The importance of materials engineering is stressed in the use of the materials in demanding industries such as construction, marine applications, or chemical processing. Stainless steel grades 316 and 316L are best solutions to consider when strength, corrosion resistance, and versatility are all critical factors. But if one has to select these for his or her project, he or she has to look into their yield strength relative to other properties. This article deals with 316 stainless steel yield strength, among others: the low-carbon 316L stainless steel yield strength, highlighting their differences, benefits, and best applications. Keep reading to find out everything you need to know to make the right choice between these performance alloys.

Introduction to Stainless Steel

Stainless steel is known for its durability and versatility across different industries, owing to its properties of corrosion resistance, heat resistance, and wear resistance. Primarily, it consists of iron, chromium, and other alloying elements such as nickel and molybdenum, which serve to improve strength and impart protective properties. The stainless steel owes its corrosion resistance from rust and tarnish over the years to the presence of chromium of not less than 10.5 percent in the alloy. This material is produced in different grades, the performance characteristics of which meet specific needs, such as structural-grade, chemical-grade, or marine-grade. Stainless steel finds its application both within industrial products and consumer products due to its strength, agreeable maintenance conditions, and good looks.

What is Stainless Steel?

Stainless steel is a multi-functional alloy mainly comprising iron and chromium, with varying compositions of elements such as nickel, carbon, manganese, and molybdenum. When introduced in the composition in a concentration of at least 10.5%, chromium produces a passive protective coating on the surface called a chromium oxide layer, which protects the steel from corrosion and oxidation. This self-healing layer is what imparts the various corrosion resistivity properties to stainless steels.

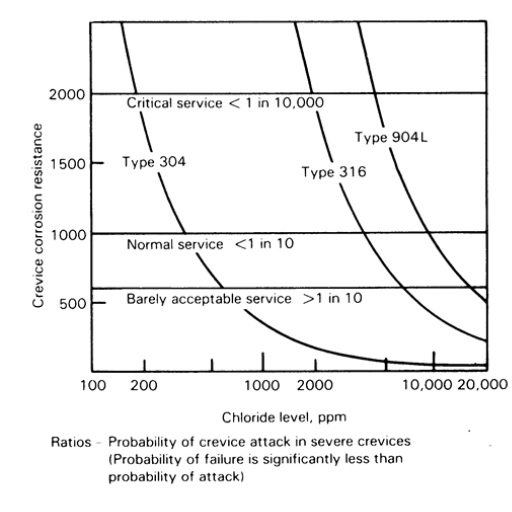

The different grades of stainless steel are determined by their composition and applications. For example, austenitic stainless steels like types 304 and 316 being highly resistive to corrosion find their use in kitchenware, medical instruments, and marine equipment. On the other hand, ferritic stainless steels are magnetic, generally cheaper, and so are used in the automotive and structural industries. Duplex stainless steels provide a somewhat high-service-grade strength and resistance to stress corrosion cracking, thus being useful in industrial working environments such as chemical plants.

As far as properties go, stainless steel offers a tremendous tensile strength level, from 515 MPa beyond 1,000 MPa, which depends on grades. For instance, 316 stainless steel has better resistance against chlorides and could find application in marine or saline environments. It withstands cryogenic conditions to about 1,400°F (760°C) without any integrity loss of its structure.

Being aesthetically unique in design, with an almost unmatched strength and corrosion resistance, stainless steel continues to see applications in various industries ranging from construction to transportation to energy to medical fields. With the evolving technologies of production, manufacturing stainless steel has become more value engineering-wise and greener, further consolidating its position as one of the most reliable and sustainable materials.

Overview of Stainless Steel Grades

Stainless steel is categorized into various grades, each tailored to meet particular strength, corrosion resistance, and durability requirements. These grades are classified into four primary families based on their microstructure and alloy composition: austenitic, ferritic, martensitic, and duplex. Here is a closer examination of these categories and their respective applications:

- Austenitic Stainless Steel

Austenitic stainless steels, encompassing grades like 304 and 316, are the most commonly used. These grades contain high levels of chromium and nickel, making them exceptionally resistant to corrosion and oxidation. Type 304 is widely used in kitchen equipment and automotive trim due to its versatility and affordability, while Type 316, with added molybdenum, offers superior resistance to chlorides and saline environments, making it ideal for marine and chemical industry applications.

