The versatility, efficiency, and accuracy of modern waterjet cutting technology make it a contemporary wonder in the field of manufacturing and material processing. But what is the precise level of power it possesses? More importantly, does it have the capability to slice through one of the most common and toughest materials to use—steel? This article examines the scientific principles and capabilities of waterjet cutting, concentrating on its steel cutting capabilities and precision. Whether you’re in the manufacturing industry, engineering field, or simply curious about modern techniques, this guide from water jet technology aims to simplify the complex mechanics and diverse applications of waterjet technology. Get ready to learn how such a tool is transforming fabrication processes in today’s world.

How Does a Waterjet Cutter Work?

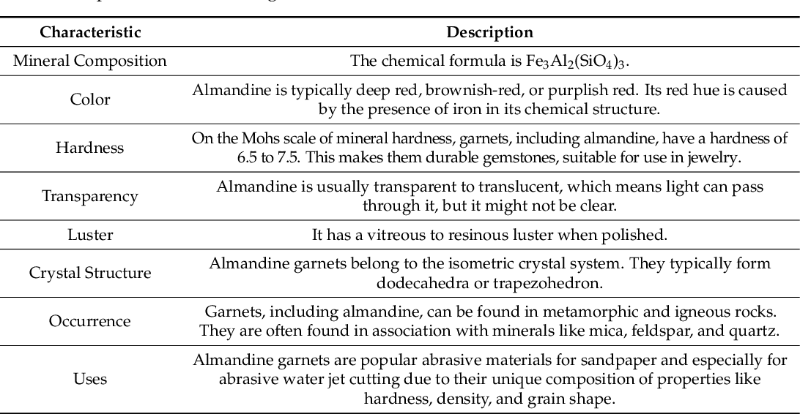

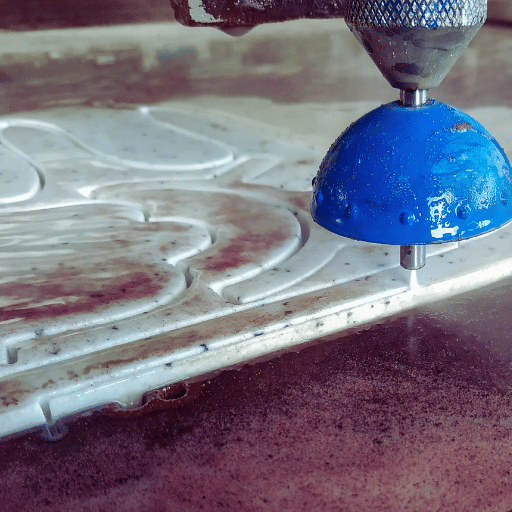

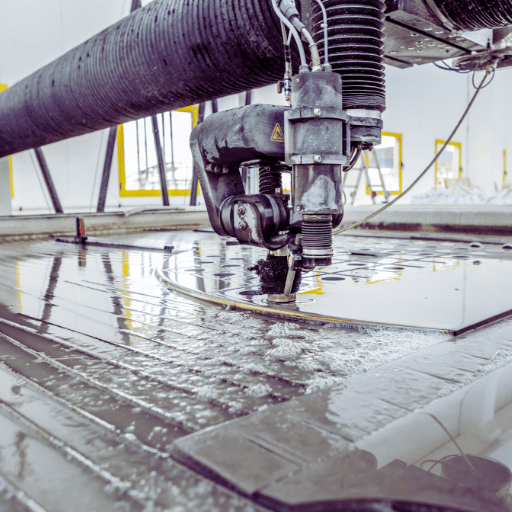

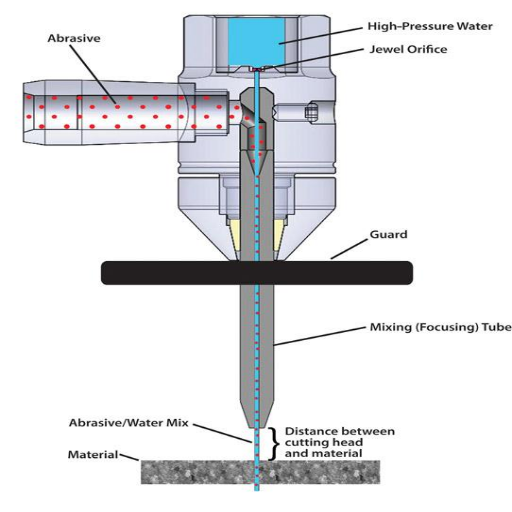

A waterjet cutter uses a high-pressure stream of water, often containing abrasives, to cut various materials with precision. The process begins with water pressurization to over 50,000 PSI, which is then directed to flow through a narrow opening to form a high-velocity jet. Added abrasives, like garnet, increase cutting power and enable the cutter to penetrate steel. The jet erosion for material removal along the cutting path results in clean and precise mechanisms without the introduction of heat, which enhances the risk of thermal distortion. These characteristics enhance waterjet cutting across different applications that require accuracy and integrity.

