ASTM A36 steel figures in more construction and manufacturing blueprints than almost any other alloy, and for good reason. Its combination of stiffness, impact resistance, and price point makes it a default choice when engineers need something that works. Even seasoned spec writers stop to check the material sheet now and then, because the little details still matter. The paragraphs that follow will break down the chemistry plate, list the standardized yield and tensile numbers, and then walk through the half-dozen trades where A36 shows up most often; by the final section the reader should have a solid grasp of why this steel keeps earning repeat business after more than seventy years on the market.

What is the Chemical Composition of ASTM A36 Steel?

|

Parameter |

Value |

|---|---|

|

Carbon |

0.25–0.29% |

|

Copper |

0.20% |

|

Iron |

98.0% |

|

Manganese |

1.03% |

|

Phosphorus |

0.040% |

|

Silicon |

0.280% |

|

Sulfur |

0.050% |

Understanding the Low Carbon Content

Low-carbon content-price ASTM A36 steel, fixed at about 0.25 to 0.29 percent, quietly governs almost every performance characteristic engineers notice. The modest percentage keeps the alloy soft enough to bend, hammer, or machine without expensive preparation. Because brittleness is all but ruled out, the plate absorbs fatigue and still stretches a bit before it finally breaks. That rare balance of strength, ductility, and weld ease lets project teams reach for A36 in new girder lines, high-rise skeletons, and plate-work sign frames.

The Role of Manganese and Silicon in ASTM A36

Manganese and silicon together steer both the mechanical toughness and the chemical stability of ASTM A36. The manganese addition lifts hardness and overall strength, tightening the tensile profile while quietly knocking down oxygen impurities inside the melt. A standard specification lists manganese at 0.60 to 1.20 percent, which preserves the mild steel’s ductility even after hot rolling and heavy wear. Skimming off oxygen also makes the plate resist early pitting in aggressive service.

Silicon plays a parallel role by trapping any remnant oxygen during production, though its effect is more on the elastic limit than on hardness per se. Typical ladle chemistry keeps silicon between 0.15 and 0.40 percent, a window that stops cracks from opening during rapid cooling. When the two elements work in tandem, ASTM A36 reliably clears the toughest auditing of bridge inspectors or fabrication engineers, which is why it still dominates American plate inventory.

Other Alloying Elements Present in A36 Steel

|

Key Point |

Details |

|---|---|

|

Carbon |

0.25–0.29% |

|

Manganese |

1.03% |

|

Silicon |

0.28% |

|

Copper |

0.20% |

|

Sulfur |

0.05% |

|

Phosphorus |

0.04% |

|

Iron |

98% |

|

Density |

2.84 lb/in³ |

|

Yield Str. |

36,259 psi |

|

Tensile Str. |

58,000–79,800 psi |

|

Hardness |

67–83 Rockwell |

|

Magnetism |

Ferrous magnetic |

How Do the Mechanical Properties of A36 Carbon Steel Affect Its Use?

Examining Tensile Strength and Yield Strength

The tensile strength and yield strength of A36 Carbon Steel are essential for its functionality in varied structural applications. The tensile strength of A36 steel ranges from 58,000 psi to 79,800 psi, which means that the A36 steel can endure a maximum stress of 58,000 to 79,800 psi while being stretched or pulled before failing. This is beneficial in the machining of ASTM A36. The tested tensile strength ensures A36 steel is suitable for large loads in structural frameworks, including bridges, buildings, and construction equipment.

Yield strength is critical for A36 steel; it’s approximately 36,259 psi. This value underscores the vital importance of yield strength as it measures the stress level at which a component begins to deform plastically. The lower yield strength makes A36 steel preferred when mild forming, machining, and welding are needed. This is particularly true in the case of mild and hot-rolled steel. The balance of yield and tensile strength is crucial to ensure structural integrity while providing flexibility in manufacturing processes. Alongside the mechanical properties of A36 steel, its affordability and wide availability make it attractive in various engineering and industrial applications.

