For those with a stake in structural steel tubing, knowledge of properties, applications, and comparisons within the ASTM A500 standard is paramount. Widely regarded as a specification for strength and general-purpose usage, ASTM A500 Grade B is exploited by the construction, infrastructure, and engineering sectors. How does it fare in comparison to Grade C, though, the other featured material in the same standard? In this article, we investigate the properties of ASTM A500 Grade B while drawing comparisons with Grade C, accompanied by applications, aiming at providing data for decision-making. For the professional, engineer, or curious about structural steel, this article will give you much-needed insight that will aid you in the material selection process.

Introduction to ASTM A500

ASTM A500 is the specification for cold-formed welded and seamless carbon steel structural tubing. Due to its high strength-to-weight ratio and excellent weldability, it finds general applications in construction and structural work. This specification defines several grades, among which Grade B and Grade C are distinguished on mechanical properties like tensile strength and yield strength. These grades give flexibility for engineering concerns where it may have to perform optimally in various projects. ASTM A500 tubing serves as an excellent choice in industries that require efficient and durable structural components.

What is ASTM A500?

ASTM A500 is a specification developed by ASTM International that prescribes the standards for cold-formed welded and seamless carbon steel tubing for structural purposes. Consequently, the basic purpose of the ASTM A500 standard is to assure that the tubing has adequate qualities of reliability, durability, and serviceability to satisfy different engineering demands in areas such as construction, infrastructure development, and manufacturing.

The specification categorizes tubing into four grades—Grade A, Grade B, Grade C, and Grade D—each presenting different mechanical qualities for the aptitudes of diverse kinds of applications. To cite an example, Grade A has a minimum yield strength of 33 ksi (kilopounds per square inch) and tensile strength of 45 ksi; thus, it finds use in general applications. On the contrary, Grade C and Grade D meanwhile possess much higher minimum yield strengths, with Grade C being 46 ksi and Grade D being 50 ksi, thus guaranteeing total performance for higher-end applications.

The tubing in ASTM A500 is often manufactured in round, square, and rectangular cross-sections to allow a certain degree of versatility in structural designs. This specification further defines tolerances for dimensions, straightness, and thickness to guarantee the needed precision and consistency in construction projects.

The strength-to-weight ratio being high is yet another advantage of ASTM A500 tubing, making it a cheaper alternative to some other materials, hot-rolled steel included. Another great trade advantage is weldability, making fabrication and construction itself more efficient. With its grading system combined with the quality guidelines that steel manufacturers have to follow, ASTM A500 maintains its position as a crucial name in structural solutions, which are both strong and timely.

Overview of ASTM A500 Grades

ASTM A500 defines several grades of cold-formed welded and seamless carbon steel tubing used for structural applications. The grades are primarily classified as Grade A, Grade B, Grade C, and Grade D, with each grade offering distinct mechanical properties to suit specific project requirements. Below is a breakdown of the grades and their key characteristics:

- Grade A: This grade is known for its lower tensile and yield strength compared to the other grades, making it suitable for general structural applications that do not require high levels of strength. The minimum yield strength is 33 ksi, and the minimum tensile strength is 45 ksi.

- Grade B: Commonly used in a variety of structural applications, Grade B provides a good balance of strength and ductility. It features a minimum yield strength of 42 ksi and a minimum tensile strength of 58 ksi.

- Grade C: With increased strength, Grade C is designed for demanding structural requirements. It has a minimum yield strength of 46 ksi and a minimum tensile strength of 62 ksi. This grade delivers enhanced performance for applications subjected to higher loads.

- Grade D: Grade D offers the highest strength within the ASTM A500 specification, making it ideal for heavy-duty structural applications. The minimum yield strength for Grade D is 50 ksi, with a minimum tensile strength of 70 ksi, ensuring incredible durability and load-bearing capacity.

Benefits of the Grades

The ASTM A500 steel grades offer a wide range of benefits, tailored to meet varying structural and engineering demands. Below are the key advantages of these grades, highlighting their performance and versatility:

- Strength and Durability: Each grade exhibits exceptional yield and tensile strength, making them reliable for both light and heavy-duty applications. For example, Grade D provides a robust minimum yield strength of 50 ksi and a tensile strength of 70 ksi, ensuring longevity and reduced risk of structural failure even under substantial loads. This makes it highly suitable for demanding projects like bridges and high-rise buildings.

