Choosing the proper piping for designing fire sprinkler systems is a crucial step because it determines the system’s reliability, functionality, and compliance with regulations. The numerous available options for piping–each with different advantages and drawbacks–make it all the more important to understand their performance under varying conditions. In this article, we discuss the most popular materials used for pipes in fire sprinkler systems and analyze their applications, considering their durability, cost, and compliance with legal standards. This guide is valuable to building contractors, facility managers, and design professionals, as it provides information that helps them enhance their fire protection infrastructure.

What are the types of fire sprinkler pipes available?

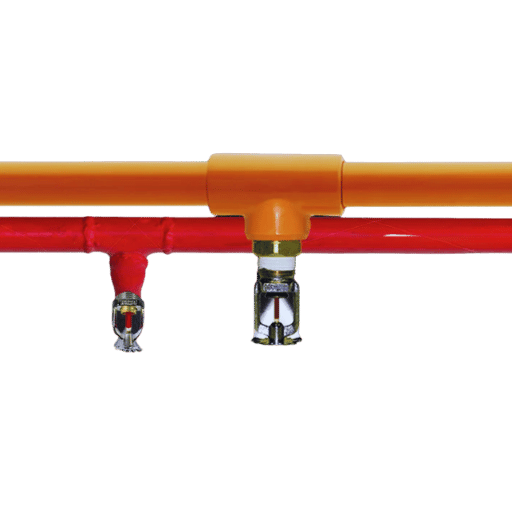

Different styles of fire sprinkler pipes exist, tailored to distinct purposes:

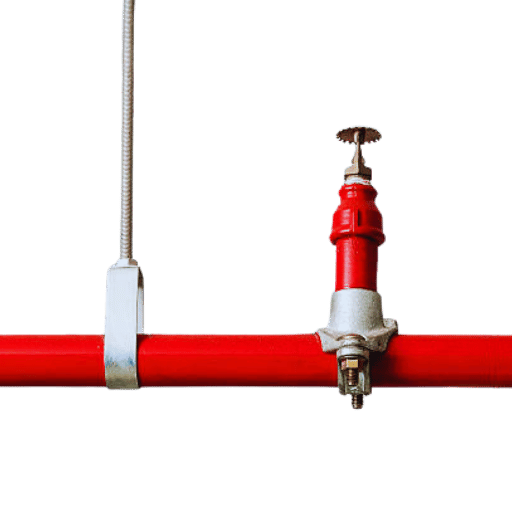

- Steel Pipes: These are the classic choice owing to their durability and strength. Black and galvanized steel pipes can withstand high temperatures and are often found in industrial and commercial buildings.

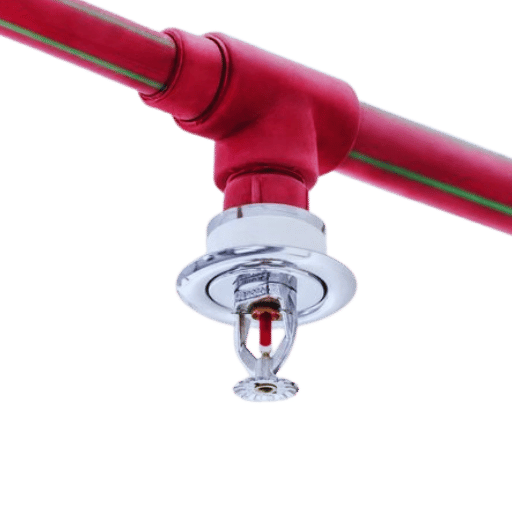

- CPVC Pipes: CPVC pipes are both lightweight and corrosion-resistant, making them ideal for residential and light commercial structures. Being easy to install works in their favor, but overheating during installation is a significant hindrance.

- Copper Pipes: Prized for being corrosion-resistant, copper pipes are typically used in specialty applications or in regions that require high environmental durability. However, they do come at a higher price.

- PEX Pipes: Flexible, inexpensive, and frost-resistant, PEX pipes are ideal for homes but not as suitable for large commercial systems.

The choice of pipe depends on several criteria, including the gas requirements, environment, local fire safety regulations, and more. Each type of pipe comes with its own set of pros and cons.

