Stainless steel is a highly flexible material, and it has become central to modern-day engineering, building, and manufacturing processes. Steel has become a very popular material because of its unparalleled strength, ability to withstand degradation without any effort, and attractive appearance. It is widely used in many industries, from the production of industrial equipment to the creation of common household products. In this article, readers will be able to learn about what makes stainless steel special, the categories of stainless steel that are available, and their applications in different fields. Whether a practitioner or a consumer who wants to learn more about the elements that make up this very important resource, such a detailed stainless steel is going to tell why this metallic element will not go away anytime soon.

Composition and Types of Stainless Steel

Stainless steel is mostly made up of iron and chromium with some other components, such as nickel, carbon, and manganese. Stainless steels are characterized by at least ten and a half percent of chromium that creates a thin passive oxide layer over the surface and is thus responsible for resistance to corrosion.

The basic grades of stainless steel are classified in four groups under stainless steel description as listed below:

|

Type |

Chromium |

Nickel |

Carbon |

Key Properties |

Applications |

|---|---|---|---|---|---|

|

Austenitic |

16-26% |

Up to 35% |

≤ 0.15% |

Corrosion-resistant, versatile |

Food, medical, construction |

|

Ferritic |

10.5-30% |

≤ 0.2% |

≤ 0.2% |

Cost-effective, magnetic |

Automotive, industrial |

|

Martensitic |

10.5-18% |

≤ 2% |

Up to 1.2% |

High strength, hardenable |

Cutlery, surgical tools |

|

Duplex |

19-32% |

4-7% |

≤ 0.03% |

Strong, stress-resistant |

Marine, chemical plants |

|

Precipitation-Hardened |

Varies |

Varies |

Varies |

High strength, corrosion-resistant |

Aerospace, marine |

Each kind offers distinct benefits in line with the needs of various sectors and use cases.

What is Stainless Steel Made Of?

Stainless steel is foremost a metal alloy containing iron and at least 10.5% chromium that offers a characteristic resistance against corrosion. As well, other elements may be found in certain amounts in order to strengthen and soften nickel, or further protect the surface from chloride attack, that is, molybdenum, and carbon to regulate the strength and the hardness, respectively. Other components, such as manganese, silicon, or nitrogen, could also be added in moderate proportions in order to modify certain characteristics of the alloy. These are the factors that determine the classification and peculiarities of stainless steel, which are adjustable in description to most of the industries, construction, or marketing purposes.

Different Types of Stainless Steel

One can classify stainless steel into five most common categories, which consist of Austenitic, Ferritic, Martensitic, Duplex, and precipitation hardening types.

|

Type |

Key Feature |

Corrosion |

Magnetic |

Hardenable |

Common Use |

|---|---|---|---|---|---|

|

Austenitic |

High Nickel |

High |

No |

No |

Food, Medical |

|

Ferritic |

Low Nickel |

Moderate |

Yes |

No |

Automotive |

|

Martensitic |

High Carbon |

Moderate |

Yes |

Yes |

Tools, Blades |

|

Duplex |

Mixed Structure |

Very High |

Yes |

No |

Offshore |

|

Precipitation |

High Strength |

High |

Yes |

Yes |

Aerospace |

Grades of Stainless Steel Explained

Iron-based alloys known as stainless steels, widely used in pan and pot making industries, are divided into various types depending on the elements present in them, like carbon content, nickel, chromium, and molybdenum or any other alloying element in them, and their working condition or intended use. The next paragraphs provide a stainless steel description: the typical grades seen in use are as follows:

|

Grade |

Family |

Key Feature |

Applications |

Corrosion |

Cost |

|---|---|---|---|---|---|

|

304 |

Austenitic |

Versatile |

Kitchen, Food, Arch. |

High |

Medium |

|

316 |

Austenitic |

Marine-resistant |

Marine, Medical |

Very High |

High |

|

430 |

Ferritic |

Low-cost |

Appliances, Decor |

Moderate |

Low |

These grades vary depending on their potential to withstand wear and tear and corrosion; they are thus chosen to carry out the functions intended.

