In the case of industrial pipelines, the material specification understanding is the key to safety, efficiency, and performance. The API 5L X52 seamless pipe is the best option for oil, gas, and industrial applications mainly because it can endure the most extreme conditions. This guide is an all-inclusive resource for you, providing a detailed account of the characteristics, standards, and practical applications of API 5L X52 pipes. This article is useful for project managers, engineers, and buyers since it contains insights on the effective selection and application of these pipes. Come along with us as we delve into the specifications, grades, and advantages that make this pipe one of the most durable materials in the industry for pipeline applications.

Overview of API 5L X52 Pipe

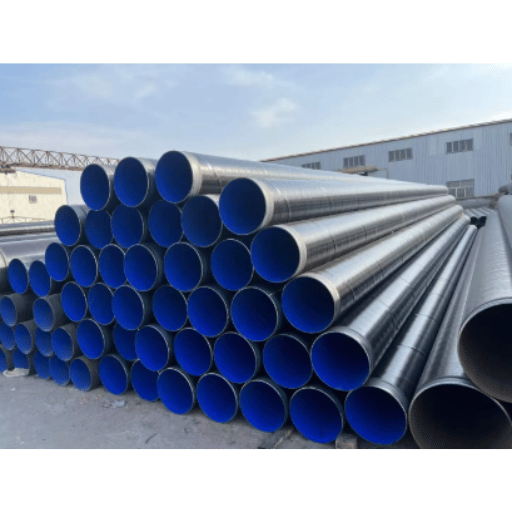

Pipes made of API 5L X52 are high-strength, seamless pipes that are extensively utilized in the oil & gas sector to easily transport crude oil, natural gas, and other fluids. Because they can operate in extremely difficult environments with high pressure and very high temperatures, they are accepted by the industry as meeting the highest standards for being durable and performing well. The pipes belong to the API 5L standard, which states the values of the physical, mechanical, and chemical properties that are very important for pipe-line use. The grade “X52” indicates a minimum yield strength of 52,000 PSI, which is a guarantee of reliability in the case of demanding projects. API 5L X52 pipes have the properties of being corrosion resistant and easy to weld, thereby making them a very trustworthy option for the whole spectrum of operations both offshore and onshore.

Introduction to API 5L X52

The API 5L X52 pipe is a super-strong, either seamless or welded, steel pipe, which is mainly used for the transportation of oil, gas, and water in the pipeline systems. The pipe’s excellent composition gives it the properties of being corrosion resistant, having high mechanical strength, and good weldability, thus making it fit for onshore and offshore areas both. Its trustworthy performance under high-pressure conditions establishes further its usage in important pipeline applications.

Importance of Specifications

The specifications have a very significant impact on the reliability and performance of the API 5L X52 pipes. These specifications assure, among other things, that the composition of the material, the tensile strength, and the weldability of the pipes fulfill even the most demanding application areas of oil, gas, and water transportation. They introduce a very high level of consistency, safety, and quality assurance that makes sure the pipes work optimally even in difficult climates, whether onshore or offshore.

Types of Pipes: Seamless vs. Welded

⚙️ Seamless Pipes

- ✓ Formed without any welding

- ✓ Uniform structure

- ✓ Increased strength

- ✓ Suitable for high-pressure applications

- ✓ More resistant to rust

🔧 Welded Pipes

- ✓ Produced by fusion of metal plate edges

- ✓ More cost-effective

- ✓ Available in larger dimensions

- ✓ Suitable for low-pressure applications

- ✓ Lower initial investment

💡 Decision Factor: The choice between these two options is determined by the needs of the particular project, including pressure ratings, finance, and the environment of use.

Technical Specifications of API 5L X52 Pipe

API 5L X52 pipes are produced in compliance with a number of stringent international standards, making the pipes adaptable for diverse industrial applications. The technique promotes resilience, durability, and plasticity in the pipeline, which makes it reliable for use in both the onshore and offshore pipelines.

📊 Key Technical Specifications

Dimensions and Sizes

API 5L pipes are available in a broad range of sizes to meet various applications. The flexibility of the various size options provided ensures compatibility with differing pipeline operational requirements.

📏 Standard Size Ranges

Outer Diameter

Ranges from 0.405 inches (10.30 mm) to 80 inches (2,032 mm)

Wall Thickness

Varies between 0.02 inches (0.5 mm) to 2 inches (50 mm)

Length Options

- Plain Ends (PE): 20-40 ft (6-12 m)

- Beveled Ends (BE) or Threaded Ends (TE): For specific applications

Grades of API 5L X52

API 5L X52 has two main grades, which are PSL1 (Product Specification Level 1) and PSL2 (Product Specification Level 2). Although both grades are up to standard quality requirements, the PSL2 grade has more rigorous chemical composition and mechanical property controls that allow it to be used in applications needing high performance, excellent weldability, and toughness. These grades are a great choice for pipeline projects as they are able to adjust to different operational and environmental conditions.

Chemical Composition

API 5L X52’s chemical composition is grade dependent, with PSL2 being more conservative in terms of the amounts of key elements. Carbon content for PSL2 is usually lower, while limits for phosphorus and sulfur are strict which leads to better toughness and weldability. So, it is these precise chemical specifications that make the material able to resist difficult operational and environmental conditions.

Manufacturing Standards for API 5L X52 Pipe

The production of API 5L X52 pipe is a quality and technical standards process that the manufacturers have to go through and finally get the product that is reliable and can perform well. The above-mentioned standards and procedures are the main foundation of producing super quality pipes that will be safe and efficient even in the hardest areas of usage.