Impact of Low-Carbon Steel on Ductility and Welding Properties

Low-carbon steels, like grade A36, have a remarkable ductility, which is crucial for applications involving extensive deformation without breakage. The low carbon content, usually under 0.3%, fosters a more homogeneous and softer microstructure, which improves elongation. Studies have demonstrated that low-carbon steel can achieve elongation between 20 and 25%, which is particularly advantageous for forming and shaping operations.

Furthermore, low-carbon steels possess better weldability due to the lower carbon content, which leads to less carbide precipitation during welding. This also diminishes the tendency of the material to undergo brittleness in the heat-affected zone (HAZ). Its low hardenability permits the microstructure around the welds to stay ductile and tough after solidification. This makes low-carbon steel compatible with many common welding processes, including arc, MIG, and TIG welding, and results in strong and dependable welded joints for structural and industrial uses. These combined characteristics continue to make low-carbon steel a primary material for industries that require performance, cost-effective solutions, and consistent quality.

Assessing Impact Strength at Room Temperature

Impact strength at ambient temperature is a critical metric of a material’s capacity to withstand unexpected loadings without failing. Low-carbon steel has this attribute, which is observed to be high because the material is ductile and can absorb energy effectively. This measure of strength can be evaluated using standardized tests like the Charpy impact test. Evidence suggests that low-carbon steel withstands impacts well and can be used in structural applications where such resistance is critical.

What Are the Applications of ASTM A36 in Industry?

