Black steel pipe is an immensely versatile material that finds use in construction, fabrication, and other industrial applications. However, concerning water systems, issues often arise regarding the appropriateness and safety of these applications. Can black steel pipe be used for water distribution, or are there limitations to its functionality in this regard? This article looks into the properties of black steel pipe, its usual applications, and factors that affect its compatibility with water systems. By the end of this article, you will clearly understand whether black steel pipe is the right choice for your requirements and how it compares to market alternatives.

Introduction to Black Steel Pipe

Black steel pipe is a strong, cheap, and versatile material for any type of industrial and structural application, from gas transport to fire sprinklers and steam systems. However, it is usually not recommended for water distribution. The primary reason is that it corrodes when in contact with water, thus damaging pipes and contaminating the water supply. In contrast, for water systems where long-term reliability and safety are paramount, usually galvanized steel or copper pipes are preferred.

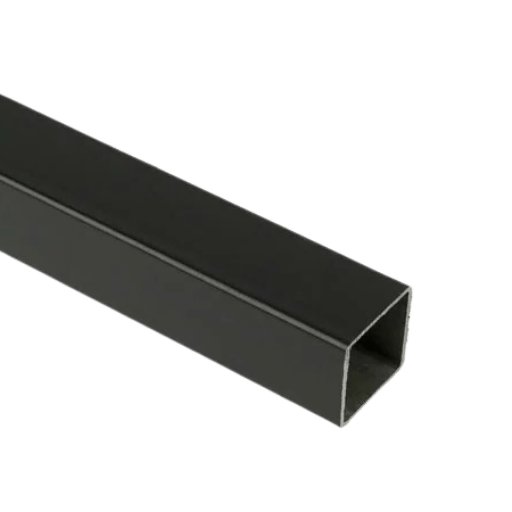

What is Black Steel Pipe?

Black steel pipe is a pipe made of steel, uncoated and having a dark-colored iron oxide scale on the surface. The pipes are primarily used in applications where corrosion resistance is not needed, such as gas transportation, fire sprinkler systems, and oil and steam-based systems. The pipe can withstand high pressure, yet it is not suitable for water distribution since it will rust and corrode if moisture contacts the pipe.

Common Uses of Black Steel Pipe

Black steel pipes are commonly used in the following places:

- Gas Distribution: It is used for natural gas and propane distribution due to its high durability and resistance to pressure.

- Fire Sprinkler Systems: Being a choice for fire suppression systems, the water flow is brief and thus less prone to corrosion risk.

- Oil and Steam Systems: It has good strength, which makes it capable of carrying oil, steam, and other industrial fluids in high-pressure systems.

Differences Between Black Steel Pipe and Galvanized Pipe

Black Steel Pipe for Water Systems

Is Black Steel Pipe Safe for Potable Water?

Black steel pipes are not usually recommended for water supply because of rusting and corrosion hazards. While galvanized pipes have a zinc coating to prevent rusting, black steel pipes lack such protection. Over an extended period, the rusting and particulate matter can leach into the water, creating potential health hazards and degrading water quality.

Another factor that affects black steel pipes is the formation of scales internally, which affects water flow and aids in bacterial growth. In the interest of health and safety, numerous regions have forbidden the use of black steel pipes in food service applications to meet potable water standards. For use in water distribution, PVC, copper, or galvanized steel offer great options that meet safety and durability requirements when delivering clean drinking water.

The applications of the material, such as for gas transport or fire suppression systems, demonstrate that its structural properties allow for non-potable use, reaffirming the material’s unsuitability for potable water purposes.

Advantages of Using Black Steel Pipe for Water

- ✓Strength and Durability: It is said that black steel pipes are strong; they withstand high pressures and are subjected to mechanical stresses, making them suitable for specific water distribution applications.

- ✓Cost-Effectiveness: Black steel pipe is relatively inexpensive when compared to some alternatives, and thus provides an inevitable trade-off between price and performance in the appropriate installation.

- ✓Resistance to Heat: These black steel pipes can hold up to high temperatures, which would be necessary in cases where heated water may be flowing through them or when they are exposed to elevated thermal states.

- ✓Wide Availability: These pipes are available in a wide range of sizes, making them fairly simple to procure and install for particular works.

Note: Given that black steel pipe tends to corrode over time, thereby affecting water quality, it is generally not recommended for potable water systems. Its use is more common in settings involving non-drinking water or industrial applications. Always consult regulatory standards and project requirements when selecting materials.

Drawbacks and Safety Concerns

The limitations and safety concerns of black steel pipes need to be addressed for suitable application and safe functioning. Corrosion, for instance, is one big concern. Despite being robust, black steel pipe is in danger of corrosion over time if exposed to moisture or oxygen, making it structurally weaker and eventually leading to leaks or failures. This limitation makes it unsuitable for any application involving continuous exposure to water or a humid environment.

