The galvanized pipe was once considered modern due to its strength and resistance to corrosion. As aging pipes, they may develop several issues that can seriously threaten a home’s plumbing system and water quality. Therefore, it is essential to recognize the warning signs of deteriorating galvanized pipe to minimize damage and preserve the safety of one’s water supply.

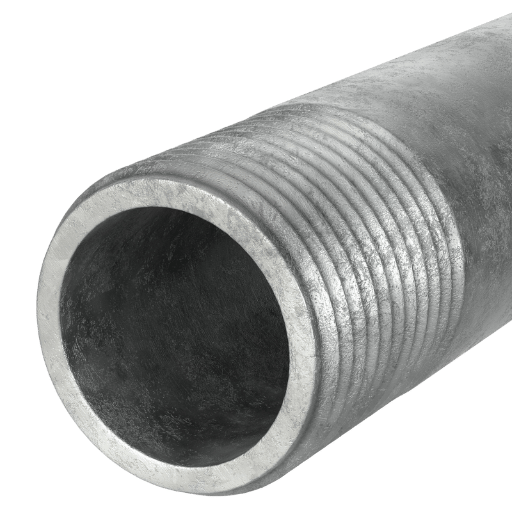

What Does a Galvanized Pipe Look Like?

Galvanized pipes are steel pipes coated with zinc to inhibit corrosion; from a cosmetic viewpoint, they are metallic gray or silver, and can eventually assume a dull or washed-out appearance because of the zinc coating wearing off. Old galvanized pipes develop discoloration; rusty stains appear on the surface in brown or orange. They are thicker and heavier compared to contemporary copper or plastic pipes and are threaded for joining pipe sections.

Identifying Galvanized Pipe in Your Home

To locate the galvanized pipes in your home, start by inspecting any exposed plumbing, which may be in the basement, utility rooms, or under sinks. Here’s what you need to check for:

🔍 Quick Identification Checklist

- ✓ Color: The new galvanized pipes usually possess a metallic grayish or silvery-like color and may become dull or rusted with time.

- ✓ Magnetic Test: Use a magnet for verification—most galvanized pipes will attract a magnet, unlike copper or plastic pipes.

- ✓ Threaded Fittings: At the joints, there may be threaded fittings. Such fittings are very characteristic of galvanized pipes.

- ✓ Professional Help: When in doubt, always rely on a professional to ensure correct identification.

Differences Between Steel Pipe and Galvanized Steel

Visual Indicators of Rust and Corrosion

🎨 Color Changes

Rust appears as reddish, brownish, or orange flaky deposits on steel or iron surfaces. Corroded areas on metals like aluminum or copper appear white, green, or blue and are usually magnetically detected.

✋ Surface Texture

Affected spots might feel rough, brittle, or uneven, and are easy to flake away or crumble when touched.

🔘 Pitting

Small holes or depressions on the material’s surface are a standard indicator of advanced corrosion.

💧 Staining

Discolorations or streaks emanate outward from the stained areas, adorning adjacent surfaces with corrosion.

Why Does Galvanized Plumbing Corrode?

The Role of Zinc in Preventing Corrosion

Zinc acts as a protective reservoir for steel or iron in galvanized plumbing systems, providing dual mechanisms of corrosion protection. First, the zinc coating forms a barrier layer that prevents oxygen and moisture from directly contacting the underlying metal. Second, zinc acts as the cathodic protector by forming a sacrificial anode. This means that zinc will corrode before steel or iron, as it is more reactive when exposed to corrosive elements, thus preserving the base material.

📊 Research Insight: The service life of the galvanized pipe generally depends on the thickness of the zinc coating and on the quality of water it meets. Thin layers of zinc coating will deteriorate quickly in soft or acidic water, as zinc is more reactive under these conditions. Hence, in some areas, galvanized plumbing can last about 40 to 50 years under ideal conditions, but is minimal in aggressive environments or with poor maintenance.

Nowadays, the adhesion and uniformity of zinc coatings are improved by modern galvanization techniques, such as hot-dip galvanizing, thereby increasing their corrosion resistance. Improvements in protective techniques ensure a higher-performing life, making zinc an excellent element for countering corrosion-induced structural degradation.