How do CPVC pipes compare to steel pipes?

CPVC pipes and steel pipes differ significantly in material properties, installation, and cost. Lightweight, corrosion-resistant, and easier to install, CPVC pipes often require fewer tools and labor compared to other alternatives. These pipes are affordable and manage hot and cold water well, outperforming other materials. Steel pipes, however, are highly durable and can withstand extreme conditions, making them suitable for commercial and industrial systems. Though they do stand up over time, they tend to corrode, and on the whole, require more maintenance. Depending on needs, budget, and long-term requirements, the choice between the two falls.

Are copper pipes an efficient alternative?

Copper pipes are an adequate substitute due to their durability, the material’s resistance to corrosion, and their ability to sustain both hot and cold water. Also, they are self-treating antimicrobials that help lower the chance of contaminating water systems. On the other hand, copper pipes tend to be more costly than some alternatives, and their installation requires higher-end craftsmanship. Their efficacy relies on the particular needs of the system as well as budget limitations, and is always dependent on the system in place.

What is the role of ASTM standards in selecting piping material?

The role of ASTM standards in the quality and safety of piping materials cannot be overstated. Standards include instructions regarding the manufacture, testing, and use of materials within defined industry standards. Adhering to ASTM standards allows engineers and contractors to select materials designed for specific applications and bearing conditions confidently. In addition, these standards improve uniformity and dependability across the board, which minimizes failure and inefficiencies over time.

How do cpvc fire sprinkler systems work?

What makes CPVC suitable for sprinkler systems?

Due to its resistance to extreme heat and corrosion, CPVC is used in fire sprinkler systems because it is the most efficient material, along with its durability in various environments. During a fire, CPVC can withstand elevated temperatures and resist structural damage under high pressure. Besides being easy to maintain, this material is also cheaper than others in the construction industry, making it a good choice for both residential and commercial properties. The industry standard compliant with this material ensures that it works best with fire protection systems.

How does CPVC’s compatibility with other materials affect its use?

The compatibility of CPVC with other materials greatly increases its practicality and adaptability in fire protection systems. With proper solvent cementing, it can be joined with numerous fittings and components, forming durable and leak-free bonds. Moreover, CPVC’s resistance to corrosion and scaling enables integration with metal components without the risk of chemical reactions or material degradation. These factors streamline system design and guarantee dependable functionality in a wide range of applications.

What are the advantages of using steel pipes?

How does corrosion resistance impact the lifespan of steel systems?

Corrosion resistance greatly improves the lifespan of steel systems because it halts deterioration from environmental moisture, chemicals, and oxygen exposure. Strong, corrosion-resistant steel maintains its internal structural integrity and operational functionality over time, reducing the need for overall repairs and replacements. This further guarantees the reliability of the system’s function, making it effective and durable for practical use.

Can steel fire sprinkler systems be cost-effective?

Indeed, steel fire sprinkler systems can be economical. Their maintenance and replacement costs over time are greatly lessened because of their resistance to damage and durability. Moreover, steel’s long lifespan makes it a dependable investment for residential and commercial properties, particularly in fire protection systems. Although the installation cost might exceed that of some alternatives, the reduced need for repairs and the system’s proven reliability pay off economically in the long run.

How to ensure effective sprinkler system design?

What considerations are critical when designing fire sprinkler systems?

When designing fire sprinkler systems, the following key factors must be evaluated to ensure efficiency and appropriate functionality with prevailing codes and standards:

- Risk Assessment: Analyze the fire risk profile of the property, considering its construction type, occupancy, and potential ignition sources.

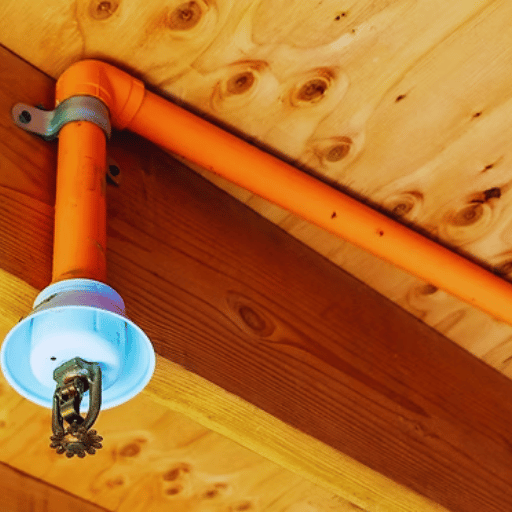

- System Coverage: Achieve full coverage by determining the best positioning of sprinkler heads to avoid gaps in the protective area.

