Black steel is a distinct material with various applications and is widely used across multiple industries. Its special properties and uses are often misunderstood. An in-depth analysis of what differentiates it from all other types of steel, its main advantages, and the myriad ways in which it is used in construction, manufacturing, and so on is presented. For all professionals and laypeople interested in its characteristics, this article offers valuable insights into why black steel remains a crucial component in contemporary engineering and design.

What is Black Steel?

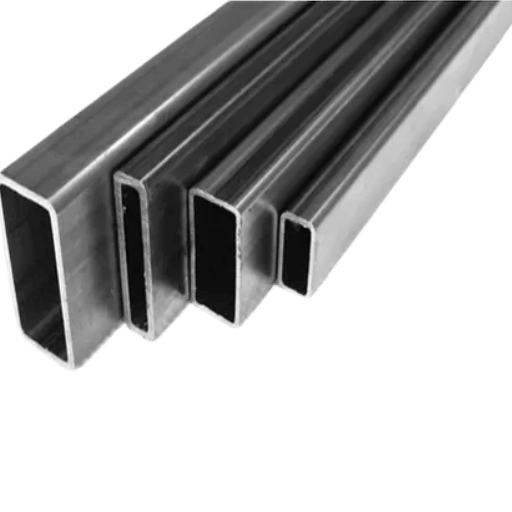

This term is typically understood by many to refer to any type of steel with a black, scaled surface that is produced during the treatment process. It is generally made by hot rolling, where the steel is worked in its hot state, thereby giving the surface a powerful but unfinished character. They always look different from other steels since they are never coated or galvanized. Black steel is typically used in various applications where aesthetics are not a primary concern. Still, rather than strength and function, construction, piping, and structural components are the main priorities.

Definition and Composition

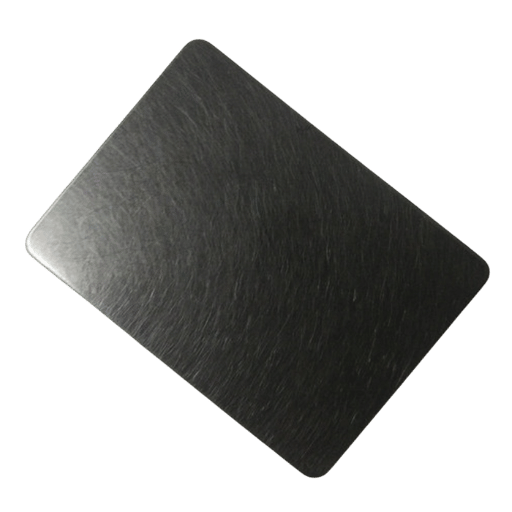

Black steel is a type of steel characterized by a dark-colored oxide coating that forms during the manufacturing process. Mainly, carbon steels consist of iron and carbon. Since no further coating or galvanization is applied, the black steel material retains its natural appearance while being considered very strong and durable. Such steel finds its application in industrial areas, especially wherever surface finish is not a primary concern, making it the preferred choice over rolled steel.

How Black Steel is Manufactured

- Hot Rolling Process: Steel is heated above its recrystallization temperature

- Shape Formation: The heated steel is rolled into the desired shape

- Temperature Control: High temperature prevents hardening during the rolling phase

- Oxide Layer Formation: A thin layer of oxide forms on the surface, imparting the black finish

The procedure is inexpensive and best suited for producing steels with maximum strength and durability, where the surface finish is not a significant concern.

Common Uses of Black Steel

Construction

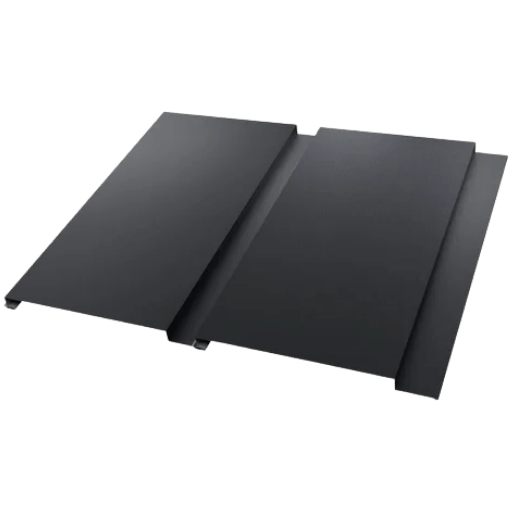

Structural components, frames for buildings and bridges

Industrial

Pipes, tubes, storage tanks, shipping containers

Manufacturing

Appliances, automotive parts, heavy equipment

Black Steel vs. Carbon Steel

Key Differences Between Black Steel and Carbon Steel

Advantages of Black Steel Over Carbon Steel

✓ Superior Corrosion Resistance

The black oxide coating protects against rust or any kind of weathering, be it environmental action, with moisture, and so on, on components like water supply pipes.

