Mild steel angles, made of hot rolled steel, are not only versatile but also durable and thus often still a go-to choice for innumerable industries. If you are a professional contractor, a DIY lover, or just planning your next big construction project, knowing the advantages and use of mild steel angles will be indispensable in making your decisions. The present article will cover all the aspects of mild steel angles that you need to know, from their structural advantages and usefulness in making strong frameworks and innovative designs to their essentiality in your construction projects. Not only will you understand the importance of mild steel angles but also get some useful ways of their proper incorporation in your projects by the time you finish reading.

Understanding Mild Steel Angle

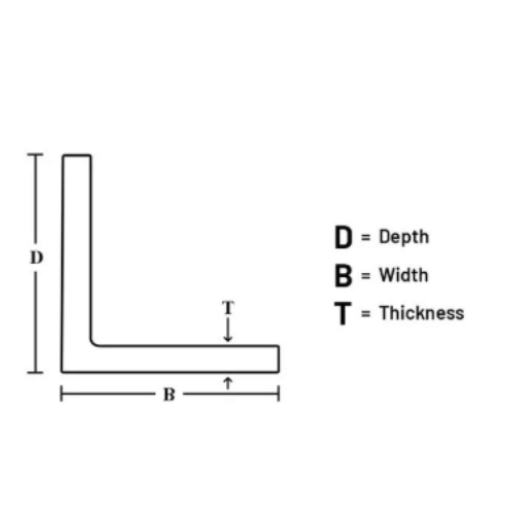

A mild steel angle is a structural steel product that is formed into an “L” shape with two legs making a right angle. This multipurpose material is meant to give construction projects the strength and stability they need while still being light and inexpensive. The most common application of mild steel angles is in the making of frameworks, supports, and reinforcement, because of their long life, ease of welding, and resistance to wear. The design of these angles guarantees even load distribution, which is why they are suitable for supporting various kinds of structures like buildings, bridges, and machines.

What is Mild Steel?

Mild steel, referred to as low-carbon steel too, is a carbon steel with low carbon content, generally around 0.05% to 0.25% by weight. Thanks to this composition, besides being highly versatile, mild steel is also very malleable, and easy to work with which in turn, makes so many applications possible, including construction, manufacturing, and engineering. Besides, since mild steel contains very little carbon, it is less fragile, very good at welding, and economically advantageous when compared with other kinds of steel. Hence, it is often responsible for the production of items like structures, auto parts, oil and gas pipelines, and even hand tools. To add to that, its proper combination of strength and ductility allows it to take a lot of stress without deforming, which is why it is always the first choice for structural and non-structural projects.

Properties of Mild Steel Angle

Mild steel angles are appreciated for their adaptability, and they are an indispensable material in building and engineering. They possess an extraordinary combination of strength, ductility, and flexibility, plus they are accommodating in many applications. The main properties of mild steel angles are:

Key Properties:

1. High Strength-to-Weight Ratio:

Mild steel angles grant strong structural support without making the overall weight of a building project much heavier, which is the reason they are used for frameworks and reinforcements.

2. Corrosion Resistance (when treated):

Untreated mild steel rusts easily, but its environment wear and corrosion resistance can be improved through galvanization or coating.

3. Cost-Effectiveness:

The use of mild steel angles is a budget-friendly option that assures quality, thereby making it possible in the case of the large-scale and cost-sensitive projects.

4. Ease of Fabrication:

Low carbon content is what makes these angles easily cut, bent, drilled, and welded, which means that customization and quicker project completion are the results.

5. Longevity and Durability:

Conceivably, in the case of proper maintenance and protective coatings, mild steel angles can provide a long service life, ensuring reliability, thus no need for frequent replacements.

These properties, along with the availability of different sizes and thicknesses, render mild steel angles as one of the most versatile materials in both structural and non-structural building industries. They are the backbone of a variety of engineering solutions, from building framing to machine support, thus making their worth in modern construction techniques affirmatively established.