Impact of Water on Galvanized Steel Pipes

Water longevity and performance are greatly influenced by water quality, which is a concern for maintaining the pipe. Significant concentrations of calcium and magnesium in hard water can cause scale to form on the interior of pipes, reducing the effective diameter and inhibiting water flow. Such scaling further increases internal corrosion, especially where water movement is slow. In contrast, soft water offers little chance of scaling. Still, it may instead be acidic, thereby making the zinc layer more prone to corrosion and exposing the underlying steel to rusting.

⚠️ High-Risk Water Conditions

- High chloride content (seawater or excessive chlorination) rapidly breaks down the protective zinc coating.

- Stagnant water leads to uneven corrosion patterns, as a passivation layer may not regenerate effectively.

- Varying pH levels, temperatures, and mineral content will lead to markedly shorter lifespans.

Galvanized steel pipes used for municipal water supply typically last from 40 to 50 years under ideal conditions; however, the effect can be some temporary obstruction to some extent with the use of modern water treatment systems, regular maintenance, and periodic inspections for prolonged structural integrity and product-bearing functional life of the galvanized piping system.

How Rust Compromises Water Quality

Rusting occurs when galvanized steel pipes react with oxygen and moisture, forming iron oxide. Thus, rusting can contaminate water systems in many ways. First, rust particles can break loose from inside the pipe, discoloring water and often appearing as a reddish-brown stain. In addition to stains, rust can contaminate water and increase its turbidity, reducing water clarity and making it difficult to treat effectively.

Chemical alteration in water is another concern when exposed to rust. If dissolved iron levels in galvanized water become too high, they can spoil the taste and smell, making it less appetizing. Moreover, elevated levels of iron oxide may encourage the growth of iron bacteria that form biofilms within pipes; these biofilms further degrade water quality and, in some cases, can block pipe flow.

🏥 Health Considerations: Being of utmost importance, iron, if present in too high amounts in water, will cause a significant strain on filtration systems. Also, infrastructure may be impaired over the long term. Studies suggest that prolonged exposure to rust-contaminated water may also increase the leaching of trace metals, such as lead, from old plumbing systems, posing increasing health and environmental safety concerns.

When Is It Time to Replace Your Galvanized Pipes?

Signs It’s Time to Replace

1. Persistent Low Water Pressure

Low water pressure throughout your home may indicate the accumulation of rust and mineral deposits in galvanized pipes, which can affect your water supply lines. These deposits concentrate and narrow the pipe diameter, restricting water flow and thereby reducing efficiency over time.

2. Discolored Water

Water that appears brown, yellow, or orange indicates corrosion and rust in the piping system. These discolorations often mean that the zinc coating of galvanized pipes has worn down, allowing rust to seep into your water supply.

3. Frequent Leaks

Corroded pipes can develop cracks and leaks, leading to water damage and repairs that may be very costly. Leakage in several locations or multiple points suggests the entire piping might be affected and cis oming to the end of its lifespan.

4. Age of Your Plumbing System

Galvanized pipes were commonly installed in homes built before the 1960s, giving them a lifespan of about 40-60 years. Should the house still use this plumbing system and fall within this age range, replacement is commonly the best course of action to avert catastrophic failures.

5. Visible Signs of Corrosion

Examination of exposed water pipes for rust, erosion, or discoloration is an essential test of the plumbing condition. Severely corroded pipes are prone to blockage problems and structural issues.

6. Testing for Heavy Metals

Testing for heavy metals like lead and cadmium will be important if your home holds older galvanized pipes. Trace amounts, or even an abundance, of these metals in the water, due to deteriorating pipes, can become a health hazard over time.

Common Plumbing Problems with Old Pipes

Older plumbing is prone to problems that can cripple its operation or make it unsafe. Below are a few of the most recurrent troubles of aging water-course systems:

Corrosion and Material Degradation

Pipes made of galvanized steel or iron are subject to corrosion over time, which weakens them. Corrosion can bring in leaks, reduce water flow, and contaminate water with rust particles. A 2022 study found that older homes across the United States with galvanized pipes are at risk of lead and iron seeping into water, further deteriorating water quality.

Frequent Leaks

Minor cracks and pinholes can develop in aging pipes because of sustained pressure, temperature changes, or material fatigue. Thanks to these leaks, some water tariffs are rising while low water pressure is falling down the list of complaints. EPA data indicates that household leaks waste nearly 1 trillion gallons of water every year in the U.S., with aging infrastructure largely to blame.

Clogging and Reduced Flow

Over time, mineral deposits or sediments slowly accumulate in the piping, especially in hard-water areas. As a result, the flow is limited. It causes inefficiency and puts pressure on appliances such as water heaters, raising energy consumption and maintenance costs.