✓ Enhanced Ductility

To be formed or bent more than carbon steels would be of value in those fabrication processes requiring this property.

✓ Eco-Friendly Production

In the making, the black steel bears weaker environmental pollution than galvanization processes.

✓ Cost-Effective Solution

An economical option, black steel helps give an edge by reducing project costs for large projects and applications where cost is critical.

When to Choose Black Steel vs. Carbon Steel

Choose Black Steel When:

- → Strength and low cost are priorities

- → Surface finish is not critical

- → Heavy-duty industrial applications

- → Transporting oil, gas, or water

- → Indoor use or low-risk environments

Choose Carbon Steel When:

- → Higher precision is required

- → Enhanced durability is needed

- → Customization is essential

- → Outdoor or high-risk conditions

- → Structural components and automotive parts

Corrosion Resistance in Black Steel

Understanding Corrosion Resistance

Essentially, corrosion resistance refers to a material’s ability to resist deterioration due to oxidation or other chemical processes that may occur over time. In the case of black steel, corrosion resistance is significantly lower than that of typical steels due to its unfinished surface, making it more susceptible to environmental factors. Exposure of black steel to moisture or high humidity can cause the steel to start surface rust within weeks in a geographical place with the proper levels of precipitation or salt in the air.

Factors Affecting Corrosion in Black Steel

- Moisture and Humidity: Longer duration of exposure to moisture will expedite corrosion and promote rust.

- Environmental Contaminants: Presence of chlorides, sulfates, or industrial pollutants increases corrosion rate.

- Temperature Fluctuations: Abrupt or frequent temperature changes might induce condensation, which then may expedite rust formation.

- Protective Coatings: Any kind of coating protects steel against presence of corrosive elements; absence, or deterioration thereof, causes exposure.

- Maintenance Practices: Poor maintenance allows potential corrosion issues to go unnoticed and worsen over time.

Maintenance Tips for Enhancing Corrosion Resistance

🧽 Regular Cleaning

Cleaning removes dirt, salts, and contaminants using non-abrasive methods to prevent damage to coatings.

🔍 Inspect for Damage

Regularly conduct inspections to identify areas where the surface may have scratches, cracks, or coating degradation.

🎨 Apply Protective Coatings

Touch-up paint, primers, or protective coatings to maintain the barrier against moisture.

💨 Implement Moisture Control

Store in controlled environments with good humidity and ventilation, or use dehumidifiers as needed.

🛡️ Use Corrosion Preventatives

Apply rust inhibitors or anti-corrosion oils to uncoated surfaces that are exposed to harsh conditions.

📅 Schedule Preventive Maintenance

Establish a schedule for regular maintenance activities to ensure preventive measures are implemented consistently.

Comparative Analysis: Black Steel vs. Mild Steel

Differences in Properties and Applications

Black Steel Characteristics

Composition: Uncoated steel with a dark anodized finish coming straight from the mill

Properties: Stronger and more heat-resistant, yet liable to rust

Applications: Gas lines, structural framework, automotive hardware

Mild Steel Characteristics

Composition: Low-carbon steel (0.05% to 0.25% carbon content)

Properties: Malleable and ductile, high weldability, and machinability

Applications: Construction, household appliances, and chassis for automobiles

Cost Considerations: Black Steel vs. Mild Steel

Mild Steel Pricing

per pound

Black Steel Pricing

per pound

Cost Analysis Note: Mild steel usually cost 15-25% less per ton compared to black steel depending on the fluctuation of prices in a respective region and specifications of grade. However, one should also consider other expenses that may include treatment post-processing for black steel and fabrication costs for mild steel when compiling a project budget.

Choosing Between Black Steel and Mild Steel

Decision Factors

- Project Requirements: Strength, corrosion resistance, weldability

- Environmental Conditions: Indoor vs outdoor, moisture exposure

- Budget Considerations: Material cost, fabrication, maintenance

- Sustainability Goals: Recyclability, environmental impact

Performance Comparison

Tensile Strength: Black steel offers higher tensile strength, making it suitable for heavy-duty structural applications.