Sometimes these pipes cannot cope with high pressures, which pose hazardous situations. Black steel pipes are generally used in low and medium-pressure systems. Therefore, using these pipes beyond their design limits may lead to breakage and pose hazards from both industrial and residential perspectives. It is also challenging to handle installation in intricate or confined spaces, as special tools are needed for cutting and threading.

The black steel pipes are not flame-retardant, and thus they present safety risks during installation or operation where the pipes are subjected to extreme heat or areas prone to fire risks. Also, suppose these types of piping are mishandled in gas distribution systems without adhering to regulations. In that case, the increased occurrence of leakages can well be the cause of explosion hazards or health hazards from carbon monoxide poisoning. To mitigate these hazards, there must be strict adherence to safety codes, inspections at appropriate intervals, and the use of alternative materials where needed.

Installation Considerations

Installation Tips for Black Steel Pipes

- Choose the Correct Pipe Size: The diameter is essential for ensuring the project runs properly and serves its intended function. Ensure accurate measurements to avoid installation errors that could lead to nasty consequences afterward.

- Prepare the Pipe Ends: Inspecting and cleaning the pipe ends is essential; any dust or roughness must be removed, and the threading must be proper for a good joint.

- Use Thread Sealant: A thread sealant or Teflon tape must be applied to have a tight and leak-proof joint. Do not overtighten, as this can damage the threads.

- Secure Pipes Properly: Use proper brackets or clamps to securely keep the pipes from moving. Movement creates undue stress on joints when pipes vibrate.

- Inspect Connections: Check once more that all joints and fittings are sealed tight after assembly, perform a pressure test for any leaking, and put the system into working order from there.

- Follow Local Codes: Building codes and local regulations must be observed to ensure the safety of the system and its conformity with the pertinent standards.

Required Fittings and Tools

Specific types of fittings and tools are required for assembling a reliable and efficient piping system. An enumeration of commonly needed types of fittings and tools follows:

Pipe Fittings

- Elbows: Change the direction of the pipe to a certain angle, usually 45° or 90°.

- Tee Fittings: To combine or split the flow in three directions, ensuring that the system remains plumb.

- Couplings: Used to join two pipes either to increase the length or to repair a section.

- Reducer Fittings: Provide a transition between different pipe diameters to regulate flow rates.

Valves

- Ball Valves: Provide even on/off control with excellent leak-proof ability. They work best for high pressure.

- Gate Valves: Meant to close by lifting a gate or lowering it to open.

- Check Valves: Prevent backward flow so the medium flows in a single direction.

Support Components

- Pipe Clamps and Hangers: Secure the pipes to walls, ceilings, or structures, thereby minimizing vibration and movement.

- Expansion Joints: Absorb dimensional variations due to thermal changes in the system and thereby prevent damage.

Tools

- Pipe Cutters: Provide a clean and precise cut for plastic, metal, or PVC pipes.

- Threading Tools: The ends of the pipes need to be threaded for threaded connections.

- Tube Benders: Used for bending pipes without compromising the structural integrity or obstructing flow capacity.

Wrenches

- An adjustable wrench provides grip on fasteners and fittings.

- A torque wrench is highly recommended to prevent over-tightening and apply the torque to specification.

Sealing Materials

- Teflon Tape (Thread Seal Tape): Teflon tape will seal the threaded connections waterproof and is intended to prevent leaks.

- Pipe Sealant Compounds: Are used to enhance the seal of the joint, especially with pressurized systems.

For the system to function properly with minimum maintenance troubles, it must be installed according to fitting and tooling specifications.

Common Installation Mistakes to Avoid

Improper Fitting Selection

The selection of fittings that are incompatible with systems in terms of pressure, temperature, or material requirements is bound to cause failures or leaks in the system. For example, going even 10% above the pressure rating of fittings in carbon steel pipes can contribute to the risk of catastrophic failure.

Incorrect Application of Sealing Materials

Inappropriate use of sealing materials like Teflon tape may undercut the integrity of the joints. If used in excess, tape layers can interfere with threading and stress the joint to the point where minor fractures begin, according to studies.

Over-Tightening Connections

Too much torque is perhaps the most common error committed while assembling threaded connections. This may result in stripped threads, deformation of the components, or overstressing. A torque wrench is an appropriate tool to apply the specified torque values, thus improving system reliability.

Neglecting to Clean Threads and Sealing Surfaces

Contaminants such as dirt, oil, or debris on threads or sealing surfaces will not permit sealing. It is of utmost importance to ensure clean surfaces, as this can reduce the probability of leakage by 30%, according to technical guidelines.

Failure to Account for Thermal Expansion

What system designers regularly miss is the temperature variations under operating conditions, which cause the piping and fittings to expand or contract. Improper allowances for thermal expansions can cause joint fatigue, cracking, or deformation with time.