Poor Water Quality

They deteriorate, and with time, the pipes leach harmful substances into the water. For example, lead pipes or fittings of older infrastructure can leach lead into drinking water, posing severe health risks, especially to children and pregnant women. The Centers for Disease Control and Prevention (CDC) confirms that no level of lead in drinking water is safe.

Root Intrusion

Root intrusion is another common problem faced by older underground piping systems. Tree roots naturally grow toward any source of moisture, often penetrating cracks or weak spots in pipes. This causes blockages that can lead to backups and require costly repairs.

Noisy Plumbing

Noisy plumbing can be associated with aging water systems, where pipes bang or hammer as water flows. Usually, this noise is due to loose fittings, aged support brackets, or pressure imbalances in the system.

💡 Key Takeaway: Therefore, depending on the material used in the plumbing system, it is imperative to modernize it to detect the onset of such issues through preventive maintenance, ensuring the functionality of the water infrastructure within the house.

The Lifespan of Galvanized Pipes

Galvanized pipes, widely used in the past for residential and commercial plumbing systems, were designed to last around 40 to 50 years under ideal conditions. These pipes are steel pipes coated with zinc to prevent rusting and corrosion. However, over time, the zinc coating can erode, leading to rust formation inside the pipe; this rust reduces water flow, increases the likelihood of leakage, and compromises the integrity of the entire system.

The expected lifespan of pipes varies with factors such as water quality, humidity, and age-related maintenance; hard water with higher mineral content may accelerate corrosion, thereby shortening the pipes’ remaining lifespan. Moreover, in such humid regions, it tends to rust on the outside of the pipe, leading to early failure.

Research has shown that galvanized pipes in homes built before 1960 show more signs of advanced aging today. Most building codes nowadays recommend, or even require, replacing galvanized piping with safer, more durable alternatives, such as copper or PEX.

⚡ Important: Homeowners and property managers should arrange regular inspections to assess the condition of the existing galvanized systems, enabling upgrades to be planned and carried out without delay and ensuring the safe and efficient delivery of water.

How Do Pipes Cause Low Water Pressure?

Effects of Buildup on Water Flow

Over time, the inside of a galvanized steel pipe can get pretty dirty from calcium and magnesium mineral deposits, rust, and other debris. The gradual accumulation of this material narrows the internal diameter of these pipes, a process known as scaling. For instance, the pipe with a wide diameter back then, expressly for efficient water flow, may now be constricted to the point where water movement is complex.

📉 Impact on Flow Capacity

Research has shown that even a slight change in diameter can significantly alter water pressure and flow rate. Industry research indicates that a 10% reduction in pipe diameter could reduce water flow capacity by almost 40%. Such conditions reduce pressure and place significant strain on the water heater, pump, and other appliances connected to it, leading to premature wear and energy inefficiency.

In addition, turbulent flow occurs in the pipe when its surfaces are irregular or rough due to mineral deposition. Such an effect is all the more pronounced in older plumbing networks that have not been maintained or modernized.

These are some of the critical factors to emphasize when maintaining plumbing systems: regular inspections and timely pipe replacements help prevent internal build-up and ensure smooth water flow.

Discolored Water and Other Warning Signs

Discolored water is a clear red flag signaling a plumbing issue. It usually implies the presence of corrosion, pipe sediment, or the entrance of foreign contaminants. Brown or reddish water may indicate rust or iron deposits from older pipes, especially in homes with galvanized steel plumbing. On the other hand, a greenish-blue discoloration could indicate corrosion of copper pipes, potentially raising copper levels in drinking water.

Another red flag is when the water smells or tastes fishy. A metallic taste or sulfur smell indicates chemical imbalance or bacterial contamination. Also, visibly suspended sediment is a sign of dying pipes or a bigger underlying problem with the water source.

Sometimes decreased water clarity precedes visual turbidity, with the presence of air bubbles, excess minerals, or microbial contamination. Each of these issues can pose a significant question mark for water safety or interfere with the efficient operation of appliances that rely on clean water.

🔧 Action Required: The sooner these signs are evaluated and tested under contract, the less expensive and hazardous they will be considered for household use.

Conducting a Home Inspection for Leaks

To conduct a home inspection for leaks, carry out these orderly procedures:

- Examine the visible plumbing fixtures, such as faucets, showerheads, and under-sink pipes, for dripping or pooling water.