Key Properties and Benefits of Stainless Steel

Corrosion Resistance and Durability

Stainless steel is mostly sought after because it is resistant to corrosion and does not wear easily. When corrosion becomes a problem, the explanation is simple: the chromium present in stainless steel helps to form a non-reactive layer of oxide on the surface that shields the metal from oxygen in the air or other chemicals. Of interest are certain grades, e.g. 316, which exhibit increased resistance in such environments e.g., marine, medical, thanks to the larger concentrations of molybdenum present in the steel. Besides these, the stainless steel description includes strength and maintenance for a long period without deformation owing to its remarkable properties; therefore, it is used for difficult materials quite efficiently.

Mechanical Properties of Stainless Steel

|

Property |

Description |

|---|---|

|

Tensile |

Max stress before breaking |

|

Yield |

Stress at plastic deformation |

|

Ductility |

Ability to deform without breaking |

|

Hardness |

Resistance to deformation |

|

Fatigue |

Withstands cyclic stress |

|

Creep |

Resists deformation under load |

|

Elongation |

Stretch before fracture |

|

Elastic |

Resists elastic deformation |

Environmental Benefits of Using Stainless Steel

- Recyclability: This is a major advantage of stainless steel as it is composed of components that can be recycled, thus making stainless steel products without creating more waste or exploitation of nature.

- Longevity: Due to its nature, this material is quite long-lasting, and even as time passes, with constant use, it does not need to be replaced as often, hence conserving resources in the long run.

- Low Maintenance: Stains and dirt will simply wash off because stainless steel scrapes very easily and quickly, and does not need any chemicals to be cleaned safely.

- Energy Efficiency in Production: In addition, electricity consumption in stainless steel has been reduced due to new developments in its manufacture, which in turn has led to gains in sustainability.

- Non-Toxic and Hygienic: One more benefit of a stainless steel kitchen is that it is not poisonous and does not emit harmful elements either in the environment or to users.

- Resistance to Corrosion: It can resist corrosion. There is no contamination of the air, plants, or animals that are around.

- Adaptable to Green Technologies: A stainless steel description for renewable energy sources includes the use of such construction materials in solar power and windmills.

Common Applications Across Industries

Stainless Steel in Construction and Architecture

Stainless steel can be considered crucial in building and architectural applications because it is hardwearing and strong yet versatile, and also good-looking. In most descriptions, it is mostly found in components that are either supporting or adding to the building, which are resistant to rust and do not require much care. This stainless steel material description also helps in the application of many forms of architecture, including that of modern skyscrapers and public works such as bridges. Furthermore, stainless steel is highly recyclable and thus, its use is consistent with environmental responsibility, which is aimed at the preservation of the environment in the long run.

Use of Stainless Steel in the Food Industry

The demand for stainless steel has escalated due to the wider application of the material in the food industry, particularly the hygienic properties that it possesses, its non-corrosive nature, and low maintenance. It finds maximum usage in food process machinery, tanks suitable for storage, as well as kitchen catering service machines. A bored-up material surface does not impede the taint, pigment, or quality of the food prepared, while the high temperature of the material broadens its base due to the high heat temperatures and sanitizes its implication. These properties make use of stainless steel description practical and very effective tool in the field of food protection and sanitation standards.

Stainless Steel in Medical Applications

- Surgical Tools: Such instruments primarily consist of stainless steel, because of its ability to resist rusting, breakage as well as its capacity to undergo repeated sterilization.

- Implants: There is any number of devices, stainless steel prosthetic bone plates, screws and joint implants among them, that are made of strong and hard stainless steel description which can be safely used inside the body.

- Hospital Equipment: All this includes hospital beds and wheelchairs, in addition to trays and trolleys that are likely to be of stainless steel, which is nonporous and inhibits microbial growth from the Kingdom’s viewpoint.

- Diagnostic Devices: Precise instruments and devices that require frequent sterilization are often fitted with stainless steel parts and components.

- Orthopedic Equipment: For example, some braces and external fixators are made of strong stainless steel, as it is strong and dependable.

- Dental Appliances: Different types of stainless steel instruments are made, including dental instruments like braces and orthodontic wires, because of their high tensile strength and flexibility, together with their corrosion resistance.