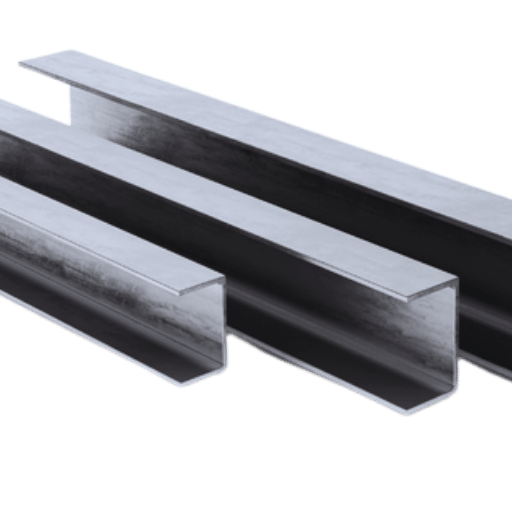

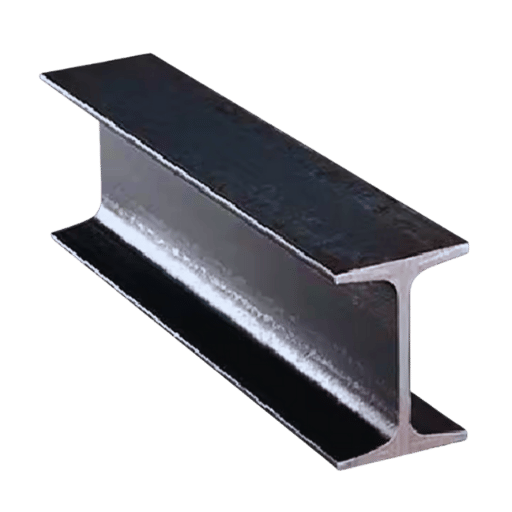

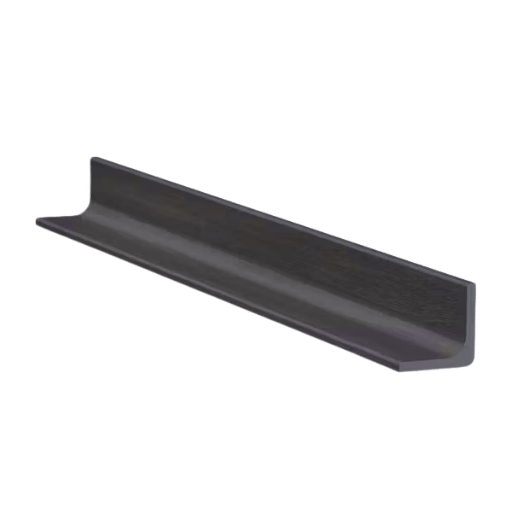

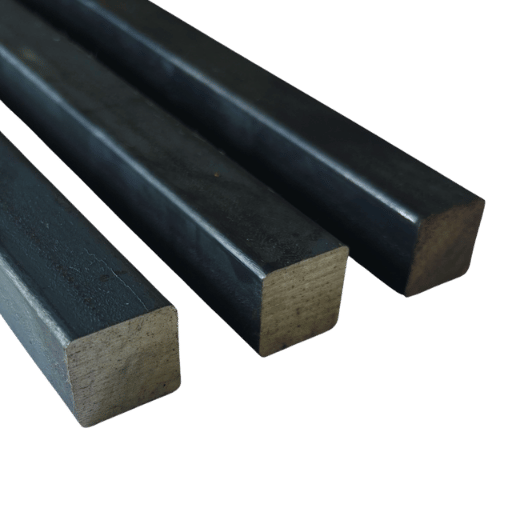

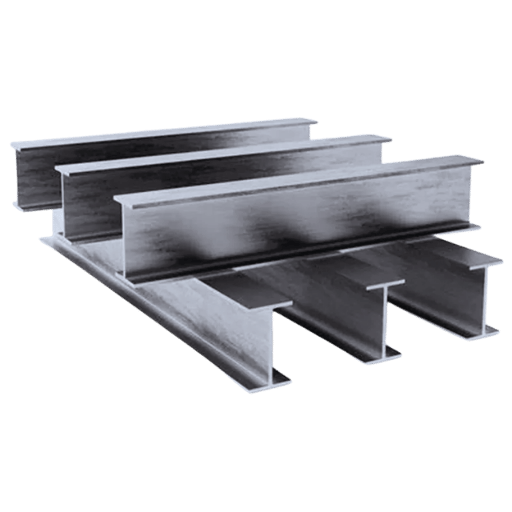

Structural Uses: I-Beams and Machinery

ASTM A36 is frequently used to construct structural I-beams and machinery frames owing to its attractive mechanical characteristics and relatively low price. I-beams fabricated from ASTM A36 steel are vital when constructing bridges, buildings, and even industrial infrastructures in load-bearing operations. These beams are especially hot-rolled steel, offering good strength-to-weight ratios that enhance material utilization while preserving structural integrity.

In machinery applications, components that undergo moderate stress and wear can use ASTM A36 steel. Its weldability and machinability provide design flexibility, a great benefit when fabricating equipment, supports, and machine bases. In the industry, ASTM A36 steel has tensile strength of 400–550 MPa (58–80 ksi) with 20% elongation in two inches. This provides excellent performance, which is guaranteed under dynamic and static loading. With these attributes and its low cost, it is highly favored in numerous industrial fields.

ASTM A36 in Automotive and Oil Rigs

The automotive and oil rig industries extensively use ASTM A36 because of its structural characteristics and cost advantages. In the automotive sector, ASTM A36 manufactures frames, brackets, and other parts that demand high tensile strength and ductility. The material must also withstand dynamic stresses and vibrations to ensure vehicle safety and durability. Further, the material’s weldability enables incorporation into multifaceted designs, improving assembly efficiency.

Similar tendencies are observed in the oil and gas industry, where ASTM A36 is used to construct oil rig structural parts, platforms, beams, and supporting structures. Offshore operations require materials that can withstand harsh and highly saline environments and extreme hot and cold temperatures. ASTM A36 is strong, has good corrosion resistance, and is tough, although it needs to be adequately coated. The material also possesses satisfactory mechanical properties, which are critical in these industries; for example, a minimum yield strength of 250 MPa (36 ksi) is commonplace. In addition to these characteristics, the material is readily available and easy to machine, making ASTM A36 a practical and dependable choice for vital uses.

Role in Non-Structural Steel Applications

ASTM A36 is crucial to non-structural steel applications because of its wide use and simple fabrication processes. It is often utilized for parts of machines and automobiles, as well as equipment that experiences low stress levels. Its affordability makes it an appropriate choice for low-demand projects that do not require high performance, coupled with machinability and weldability, which streamline fabrication processes.

How Does the Heat Treatment of ASTM A36 Steel Affect Its Properties?

