The ASTM A105 Carbon Steel Blind Flange is a significant part of industrial applications, guaranteeing reliable performance and safety in pipelines. This article will give a thorough understanding of the specification, characteristics, and applications of ASTM A105 blind flanges. Whether you are looking at their usage in high-pressure situations or striving to meet industry regulations, this guide will provide you with the necessary knowledge. At the end of the article, you will get a complete picture of their main advantages, standards, and practicality, thus being able to make the right choices for your projects.

Introduction to ASTM A105 Flanges

Flanges made of ASTM A105 are primarily carbon steel forged parts that serve in the piping systems of high-temperature and high-pressure applications. These flanges are made in a way to fulfill the specific mechanical and chemical properties dictated by the ASTM A105 standard, thus assuring their durability, reliability, and being fit for use in many sectors including oil and gas, petrochemical, and power generation. A105 flanges have a good reputation for being strong and resistant to wear therefore they are often selected for their capability to bear difficult operating conditions and at the same time having a consistent performance.

Overview of Flanges and Their Importance

Flanges are of utmost importance in piping systems as they offer a trustworthy technique for joining pipes, valves, pumps, and other devices. They facilitate easy assembling and disassembling for the purpose of maintenance and repairs, at the same time providing a safe sealing to resist leakages when used in high-pressure and high-temperature applications. Their necessity is recognized in various industries, including oil and gas, petrochemical, and power generation, that require durable and performing parts for the operational safety and efficiency.

What is ASTM A105?

ASTM A105 is a specification set forth by the American Society for Testing and Materials (ASTM) that includes carbon steel forged parts, mainly intended for piping systems. These are components like flanges, fittings, valves, and other important pieces that have been engineered for use under extreme pressure and temperature conditions. ASTM A105 assures the materials to be very good in mechanical properties, durability, and strength thus making them appropriate for vital industrial applications such as oil and gas, petrochemical, and power generation.

💡 Key Insight

ASTM A105 flanges are specifically engineered for critical industrial environments where material integrity and performance consistency are non-negotiable requirements.

Applications of A105 Flanges

A105 flanges have become quite common in all sorts of industries and performance environments, mainly because of their unmatchable strength and durability. They are predominantly used in oil and gas pipelines, petrochemical businesses, and power generation systems. Such flanges are perfect for top-notch, hot applications, by ensuring safe connections with very little chance of breakdown. Their usage also extends to industrial processing plants and refineries where material resilience and resistance to corrosion are required. Their versatility and meeting of ASTM standards is a reason why they are often chosen for the important infrastructure projects.

Specifications of ASTM A105 Carbon Steel Flanges

📋 Technical Specifications Overview

1. Material Composition

- The predominant material is carbon steel that is having a maximum carbon content of 0.35%.

- It also involves manganese (0.60–1.05%), phosphorus (maximum 0.035%), sulfur (maximum 0.040%), and silicon (0.10–0.35%).

2. Pressure Class Ratings

The pressure class ratings available are Class 150, 300, 600, 900, 1500, and 2500, thus making them appropriate for different pressure and temperature conditions.

3. Sizes

Commonly, they are presented in dimensions from ½ inch to 48 inches, it is most of the time according to the project specifications.

4. Temperature Range

Their working temperature range is from -29°C to 425°C (-20°F to 800°F), thus they can be used in a wide array of industrial processes.

5. Standards Compliance

The production of the flanges is according to ANSI/ASME requirements, which guarantees their compatibility and that they are reliable.

6. Surface Finish

The finishes provided are raised face (RF), flat face (FF), or ring-type joint (RTJ) which are suitable for effective and secure sealing.

The specifications stated make it possible for A105 flanges to be strong, reliable, and versatile thus they can be used in different industries.

Material Composition and Properties

ASTM A105 flanges are made from steel that is forged and thus very durable limiting their use to high-pressure and high-temperature applications only. The constituent materials generally consist of carbon, manganese, phosphorus, sulfur, and silicon which by and large elevate the strength, ductility, and wear resistance. This powerful mix of features grants dependable operation through a variety of industrial use cases.

Mechanical Properties of A105 Flanges

ASTM A105 flanges have impressive mechanical characteristics, such as very high tensile strength, good yield strength, and heat resistance. The above-mentioned characteristics make the flanges capable of enduring large stresses in high-pressure and high-temperature situations, thus they are considered a reliable selection for tough industrial applications.