- Sterilization Containers: Instruments used in surgery need to be sterilized, which is usually done in containers that are made of stainless steel to enhance their durability and so that they can be subjected to heat at very high temperatures and pressure.

- Catheters and Needles: This includes the manufacturing of hypodermic needles and even some of the catheter parts, which are produced from stainless steel because of its microbiological and precision engineering.

Maintenance and Care Tips for Stainless Steel

Cleaning and Polishing Techniques

The proper care, including cleanliness and polishing of stainless steel, is a must to understand to retain its initial purpose and appeal. As part of normal maintenance, stainless steel surfaces must be wiped with a soft cloth or sponge with warm water or delicate like dishwashing soap. Do not use abrasives, as these may scratch the chromium oxide protective layer, which makes stainless steel corrosion resistant.

This is because polish can be used, such as a dedicated stainless steel polish, but if there are fingerprints, smudges, or light scratches on it, a baking soda and water mixture will help. If you polish in the direction of the grain, it will produce the desired effect. In addition, there are products available, such as mineral oils or commercial stainless steel protectors, that prevent the steel from getting stained in the future. It appears that searches conducted through the Google search machine show that the number of people looking for environmentally friendly stainless steel description cleaning materials is very high, an indication of the many people seeking safer and non-toxic cleaning solutions. As such, products including vinegar or lemon juice diluted in water can polish the surfaces more effectively, safely, and without chemicals.

Preventing Rust and Corrosion

Stainless steel isn’t entirely exempt from rusting and corroding, especially when it is exposed to any kind of moisture or hostile conditions. That’s why it is important to learn how to manage stainless steel surfaces and recognise the need for cleaning. Light wiping with a soft cloth to remove water and dirt, for instance, can reduce water retention, as water is one of the main causal factors of stainless steel corrosion. Coating surfaces with a thin film of oil or synthetic rust-resistant product is also a means of protection against oxidation.

Long-term Care for Stainless Steel Products

To maintain stainless steel items for a long time, I devote my energies toward the proper care and maintenance of these items. I use soft and non-abrasive materials on metallic surfaces installed on stainless steel, descriptions of patterns so that no microbial growth is accumulated for shelf life innovations, reducing the risk of corrosion. Furthermore, I use a protective film if needed, which facilitates the protection of the stainless steel from humidity and other environments. Such measures help me preserve the aesthetic look and use proper countermeasures with proper maintenance in place by extending the use of stainless steel products.

Recent Trends and Innovations in Stainless Steel Technology

Advancements in Stainless Steel Manufacturing

Recent trends in stainless steel manufacturing are targeting mainly efficiency, depending on the requirement, materials that can be produced, as well as the effectiveness of corrosion resistance and impact strength of the material. New technologies such as powder metallurgy and 3D printing make it possible to manufacture difficult and intricate parts with little waste. In addition to that, the focus on high-strength, stainless steels has continuously been updated, such that it is more resistant to corrosion and thus applicable in much more aggressive environments. The industry has also put a lot of focus on ‘greenship’, for example, recycling stainless steel and applying more energy-efficient manufacturing techniques. The fundamental purpose of these innovations is to satisfy the ever-increasing appetite of the clientele for more durable quality materials and to work as a supportive measure for pollution control.

Trends in Sustainable Stainless Steel Production

1. Employment of Reused Elements

The stainless steel industry has, in the recent past, demonstrated the worthiness of adopting the use of recycled materials. At present, over 50% of the 50 million tons of stainless steel worldwide contains recycled materials, which reduces dependence of heavy industries on raw materials as well as on carbon emissions.

2. Production Efficiency

In order to save on energy consumed along the production process, manufacturers are switching to energy-efficient methods such as electric arc furnaces. This reduces the environmental impacts associated with the production of stainless steel.

3. L-C Alloys Development

The improved materials engineering has also resulted in the development of low-carbon stainless steels, which help reduce greenhouse gases and comply with environmental policies.

4 Water Management During Production

The use of sustainable water management practices, such as closed-loop systems, helps to reduce the risks of wasteful water consumption manipulation as well as pollution during the production process.

