Steel pipes are a crucial element in several industries, including construction, plumbing, energy, and transportation. There are several defining standards that enhance their use, and ASTM A53 is one critical standard for ensuring quality, dependability, and performance. So, what is ASTM A53 steel pipe all about, and why is it so important in today’s industries? This text explores the specifications, applications, and a broader understanding regarding ASTM A53 steel pipe standards. From understanding its many usages to choosing one for your next project, this book provides a thorough foundation on the subject.

Introduction to ASTM A53

ASTM A53 is a standard specification for steel pipes used in various industrial, commercial, and residential fields. The pipes are generally used in mechanical and pressure applications, in addition to some structural work. The specification covers seamless and welded steel pipes, made in three types (Type F, Type E, and Type S) and two grades (Grade A and Grade B) that vary in tensile strength and chemical composition. ASTM A53 stands high with regard to durability and versatility and under good manufacturing and testing standards, making it one of the most preferred across industries.

Overview of ASTM A53

ASTM A53 is a versatile carbon steel pipe used for structural, mechanical, and low-pressure applications, available in seamless, welded, black, and galvanized types.

|

Aspect |

Details |

|---|---|

|

Material |

Carbon steel |

|

Types |

Seam/Welded |

|

Finish |

Black/Galv. |

|

Applications |

Structural |

|

Pressure |

Low-pressure |

|

Sizes |

NPS 1/8-26 |

Importance of ASTM A53 in the Industry

ASTM A53 steel pipes remain vital in various industries because of their reputation for reliability and adaptability. Considering the ability of these pipes to handle enormous pressures under different environmental conditions, they are frequently utilized in building, engineering, or plumbing applications. For instance, ASTM A53 seamless and welded pipes are used for the conveyance of water, gas, and steam in large infrastructure projects.

In general, it brings to ASTM A53 a certain appeal because the pipes adhere to high manufacturing and testing standards. The pipes are manufactured to meet specified mechanical properties, making ASTM A53 pipes suitable for very demanding industrial applications. The tensile strength programmed is from 330 MPa (Grade A) to 415 MPa (Grade B). They may resist deformation and mechanical failure in a stressed condition.

In recent times, steady growth in demand for ASTM A53 pipes has been witnessed due to the investments towards infrastructure development and energy sector at the global level. Construction alone accounts for a very large share of demand for ASTM A53 pipes, wherein these pipes are used for structural support in beam and column applications. Further, their use extends to the automotive sector and commonly into vehicle exhaust systems and precision machinery components.

The trust that ASTM A53 enjoys stems from its strict compliance with industry standards that guarantee products of uniform quality and consistent performance. This reliability has cemented it as a preferred alternative for cost-conscious engineers and manufacturers who do not compromise safety and durability.

Comparison with ASTM A106 and ASTM A500

ASTM A53 allows seamless or welded pipes for general use, ASTM A106 requires seamless pipes for high-temperature applications, and ASTM A500 is a structural-grade pipe with higher strength.