- Water Supply: Confirm the availability of the water supply in terms of pressure and flow rate; it must meet the system’s operational needs in case of a fire.

- Compliance with Standards: Ensure that local, national, and International fire safety codes and regulations, such as NFPA standards, are also followed.

- Maintenance Accessibility: Design the system in a manner that facilitates regular inspection, testing, and maintenance procedures with minimal intrusion.

- Integration with Other Systems: Verify that the sprinkler system integrates properly with other fire protection devices, such as fire detection, alarm systems, and fire extinguishers.

Taking these considerations into account will ensure that fire sprinkler systems are designed for dependability and efficiency in addressing fire hazards.

How do pipe and fitting choices affect system performance?

Choosing the right pipes and fittings significantly impacts the effectiveness and reliability of a fire sprinkler system. Factors such as material make-up, internal diameter, mechanical strength, and corrosion resistance are focal points. For example, steel pipes (black or galvanized) possess great strength and durability, making them ideal for high-pressure systems, but they may be prone to corrosion from moisture over time.

On the other hand, CPVC (chlorinated polyvinyl chloride) pipes are lighter in weight and non-corrosive, making them suitable for some applications as a cheaper and low-maintenance option. Industry reports suggest that installations using CPVC pipes can cut the time by 25% compared to steel due to their lightweight nature and ease of handling and joining. However, CPVC becomes less ideal for high-temperature environments where material deformation may occur.

Fittings, in conjunction with pipes, also affect the functionality of sprinkler systems. Custom-made fittings reduce water flow friction losses, assuring cost-effective energy use. Research shows that improperly fitted or poorly selected fittings can lead to a 30% increase in hydraulic losses, which is detrimental to sprinkler performance in large-scale systems.

Equally crucial for deciding what pipe and fittings to select is the pressure and flow rate of the system. Also, adhering to fire codes, such as those from the National Fire Protection Association (NFPA), ensures the system is compliant and works efficiently. Attention to detail, such as the accuracy of design and the selection of materials for parts and pipes, increases the reliability and performance of the fire sprinkler system.

What are the key maintenance tips for fire sprinkler pipe systems?

How can corrosion be prevented in fire sprinkler system piping?

Corrosion of fire sprinkler system piping is easier to control if proactive steps and scheduled maintenance are executed. The main steps are as follows:

- Using Corrosion-Resistant Materials: Selecting pipes and fittings made of galvanized steel, stainless steel, or CPVC eliminates corrosive risks.

- Implementing Nitrogen Purging: With the use of nitrogen, oxygen within the system can be replaced, preventing the oxidation reaction that causes corrosion.

- Ensuring Proper System Design: The system should be designed to prevent stagnant and trapped water, as standing water can accelerate corrosion.

- Conducting Routine Inspections: Inspections should be done routinely to eliminate early signs of deterioration before it results in critical damage.

- Applying Corrosion Inhibitors: Where necessary, chemical treatments can be used to treat internal corrosion of the piping.

Adopting these techniques ensures the long-term functionality of fire sprinkler systems while extending their lifespan.

What role does regular inspection play in system reliability?

Consistent checkups are essential for maintaining a reliable system and preemptively resolving issues before they cause breakdowns. Inspections allow for the detection of wear, corrosion, blockages, and other problems that can negatively impact performance. Solving these issues in advance ensures the system remains functional and compliant with operational safety standards, thereby reducing unpredictable failures.

Frequently Asked Questions (FAQs)

Q: What materials do fire sprinkler systems use?

A: Fire sprinkler systems incorporate structural materials such as steel pipes, as well as BlazeMaster CPVC, which is a type of chlorinated polyvinyl chloride.