- Versatility: With four distinct grades, ASTM A500 steel caters to diverse applications. Grades A and B are preferred for standard structural uses such as residential construction, while Grades C and D are designed for industrial purposes requiring higher strength, such as machinery components or large-scale infrastructures.

- Weight Efficiency: Due to their high strength-to-weight ratio, these steel grades allow for the use of lighter materials without compromising structural integrity. This attribute not only reduces material costs but also facilitates easier transportation and installation, especially in cost-sensitive projects.

- Weldability: ASTM A500 steels are known for their excellent weldability, which eases fabrication processes and ensures strong, consistent welds. Engineers often rely on these steels for applications where welding is a critical component, as it guarantees enhanced structural performance.

- Cost-Effectiveness: By balancing strength, durability, and ease of fabrication, ASTM A500 grades provide cost savings over time. Their long lifespan and reduced maintenance needs contribute to lower overall project costs compared to alternative materials.

- Sustainability: These grades align well with modern construction standards focused on sustainability. The material is often produced using recycled steel and can be recycled at the end of its lifecycle, reducing environmental impact and supporting eco-friendly initiatives.

Overall, the combination of reliability, performance, and adaptability makes ASTM A500 steel grades a trusted choice across a range of industries, delivering consistent results under varying operational conditions.

Importance of ASTM A500 in Construction

ASTM A500 specification has come to occupy the center stage in modern construction when it comes to the production of cold-formed welded carbon steel tubing. Owing to the great variety of applications it finds and the high strength-to-weight ratio it boasts of, it enters great demand in structural and architectural applications. There are also reports released lately stating that ASTM A500 steel tube used in construction for bridges, buildings, and infrastructural works greatly enhances the overall integrity of the framework, thereby diminishing wastage of materials. Uniformity in chemical composition and mechanical properties imparts predictable performance, which is an utmost requirement especially in safety-critical assemblies.

A significant fact worth knowing is that ASTM A500 Grade C, having a minimum yield strength of 50 ksi (kilo-pounds per square inch), is up to 39% stronger than other commonly used structural steels and hence is the best building material for load-bearing designs. Besides, having the advantage of being lightweight, it allows for the reduction of transportation and erection costs which are very considerable when compared with alternatives such as concrete or heavyweight steel grades. Environmentally, ASTM A500 fares better since its production sequesters lesser carbon footprint and can be combined with recycled materials, thereby enhancing its choice for environmentally conscious construction projects. This magnificent fusion of strength, efficiency, and sustainability has since made it a vital option in varied structural applications.

ASTM A500 Grade B Specifications

ASTM A500 Grade B is a standard specification for cold-formed welded and seamless carbon steel structural tubing. Specifications are as follows:

- Tensile Strength: Min. 58,000 psi (400 MPa).

- Yield Strength: Min. 46,000 psi (317 MPa).

- Elongation: 23% for round tubes computed using wall thickness and diameter.

- Shape Availability: Square, rectangular, and round tubing.

- Applications: Used in construction, welded structures, and load-bearing frameworks.

The various properties make it suitable for a wider range of structural and architectural uses.

Chemical Requirements of ASTM A500 Grade B

ASTM A500 Grade B sets specific chemical composition limits to ensure structural integrity and performance. The material is predominantly composed of carbon and manganese, with allowances for other elements to enhance strength, ductility, and weldability. Below are the chemical composition requirements:

- Carbon (C): Maximum of 0.26%

- Manganese (Mn): Maximum of 1.35%

- Phosphorus (P): Maximum of 0.035%

- Sulfur (S): Maximum of 0.035%

- Copper (Cu): Minimum of 0.20% when required for enhanced corrosion resistance

These limitations are carefully designed to prevent undesirable brittleness while maintaining optimal structural properties. The balance of elements ensures the material performs reliably across varying environmental and load-bearing conditions, making it an ideal choice for both industrial and architectural applications.