|

Aspect |

ASTM A53 |

ASTM A106 |

ASTM A500 |

|---|---|---|---|

|

Type |

Seam/Welded |

Seamless |

Structural |

|

Use |

General |

High-temp |

Structural |

|

Strength |

Moderate |

High |

Higher |

|

Finish |

Galvanized |

Bare |

Smooth |

|

Cost |

Lower |

Higher |

Moderate |

Types of ASTM A53 Pipes

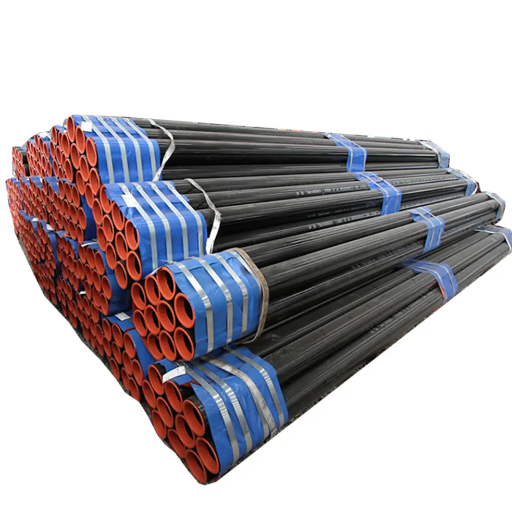

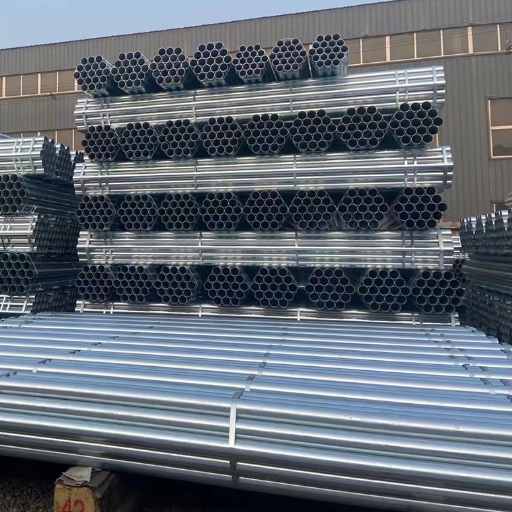

ASTM A53 pipes are available in seamless, welded, black, and hot-dipped galvanized types, with Grades A and B.

|

Type |

Grade |

Finish |

Process |

|---|---|---|---|

|

Seamless |

A, B |

Black/Galv. |

No weld |

|

Welded |

A, B |

Black/Galv. |

Welded |

|

Black |

A, B |

Black |

Any |

|

Galvanized |

A, B |

Zinc-coated |

Any |

Seamless Pipes Versus Welded Pipes

Comparing seamless pipes and welded pipes, one must consider the manufacturing process, properties, and applications.

Seamless pipes are manufactured using solid steel billets. The billets are heated and pierced to form a hollow tube. The absence of a welded seam adds to their inherent strength, contributing to higher strength and ability to withstand pressure. Therefore, seamless pipes are preferred for high-pressure systems, such as oil and gas pipelines or power plants. The homogeneous structure provides greater resistance against high temperatures and corrosive environments. However, seamless pipes generally come at a premium since their production requires more complex procedures.

Welded pipes, on the other hand, are manufactured by rolling steel plates or coils into a cylindrical shape and then welding the longitudinal seam. Modern welding methods provide great precision in the operation, resulting in ERW pipes of very high quality. Welded pipes are often chosen for lower-pressure pipe jobs, as the manufacturing process allows the piping to be cost-efficient and permit very large diameters. These diverse and affordable pipes find usage in agriculture, water distribution, and construction.

Statistics show that seamless pipes have better tensile strength capacity and pressure rating than the welded types. For instance, a seamless steel pipe can sustain more than 20% higher pressure than a welded pipe of similar dimensions. Nevertheless, welds are affected by defects that can cause leaks, making the seamless pipe a solvent for the viability of those critical applications. Welded pipes have, however, witnessed enhancement in durability and reliability due to the advancement in welding technology, thus largely bridging the performance gap between the two.

Therefore, the choice between seamless and welded pipes depends on particular considerations such as the application, operating pressure, temperature specifications, and budgetary constraints faced by the buyer. By evaluating the strengths of each pipe type, the users can decide accordingly for their industrial needs.

A53 Grade B: Characteristics and Uses

A53 Grade B is a carbon steel pipe specification defined under ASTM standards, known for its robustness, versatility, and suitability for a wide range of industrial applications. These pipes are available in both seamless and welded forms, catering to diverse operational needs. They are commonly used in applications such as structural support, fluid transportation, and mechanical systems due to their outstanding strength and durability.