Dimensional Standards and Nominal Sizes

The ASTM A105 flange types comply with various global dimensional standards such as ASME B16.5, ASME B16.47, and API 605. The compatibility and uniformity across the applications are assured by these standards. The nominal size of these flanges usually falls between 1/2 inch and 24 inches, thus being able to serve numerous piping systems.

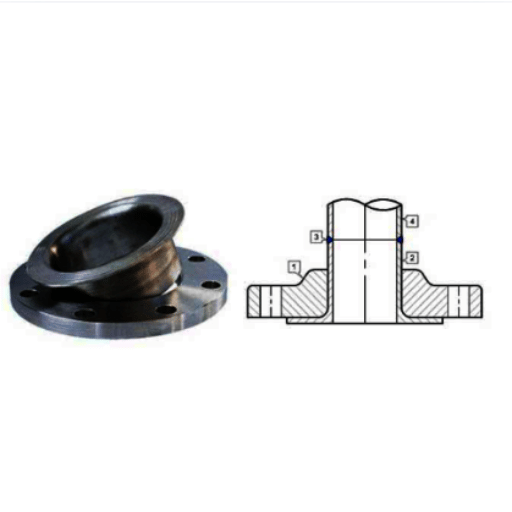

Types of A105 Flanges

ASTM A105 flanges come in different types and sizes for different applications. The most common types are as follows:

1. Weld Neck Flanges

These flanges are suitable for high-pressure applications and provide a robust connection with excellent stress distribution.

2. Slip-On Flanges

These flanges are easy to install, suitable for low-pressure systems, and require fillet welding for attachment.

3. Socket Weld Flanges

These flanges are the best option for small-diameter pipes as they provide a smooth bore for smoother flow.

4. Blind Flanges

Blind flanges are used to shut down the ends of piping systems and are important for maintenance and pressure testing.

5. Threaded Flanges

These flanges are perfect for non-welding systems and can simply be screwed onto the pipes.

6. Lap Joint Flanges

Generally used with stub ends, these flanges allow for easy alignment and are often found in areas where frequent assembly and disassembly take place.

Every single kind of A105 flange is designed and produced according to the particular needs of the users, thus granting their dependability in numerous industrial applications.

Blind Flanges: Definition and Uses

Blind flanges are solid disk-shaped components that serve the purpose of blocking or isolating the flow of fluids through an entire piping system. They are usually used at the termini of pipelines, valve passages, or pressure vessel connections at the end of piping systems in order to guarantee safety during maintenance, or to prevent the fluid from moving within the system. Unlike other types of flanges, blind flanges have no opening, which makes them suitable for high-pressure applications where full closure is required. The combination of their versatility and strength has made them indispensable in industries such as oil and gas, petrochemical, and power generation.

Raised Face vs. Flat Face Flanges

The main point of distinction between raised face (RF) and flat face (FF) flanges is sealing surfaces. The selection of one over the other is based on the factors such as the application’s pressure, the temperature, and the equipment compatibility.

Comparison of Threaded and Welded Flanges

The choice between the two is influenced by factors such as ease of installation, operating conditions, and reliability requirements over time.

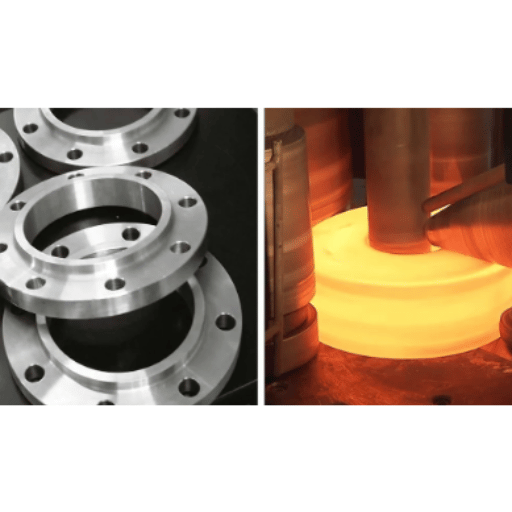

Manufacturing Processes for A105 Flanges

A105 flange production comprises various essential processes that give rise to the products having good mechanical properties, high precision, and being compliant with the relevant industry standards:

Selection of Raw Material

The forged carbon steel (A105) is selected because of its great strength and the fact that it can be used at high-pressure locations. Before the start of manufacturing, the material undergoes a thorough quality check.