- Ferritic Stainless Steel

Ferritic stainless steels, such as grades 430 and 446, are notable for their excellent resistance to stress corrosion cracking and high-temperature oxidation. These steels possess a lower nickel content, which helps reduce costs while maintaining good corrosion resistance. They are commonly used in automotive exhaust systems and household appliances.

- Martensitic Stainless Steel

Grades like 410 and 420 fall under the martensitic family. These stainless steels are characterized by their high carbon content, which imparts exceptional strength and hardness. However, they offer moderate corrosion resistance compared to austenitic grades. Martensitic stainless steels are often used in the production of cutlery, surgical instruments, and turbine blades.

- Duplex Stainless Steel

Duplex grades, such as 2205, combine the best properties of austenitic and ferritic stainless steels. They provide enhanced strength, excellent corrosion resistance, and improved weldability. These properties make duplex stainless steels particularly suitable for use in the oil and gas, chemical processing, and desalination industries.

Each grade within these families is carefully designed to optimize specific performance metrics. For instance, the tensile strength of Type 316 can range between 515-620 MPa, while duplex stainless steels like 2205 may exhibit strengths of 600-800 MPa, reflecting their broad utility across demanding industrial applications. Understanding these differences is crucial for selecting the right stainless steel for any given purpose, ensuring longevity, safety, and cost-effectiveness.

Importance of Yield Strength

Yield strength is a paramount property in the field of materials as it determines the stress level at which a material begins to deform plastically. Beyond this point, the material cannot regain its shape, thus making yield strength an important factor considered during engineering and construction. Materials with adequate yield strength are chosen so that the structure remains intact and to avoid failure under load.

Yield strength may vary considerably, for instance, in carbon steels from 250 MPa of mild carbon steel to around 500 MPa in a high-strength grade like A572. Stainless steel offers a versatile performance with austenitic grades such as Type 304 offering yield strength values of roughly 215 MPa, while duplex stainless steels such as 2205 yield far higher values between 450 and 550 MPa, making the duplex stainless steel series the preferred choice for more demanding services where both high stresses and corrosion resistance are required.

Yield strength becomes especially critical when there are varying loads or harsh operating conditions, such as those found in the infrastructure of bridges, pressure vessels, and gas pipelines. Choosing materials of apt yield strength helps keep safety margins as well as costs and performance in check. On the whole, knowledge about and prioritization of yield strength of a material during selection truly empowers an engineer to design robust and reliable systems to meet the specific requirements of each application.

Mechanical Properties of 316 Stainless Steel

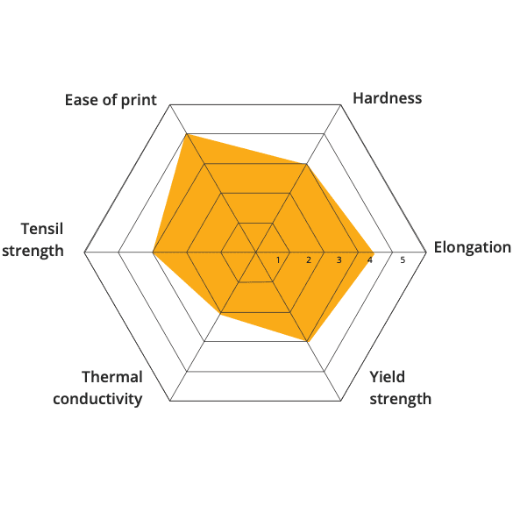

316 stainless steel is known for its great mechanical properties and is employed when the environment cannot be compromised. It has a tensile strength of 579 MPa (84,000 psi) and a yield strength of 290 MPa (42,000 psi). The elongation to break is about 50%, hinting toward good ductility. Having this, 316 is resistant to corrosion and can maintain its strength and toughness in a broad temperature range until cryogenic temperatures. These traits offer great prospects from which the working applications demanding durability and resilience may benefit.

Yield Strength of 316 Stainless Steel

Yield Strength being the ability of a material to resist forces that tend to induce non-permanent deformation, a usual value for annealed grades of 316 stainless steel is estimated to be about 290 MPa (42,000 psi). This value may, however, increase or decrease, depending on treatments effected on the material, such as its cold work, which tends to drastically improve its strength. The cold-working of 316 stainless steel, for example, may bring the yield strength anywhere from 515 MPa (75,000 psi) up to 758 MPa (110,000 psi).