Machinability: Mild steel’s ease of machining, bending, and cutting makes it ideal for intricate designs.

Recyclability: Mild steel’s recyclability makes it attractive for sustainability-focused industries.

Latest Trends in Black Steel Fabrication

Innovations in Steel Fabrication Techniques

Automated Robotics

Consider robotic applications for cutting, welding, and assembly of steel components, where the benefits include reduced errors and reduced production times, with higher consistency.

CAD/CAM Software

CAD and CAM software of the highest design enable intricate designs with extreme precision, and optimize the use of materials while minimizing wastage.

3D Printing Technology

Additive manufacturing technologies for custom steel components with complex geometry are of particular usefulness in aerospace and construction.

Sustainable Techniques

Energy-efficient laser cutting, eco-friendly coating, and HSLA steel development to improve performance with minimal impact on the environment.

Market Demand for Black Steel Products

Global Market Growth Projection

CAGR (2023-2030)

Species migration per decade

Key Growth Drivers:

- → Infrastructure development in emerging economies

- → Urbanization and sustainable construction projects

- → Renewable energy sector expansion

- → Automotive industry recovery

Future Prospects for Black Steel in Various Industries

🌿 Renewable Energy

Increasing usage of support structures for solar panels and wind turbines due to their durability and high tensile strength. Expected growth in sustainable energy infrastructure projects.

🏗️ Construction Industry

Sustainable urbanization demands green buildings and modular construction, where strength and customization options play a key role.

⛽ Oil & Gas Industry

The demand for high-quality pipelines and structural components remains; black steel remains predominant in key infrastructure.

🌊 Marine Structures

With advancements in coatings and anti-corrosion technologies, applications are expanding in extremely challenging marine environments and heavy machinery sectors.

Frequently Asked Questions (FAQs)

❓ What is black steel and how does it differ from regular steel?

Black steel is steel that has undergone a finishing process, resulting in a black finish. This steel differs from ordinary ones, which may have a shiny surface, black steel having on the contrary a dark appearance due to iron oxides present. This finish may provide some resistance against corrosion, but it will most definitely be vulnerable to corrosive agents given enough time.

⚖️ What are the differences between carbon steel and black steel?

The most significant difference between carbon steel and black steel lies in their surface treatment. Carbon steel can be classified as low-carbon, medium-carbon, or high-carbon steel. Typically, black steel refers to carbon steel that has undergone some treatment to achieve a blackened surface. Another application where black steel is often used is for piping purposes due to its structural strength.

🔧 How does the carbon content affect black steel?

Carbon content in black steel determines the steel’s hardness and tensile strength. More carbon equates to greater hardness but less ductility, resulting in increased brittleness. For less carbon means the steel is very ductile but soft. Understanding these differences is crucial when selecting steel for specific purposes.

⚡ Can black steel be welded easily?

Yes, you can cut and weld black steel like any other kind of steel. However, a bit of preparation is required to weld the finish of the black steel, as its oxide layer may compromise the weld’s quality. Fabricators of steel often suggest cleaning the weld site to get strong joints.

🏭 What types of applications are best suited for black steel?

Typically, black steel is favored in construction and heavy industrial work, particularly when piping and structural work are involved. Its properties of strength and hardness make it suitable for very demanding applications. Black finishes offer some protection against rust and corrosion.

🔬 How does black steel compare to alloy steel?

Black steel is commonly a type of carbon steel, whereas alloy steels contain additional alloying elements to modify their properties to some extent. Alloy steels may offer improved resistance to corrosion, enhanced tensile strength, and superior overall performance in specific applications. The project specifications determine whether black steel is used over alloy steel.

Key Takeaways

✓ Versatile Material

Black steel provides great strength for cost and is the true material for industrial use in cases where surface finish does not matter.

✓ Smart Selection

Choose black steel for the tougher applications and mild steel for projects demanding easy fabrication and customization.

✓ Future Growth

Increasing demand in new energy, building, and infrastructure will ensure that black steel remains a hot material in future development.

Reference Sources

- Various Types, Grades, and Sizes of Rebars for Construction – This source discusses carbon steel, also known as tempered steel, which is the most commonly used type in construction.

- Superhydrophobic Metal That Won’t Sink: A Research Article from the University of Rochester about the New Metallic Structures.

- Black Steel Pipe Supplier In China

- Steel