMMEDIATE ACTION REQUIRED:

- Immediately Evacuate – Never use electrical devices or naked flames while leaving the premises

- Seek Help – Notify gas provider or emergency services from a safe distance

- Do Not Attempt Repairs – Only licensed professionals may perform repair works on gas lines

- Shut Off Gas – Only if it is safe to do so and you know how to do it

- Observe All Instructions – Do not attempt re-entry until authorized by a technician

Maintenance Routines for Black Steel Pipes

Regular Inspection Methods

Visual Inspection

Identify corrosion, rust, or physical damage

Ultrasonic Testing

Detect internal defects without damage

Pressure Testing

Validate operational pressure capacity

Signs That Indicate Replacement is Needed

- Visible rust or corrosion, especially at the joints and connections

- Gas leak indications – unexplained odors, hissing noises, or rising gas bills

- Age factor – 40 to 50 years and beyond are more or less not meeting the modern safety standards

- Physical damages: dents, cracks, or structural compromise

- Code violations – when any system no longer meets current standards used in practice

Cost Comparisons of Black Metal Gas Pipes

Material Cost Analysis

Budget Planning Factors

💰 Material Costs

Prices vary depending on the kind and quality of materials. Opt for corrosion- and rust-resistant materials for less maintenance in the future.

👷 Labor Expenses

It is important to hire a licensed person for his safe and code-compliant installation.

📋 Permit Fees

Almost every jurisdiction issues permits for gas line work. Check your local laws.

🔍 Inspection Costs

Quite often, inspections must be carried out to ensure that safety standards are followed and that the codes are complied with.

💡 Pro Tip: Long-Term Savings

Improper installation leads to wastage of cost and material aging. Whereas professional installation entails optimal working of the set-up and energy efficiency over the years, resulting in reduced operational costs and costly repairs.

Environmental Impact of Using Black Pipe

♻️ Recycling and Sustainability

🌿 Sustainability Advantages

- Highly recyclable without losing quality

- May be melted efficiently and reused

- Reduction of raw material extraction

- Longer duration of use and less waste generation

🌍 Environmental Impact

- Reduced energy consumption when reprocessed

- Reduced greenhouse gas emissions

- Environmentally friendly construction process

- Embody circular economy principles

Environmental Footprint Comparison

Steel gas lines: Durable, but something that has to be made with a lot of energy and emissions from steel-making.

Plastic alternatives: Low production footprint, but may have issues for long-term degradation and microplastic pollution.

Key considerations: Maintenance and leak prevention play a role in emissions mitigation regardless of material choice since gas pipelines can leak greenhouse gases over time.

Frequently Asked Questions (FAQs)

Conclusion

Key Takeaways

Being considered a cost-effective alternative in residential, commercial, and industrial gas installation systems, black metal gas pipes are trusted for a number of reasons: durability, strength, and the ability to take pressure for conveying natural gas and propane safely.

Remember:

- Proper installation by qualified and licensed professionals remains a foremost safety aspect.

- Periodic inspection and maintenance prevent expensive repairs.

- Awareness of codes and local regulations ensures rational compliance.

- The use of good materials in the correct way guarantees long-term value.

Always consult with qualified professionals for gas line installation, maintenance, and repairs to ensure safety and code compliance.