Cold-working results in higher yield strength, thereby allowing applications for cold-worked 316 stainless steel where it is required to possess high strength and corrosion resistance, such as for marine, chemical, and pharmaceutical uses. Such an alloy also exhibits mechanical strength even under extreme environmental conditions and therefore ensures durable applicability in both high-temperature and cryogenic environments. The versatility therefore leads to the widespread acceptance of 316 stainless steel in many sectors.

Comparison with 304 Stainless Steel

316 stainless steel contains molybdenum, offering superior corrosion resistance, especially in chloride-rich environments, while 304 is more cost-effective and suitable for general applications.

|

Parameter |

304 |

316 |

|---|---|---|

|

Molybdenum (Mo) |

None |

2.0-3.0% |

|

Corrosion |

Moderate |

Superior |

|

Cost |

Lower |

Higher |

|

Applications |

General, indoor |

Marine, chemical |

|

Strength |

Moderate |

Higher |

Effect of Temperature on Mechanical Properties

The mechanical properties of 316 stainless steel are largely impacted by temperature. At high temperatures, the alloy is able to retain its strength and corrosion resistance, but its tensile strength and yield strength vary and decrease with temperature. Since, at room temperature (nearly 20°C or 68°F), 316 stainless steel has a tensile strength of approximately 515 MPa and the yield strength is in the range of 205 MPa, as the temperature goes up to 800°F (427°C), the tensile strength lowers down to roughly 345 MPa, and the yield strength drops even further to around 138 MPa.

This material also showcases great creep resistance against forces and temperature, which is highly important for applications exposed to these constant loads at high temperatures. In other words, the corrosion resistance is a capability of the alloy to withstand deformation with time, at high heat, and stress. Thus, 316 stainless steel seems to prime for use in industries such as power generation and chemical processing.

316 stainless steel portrays great toughness at cryogenic ranges. At cryogenic temperatures, this alloy remains ductile and does not behave in a brittle manner unlike several materials that turn brittle in the low-temperature environment. One example of its use in these cryogenic conditions is for LNG storage or transportation.

Knowing about these temperature effects will be essential when selecting 316 stainless steel for temperature-sensitive applications. When designing components, engineers must take these variations into consideration to assure best possible performance, durability, and lifespan at those thermal conditions.

Chemical Composition and Physical Properties

316 stainless steel is primarily composed of iron, chromium (16 to 18 percent), nickel (10 to 14 percent), and molybdenum (two to three percent), alongside minor quantities of manganese, silicon, and carbon. Its corrosion resistance is enhanced by molybdenum, especially in chloride-bearing environments. Its physical properties include great durability, good resistance to oxidation, and tensile strength of about 515 MPa. The alloy is good for industrial plants requiring design integrity at varying temperatures.

Alloying Elements in 316 Stainless Steel

316 stainless steel is a molybdenum-bearing grade that excels in corrosion resistance, particularly in environments exposed to seawater or heavy chemical exposure. Its alloying elements each contribute distinct properties:

- Chromium (16-18%): Chromium is crucial for forming a stable oxide layer on the surface, which protects the steel from oxidation and corrosion. This passive layer is self-healing, ensuring long-term durability even under harsh conditions.

- Nickel (10-14%): Nickel enhances the material’s ductility, toughness, and resistance to corrosion, particularly in acidic and chloride environments. It also supports the austenitic microstructure of 316 stainless steel, which provides its non-magnetic and formable characteristics.

- Molybdenum (2-3%): The standout addition, molybdenum, significantly bolsters resistance to pitting and crevice corrosion caused by chlorides, making it invaluable for marine or chemical applications.

- Carbon (Max 0.08%): Carbon ensures strength and hardness, while its controlled presence prevents carbide precipitation at grain boundaries during welding, which could otherwise affect corrosion resistance.

- Manganese (Max 2%): Manganese improves hot-workability characteristics and minimizes the adverse effects of sulfur content.

- Silicon (Max 0.75%): Silicon aids in enhancing oxidation resistance at elevated temperatures and improves the alloy’s overall strength.

- Phosphorus and Sulfur (Max 0.045% & 0.03% respectively): These elements are kept at minimal levels to ensure better machinability and to prevent brittleness.