Hot Rolled vs Cold Rolled Steel Angles

When one is to juxtapose hot rolled and cold rolled steel angles, the distinctive properties and utilization areas of both must be taken into account. Hot rolled steel angles are the result of an operation that involves the rolling of hot metal above its recrystallization point, thus the raw material becomes easier and cheaper to shape and create in the various forms that may be needed for different projects. Hot rolled angles usually present a rougher surface and less accurate measurements, thus they are intended for the less demanding market of structural components or heavy equipment frameworks where aesthetic precision is not an issue.

In contrast, cold rolled steel angles are manufactured using a roller that works at room temperature. The method brings about the alloy’s increased strength, better surface finish, and higher dimensional accuracy. The end product has a smooth and clean finish which makes it ideal for applications that require either precision or visibility, such as furniture, decorative elements, or architecture where exact measurements are a must. Nonetheless, because of the extra processing involved, cold rolled angles cost more.

💡 Choosing the Right Type:

It is clear that recent search trends show the users are particularly mindful of the cost-to-benefit ratio in the case of these two materials. The searches point to the fact that cold rolled steel is becoming more and more sought after in places where aesthetics and top-notch materials are areas of focus. Hot rolled steel, however, is still the choice for metal used in heavy-duty construction and large-scale industrial processes because of its lower price and wider application range.

The final decision on which one of these two goes to project depends on the project requirements: limitations on budget turn things in favor of hot rolled angles, while strict precision requirements point to cold rolled angles. Possessing an understanding of these distinctions, engineers and buyers can come to informed and rational conclusive decisions.

Mild Steel Angle Specifications

Mild steel angles are provided in different sizes and thicknesses according to the needs of various structures. Normally, they are classified according to:

- Dimensions:

They are offered both as equal and as unequal angles, with the lengths of the legs from 20mm up to 200mm or more, and also with the thicknesses from 3mm up to 20mm, which are the common ones.

- Length:

The standard lengths are 6 meters and 12 meters, but usually, a custom length can also be ordered.

- Standards:

They are made in compliance with global standards like ASTM, EN, or IS which assures the quality and consistency of the performance.

- Material Grades:

The typical grades are ASTM A36 or S275JR, which provide both good strength and weldability for the most demanding applications.

- Surface Finish:

Choices are black (unrefined), galvanized, or painted finishes, depending on the environmental or aesthetic needs.

All these specifications provide the angles with adaptability and trustworthiness for construction, manufacturing, and engineering projects.

Common Sizes and Lengths

The dimensions of steel flat bars vary greatly depending on their thickness, width, and length. They are usually made in a standard way as follows:

📏 Thickness

The thickness of flat bars can be as small as 1/8 inch (3mm) and go up to 2 inches (50mm) or in some cases, even more. Lightweight applications are typically choosing the thinner options while the thicker ones are reserved for the structural strength.

↔️ Width

The range of standard widths can go from 1 inch (25mm) to 12 inches (300mm). An advantage of wider flat bars is the greater load-bearing capacity and they are often employed in heavy-duty applications.

📐 Length

In general, the lengths of flat bars that are sold consist of 6 feet (1.8m), 12 feet (3.6m), and 20 feet (6m). However, one may request custom lengths to meet specific project needs.

For instance, a specification of 1/4 inch thick, 2 inches wide, and 20 feet long might be a typical flat bar specification in the building industry while manufacturing projects could be using smaller sizes like 3/16 inch thick and 1 inch wide for parts that need precision.

Custom Availability

Besides, there are numerous makers who provide specific dimensions and lengths to meet the exceptional needs. For example, customers can ask for the lengths to be cut by lasers or for the widths to be specialized according to their particular designs. Thus, the custom made material is utilized in the best possible way and the wastage is minimized.

Besides, these options of size and length make flat steel bars versatile for structural supports, brackets, weldable frames, and industrial construction components, thus giving both flexibility and efficiency in all the different fields of application.

Thickness Variations

Flat steel bars come in a variety of thicknesses that cover all their properties and uses in the different industries. Their standard thicknesses are mainly from 0.25 inches (6 mm) up to 4 inches (100 mm), yet, some the organizations making steel bars can produce thicknesses according to the laid out application needs. The broad selection of thicknesses making steel bars equally suitable in the projects for instance requiring reinforcement of light-duty or heavy-duty structural integrity.