What is a Waterjet?

A waterjet is a sophisticated tool for cutting that uses a jet of water pressurized to cut through materials like metals or concrete. Often pressurized to over 60,000 PSI, the water stream is also focused and sped up through a nozzle. For harder materials, garnet and other abrasives are incorporated into the water stream, allowing effective cutting of metals, stones, and composites. Its use spans the aerospace, automotive, and manufacturing industries, where high precision cuts are demanded since waterjets do not produce heat-affected zones (HAZ) or alter the material’s properties. Additionally, waterjet cutting is eco-friendly because it doesn’t release toxic fumes or cut pieces of materials that could be reused, reducing waste.

How is Abrasive Used in the Cutting Process?

Abrasive materials like garnet and aluminum oxide are vital for the waterjet cutting technique, especially when dealing with thicker and tougher materials. These abrasives are blended with water in a pressurized mixing chamber, where they are pumped into a nozzle that releases them at supersonic velocities. This fusion of water and abrasive generates a powerful stream capable of eroding even the toughest materials with optimal precision. Recent sources confirm that modern advancements in waterjet technology have increased the efficiency and accuracy of abrasive application, further corroborating this claim. Optimizing flow rate, size of particles, and other factors allows for cleaner cuts, reduced waste, prolonged lifespan of waterjet components, and other factors, which results in a refined and cost-effective procedure.

What Role Does Water Pressure Play?

Water pressure is essential for the smooth operation of household functions, safeguarding the plumbing infrastructure, and sustaining convenience during routine activities.

What Materials Can a Waterjet Cut?

Can a Water Jet Cut Metal?

Indeed, a water jet can cut metals with great precision and efficiency. It can cut steel, aluminum, titanium, and copper, with no thermal damage or material alteration. A pressurized stream of water, sometimes from abrasives for tougher metals, allows this.

Is it Suitable for Harder Materials?

Indeed, water jet cutting is effective for tougher materials. It can cut hardened steel, ceramics, and stone with embedded abrasive particles. This method prevents structural changes to the material during the cutting process due to the avoidance of heat generation.

How Does it Compare to Plasma Cutting?

While plasma cutting is confined to conductive metals like steel, aluminum, and copper, waterjet cutting can handle almost any material, including metals, composites, stone, glass, plastics, rubber, food, and even paper.

| Parameter | Waterjet | Plasma |

|---|---|---|

|

Materials |

Almost all |

Conductive metals |

|

Thickness |

Up to 18 inches |

Up to 6 inches |

|

Accuracy |

High (0.001″) |

Moderate (0.015″) |

|

Heat Effect |

None |

Heat-affected zone |

|

Speed |

Slower |

Faster |

|

Cost (Run) |

Higher ($30/hr) |

Lower ($15/hr) |

|

Eco-Friendly |

Yes |

No |

|

Safety |

High |

Moderate |

|

Applications |

Versatile |

Limited to metals |

What Are the Advantages of Waterjet Cutting?

Does it Provide Precision Cutting?

Indeed, laser technology allows for cutting with extraordinary accuracy, hence providing a high level of clean edges and finely detailed parts.

Is it an Eco-friendly Option?

Certainly, waterjet cutting eco-friendly practice because it uses water and abrasives, which are non-toxic materials. It also has no negative environmental impact, unlike traditional cutting methods that use gas, steam, or heat, since there is no production of harmful gas or steam. One of the advantages concerning environmental sustainability is very little waste is created due to water-jets having a high precision cutting method. Another advantage is that the water being used can often be filtered and reused. Because of all the benefits listed above, it is suitable for industries practicing eco-waterjet cutting.

Can it Cut Without Heat?

Correct- Waterjet cutting is a water-based cutting method that does not utilize any heating or cooling processes. Waterjet cutting does not create any heat-affected zones, which would compromise the material being worked on. Unlike other cutting types, such as lasers or plasma, water-based cutting methods maintain the material’s structure without changing its makeup.