316 stainless steel is commonly chosen for applications requiring superior corrosion resistance and mechanical strength. Industries such as marine construction, chemical processing, medical device manufacturing, and food preparation rely on this alloy due to its exceptional performance under demanding environments.

Physical Properties of 316 and 316L

316 and 316L stainless steels exhibit a wide range of physical properties that make them highly versatile and suitable for demanding applications. These properties include density, melting point, thermal conductivity, and more, which contribute to their performance across various environments.

- Density: Both 316 and 316L stainless steels have a density of approximately 8.00 g/cm³, ensuring high strength-to-weight ratios that make them ideal for structural and industrial use.

- Melting Point: The melting range falls between 2,500°F and 2,550°F (1,370°C to 1,399°C), allowing these steels to withstand high-temperature applications without deformation or loss of integrity.

- Thermal Conductivity: With a thermal conductivity of 16.2 W/m·K at room temperature, these alloys provide reliable performance in environments requiring heat dissipation or thermal management.

- Electrical Resistivity: The electrical resistivity is approximately 0.74 µΩ·m (microohm meter), supporting applications where electrical insulation or controlled conductivity is essential.

- Magnetic Properties: Both grades are non-magnetic in their annealed condition, making them suitable for use in sensitive electronic and medical applications.

Comparison of 316 and 316L Chemical Composition

316 and 316L stainless steels share similar chemical compositions, but 316L has a lower carbon content (0.03% max vs. 0.08% max in 316), enhancing its weldability and resistance to intergranular corrosion.

|

Parameter |

316 |

316L |

|---|---|---|

|

Carbon (C) |

≤ 0.08% |

≤ 0.03% |

|

Chromium (Cr) |

16.0-18.0% |

16.0-18.0% |

|

Nickel (Ni) |

10.0-14.0% |

10.0-14.0% |

|

Molybdenum (Mo) |

2.0-3.0% |

2.0-3.0% |

|

Weldability |

Moderate |

Excellent |

|

Corrosion |

Moderate |

Superior |

Corrosion Resistance of 316 Stainless Steel

316 stainless steel is very resistant to corrosion, especially in the presence of chlorides, acids, and alkalis. It is molybdenum that enhances 316 stainless steel against pitting and crevice corrosion. Thus, 316 stainless steel finds application in marine settings,Chemical processing, and pharmaceutical machinery, all of which are commonly subjected to severe corrosive attacks from the environment. Withstanding environmental and chemical stresses, it provides lasting durability and reliability.

Understanding Corrosion Mechanisms

Corrosion is a natural course of progression that sees refined steel slowly deteriorate back to its ore state, one such interaction being chemical in nature, with its environment. Mainly electrochemical reactions drive the corrosion process. Oxidation is one of the key mechanisms, and a classic example: in the presence of oxygen and moisture, metal atoms lose electrons that create an unstable layer on the surface. Iron, for example, is often found to be oxidized beyond repair, with iron oxides compromising structural strength.

Types of corrosion considered are uniform corrosion if it corrosively attacks a surface evenly; localized corrosion, which includes pitting corrosion when tiny pits or cavities form; or galvanic corrosion that occurs between two different metals in contact in a conductive liquid. It has been found that failure rates of concentrated pits can be ten times faster than uniform corrosion.

Climatic and environmental parameters greatly optimize such behavior. Important studies indicate materials exposed to high salinity, such as marine environments, as highly susceptible to accelerated corrosion rates. In other words, stainless steel grades without sufficient protective alloying can start developing pits within weeks in chloride ion environments. To deal with such problems, more advanced materials such as 316 stainless steel are equipped with molybdenum and chromium to block the corrosive reactions, therefore promising longer life in aggressive environments.

The comprehension and opportunity to prevent corrosion mechanisms are essential for construction, transportation, and energy production industries. Today, ongoing research advances with better material science and new protective coatings, and engineering attempts to mitigate these problems toward a safer and more efficient application.

Factors Affecting Corrosion Resistance

Several factors influence the corrosion resistance of materials, each playing a vital role in determining the susceptibility of a material to corrosive environments. Below is a detailed list of these factors:

- Material Composition

- The chemical makeup of a material significantly affects its ability to resist corrosion. For instance, alloys containing elements such as chromium, molybdenum, and nickel exhibit higher corrosion resistance.