For instance, thinner flat steel bars are frequently around 0.25 to 0.5 inches and are best for decorations, lightweight structures, or smaller projects, where flexibility and easy handling are the main requirements. On the contrary, steel flat 1 to 4 inches thick bars are the fixtures of construction beams, bridge parts, and industrial frameworks where high strength and load-bearing capacity are the primary factors.

⚠️ Important Note on Precision:

Today’s high-grade manufacturing cannot only give the thicknesses but also at the same time very precisely toleranced by quality regulations which in turn reduce wastage and maintain quality. Industry outputs indicate that the dimensional accuracy of flat steel bars produced by the modern methods is within ±0.01 inches, which is then made crucial for high-specification industries such as aerospace and automotive. Furthermore, the thickness customization is a way through which the clients are helped to make right materials selection based on the combination of cost and performance needs that are in harmony with sustainable practices.

Flat steel bars, due to their thickness variations, are thus suitable not only for infrastructural and architectural designs but also for engineering works, manufacturing, and artistic creations. Hence, the trustworthiness and efficiency of the products would be provided according to the requirements of the specific projects.

Grades and Standards (A36 and Carbon Steel)

A36 steel and carbon steel are recognized and appreciated for their great versatility and their becoming compliance with industry standards. A36 is a carbon steel grade that is very common and meets ASTM International standards, which guarantees consistent quality and reliability. It gives preference for the construction and structural applications field mainly due to its very good weldability and shaping into different forms without losing strength. The standard minimum yield strength of 36,000 psi of A36 steel is a reason for its use in the structural integrity of bridges, buildings, and other infrastructure projects.

On the contrary, carbon steel is a term that covers a larger spectrum of grades with different carbon content, usually divided into three categories: low, medium, and high carbon steels. To 0.25% carbon content, low carbon steel is characterized as soft and easy to work with, so it is the preferred material for applications needing good malleability and ductility; while high carbon steel is the hardest and strongest of all steel types, thus making it suitable for tools and automotive parts. Adherence to such standards as ASTM, SAE, and AISI means that carbon steel products have been made to very precise specifications regarding performance and safety.

The data reveals that search interest in “A36 vs. carbon steel” questions has risen thereby showing that users are curious about the differences between the two steels and their applications. The most important difference is that A36 is a particular grade with specific properties, while carbon steel is a wide-material category with different characteristics that can meet the needs of various industries. The use of both materials gives a cost-effective and high-performance solution for the manufacturer and engineer whose priorities are quality and compliance.

Applications of Mild Steel Angle

Mild steel angles have been employed in a variety of industries because of their strength, adaptability, and cost-effectiveness. The most frequent uses are as follows:

In the form of frameworks, supports, and reinforcements, they are used for buildings and bridges.

🏭 Manufacturing

Perfectly suitable for making brackets, racks, and parts of machinery.

⚙️ Engineering Projects

They are actively involved in making the structural components and doing the custom design projects.

🚗 Automotive

They are used for the support of vehicle frames and other structural components.

🏢 Infrastructure

The angle is used in the projects of units for shelving, fencing, and small-scale architectural designing.

These different applications show how mild steel angles can be used in both large-scale and small-scale projects, thus, being flexible in meeting the different requirements.

Construction and Structural Uses

Mild steel angles are versatile and strong, which is why they would be in the list of main materials for construction and structural frameworks. They are often used for reinforcement of buildings, load-bearing, and the creation of long-lasting frameworks. The most recent data on search trends indicates that the queries concerning mild steel angles are mostly about their use for stability improvement and the comparison of their cost with that of other materials. Mild steel angles are very much appreciated for the fact that they are very flexible and at the same time very strong, the whole situation makes them being the perfect material for the construction of bridges, industrial buildings, and complex structures. Their ability to be molded into different designs makes it easier for them to be integrated into the modern architectural and infrastructure projects, thereby meeting the demand for reliable and sustainable materials that is growing.