Key Characteristics:

- Material Composition: A53 Grade B pipes primarily consist of carbon steel, with trace amounts of manganese, phosphorus, and sulfur to enhance strength and flexibility.

- Tensile Strength: The minimum tensile strength is 60,000 psi (415 MPa), while the yield strength is 35,000 psi (240 MPa), ensuring excellent performance under pressure.

- Temperature Resistance: These pipes perform reliably in temperatures ranging from -29°C (-20°F) to 427°C (800°F), making them ideal for hot and cold environments.

- Pressure Rating: A53 Grade B pipes can withstand high-pressure levels, making them suitable for steam, water, gas, and air conveyance under elevated pressures.

Common Uses:

- Pipeline Systems: Utilized in transporting oil, gas, water, and steam over long distances due to their strength and corrosion resistance when paired with proper coatings.

- Structural Applications: Widely employed in the construction of buildings, bridges, and machinery frames, providing reliable support in industrial environments.

- Mechanical Parts: Often used for manufacturing mechanical components such as rollers, shafts, and cylinders, thanks to their machinability and adaptability.

These exceptional properties make A53 Grade B pipes a preferred choice across industries ranging from construction and oil & gas to utilities and manufacturing. When paired with thorough quality testing and appropriate protective measures, they ensure long-lasting and efficient performance in demanding scenarios.

Hot-Dipped Galvanized Steel Pipe

Hot-dipped galvanized steel pipe is a versatile and sturdy material, used in many industries that demand ultimate corrosion resistance and durability. The galvanizing of steel pipes consists of dipping the steel pipes in molten zinc to provide a tightly adhering coating. The zinc coating acts as a barrier against moisture and oxidation and other environmental factors that would otherwise cause corrosion, thereby greatly increasing the working life of the pipes.

Durability is one of the most noticeable benefits of hot-dipped galvanized steel pipes. Research has shown that galvanized steel can last for over 50 years under rural environmental conditions and 20-25 years depending on the nature of the environment, whether it is urban or coastal. The snag here is that such service life drastically reduces maintenance and replacement cost. Additionally, galvanized pipes have high tensile strength; therefore, they are used as ideal solutions for structural and industrial applications, including scaffolding, handrails, and underground piping systems.

Additionally, these pipes efficiently carry water, gas, and other fluids at different pressure levels, preventing contaminants from entering the system, thanks to their protective coating. The zinc coating has a smooth finish and bonds well to make sure that protection is imparted uniformly – this extends to seams and corners as well – where uncoated pipes would otherwise remain vulnerable.

Being hot-dipped galvanized steel pipes also conform to environmental standards, since the materials used in their production- steel and zinc- are recyclable. Because of this factor of sustainability, they are highly preferred in greener construction and infrastructure projects.

Specifications and Standards

Hot-dipped galvanized steel pipes conform to internationally well-known and regional standards for assuring the quality and reliability of the product. Commonly used standards are ASTM A123, which covers the zinc coating process, and ASTM A53, which covers the mechanical and structural properties of the pipes. By these measurements regarding thickness, tensile strength, and corrosion resistance, these pipes shall be able to perform their functions as expected. It is the adherence to these standards that guarantees a given pipe’s life and suitability for diverse applications, be it plumbing or engineering construction.

ASTM A53 Standard Specification

ASTM A53 is a standard specification for pipe, steel, black and hot-dipped, zinc-coated, welded, and seamless. This specification covers seamless and welded steel pipe designed for general use, including mechanical and pressure applications, as well as for steam, water, gas, and air lines. ASTM A53 pipes are divided into three types and two grades to suit different industrial requirements:

- Types of Pipe:

- Type F: Furnace-butt welded, suitable for applications requiring minimal mechanical performance.

- Type E: Electric-resistance welded (ERW), known for its strength and reliability under higher-pressure applications.

- Type S: Seamless pipe, providing the highest integrity and used in critical applications.