- Example Data: Stainless steels with 18% chromium and 8% nickel (commonly known as 304 stainless steel) demonstrate exceptional resistance in many environments.

- Surface Condition

- The smoother and cleaner a material’s surface, the less likely it is to corrode. Irregular surfaces, scratches, or residual contaminants can act as initiation sites for corrosion.

- Polished finishes, such as electropolishing, can further enhance resistance by eliminating imperfections.

- Environmental Factors

- Corrosion rates are heavily influenced by the surrounding environment, including humidity, temperature, and the presence of corrosive agents like chlorides or acidic compounds.

- Example Data: Higher chloride concentrations, such as in marine environments, accelerate corrosion, with stainless steels requiring additional protective measures.

- pH Levels

- Materials are more susceptible to corrosion in highly acidic (low pH) or highly alkaline (high pH) environments. Certain materials like titanium exhibit superior stability across a broader pH range.

- Exposure to Stress

- Materials under mechanical stress or deformation are prone to stress corrosion cracking, a process combining corrosive and mechanical damage. This form of corrosion particularly affects metals such as stainless steels in chloride-rich environments.

- Temperature Variations

- High temperatures can exacerbate corrosion processes by increasing reaction rates. For instance, materials may experience oxidation (rust) at elevated thermal conditions if not properly protected.

- Protective Coatings and Treatments

- The application of surface treatments such as anodizing, galvanizing, or painting can drastically improve corrosion resistance.

- Zinc coatings, for example, protect steel substrates through both barrier protection and sacrificial action in corrosive conditions.

- Design and Geometry

- Poor design choices, such as sharp corners, crevices, or areas difficult to clean and dry, can trap moisture and contribute to localized corrosion. Ensuring proper drainage and accessible surfaces reduces this risk.

- Time of Exposure

- The duration that a material is exposed to corrosive conditions directly affects the level of corrosion. Short-term exposure allows materials to perform better compared to prolonged interaction with aggressive substances.

- Electrochemical Potential

- Metals with a more negative electrochemical potential are less noble and more likely to corrode in a galvanic couple. Selecting compatible materials helps mitigate galvanic corrosion.

By understanding and managing these factors, industries can better predict and control corrosion challenges, ensuring the durability and reliability of critical infrastructure.

Applications Benefiting from Corrosion Resistance

Corrosion resistance comes in handy in many industries where material degradation could become a safety risk, inefficient operations, and additional costs. Some of the key sectors for corrosion-resistant technologies include:

1. Aerospace Industry

Aircraft and spacecraft components are regularly subjected to extreme environmental conditions with temperature variations, high humidity, and salt-laden atmospheres. Such corrosion-resistant alloys are considered seriously for titanium and aluminum-based materials and coatings to ensure strength and reduce maintenance. Advanced coatings have seen aircraft life being extended for about 10-15 years, thereby majorly improving safety while offsetting long-term costs.

2. Marine and Offshore Structures

Ships, oil platforms, and offshore wind turbines operate in seawater environments characterized by high salinity and persistent moisture, aggressive cases for corrosion. The use of stainless steels, duplex steels, and specialized marine coatings greatly enhance resistance to pitting and crevice corrosion. It is noted that maintenance for marine vessels using protective coatings is generally reduced by some 40%.

3. Construction and Civil Engineering

Bridges, pipelines, and enemy reinforcements are subjected to environmental pollution, water exposure, or de-icing salts. Corrosion-resistant reinforcement, such as epoxy coatings and weathering steel, is appropriate for the enhancement of life expectancy of these structures. Some studies have shown an average of 20 years in life extension for investments in corrosion protection applied to bridges, which in turn reduces the number of major repairs.

4. Biomedical Sector

Implants, surgical instruments, and medical devices are designed to be body fluid-compatible, which could otherwise corrode conventional materials. Materials such as titanium and cobalt-chromium alloys and biocompatible coatings provide durability and resistance against degradation inside the human body. Titanium implants, for instance, are highly corrosion-resistant in the long term, allowing for reliable functionality for decades.

5. Chemical Processing Plants

Plants that process aggressive chemicals-type acids and alkalis depend on the demands of high-performance materials for facing corrosive damages. Nickel alloys, coatings of Teflon, and fiber-reinforced plastics are generally used to maintain equipment efficiency and safety. Improvements in corrosion control have been considered to reduced plant unplanned downtime by 25-30%.