Exploring Annealing and Its Effects

The annealing heat treatment process improves the mechanical properties of ASTM A36 steel by changing its microstructure. The procedure involves heating the steel to a certain temperature, holding it at that temperature for some time, and cooling it gradually. This method improves internal stresses and ductility and refines grain structure, leading to enhanced manufacturability.

For ASTM A36 steels, the annealing temperature is between 1,650°F and 1,750°F (900°C and 955°C). During the slow cooling phase, which can occur in air or a furnace, the microstructure becomes uniform and composed of ferrite and pearlite. Research shows that annealed ASTM A36 steel has better toughness and lower hardness than the as-rolled steel; thus, it can be used in applications that need better formability while retaining some strength.

Data analysis reveals that the annealing process enhances elongation percentages and impact energy values for ASTM A36 steel, traits that greatly augment its usefulness in fabrication and structural applications. The trade-off, however, involves a slight reduction in yield and tensile strength, which may be critical during selection for high-load or stress components. In the end, the annealing process offers a versatile strategy for modifying ASTM A36 steel for targeted engineering applications, underscoring its adaptability and optimization in performance.

Understanding Surface Finish After Heat Treatment

The type of heat treatment, its process, material composition, and any protective precautions taken dictate the surface finishing after heat treatment. Heat treatments like annealing, quenching, or tempering can cause oxidation at elevated temperatures, leaving scales or discoloration on surfaces. Inert gas atmospheres and vacuum furnaces are effective for avoiding such issues. These imperfections on the surface can be rectified by finishing processes such as grinding, polishing, or sandblasting to make hot-rolled steel smooth and presentable after heat treatment. Maintaining surface quality and performance requirements is critical; the heat treatment environment controls this.

What Are the Differences Between ASTM A36 and Other Steel Grades?

Comparing ASTM A36 with 1018 Steel

| Parameter | ASTM A36 | 1018 Steel |

|---|---|---|

|

Carbon (%) |

0.26 |

0.18 |

|

Manganese (%) |

0.75 |

0.6-0.9 |

|

Tensile (psi) |

58,000 |

63,000 |

|

Yield (psi) |

36,300 |

53,700 |

|

Elongation (%) |

20 |

15 |

|

Machinability |

Good |

Excellent |

|

Weldability |

Good |

Excellent |

|

Cost |

Lower |

Higher |

|

Applications |

Structural |

Precision parts |

Hot-Rolled vs. Cold-Drawn A36 Steel

| Parameter | Hot-Rolled | Cold-Drawn |

|---|---|---|

|

Process Temp |

High |

Room |

|

Surface |

Rough |

Smooth |

|

Strength |

Lower |

Higher |

|

Tolerances |

Looser |

Tighter |

|

Cost |

Lower |

Higher |

|

Workability |

Easier |

Harder |

|

Stress |

Reduced |

Increased |

|

Applications |

Structural, Rails |

Precision, Aesthetic |

Evaluating ASTM A36 Carbon Steel Material Against Alloy Steel

| Parameter | ASTM A36 | Alloy Steel |

|---|---|---|

|

Carbon (%) |

0.25-0.29 |

Varies |

|

Strength |

Moderate |

High |

|

Weldability |

Excellent |

Good |

|

Corrosion |

Low |

High |

|

Cost |

Low |

Higher |

|

Applications |

Structural |

Specialized |

Frequently Asked Questions (FAQs)

Q: What is ASTM A36 steel, and what are its main components?

A: A36 steel is a low-carbon structural alloy widely specified for beams, plates, and brackets. The chemistry is mostly iron, plus a carbon cap around 0.29 percent, with small allowances for sulfur, phosphorus, silicon, and copper to fine-tune weldability and toughness.

Q: What are the typical physical properties of ASTM A36 steel material?

A: The density is nearly 7.85 grams per cubic centimeter, and average tensile figures run from 400 to 550 megapascals. Yield strength is at least 250 megapascals, and elongation in a standard section hits roughly 20 percent, all of which confirms its role in heavy framing.

Q: How does the machinability of ASTM A36 compare to other steels?

A: Machinability is rated at about 72 percent of a baseline steel, which puts it on the good side but trails AISI 1018. Tools remain effective for turning and milling operations, though operators often swap inserts sooner than they would with higher-grade free-machining grades.