5. Lifespan and Recyclability Emphasis

The extended life span and often the ability for the stainless steel description to be reused are also strengths of the stainless steel in other eco-friendly applications.

Future of Stainless Steel in Various Industries

The outlook for crude stainless steel looks optimistic across different sectors. This will be through the consumption of clean products, energy saving, new uses, and most importantly, the stainless steel description.

Frequently Asked Questions (FAQs)

Q: What are the different kinds of stainless steel?

A: Stainless steels are divided into families depending on the elements they contain and their enhanced properties. The most used classes of stainless steel consist of the austenitic, ferritic, and martensitic grades. The austenitic stainless steels are commonly used because they have high chromium and nickel contents, both of which confer a very good ability to resist corrosion and deformation. Ferritic stainless steels have magnetic properties since they include chromium and reduced amounts of nickel. Martensitic stainless steel is particularly useful because of its ability to withstand force and harden under conditions of cutlery or surgical equipment application.

Q: What is the process of producing stainless steel?

A: Stainless steel, being an alloy metal, is the result of combining iron and carbon with other alloying metals such as chromium, nickel, and molybdenum. In these stages, raw materials are put into a furnace, where the liquid metal is obtained from the ferrous raw material. This steel is then further processed to decrease the amount of out-of-specification elements, the composition of alloying elements is adjusted, and the content of chromium is made not less than 10,5 %, to preserve the corrosion resistance of the alloy. A range of processes, like casting, rolling, and forging, is employed to form different types of stainless steel products.

Q: What are the ingredients in stainless steel?

A: For the most part, stainless steel is made of iron, which is also the base ingredient, plus about 10.5% or more of chromium and a combination of other alloying metals like nickel, molybdenum, and magnesium. These elements help to give stainless steel its several properties, including high resistance to corrosion, strength, and longevity. The proportions may change depending on what type of stainless steel is being manufactured.

Q: What attributes does stainless steel possess?

A: Because of its remarkable rust and corrosion resistance, stainless steel is a durable material that has a great use in different industries. Its other features include high strength, easy maintenance, and aesthetic enhancement. The magnetic properties are different; for example, austenitic stainless steel is commonly non-magnetic, whereas ferritic stainless steel is magnetic. Furthermore, high temperature resistance and recyclability are also important factors in the steel industry.

Q: What are the uses of each family of stainless steels?

A: Various applications require certain stainless steel families due to their functional characteristics. Austenitic stainless steels, which have a very good resistance to corrosion used for food processing equipment, chemicals, and food environments. Ferritic stainless steels are many times the choice for automotive industries, and martensitic stainless steels for texturing tools. The advantages derive from the combination of the two components: its ferrous nature provides strength, whereas the latter supports corrosion resistance.

Q: What is the importance of chromium content in stainless steels?

A: In terms of corrosion resistance, chromium is the single most important element in stainless steel description, which contributes to this property. Steel should have at least 10.5% chromium to be considered stainless. The oxide film is self-healing and therefore will remain for as long as the steel contains chromium, protecting the steel from rusting and corrosion. When the chromium content is increased, the material’s ability to withstand various corrosive conditions is also enhanced. This makes it more applicable in environments that are highly demanding.

Q: Why is stainless steel different from ordinary steel?

A: Because of its higher chromium and nickel content, stainless steel can withstand corrosion much better than ordinary steel, which is the main contrast between the two. As a result, while the latter will rust away when exposed to water, the former will not, even when strongly attacked by harsh conditions. Regarding maintenance and aesthetics, stainless steel scores better, but it is costly in comparison to conventional steel.

Q: What are the different varieties of stainless steel screws?

A: Different types of stainless steel fasteners include bolts, screws, nuts, and washers for various purposes. The most commonal grades used for stainless steel fasteners are A2 (304) and A4 (316), which provide adequate resistance to corrosive effects and high strength. Austenitic stainless steel fasteners are more common for sea applications than ferritic stainless fasteners, which are used in less aggressive environments. Calculating the risk of corrosion and the strength needed, the type of fastener, together with its grade, is chosen accordingly.