- Grades:

- Grade A: Lower strength and commonly used for lighter-duty projects.

- Grade B: Higher strength with superior performance under pressure, making it more suitable for industrial and structural use.

- Key Requirements:

- Pipe Sizes: The specification includes nominal pipe sizes from 1/8 inch to 26 inches, with wall thicknesses suitable for various pressure levels.

- Material Testing:

- Tensile strength requirements for Grade A pipes must meet a minimum of 330 MPa (48,000 psi), while Grade B pipes must meet a minimum of 415 MPa (60,000 psi).

- Yield strength needs to be no less than 205 MPa (30,000 psi) for Grade A and 240 MPa (35,000 psi) for Grade B.

- Coating:

- Hot-dipped galvanized pipes under ASTM A53 must comply with strict zinc coating requirements to ensure corrosion resistance. Coating thickness is usually around 1.8 oz/ft² on both sides for consistent endurance.

- Applications:

ASTM A53 pipes are versatile and are employed across a variety of industries, including:

-

- Construction: As structural columns or in scaffolding.

- Plumbing and Piping: For fluid, gas, and steam transportation.

- Energy: Widely used in oil and natural gas pipelines due to its pressure-handling capabilities.

- Additional Considerations:

Pipes under this specification undergo several tests, including flattening tests, hydrostatic tests, and nondestructive electric tests to ensure conformity with mechanical and structural standards.

ASTM A53 remains a benchmark standard for steel pipes, ensuring quality, durability, and performance for essential applications across industries.

Mechanical Properties and Chemical Requirements

ASTM A53 steel pipes are designed and manufactured to meet stringent mechanical and chemical standards, ensuring their reliability and performance across demanding applications. Below are the detailed specifications for mechanical properties and chemical composition:

Mechanical Properties

- Tensile Strength:

- Grade A: Minimum 330 MPa (48,000 psi)

- Grade B: Minimum 415 MPa (60,000 psi)

- Yield Strength:

- Grade A: Minimum 205 MPa (30,000 psi)

- Grade B: Minimum 240 MPa (35,000 psi)

- Elongation:

- The elongation percentage varies depending on pipe size, but a standard range is between 23-30%, highlighting the steel’s ductility.

Chemical Composition

The chemical composition of ASTM A53 pipes is strictly regulated to ensure uniformity and structural integrity. Below is a breakdown of the maximum percentages for key elements:

- Carbon (C):

- Grade A: 0.25% max

- Grade B: 0.30% max

- Manganese (Mn):

- 0.95% max for both Grade A and Grade B

- Phosphorus (P):

- 0.05% max for both grades

- Sulfur (S):

- 0.045% max for both grades

- Copper (Cu), Nickel (Ni), Chromium (Cr), and Molybdenum (Mo):

- These elements must not exceed 1% in total, ensuring controlled alloying.

Additional Notes

- Pipes manufactured under ASTM A53 must meet specific flattening and bending requirements, demonstrating excellent flexibility and structural resilience.

- Grade A pipes are primarily used for lower-pressure applications, whereas Grade B pipes are favored for higher-pressure systems due to their superior strength.

By adhering to these stringent standards, ASTM A53 ensures consistent performance and a high level of trust among engineers and industries worldwide.

Wall Thickness and Outside Diameter Standards

Wall thickness and outside diameter are specifically defined for various applications from ASTM A53 to meet their exact rigorous demands. These dimensions find their measurements in nominal pipe size (NPS) and schedule numbers corresponding to the wall thickness and pressure capacity.

ASTM A53 Pipes are manufactured in three types—Type E (Electric Resistance Welded), Type F (Furnace Welded), and Type S (Seamless), with each type catering to a specific range of wall thicknesses. For example, a Schedule 40 NPS 2 pipe has an outside diameter of 2.375 inches (60.3 mm) and a wall thickness of 0.154 inches (3.91 mm). Schedules with greater thickness, such as Schedule 80, furnish more wall thickness for higher pressure systems.