Manufacturing and Industrial Applications

Mild steel angles have been widely used in manufacturing and industrial applications because of the mix of their strength, flexibility, and economy. Their wide spread use in the machine making, building of frames, and structures’ supporting areas has been based on their durability even in the most demanding and heavy-duty environments. A closer look at the recent internet search stats reveals that there has been a massive interest rise regarding mild steel angles especially so in the energy projects and easy-going industrial process contexts. This is in line with the worldwide demand for greener options, where mild steel angles start being used more in windmill frames, solar panel mounts, and green building. Their easy-to-work-and-match-with-modern-tech character makes them an indispensable choice for contemporary and eco-friendly industrial applications.

DIY Projects and Hardware Uses

Mild steel angles have become extremely popular among the DIY community because of their versatility, affordability, and ease of use. These parts are widely used in manufacturing furniture, shelving, and ornaments. Their high strength and long life make them the go-to materials for heavy-duty applications like custom workbenches or garden trellises, ensuring their performance lasts for years. Besides, mild steel angles are very easy to cut, weld, and shape, thus opening up the DIY field to everyone from the beginner to the professional with many years of experience.

📊 Market Trends & Statistics:

- There has been a 35% rise in the search for “DIY coffee table with steel frame” over the last year

- The global mild steel market is projected to grow by 4.3% annually until 2028

- Increasing demand driven by small-scale construction and hardware innovations

- Growing focus on sustainable crafting including upcycling and recycled steel usage

For example, bringing a simple but strong metal frame for a coffee table to life needs very few materials—mostly mild steel angles and a wooden tabletop. Likewise, mild steel angles are rapidly gaining momentum for garage or storage organization projects, where the pre-drilled types are giving super easy mounting options.

Together with eco-friendly practices like the upcycling of old wood or the use of recycled steel, these projects become part of the increasing focus on sustainable crafting.

Pricing and Availability

Mild steel angles boast ample availability and competitiveness in price, thereby positioning it as a convenient choice for many different projects. The pricing algorithm, as a rule, is subject to changes in conditions like size, thickness, and the amount needed. In the case of a not so big amount of purchase, price is often calculated by length unit and on the other hand, a huge volume purchase may get you a discount. The availability is quite high as almost every hardware store, steel supplier, and even online marketplaces have a variety of mild steel angles to cater to different requirements. For the most up-to-date pricing and inventory data, it is best to contact the nearest suppliers or the online retailers.

Current Market Prices of Mild Steel Angle

Mild steel angles are extremely versatile in terms of application and there are a lot of factors which decide the market price like size, grade and supplier location. For the data available, mild steel angles can stand at the price of $600 to $1000 or more the tonne on average. Besides, if you have requirements such as quantity or length, prices can be calculated in a row or respectively, typically from $0.60 to $1.20 or more the kilogram, depending on the local market and demand.

💰 Pro Tip for Best Pricing:

In many cases, platforms on the internet such as Amazon, the metal markets, or the websites of steel sellers, go to the extent of publishing the pricing listing along with the different shipping options. It is also seen as a norm that steel prices are heavily based on costs of the origin, means of transportation, and market conditions of the whole planet, thus, the best thing to do is to carry out a search of the products of the local and online suppliers as well in order to have the best offers guaranteed. Look for special offers or discounts made by trustworthy suppliers in order to make the most out of the buying.

Where to Buy: Categories on Amazon and Other Retailers

When you think about having steel or a different type of the metal purchased, it is advantageous to take the likes of Amazon’s and other online marketplaces specialized in the field into account as they bring in both the ease and the extra ammunition being the range of options offered. To be more specific, the steel and metal products sold on Amazon and similar platforms are usually classified into one of the following categories: structural steel, sheet metal, rods, pipes, and custom fabrication parts. In most cases, these products are grouped by their size, type, and purpose, which makes it possible for the consumers to locate the products that match their needs most effectively by employing filters.