What are the Limitations of Waterjet Cutting?

Are There Thickness Limitations on Cutting Steel?

Indeed, there are limitations to thickness when cutting steel, which depends on the method of cutting (laser, saw), material type, and the equipment’s power, while laser cutters handle up to 20mm for carbon steel and 10mm for stainless steel with high-power machines.

How Does it Handle Complex Shapes?

Although waterjet cutting is precise and handles contours adeptly owing to its multi-axis CNC proportional movement, it has some disadvantages such as lower speed, higher sustained thickness, accuracy limitations, and greater expenditure upfront.

What Are the Cost Considerations?

Regarding the waterjet and laser cutting methods, the following cost factors should be evaluated:

- Initial Investment: The construction complexity of waterjet cutters, alongside the necessity for a high-pressure pump system, drives both the initial and operating costs much higher than both traditional laser cutters and modern fiber and CO2 lasers.

- Operating Costs: Due to the need for high-pressure systems, water, electricity, and abrasives, the water cutter incurs extra working costs associated with overuse. Although the electric expenses for fiber and CO2 lasers oscillate, their operating costs are overall cheaper than traditional water jet cutters.

- Material Waste: An Increase in waste material drives up costs in the long term. In regard to the precision of both methods, their efficiency varies in attempts to minimize waste material through accuracy in the cutting process.

- Maintenance: Expenses for water jet oscillate due to the lack of nozzles and recurring shipments, and maintenance. Equally, laser cuts are not replaceable due to optics, which are also subject to replacement every so often.

- Cutting Speed: High-volume work environments greatly benefit from decreased labor costs. Equally, increased worker costs burden slow operations. As water jet cutting is slower than laser cutter speeds, the water cutter increases labor expenses considerably.

- Energy Consumption: Power consumption drastically differs using both methods. The water-to-electricity ratio tends to be extremely high, depending on the pressurization required for the water. Comparatively, modern laser-cut machines benefit from significantly cheaper power requirements.

Considering these aspects is important for evaluating the long-term economic viability of each cutting method in industrial applications.

How to Choose the Right Waterjet Cutting Machine?

What Factors Affect the Choice of Waterjet Cutter?

- Material type and properties – The hardness, thickness, and composition of the material to be cut directly affect the selection of a waterjet cutter. Some materials require abrasive waterjet cutting systems to achieve the desired.

- Cutting Thickness Requirements – The waterjet system’s capabilities, as well as the pressure applied, will be determined by the thickness of the material.

- Precision and Tolerance Needs – Other industries, such as aerospace or medicine, are likely to require more sophisticated waterjet cutters controlled with high-detailed precision and tighter tolerances, proportional to the level of accuracy needed.

- Cutting speed – Different systems have different specifications that can meet the desired production demand. Thus, cutting speed reliability varies across different systems.

- Operating and Maintenance Costs – Supplies that require abrasives, energy consumption, maintenance, and expected downtimes also need to be examined in terms of their operational and maintenance costs.

- Machining space and constraints – The available workspace and physical dimensions of the waterjet must be equivalent to one another for effective performance within the set environment.

- Software and control features – Precision and efficiency can be gained dramatically with automation, CAD integration, and nesting features.

- Pump Pressure and Efficiency – The output pressure of a given waterjet pump determines the power and speed of cutting, thus being a major consideration while choosing a machine.

- Environmental and Safety Issues – The noise level, volume of water consumed, and disposal of waste materials must be within the confines of environmental and safety regulations.

- Budget and Return on Investment(RoI)- The waterjet cutter must be matched to specific needs based on the initial investment, operating cost over time, and projected ROI, which are of critical importance.

What is the Importance of Multi-axis Cutting?

In contemporary production processes, multi-axis cutting integrates precision, intricate shape capability, efficiency, improved time metrics, and minimization of errors.

How to Maintain a Water Jet Cutter?

Recommended practices for maintaining a water jet cutter focus on preventative measures aimed at achieving peak operational effectiveness. During scheduled maintenance, I actively monitor the high-pressure components for leaks, clean the filters for optimal water quality, check for any irregularities in the pump and abrasive feed system, and take proactive measures against wear, compensating for any detected issues. By adhering to best practices, I am able to minimize system interruptions attributable to equipment repairs while simultaneously extending the lifespan of the machine.