Q: Where will you most often find A36 plate in real-world construction?

A: Building skeletons, highway bridges, and the general shop floor are where A36 plate appears most. Welders like the way its chemistry sits still under an arc, and crane crews appreciate that it stays forgiving when you try to bend or cut it by hand. The truck and tractor shops also grab A36 for brackets, chassis, and quick roadside fixes that demand speed, not paperwork.

Q: What is the practical difference between hot-rolled A36 and cold-rolled steel?

A: Hot-rolled A36 passes through the rolls at a red glow, so it scales a bit and feels rough, almost like cast iron, yet bends nearly on a whim. Cold-rolled steel, by contrast, cools off slowly under a second set of passes, which polishes the surface to mirror quality and ups the tensile strength but cuts into how far you can stretch it.

Q: How well does ASTM A36 Steel resist rust and other forms of corrosion?

A: A36 steel rusts when water wedges into a scratch because it skips the chromium and nickel guarding high-performance alloys. Engineers worry when the humidity ticks up, so beams destined for salt air or acid-fume rooms usually get a zinc coat, a paint layer, or an epoxy bath long before anybody lifts them into place.

Q: What’s the connection between the microstructure of A36 steel and the way it behaves under stress?

A: A36 steel inherits its toughness from a microstructure stuffed with ferrite and pearlite. That two-phase mix keeps the alloy ductile enough to bend without snapping and strong enough to absorb sudden shock. Bridge builders and fabricators like the steel precisely for that blend of calm stretch and reliable give. Ferrite cushions, pearlite, quietly stiffening, shields against brittle failure. Move the same plate from a welding booth to a drafty skyline, and he’d still prove dependable.

Q: How do manufacturers turn raw ingots into A36 plates we see on the shop floor?

A: Producers usually run the bloom or slab through a roaring hot-rolling mill, staggering the passes until it flattens to the desired gauge. The steel cools slowly on the runout table, and that reheating-and-compressing dance leaves a rough, scale-coated finish. Accurate to within a quarter-inch is normal at that stage, so QC crews chalk up numbers rather than laser-line widths.

Q: In practical terms, how does ASTM A36 stack up against AISI 1018?

A: A36 already wears the spec title for structural jobs, trading off a bit of surface polish for easy field welding. AISI 1018, in contrast, slides neatly under the turning tool, thanks to a marginally higher carbon count and a finer alloy footprint. Strength plots show 1018 edging ahead once machining enters the picture, yet the difference fades when big assemblies meet lateral load. Neither steel is precious; each one knows its place on the beam chart.

Q: What should a machinist think about when shaping ASTM A36 steel?

A: Quality control inspectors often mention that A36 has a predictable machinability rating close to 70 percent of the ideal benchmark for mild steel. Even so, the material can harden subtly during heavy cutting, so flood coolant or staged, lighter passes are advisable to stall that effect. Rugged, uncoated high-speed steel bits can work well, though carbide tools will extend life and leave a smoother scratch when production volumes rise.

Reference Sources

1. The Effect Analysis of Coating Thickness Variation and Mixture Composition of Magnesium-Flake Glass on Epoxy Coating on Abrasive Resistance, Adhesion Strength, and Prediction of Corrosion Rate of ASTM A36 Steel Plate (Pratikno et al., 2020)

- Key Findings:

- When the coating settled at 300 μm and absorbed 10 percent of Magnesium Carbonate Flake Glass, the finished bond to steel proved strongest in the pull-off test.

- A thicker layer, 700 μm, loaded with 30 percent flake glass and simply inserted into the grinder, determined the study’s best abrasion resistance.

- Corrosion moved slowest, according to the three-cell reads, under exactly that same 700-μm, 30-percent combination.

- Methodology:

- The experiment stepped the coating thickness between 300, 500, and 700 μm while mixing the flake glass at 10, 20, and 30 percent by weight.

- Pull-off gauges measured adhesion, a tab grinder tracked wear, and a bench-top tri-cell rig forecasted rust rate.

2. Chemical Composition of Structural Steels—MIT: The study catalogs ASTM A36 and presents each specification with practical observations.

3. Steel

4. A36 steel