Forging

The steel is heated to a point where it can be easily molded and is then made into the shape that is somewhat similar to a flange with the use of forging techniques. This process gives the steel a more uniform grain structure, thus, making it stronger and more resistant to stress.

Heat Treatment

The flanges go through a series of processing treatments such as normalizing, annealing, or quenching and tempering in order to obtain the desired mechanical properties such as hardness and tough nature.

Milling

The end product’s dimensions which consist of the bolt holes, the flanges’ faces, and the surfaces where the parts connect are determined by exact machining; thus, it is guaranteed that the parts will fit together properly.

Inspection and Testing

Stringent quality assurance including checking the dimensions, testing with the specific pressure, and analyzing the material’s integrity, is performed to confirm compliance with standards like ASME and ASTM.

The A105 flanges produced through these detailed processes are able to withstand the applications of different industries and provide the same level of performance and reliability as their critical environments.

Forging Techniques and Standards

Forging process for A105 flanges starts with heating the steel to a certain high temperature to get the desired malleability, then the steel is shaped under great pressure with tools such as dies and hammers. This technique improves the grain structure, so it is more robust and lasts longer. For the manufacturers it is important to follow the requirements set by the ASME, ASTM, and API standards, which specify the chemical composition, mechanical properties and dimensional tolerances among others, to ensure that the flanges are able to perform reliably in diverse applications. By adhering to these standards, the manufacturers are able to produce flanges that not only meet the strictest industrial requirements, such as safety and efficiency but also have longer service life.

🔧 Manufacturing Best Practices

- Strict adherence to ASME, ASTM, and API standards throughout production

- Precise temperature control during forging and heat treatment processes

- Regular equipment calibration and maintenance

- Comprehensive documentation and traceability protocols

Inspection and Quality Control Measures

Inspections and quality control are necessary processes to ensure that the forged flanges conform to the industry standards and performance expectations. Inspection involves checking the dimensions, and performing non-destructive testing (NDT) such as ultrasonic or magnetic particle inspections, and material verification that confirms compliance with ASME, ASTM, or API specifications. Good documentation and regular audits allow having a traceability and an adherence to the quality protocols, thus, minimizing risks and guaranteeing reliability in critical applications.

✓ Quality Control Checklist

Dimensional accuracy verification

Non-destructive testing (ultrasonic, magnetic particle)

Material composition analysis

Pressure testing and leak detection

Standards compliance verification (ASME, ASTM, API)

Documentation and traceability audit

Common Challenges in Flange Production

Flange production is accompanied by a number of challenges that can have a negative impact on the quality and reliability of the finished product. Precise dimensional tolerances, which go a long way in assuring the correct fit and function, are one of the primary challenges in manufacturing. Besides, the choice and quality of materials will have an effect on the product, as if the materials are below standards, the product will have a decreased life or be unable to withstand pressure. Further, to be able to achieve the same quality in forging and heat treatment processes, one has to carefully control the process so that defects such as cracks or inclusions do not occur. Sometimes, production is delayed due to equipment breakdown or supply chain disruptions, which can make timelines even more complicated. To overcome these challenges, it is necessary to use robust quality control, advanced testing methods, and streamlined production workflows to be able to provide high-performance flanges for their intended applications.

Reference Sources

1. Texas Flange – The Definitive Guide to Carbon Steel A105 Flanges

Gives very precise details about the use and technical requirements of A105 flanges, especially in case of high-pressure and high-temperature conditions.

2. SSM Alloys – ASME B16.5 A105 Flange

Mentions everything about A105 flanges, from their compatibility to limitations and even the circumstances of their application in non-corrosive areas. →

3. Ganpat Industrial Corporation – Advantages of Using Carbon Steel A105 Flanges

Points out that A105 flanges have diverse uses and thus are applicable in several industries.→

Frequently Asked Questions (FAQs)

Conclusion

ASTM A105 carbon steel flanges represent a critical component in modern industrial piping systems, offering exceptional strength, reliability, and versatility across diverse applications. From high-pressure oil and gas operations to demanding petrochemical processes, these forged carbon steel flanges have proven their worth through rigorous adherence to international standards and superior mechanical properties. Understanding their specifications, types, manufacturing processes, and proper applications ensures optimal performance and safety in your industrial projects. By selecting the appropriate flange type and maintaining strict quality control measures, engineers and project managers can confidently specify A105 flanges for their most critical infrastructure needs.