Q: What role does CPVC play in fire sprinkler systems?

A: CPVC pipes perform well in sprinklers due to their lack of corrosion, and are cheaper and easier to install in comparison to BlazeMaster CPVC.

Q: What benefits does each provide when compared to steel for fire suppression systems?

A: CPVC’s benefits over steel include less weight, as well as a slower installation time and lower pricing with zero giveaways to fire protection capabilities.

Q: Can CPVC blend in with the other pipes in a water-based fire suppression device?

A: Indeed, other parts from water-based fire protection systems can be used with CPVC without any problems.

Q: Why is Schedule 40 important for pipes connected to fire sprinkler systems?

A: Schedule 40 indicates a specific strength of the pipe wall and is used in fire sprinkler systems, as it provides the necessary strength and durability for commercial business applications.

Q: Are any materials associated with the fire sprinkler systems used stamped with any antimicrobial technology?

A: Some CPVC systems, which include BlazeMaster CPVC, incorporate bacteria-killing technology, guaranteeing no bacteria will form and that clean water is supplied within fire suppression systems.

Q: What is the primary distinction between a wet pipe system and a dry pipe system?

A: A wet pipe system keeps water in the pipes ready for immediate discharge when activated, while a dry pipe system keeps air in the pipes and only fills with water when a fire is detected. This is typically used in freezing environments.

Q: What is the relationship of NFPA 13 with the fire sprinkler systems regarding the use of materials?

A: NFPA 13 is a standard that addresses the design and installation of fire sprinkler systems and impacts the choice of materials such as CPVC and metallic pipe to ensure industry standards for fire protection are complied with.

Q: What are the benefits of using thermoplastic materials like CPVC in standard fire sprinkler systems?

A: CPVC and other thermoplastic materials have some benefits, including no pinhole leaks, no corrosion, and flexibility. These are the reasons why many installers prefer them.

Reference Sources

1. Sprinkler System Design Modeling Using Pipe Flow Expert for The MTsN 1 Banyuwangi Girls Dormitory Building (Hutasoit & Hartono, 2024)

- Key Findings:

- This work calculated the quantity of fire sprinklers (51 pieces), the dimensions of the water tank (9 m³), and the pipe diameters (main pipes: 80 mm, branch pipes: 32 mm, sub-branch pipes: 25 mm) for a three-story dormitory building.

- The simulation using Pipe Flow Expert software showed that the design complied with the standards set by SPAN 03 03 3938-2000, concerning sprinkler systems, regarding flow velocity, pressure, and the isometric arrangement of pipes.

- Methodology:

- The layout of sprinklers, the diameter of pipes, and the volume of the water tank were determined with manual calculations.

- Validation of the design was done using the Pipe Flow Expert software to simulate the sprinkler system.

2. The Impact Of Oxygen On The Pitting Corrosion Of Fire Sprinkler System Copper Pipe (Lee Et Al., 2023)

- Key findings:

- Pitting corrosion, a form of localized corrosion, is a persistent problem with copper pipes in fire sprinkler systems. This is mainly due to the oxygen concentration in cells.

- In copper plate tests, incorporating CS-NR effectively stopped pitting corrosion. (CS-NR is an added corrosion inhibitor.)

- Methodology:

- Copper plates were tested in 3% NaCl Solution for 10 days to assess how varying the amount of CS-NR inhibitor affects corrosion protection processes in materials for commercial applications.

- Some surface characterizations of the test specimens were performed using a scanning electron microscope (SEM) and energy-dispersive spectroscopy (EDS) analysis.

3. Seismic Performance Characterization of Fire Sprinkler Piping Systems through Shake Table Testing (Rashid et al., 2022)

- Key Findings:

- The bracing of the branch and arm-over pipes significantly impacts the fire sprinkler system demand for pipe for fire.

- The piping system responding in resonance with the input excitation motion can increase the seismic demand placed on the pipes far beyond what was previously expected.

- Methodology:

-

- A fire sprinkler piping specimen with features representative of actual practices in New Zealand was subjected to a set of floor acceleration response histories from an instrumented building.

- The specimen’s seismic response was evaluated under various bracing configurations.