Thus, these dimensions remain consistent through all pipe types so that they find use in everything from low-pressure utilities to high-pressure industrial systems. Application of these standards ensures that the pipes remain safe for their assigned jobs, while still performing to the best of their ability under difficult conditions. Detailed tables for wall thickness and outside diameters are found in ASTM specifications to aid engineers in the selection of the correct grade and schedule fit for a particular requirement.

Applications of ASTM A53 Steel Pipe

ASTM A53 steel pipe is widely used across various industries due to its versatility and reliability. Its applications include:

- Water and Plumbing Systems: Ideal for transporting water in residential, commercial, and industrial settings.

- Oil and Gas Transmission: Used for low-pressure oil, gas, and steam conveyance.

- Mechanical Uses: Frequently employed in structural applications such as scaffolding, supporting frameworks, and load-bearing components.

- HVAC Systems: Plays a critical role in heating, ventilation, and air conditioning ducts and pipelines.

- Infrastructure Projects: Commonly used in construction for piling, columns, and other structural reinforcements.

These uses highlight the material’s adaptability and compliance with performance standards in demanding environments.

Mechanical and Pressure Applications

Materials that are put to pressure and mechanical applications are those that must endure extreme conditions, including high-pressure environments and mechanical stresses. Steel pipes are important in the oil and gas, chemical processing, and power industries because of their tensile strength and resistance against deformation. These materials are specially designed to withstand internal pressure so they can transport gases, steam, or high volatile liquids.

Seamless pipes can be manufactured by leveraging advanced manufacturing techniques to ensure stronger and safer performance under pressure. For instance, API 5L pipes are popular in the energy sector for their fine durability and pressure-handling ability exceeding 10,000 psi in some cases. Thick-walled and alloy-enhanced steels, on the other hand, provide improved assurance of reliability in high-temperature service, such as in boilers and heat exchangers.

By adhering to industry standards that emphasize safety and performance, such as ASTM or ASME, designers use materials that can cater to a diversity of situations and evolve performance in systems that suggest utmost mechanical integrity and high pressure.

Construction and Structural Uses

Due to its unyielding strength, flexibility, and durability, withstanding corrosion, steel is a basic term in modern construction and structural applications. Designing steel for high-rise buildings, bridges, and industrial complexes feels like deciding the resisting load against varying degrees of shocks and environmental stress.

In the construction industry, advanced structural steels, including HSLA variants, have gained popularity. Such steels offer better mechanical properties, while being lighter: They provide higher yield strength and resistance to corrosion compared to conventional mild carbon steels. For example, the weight of materials can be cut by about 25-30% in the use of HSLA steel for skyscraper frames, which greatly reduces both costs and construction time, all without compromising on safety.

Other advances include pre-fabrication technologies and fabrication techniques such as 3D laser cutting and robot welding, which improve precision while cutting down on waste. The structural steel is also being combined with advanced coatings that can resist rusting in hostile weather conditions, thereby increasing the age of buildings and infrastructure.

These statistical data prove steel to be a dominant force in construction. Roughly half of the steel produced worldwide finds its way to the construction industry. World Steel Association also claims that more than 800 million tons of steel are applied annually in construction projects across the globe. A little edge that steel has is also in its recyclability and the consequent contribution to a circular economy: At the end of the structural steel life-cycle, about 85% of it is recycled, thus making it green.

Steel’s versatility extends to mixed-material designs such as steel-reinforced concrete that combines the compressive strength of concrete with the tensile strength of steel. Such innovative uses allow the construction to meet current engineering demands, ranging from earthquake resistance to load distribution in complex architectural designs.