Reference Sources

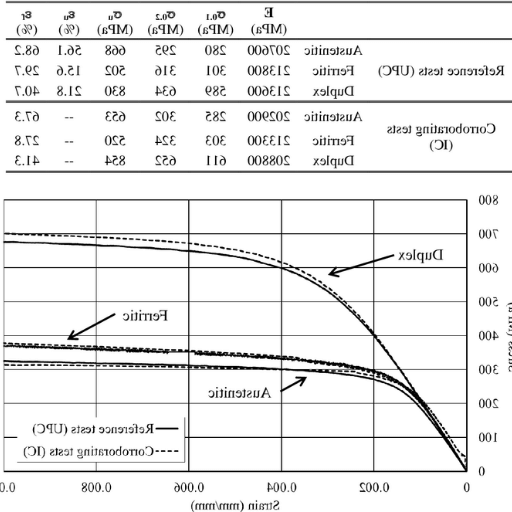

1. Commentary on the conduct of the stainless steel rebar

- Authors: Rabi, M., Shamass, R., & Cashell, K.

- Journal: Case Studies in Construction Materials

- Issue Date: 1 February 2024.

- Citation: (Rabi et al., 2024)

- Abstract: The paper provides comprehensive information or constitutes an account as regard to some stainless steel descriptions, which is beneficial for one’s understanding of their usage in building construction. Specifically, the paper studies the various existing mechanical properties, including the types of behavior one can expect from the material under the effect of different kinds of loading. The document contains experimental approaches utilized to determine the mechanical characteristics of stainless steel bar reinforcements in structures, which aids in enhancing the existing practices of designing structures.

2. Mechanisms of the Anisotropic Response in WAM-Fabricated Thin-Wall Structures made of Stainless Steel.

- Authors’ Names: Nicolas Hadjipantelis, Ben Weber, C. Buchanan, L. Gardner

- Journal’s Name: Thin-Walled Structures

- Date of Publication: February 1st, 2022

- Relevant Citation: (Hadjipantelis et al., 2022)

- Topic of the paper Field: This article considers a study of the under-investigator orientation surfaces of steel thin wall elements made by wire and arc additive manufacturing (WAAM). The paper draws in sync with the mechanical properties, which are contained in this paper due to the manufacturing orientation steel fails and materials lends logic is different steel fails and materials lends logic ductility irrespective of the spot marked. Tension Tension motives do not restrain themselves to the use of Tension test extrinsic methods Sack-well endows aspired structural endowments and indirect characterization of tensile tests. Schrift und Antwort suggests the use of these tests in structural analysis or design.

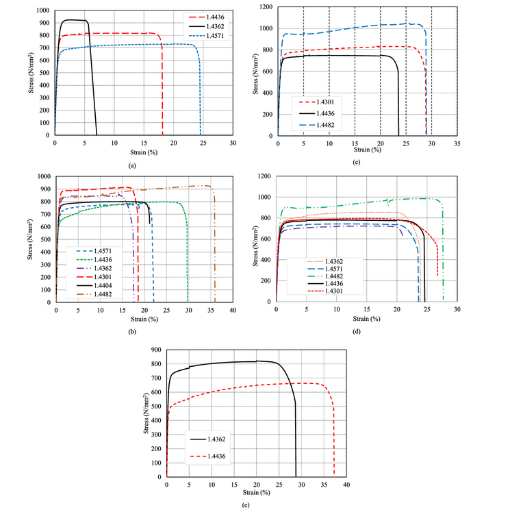

3. Detailed Analysis of Stress-Strain Curves in Various Stainless Steel Alloys

- Contributing Authors: I. Arrayagoa, E. Real, & L. Gardner

- The Journal: Materials & Design

- Printing Date: 15 December 2015

- Reference With Citation Indicator: (Arrayago et al., 2015, pp. 540–552)

- Overview: A detailed description regarding the stress-strain layout of different stainless steel alloys has been given in this lecture. It mentions the necessity of these curves as they help in understanding how a material could withstand the load applicability. In order to explain the mechanical properties of different alloys, including stainless steels in relevance to engineering, empirical results as well as theoretical frameworks form part of the investigation.

5. Corrosion