Frequently Asked Questions (FAQs)

Q: Is it accurate that a waterjet can slice through steel?

A: Indeed, a waterjet is capable of penetrating through steel, especially with the abrasive waterjet that incorporates abrasive materials into the stream of high-pressure water for more cutting efficacy.

Q: What processes are utilized for steel cutting with abrasive waterjets?

A: Abrasive waterjet cutting creates an intense stream capable of penetrating through steel and other difficult materials by infusing high-pressure water with abrasive materials.

Q: What are some waterjet suitable steel types?

A: Waterjet technology applies to various types of steel, including mild steel and stainless steel, as well as other metal components.

Q: Markedly, how does waterjet cutting differ from laser cutting regarding steel?

A: Both methods work effectively, but in comparison, waterjet cutting does not produce heat, which decreases the chances of distortion to the workpiece. Therefore, for some purposes, this makes waterjet cutting more advantageous than laser cutting.

Q: In what ways are materials cut using a waterjet vigorously?

A: The waterjet nozzle is important because it directs the stream of abrasive water under high pressure precisely on the steel and other materials to perform cutting operations.

Q: Is high pressure necessary in cutting steel with a waterjet?

A: For steel cutting, the use of high-pressure water is indeed necessary due to the need for forces sufficient for penetration and cutting of the material using water and abrasive particles.

Q: Are different thicknesses of steel separable through customized water jet settings?

A: Different thicknesses and types of steel can be optimized with custom waterjet settings, which can be tailored to attain desired precision and cutting performance.

Q: What is the advantage of water jet cutting over other methods in terms of cutting metal?

A: With waterjet cutting, users are guaranteed no heat distortion, intricate shapes, and versatility, which includes cutting steel, among others.

Q: What does the cutting head do to affect water jet cutting performance in terms of cut quality?

A: The accuracy and quality of the cut material will rely on the water and abrasive mixture’s high speed, high pressure entering through the cutting head, which controls that portion of the machine.

Q: Is there any risk concerning abrasive waterjet cutting for steel?

A: No, given the lack of excessive heat and dust products, it is fairly safe for steel and other materials, making abrasive waterjet cutting a safer and environmentally friendly option.

Reference Sources

1. An Overview on Emergency Abrasive Water Jet Cutting of Steel: Characteristic Analysis and Cutting-In Prediction.

- Authors: Y. Jiang, L. Duszczyk, A. Goorani, S. Cohn

- Journal: Experimental Techniques

- Publication Date: August 3, 2022.

- Citation Token: (Jiang et al., 2022, pp. 197–209)

- Research Summary: This study concentrates on modeling the forecasting of abrasive water jet (AWJ) cutting characteristics, particularly in times of emergencies. The model predictive cutting-in that the authors provide is important for timely AWJ process adjustments and for decision support systems in emergencies. The results show the experimental configurations and data evaluation concerning the AWJ performance to cut through steel in emergency situational conditions.

2. Application of Simple Multicriteria Decision Making (MCDM) Technique Towards the Optimization of High-Alloy Steel Cutting by Abrasive Water Jet

- Authors: E. Kawecka et al.

- Journal: Spectrum of Mechanical Engineering and Operational Research

- Publication Date: 30th July, 2024

- Citation Token: (Kawecka et al., 2024)

- Summary: The focus of this paper is on the optimization of abrasive water jet machining parameters for high alloy steel. The authors adopt an MCDM technique, more precisely the SAW method, to assess control parameters like abrasive flow rate, pressure, and feed rate. The research describes the importance of these parameters on the cutting depth and surface roughness and details the optimization techniques used.

3. The Application of Abrasive Water Injection Jet (AWIJ) Technology for Cutting High-Alloy Steel Enhanced by RSM Modelling

- By: A. Perec et al.

- Publication in: Materials

- Scheduled Release: 1 August 2024

- Cross Reference: (Perec et al., 2024)

- Abstract: The paper examines the problem of high-alloy steel cutting using abrasive water injection jet technology. The authors aim to model the process with response surface methodology (RSM) while considering the most significant factors: abrasive flow rate, pressure, and traverse speed. The results show that traverse speed has a predominant influence on surface roughness, and the study presents a mathematical model based on empirical data to assist in improving the conditions for cutting.

4. Abrasive waterjet cutting of cast iron was examined regarding its surface. This document highlights some performance metrics of an abrasive waterjet, albeit with a primary focus on cast iron.

6. Abrasive