Oil and Gas Industry Applications

Due to their various permutations of strength, durability, and adaptability suitable to the demanding environment, steels from the construction air are major players in the oil and gas industry. It is generally used in the construction of offshore platforms, pipelines, storage tanks, and refinery structure. These occasions must handle unforgiving environmental conditions, from very high-subsea pressure environments to desert climates that could very well be unforgiving, giving steel the much-needed resilience.

In fact, it has been declared in certain reports that offshore platforms built of structural steel can weigh thousands of tons and are purposefully designed to withstand the weight of drilling equipment and the dynamic force of ocean waves. It is further stated that these pipeline steel structures account for something on the order of 70% of the energy infrastructure worldwide and work to let the long-distance transmission of oil and gas safely and efficiently.

Given the corrosion resistance of structural steel in conjunction with technically advanced coatings, the lifespan of vital infrastructure is enhanced. For further illustration, storage tanks are often constructed using high-grade steel to counter wear from chemical attack. New-age yet highly efficient steel fabrication processes assist in offering more customizations through prefabricated components that minimize land costs and erection time. Also, along with technical advances in welding and joint assemblies, they promote improved efficiency and safety for oil and gas projects.

Structural steel remains indispensable in realizing the reliable, sustainable, and innovative solutions to the complex problems faced by the oil-and-gas industry. In short, they cater to the world’s energy needs while enriching engineering excellence.

Benefits of Using ASTM A53 Pipes

- Durability and Strength

ASTM A53 pipes are engineered to withstand high pressure and challenging environmental conditions, making them ideal for demanding applications in various industries.

- Versatility

These pipes are suitable for a wide range of applications, including structural support, transportation of water, oil, and gas, and mechanical systems, offering great flexibility in industrial use.

- Compliance with Standards

Manufactured to meet strict ASTM specifications, these pipes ensure reliable performance and adherence to safety and quality standards.

- Cost-Effectiveness

With their durability and extended lifespan, ASTM A53 pipes offer a cost-effective solution by minimizing maintenance and replacement costs over time.

- Easy Welding and Fabrication

The material composition makes these pipes easy to weld, cut, and fabricate, optimizing efficiency in construction and installation processes.

Durability and Strength

ASTM A53 pipes are most renowned for their durability and strength, which finds them preferred in all sorts of industries. Because these pipes are meant to withstand high-pressure conditions, they possess tensile strengths nearing 310 MPa (A grade) and 415 MPa (B grade). This high tensile strength guarantees the ability to withstand use with trust in demanding applications like fluid transportation under pressure or structural loading.

In addition to that, resistance, e.g., against corrosive elements or temperature fluctuations, significantly enhances their service life. A stronger structure of the pipe is guaranteed with the help of an advanced manufacturing process, giving uniform wall thickness. ASTM A53 pipes thus have the ability to provide a resolute, long-term solution, be it in the lines of oil and gas, building framework, or even heavy industrial equipment, according to extremely demanding needs. Due to their high strength and durability, they thus find applications in vital infrastructure and engineering projects.

Cost-Effectiveness in Projects

From the point of view of balancing quality and price, ASTM A53 pipes provide a very cost-efficient option for a wide range of jobs. They offer an attractive price before installation while providing the utmost in performance. These pipes are a common choice for projects both big and small because of the excellent level of durability that eliminates the frequent replacement or repair of the piping system and thus cuts down on maintenance cost over a period. For example, in the construction industry, wondered A53 pipes may be able to reduce material costs by at least 20% over other materials without compromising on strength and reliability.

The high versatility of ASTM A53 pipes also leads to an easy procurement and installation process. Being compatible with a wide range of applications, these pipes negate the need for any specialized materials, thus minimising logistical complexity and related costs. Further, they are compatible with conventional welding and threading techniques, which lessens the skill required for installation and offers added savings on time and expenses. All these aspects further promote their affordability while maintaining strong performance capacity in even the most demanding applications, from energy conveyance to water distribution and construction infrastructure. The very mix of economic advantages and technical capabilities spells out ASTM A53 for any budget-conscious engineer or project manager.