- Look at ceilings and walls for stains, discoloration, or peeling paint that may indicate concealed leaks.

- Inspect the water meter with all water fixtures off to see if it continues to run; if so, it indicates a leak.

- Check outdoors for any water pooling or excessive dampness that could indicate a leak, especially in irrigation and exterior faucets.

- Take remedial steps immediately to prevent further damage and water waste.

What Are Your Options for Pipe Replacement?

Comparing Copper Pipe, PEX Pipes, and PVC Pipes

Steps to Replace Your Galvanized Pipes

Turn Off the Water Supply

Shut off the water supply to your house. This system needs to be drained by opening the faucets and allowing whatever water is inside to flow out.

Inspect and Plan

Identify galvanized pipe sections to be replaced and select the appropriate replacement material (e.g., copper, PEX, or PVC), considering durability, cost, and intended use.

Cut and Remove Old Pipes

Using a pipe cutter or a reciprocating saw, cut off the galvanized pipe in careful sections. Take care not to damage nearby fittings or structures.

Prepare the Replacement Material

Measure and cut the pipes to length, cleaning and deburring the edges for a tight, secure connection.

Install New Pipes

Fit the pipelines into the existing plumbing system according to its standards, culture, and connectors, using crimps, push-together connectors for PEX; soldering for copper; and primer and cement for PVC.

Test the Connections

Water supply is turned on, and all connections will be given a final inspection to spot any leakage, if present. Tighten or reseal everything to ensure a water-tight system.

Secure and Insulate if Needed

Secure the new pipes in place using brackets or straps. Insulate exposed pipes to prevent heat loss or freezing during colder temperatures.

👨🔧 Professional Assistance

Professional plumbers are required to ensure the safe and effective replacement of galvanized pipes by utilizing their skills and industry-standard tools. Galvanized pipes, used in houses built before 1960, are susceptible to corrosion and reduced water pressure due to internal buildup over time. Engaging a professional plumber ensures the pipe replacement project is assessed correctly, planned, and executed.

❓ Frequently Asked Questions (FAQs)

Q: What does galvanized pipe look like?

A: Most galvanized pipes have a shiny, silver finish from the molten zinc protecting the pipe from corrosion. However, they can tarnish over time and lose their shine.

Q: How does corrosion affect galvanized plumbing?

A: Galvanized plumbing can corrode and rust after some time and especially when the protective zinc layer is disturbed. Corrosion can lead to leaks and discolored water, thereby impacting the entire plumbing system.

Q: What are the signs of old galvanized pipes?

A: Rusty water, low water pressure, and visible corrosion on the pipe surface are some indicators of old galvanized pipes. Living in an older home requires occasional inspection of your plumbing system.

Q: Can galvanized pipes burst?

A: Yes, galvanized pipes may indeed burst, especially if deeply corroded or under conditions of freezing temperatures. Periodic checking helps mitigate such risks by pinpointing the actual weak points in the plumbing.

Q: How long do galvanized pipes last?

A: Normal longevity varies from 20 to 50 years, depending on water quality and other environmental factors. Yet at some point, it’s time to replace your galvanized pipes to avoid plumbing issues.

Q: What plumbing issues occur due to old galvanized pipes?

A: Old galvanized pipes can be the cause of several plumbing problems, such as water leakages, low water pressure, and rusty or discolored water. These problems can affect your current residential plumbing system and may require immediate attention.

Q: When is it time to replace galvanized pipes?

A: The galvanized pipes could be replaced if there is any corrosion, if there is a pressure drop, or if there is rusty-colored water. An inspection by a plumber can assess the condition of these materials and inform a decision accordingly.

Q: What materials do I have available to substitute for galvanized pipes?

A: Other types of pipes would be CPVC pipes, copper, and PEX, all of which are better at resisting corrosion and lasting longer. Every kind of pipe has its pros, so you must talk to your plumber about what you need.

Q: What should I know about galvanized plumbing in an older home?

A: If you live in an older home, it’s vital to be aware that galvanized plumbing can lead to various issues, including reduced water quality and increased maintenance needs. Regular inspections can help maintain the integrity of your plumbing pipes and keep them functional.

Q: How do I keep corrosion from taking hold in my plumbing system?

A: Corrosion Prevention Water must be balanced and free from excessive minerals. For the plumbing materials, select those known for corrosion resistance. Additionally, keep a constant check on your galvanized pipes for any early signs of deterioration.