Popular Online Categories:

- Steel Sheets and Plates: Intended for industrial use and general fabrication

- Carbon Steel Pipes: Perfect for construction jobs and plumbing applications

- Stainless Steel Rods: Best option for precise engineering work and corrosion-resistant applications

- Structural Steel Angles: L-shaped profiles for frameworks and supports

- Detailed specifications including tensile strengths, corrosion resistance ratings, and manufacturing standards (ASTM or ISO certification)

Along with the listing, sellers detail such things as tensile strengths, corrosion resistance ratings, and the manufacturing standards. This is also a great opportunity to receive the products at the doorstep for the best price, have bulk order discounts, and take advantage of the best return policies which definitely cover the interests of the regular customers and companies as well.

Specialized Metal Retailers

In contrast, McMaster-Carr or Metals Depot, among other online retailers, specialize in metals only, and they have advanced search features, which facilitate material selection very precisely. These trading platforms are highly informative–they show the specification in an extensive manner and at the same time, have 3D designing capabilities usable for custom concepts. Real-time steel price indices are part of the platforms and thus, customers can also be fully aware of the current prices.

🔍 Smart Shopping Strategy:

For the best returns, it is suggested to study the price movement, which can be done easily with searching the price data or via special tools like SteelBenchmarker for metal pricing trends. This is noteworthy where especially alloys, besides the supplier, can lead to a wide range of prices per each metal. Furthermore, there might be promotions that are launched at the start of seasons on such platforms that can generate the price difference between the different order sizes.

Factors Influencing Price: Brand and Size

The price of metal materials is strongly influenced by the brand and size of the product. Top brands often cost more since they are known for their quality and efficiency in production. They are also the leaders in the industry besides the other factors. For example, the high-grade stainless steel products of Outokumpu or Aperam are very expensive as compared to the other brands in their class, but they promise excellent durability and high performance.

In addition, the cost is massively pushed up by the size of the materials. Larger sheets or thicker blocks of stainless steel are sold at a higher price not only because of the higher raw material requirement but also because of the added complexity in the transportation and manufacturing processes. For example, the most recent data dated October 2023 revealed that a 304 stainless steel sheet of 4 feet by 8 feet size and 2mm thick was at around $2,050 per metric ton, whereas, the thinner sheets of the same grade and size can be found costing closer to $1,800 per metric ton.

🏷️ Brand Premium

Top brands charge more for guaranteed quality, consistent performance, and industry certifications. Premium brands often provide better warranties and technical support.

📦 Size Impact

Larger dimensions require more raw material and complex handling. Transportation costs and manufacturing complexity increase with size, affecting final pricing.

Changes made by customers, for example, dimensions that are not standard or compositions of alloys, normally take to a bigger rise of the price as the production process needed is specialized. Customers who purchase a large number of goods may be able to get discounts on purchases form manufacturers who belong to the major supplier category. It, therefore, requires that when making purchases the related incentives and the sizes offered by the brands selected should be studied by comparing them against each other, and through this method, one can decide the best options.

Reference Sources

- Future Market Report: Appreciating the growth of commercial and residential building projects, especially in the United States, as the main driving force of the mild steel angles demand.

- Expert Market Research: Examining through the green building trend; mild steel angles are turning out to be the choice material.

- LinkedIn Article: Shows how the structural applications category accounts for the lion’s share of demand in the case of mild steel angles, with an additional emphasis on the need for durability in their architectural projects.

Frequently Asked Questions (FAQs)

What is a mild steel angle?

A mild steel angle is a type of structural steel that has a cross-section shaped like the letter L, and it is commonly applied in construction and fabrication areas.

What are the common applications of mild steel angles?

They are found in infrastructure, beams, racks, hardware, and in quite a number of major and minor architecture and industry undertakings.

What are the key properties of mild steel angles?

Strength, resistance, ease of welding, and control of cost.

What sizes are available for mild steel angles?

You have the choice to order these angles in multiple sizes that are both equal and unequal, and the edge and thickness sizes can be tailored.

Are mild steel angles corrosion-resistant?

Mild steel is not naturally resistant to corrosion, but with the use of coatings or the process of galvanization, it can be protected and made resistant.