Corrosion Resistance with Galvanization

Zinc coating protects steel by acting as a barrier to moisture and environmental factors, thereby increasing corrosion resistance greatly. In my opinion, this process is very effective in humiliated repellence even rusting in bad situations, thereby imparting long life to the material in such bad conditions. From this point of view, galvanized ASTM A53 pipes will be in every sense a durable solution for long-term usage.

Reference Sources

-

The Study of the Impact of Nano Carbon Additives on ASTM A53

Link to Abstract

This study explores the development of ASTM A53 mild steel with nano carbon additives for enhanced properties. -

Corrosion Rate of ASTM A53 Steel in Seawater

Link to Study

This research investigates the use of mango peel extract as a corrosion inhibitor for ASTM A53 steel in the oil and gas industry. -

Are You Properly Specifying Materials?

Link to PDF

This document provides detailed specifications and tolerances for ASTM A53 steel pipes.

Frequently Asked Questions (FAQs)

What is ASTM A53 and its significance?

ASTM A53 is a standard specification developed by the American Society for Testing and Materials (ASTM) for seamless and welded black and hot-dipped galvanized steel pipes. It is widely used in various mechanical and pressure applications due to its strength and durability. The specification outlines the requirements for chemical composition, mechanical properties, and manufacturing processes, ensuring the pipes meet industry standards.

What are the different types of ASTM A53 pipes?

ASTM A53 pipes are categorized into different types, including A53 Type F (furnace welded), A53 Type E (electric-resistance welded), and A53 Type S (seamless). Each type has specific manufacturing processes and is suitable for various applications, with Type S being preferred for seamless applications due to its structural integrity.

What is the difference between ASTM A53 Grade B and Grade C?

ASTM A53 Grade B is more commonly used and has a minimum yield strength of 35,000 psi, while Grade C has a higher yield strength requirement. Grade B is suitable for welding and is often used in pressure applications, while Grade C may be selected for more demanding structural applications due to its enhanced mechanical properties.

Are ASTM A53 pipes suitable for welding?

Yes, ASTM A53 pipes are suitable for welding. Specifically, Grade B pipes are designed to be weldable and can be used in various applications that involve welding processes. Proper welding techniques should be employed to ensure the integrity of the weld seam, especially for pipes intended for high-pressure applications.

What is the nominal wall thickness for ASTM A53 pipes?

The nominal wall thickness of ASTM A53 pipes varies based on the pipe diameter and type. The standard provides various schedule options, allowing for different wall thicknesses to accommodate the specific needs of mechanical and pressure applications. This ensures that the pipes can withstand the intended operating conditions.

How are ASTM A53 pipes manufactured?

ASTM A53 pipes can be manufactured using different processes including open-hearth and electric furnace methods. The seamless pipes are produced through extrusion or piercing, while welded pipes are created using techniques such as electric-resistance welding. Each method influences the pipe’s properties and suitability for various applications.

What are the chemical requirements for ASTM A53 steel?

ASTM A53 steel has specific chemical requirements outlined in the standard specification. These requirements include limits on carbon, manganese, phosphorus, sulfur, and other elements to ensure the steel’s strength and durability. Meeting these chemical requirements is essential for the pipe to perform effectively in its intended applications.

Can ASTM A53 pipes be galvanized?

Yes, ASTM A53 pipes can be galvanized. The hot-dipped galvanizing process provides a protective layer that enhances the corrosion resistance of the steel pipes, making them suitable for outdoor and harsh environments. Galvanized A53 pipes are commonly used in construction and infrastructure projects.

What is the hydrostatic test for ASTM A53 pipes?

The hydrostatic test is a crucial quality assurance procedure for ASTM A53 pipes. During this test, pipes are subjected to high-pressure water to check for leaks and ensure structural integrity. This test is mandatory for pipes intended for pressure applications and helps confirm that they meet safety standards.