By the application of advanced corrosion-resistant materials and technologies, customized to the needs of the industries, enterprises can safeguard their processes, lessen environmental impact, and drastically cut on their long-term costs.

Applications of 316 Stainless Steel

316 stainless steel is employed when an environment demands superior corrosion resistance coupled with high-temperature resistance. The typical applications include:

- Marine Environments: Preferred for the construction of ships, docks, and coastal structures in view of its saltwater corrosion resistance.

- Food and Beverage Industry: Used for tanks, piping, and processing machinery where hygienic conditions and durability are paramount.

- Chemical Processing: Put to use in vessels and piping systems for corrosive substances where safety and life expectancy are foremost.

- Medical Equipment: Favored for surgical instruments and implants due to being biocompatible and annealing-compatible.

- Architect-Hardware: Utilize it for exterior facades and structures exposed to severe weather in a handsome finish.

This versatility helps make 316 stainless steel an impregnable choice for a handful of tough applications.

Industry-Specific Applications

1. Food and Beverage Industry

This steel finds a key application in the production of stainless steel tanks, pipes, and processing equipment for dairy, brewery, and wine industries, with the added treatment of corrosion-resistant application, especially resistance to acid and salt. One recent study also suggested the ability of the material to resist corrosion may bring down maintenance costs for the manufacturers by 20-30% annually when compared with ordinary materials.

2. Marine Industry

The 316 stainless steel is popular in marine environments due to its resistance against chloride-induced corrosion. It is, therefore, preferred for use in an environment exposed to saltwater, such as boat fittings, coastal infrastructure works, and desalination plants. It is reported that the use of 316 stainless steel structures helps to increase the life span with a 50% increase in durability under saline environment over other alloys.

3. Pharmaceutical and Biotechnology

Due to the high level of cleanliness required in the pharmaceutical and biotech industries, 316 stainless steel is used. It has a very smooth surface that retards microbial growth, whereas the resistance to harsh cleaning agents permits the maintenance of sanitary conditions. Pharmaceutical manufacturing studies indicate that the use of this material greatly lowers contamination risks, thereby ensuring a higher degree of regulatory compliance.

4. Chemical Processing

This grade is extensively used in chemical processing plants in view of its ability to withstand high temperatures and severe chemical attacks from chemicals such as sulphuric acid and caustic solutions. Often heat exchangers, storage tanks, and reactors are fabricated from this grade, thus guaranteeing durability even in severe conditions of the plant. This change in material led to more than 15% improvements in plants’ efficiency and downtime due to corrosion-related failures.

Such wide adaptability among tough industries further keys 316 stainless steel as a premier choice for applications that demand durability, corrosion-resistance, and performance efficiency.

Comparison of 316 and 316L in Applications

316 stainless steel is stronger and better for high-pressure applications, while 316L is more corrosion-resistant and ideal for welding and environments with high chloride exposure.

|

Parameter |

316 |

316L |

|---|---|---|

|

Carbon Content |

Higher |

Lower |

|

Strength |

Higher |

Slightly lower |

|

Corrosion |

Moderate |

Superior |

|

Weldability |

Moderate |

Excellent |

|

Applications |

High-pressure, marine |

Welded, chemical, medical |

Advantages of Using 316 Stainless Steel

In my experience, 316 stainless steel offers excellent corrosion resistance, especially in harsh environments like marine or chemical applications. It ensures extreme durability, thus cutting maintenance costs and extending the lifespan of equipment. Further, it finds immense application in high-temperature operations owing to its strength and heat resistance properties. It also remains a sanitary choice for food processing and pharmaceutical industries. Above all, I see it as a material that is highly reliable and versatile for demanding applications.

Reference Sources

1. Temperature‐Dependent Deformation Behavior of 316 Stainless Steel with Heterogeneous Microstructure

- Authors: Jiahe Wan et al.

- Journal: Steel Research International

- Publication Date: December 27, 2024

- Citation Token: (Wan et al., 2024)

- Key Findings:

- The study investigates the mechanical properties and deformation behavior of a heterogeneous structured 316 stainless steel, which includes a mix of deformed and recrystallized grains.

- It was found that the yield strength of the heterogeneous structured specimen is significantly higher at cryogenic temperatures compared to room temperature, while the yield strength of the uniformly structured specimen remains largely unchanged.