📋 Main Manufacturing Standards

1. API Specification 5L

Defines the entire manufacturing process, the characteristics of the materials and the testing procedures so that the pipes can be used for the transportation of petroleum, natural gas, and water.

2. ISO 3183

About the quality and environmental sustainability aspects of the pipe used under pipeline transportation systems worldwide regarding international standards.

3. ASTM Standards

Determine the ways to conduct various material tests and validate the chemical composition in terms of durability.

Key Manufacturing Processes

- Material Selection: High-grade steel is used to meet the required chemical composition and mechanical properties

- Welding Methods: Application requirements determine whether seamless or welded (ERW, HFW, or SAW) manufacturing processes will be applied

- Heat Treatment: Pipes are subjected to heat treatment to increase their strength and toughness

- Testing and Inspection:

- Nondestructive testing (NDT) techniques (ultrasonic testing, hydrostatic tests) guarantee structural integrity

- Visual and dimensional inspections verify specifications’ adherence

PSL1 vs. PSL2 Standards

🎯 Selection Criteria: The final decision of either PSL1 or PSL2 is mainly determined by the operating conditions of the pipeline, where PSL2 would be the preferred choice for important applications needing tight safety and reliability standards.

Welding Techniques for API 5L X52 Pipe

The welding of API 5L X52 pipes involves the meticulous choosing of welding techniques that will maintain the structural integrity and performance. The compliance with the welding procedure specifications (WPS) and the industry standards is very important for the safety and reliability in the pipeline applications to be maintained.

🔥 SMAW

Shielded Metal Arc Welding – Traditional method for high-strength welds

⚡ GTAW

Gas Tungsten Arc Welding – Precision welding for critical joints

💨 GMAW

Gas Metal Arc Welding – Efficient for longer seam welds

⚠️ Critical Welding Considerations

- Preheat pipe to reduce thermal stress

- Heat treatment for stress relief (especially for thicker pipes)

- Choose filler material with same mechanical properties as pipe

- Ensure strong and durable weld integrity

Quality Control Measures

To maintain the quality of pipeline welding, it is a must to go through tough inspection and compliance with the standards at each point. The employment of skilled workers and the right recording of test results also plays a significant role in the acceptance and protection of the pipelines that have been welded.

🔍 Essential Quality Control Steps

Applications of API 5L X52 Pipe

API 5L X52 pipes are renowned for their strength, durability, and high performance under pressure, hence they have found a wide application across numerous industries. These multipurpose pipes are made to function perfectly under the most demanding conditions where safety and effectiveness are of the utmost importance.

Oil and Gas

Long-distance transport of crude oil, natural gas, and liquid fuels

Petrochemical

Transporting chemicals and industrial fluids with strength and durability

Construction

Reliable and strong piping for structural projects

Water Supply

Distribution systems for drinking and non-drinking water

Power Generation

Carrying steam, cooling water, and other critical fluids

Utilization in Oil and Gas Industry

Pipes are very significant in the oil and gas industry because they are used to convey crude oil, natural gas, and refined products over long distances. This is due to their durability, resistance to corrosion and high pressure which make them necessary for all the three operations mentioned above: upstream, midstream and downstream. They connect the wellhead piping with offshore platforms, and refinery infrastructures, their sturdiness guaranteeing reliable performance even in the harshest conditions.

🏭 Oil & Gas Operations Coverage

- Upstream: Wellhead connections and extraction operations

- Midstream: Transportation pipelines and storage facilities

- Downstream: Refinery infrastructure and distribution networks

- Offshore Platforms: Subsea and platform piping systems

Construction Sector Applications

In the construction industry, these pipes are commonly applied in structural frameworks, water distribution, and sewage systems. Their resilience, versatility, and resistance to external factors make them suitable for the heavy-duty and different conditions. They are used in all types of construction from residential to commercial, providing dependable performance, which means, durability, and safety of the infrastructures for a long period of time.

Transportation and Infrastructure

These pipes are like an artery in the human body when it comes to transportation and infrastructure. They act as the main parts in bridges, tunnels, and road systems, and also in drainage solutions. Their longevity along with the ability to stand extreme conditions makes them a must for sturdy and durable infrastructure projects.

🌉 Infrastructure Applications

Bridges

Structural support systems

Tunnels

Underground piping networks

Road Systems

Drainage and utility lines

Drainage Solutions

Stormwater management

Industry Insights and Resources

📚 Reference Sources

Savoy Piping Inc. – API 5L X52 Pipe Specification

The standard gives a description of the high-strength seamless welded steel pipes that are generally used in oil and gas industry.

API Standards – Specification for Line Pipe

The standard provides the engineers and the operators with the practices to be used for API 5L pipes.

Longma Group – What is API 5L X52 Pipe?

The role of API 5L X52 pipes in pipeline systems for transporting oil and gas is discussed.

Octal Steel – API 5L X52 Pipe Specification (PSL1 & PSL2)

The use of medium-grade API 5L X52 pipes for transmission of oil and gas through pipelines is talked about.

World Iron & Steel – Difference Between API X42 and X52 Pipe

The uses of X42 and X52 pipes in the production of petroleum and natural gas are indicated.

Frequently Asked Questions (FAQs)

🔩 Choose API 5L X52 for Your Pipeline Projects

API 5L X52 pipes represent the gold standard in pipeline materials, offering unparalleled strength, durability, and reliability for critical infrastructure projects. With stringent manufacturing standards and proven performance in the most demanding conditions, these pipes ensure safety and efficiency across oil, gas, and industrial applications.

Whether you’re planning onshore operations, offshore installations, or complex industrial systems, API 5L X52 pipes deliver the performance and peace of mind your project demands. Trust in specifications that matter for applications that count.