Improper Alignment During Assembly

If a pipe or fitting is misaligned, the connection will be subjected to abnormal stresses that will cause weakening of the joint and affect the long-term performance of the system. Precision alignment tools should be employed to avoid such risks.

Using Non-Certified Components

Using components that are non-standard or uncertified to save costs compromises safety and performance. Certified components are tested to withstand industry standards to assure durability and compatibility.

By avoiding these common mistakes, installers can ensure greater system efficiency, safety, and longevity.

Comparative Analysis

Black Steel Pipe vs. Galvanized Pipe

Black Steel Pipe vs. PVC and Copper

Cost Comparison of Different Pipe Materials

Maintenance Practices

How to Maintain Black Steel Pipes

Proper maintenance, especially for black steel gas pipes, leads directly to their longevity and proper functioning. Follow the steps below to ensure adequate upkeep:

1

Regular Inspection

Check periodically pipes for corrosion, leakage, or damage, focusing on joints or places exposed to moisture.

2

Clean Surfaces

Keep the outside of the pipes free from dirt, grease, or debris to minimize corrosion, and clean using a soft cloth with mild detergent.

3

Protect Against Corrosion

Corrosion protection should be ensured through the application of coatings or paints especially suited for metal surfaces and a black finish, more so in a humid climate.

4

Address Leaks Promptly

Fix leaks and weaknesses immediately to prevent bigger systemic issues from developing.

5

Monitor Usage

Ensure that the use of pipes is within material pressure limits to avoid unnecessary strain or damage.

Adhering to these practices will keep black steel pipe safe over time in its structural integrity and performance.

Signs of Wear and Tear to Look Out For

Getting in early to spot the wear-and-tear signs in black steel pipes is imperative, as bigger failures may ensue. Some of the visual signs include:

⚠️ Corrosion or Rust Formation

A visual inspection for rust or discoloration of a pipe should be performed, wherever possible. Corrosion occurs due to prolonged exposure to moisture or oxygen and eventually leads to a decrease in the structural integrity of the material. It has been proven that regular inspection significantly reduces the chance of corrosion-related failures.

💧 Leaks or Dripping

Even a small leak suggests the possibility of internal damage or joint failure nearby. Timely attention should be given to such leaks to prevent them from worsening and causing operational disruption.

🔨 Cracks or Splits

Visual inspection for any physical impairment to the pipe, such as cracks or splits, is necessary. These impairments could result from overpressure, temperature anomalies, or impact damage.

🔊 Unusual Sounds

Knocking or banging sounds from an operating system may signal an underlying problem. Pressure imbalances, loose fittings, or air pockets could all be possibilities.

📉 Decreased Efficiency in Operation

An evident drop in pressure or flow rate inside a system can indicate an obstruction from sediment or thinning of the walls due to corrosion.

⚗️ Visible Scaling or Deposits

Mineral deposit accumulations can block water flow and set the system under duress. This requires periodic cleaning and maintenance.

Being vigilant and looking out for these signs while making routine inspections can almost certainly help extend the working life of black steel pipes and ensure the safety and reliability of their operation.

Repairing and Replacing Black Steel Pipes

The repair and replacement of black steel pipes is a methodical process that varies with the nature of the fault and its extent. Minor damages in water pipes, such as small leaks, superficial corrosion, or localized wear, can usually be repaired. Pinhole leaks may be sealed by epoxy coatings, pipe wraps, or even sealants, simultaneously strengthening the affected sections. Performing preventive maintenance and implementing repairs at the earliest signs of malfunction are crucial for preserving the efficacy of any repair.

A replacement is needed due to heavy corrosion or structural damage so severe that constant re-grouting might be required because of recurrent leaking. Usually, black steel pipes used for water or gas lines may last anywhere from 50 to 100 years, depending on their exposure and maintenance. Depending on the system layout and compatibility of materials, one might consider replacements. In modern times, galvanized steel, PEX, or PVC pipes might be more feasible and resistant to corrosion than traditional black steel.

Whichever replacement method is accepted, proper installation must take place beforehand. This includes threaded connections, pipe fittings, and sealing materials as they provide integrity to the whole system. After installation, the system must be pressure tested regularly to guarantee reliability and minimize potential failures, thereby ensuring compliance with International Safety and Industry Standards.

Frequently Asked Questions (FAQs)

Reference Sources

- The Effects of Metal Pipes on Potable Water Quality: The document highlights that black steel pipes should not be used for supplying water because of the adverse change in metal content.

- Common Pipe Alloy Can Form Cancer-Causing Chemicals in Drinking Water: The article explains that the rusted iron pipes, including black steel, react with the disinfectants in water systems to form carcinogenic chemicals.

- Pipe (fluid conveyance)

- Black Steel Pipe Supplier In China