- The study attributes this difference to dislocation strengthening and heterogeneous deformation-induced strengthening.

- Methodology:

- Systematic investigations were conducted using tensile tests to evaluate yield strength at different temperatures, alongside microstructural analysis to understand the contributions of dislocations and grain structures.

2. The Effect of Mn and Ti Ratio on Microstructure and Mechanical and Machinability Properties of 316 L Stainless Steel Used in Biomedical Applications

- Authors: Mustafa Türkmen et al.

- Journal: Metals

- Publication Date: October 26, 2023

- Citation Token: (Türkmen et al., 2023)

- Key Findings:

- The study explores how varying the ratios of titanium (Ti) and manganese (Mn) in 316 L stainless steel affects its microstructure and mechanical properties.

- The optimal composition (0.35 wt% of both Ti and Mn) resulted in the highest yield strength and hardness.

- Higher ratios of Ti and Mn led to a decrease in mechanical properties.

- Methodology:

- The research utilized powder metallurgy techniques, including cold pressing and sintering, to create samples. Mechanical properties were characterized through tensile tests and hardness measurements, alongside microstructural analysis using optical microscopy and scanning electron microscopy (SEM).

3. Multi-response optimization of TIG dissimilar welding of AISI 1008 mild steel and AISI 316 stainless steel using grey-based Taguchi method

- Authors: O. S. Ogbonna et al.

- Journal: The International Journal of Advanced Manufacturing Technology

- Publication Date: March 3, 2023

- Citation Token: (Ogbonna et al., 2023, pp. 749–758)

- Key Findings:

- This paper presents a method for optimizing the welding parameters for dissimilar welding between mild steel and 316 stainless steel.

- The optimal settings achieved higher ultimate tensile strength, yield strength, and percentage elongation compared to initial settings.

- Methodology:

- The study employed a grey-based Taguchi optimization approach, utilizing an L9 Taguchi orthogonal array to analyze the effects of welding current, voltage, and gas flow rate on multiple performance characteristics.

Frequently Asked Questions (FAQs)

What is the yield strength of 316 stainless steel?

The yield strength of 316 stainless steel typically ranges around 30 ksi (kilopounds per square inch) to 35 ksi, making it a strong material ideal for various applications requiring high strength and durability.

How does 316 and 316L stainless steel compare in yield strength?

Both 316 and 316L stainless steels exhibit similar yield strengths, but 316L has lower carbon content, which enhances its corrosion resistance, particularly in chloride environments. This makes it suitable for marine applications and areas prone to crevice corrosion.

What are the specific properties of 316 stainless steel?

316 stainless steel is known for its excellent corrosion resistance, especially against chlorides, and possesses good mechanical properties, including yield strength and ductility. It also has a high level of toughness at low temperatures and maintains strength at elevated temperatures.

What is the difference between 304 and 316 stainless steel?

The primary difference between 304 and 316 stainless steel lies in their chemical composition. 316 contains molybdenum, which enhances its corrosion resistance properties compared to 304. Therefore, 316 is often referred to as marine grade stainless steel due to its superior performance in harsh environments.

How does the annealing process affect the properties of 316 stainless steel?

Annealing 316 stainless steel helps to relieve internal stresses and improve ductility. This heat treatment process can also enhance the material’s corrosion resistance by reducing chromium carbide precipitation, which can occur during welding or high-temperature applications.

What are the mechanical properties of 316L stainless steel?

316L stainless steel exhibits similar mechanical properties to 316, with a yield strength around 30 ksi. Its low carbon content increases corrosion resistance and reduces the risk of stress corrosion cracking in chloride environments, making it a preferred choice for many applications.

What is the role of low carbon content in 316L stainless steel?

The low carbon content in 316L stainless steel minimizes the risk of chromium carbide precipitation during welding, which can compromise corrosion resistance. This characteristic makes 316L particularly suitable for applications in harsh environments, where improved resistance to corrosion is essential.

Why is 316 stainless steel considered the best stainless steel for marine applications?

316 stainless steel is considered the best for marine applications due to its excellent corrosion resistance properties, especially against crevice corrosion and stress corrosion cracking in chloride environments. Its combination of high strength and durability makes it ideal for use in coastal and underwater applications.