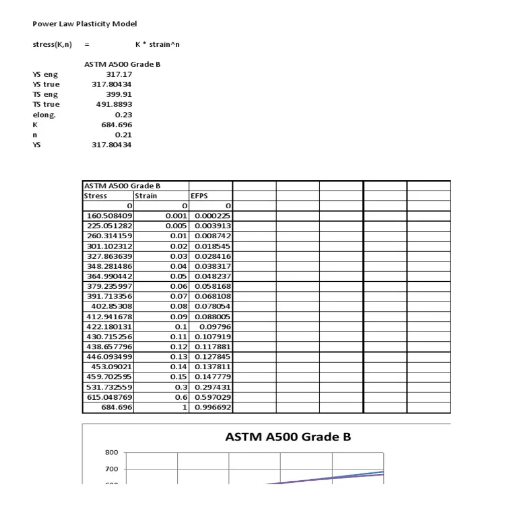

Mechanical Properties of A500 Grade B

A500 Grade B is recognized for its superior mechanical properties, making it a widely trusted material in structural and industrial applications. Below is an overview of its key mechanical specifications:

- Tensile Strength: The minimum tensile strength of A500 Grade B is 58,000 psi (400 MPa). This ensures the material can withstand significant stress before breaking, promoting durability in demanding environments.

- Yield Strength: A500 Grade B exhibits a minimum yield strength of 46,000 psi (317 MPa). This indicates its ability to withstand deformation under load without permanent distortion, making it reliable for structures requiring stability.

- Elongation: A500 Grade B typically allows a minimum elongation of 23% in a 2-inch gauge length for round and rectangular shapes. This elongation percentage demonstrates its flexibility and capacity for plastic deformation before fracture.

- Hardness: The material is engineered to achieve an optimal balance of hardness, adding to its wear resistance while retaining essential ductility.

These mechanical properties highlight the strength, flexibility, and performance of A500 Grade B, ensuring suitability for a wide range of architectural and load-bearing applications. By delivering consistency and reliability under varying conditions, A500 Grade B has solidified its reputation as a top-tier material in modern construction and engineering projects.

Dimensional Tolerances and Variations

A500 Grade B Tubing is maintained under very strict dimensional tolerances to provide consistency, quality, and performance in application. ASTM A500 specifications specify that the outside diameter (OD) of the tubing shall not vary by more than ±0.75% of the specified dimension. Wall thickness measurements require a tolerance of no more than ±10%, so all tubes would have an essentially uniform strength in the structure.

Acceptable deviations pertaining to length are ±0.125 inches for designated cut lengths up to 24 feet, while tolerances for longer uncut lengths can vary slightly but are subject to tight control so that any variations will present minimal effects during assembly or installation. Squareness of tubing (or angularity of its corners) must hold within 90° ±2° to maintain geometric stability and alignment.

Flatness tolerances strongly apply, especially for rectangular and square tubes, to keep opposite sides parallel within ±0.015 inches per inch of width. This precision allows for the optimal performance of welding, cutting, or other fabrication procedures. These tight tolerances speak volumes about the methodical nature of A500 Grade B manufacturing that sets it at a high standard required by present-day engineering and architectural projects.

Applications of ASTM A500 Grade B Steel

Structural and architectural applications arise from its strength, durability, and versatility. Some applications entail structural supports for buildings, bridges, and infrastructure. Columns, beams, and trusses are put together using this steel as it takes extremely high loads. It is also fabricated for the frames of storage racks, transportation-assisted equipment, and machining-supported equipment. Welding and machining processes are very easy for this material and therefore it is regarded highly for general fabrication.

Common Uses of A500 Grade B Pipes

Common uses of A500 Grade B pipes include structural supports, beams, columns, railings, fencing, and communication towers.

|

Use Case |

Details |

|---|---|

|

Supports |

Structural supports |

|

Beams |

Load-bearing beams |

|

Columns |

Vertical columns |

|

Railings |

Safety railings |

|

Fencing |

Durable fencing |

|

Towers |

Communication towers |

Structural Tubing Applications

A500 Grade B pipes have gained importance in structural tubing applications, considering their strength, durability, and flexibilities, across a large array of industries. These are square, round, and rectangular tubular shapes utilized mostly in the construction of frames, where they provide support for walls, roofs, and foundations. Another application is for bridges, with the pipes being light and strong to enhance load distribution and durability.

As per latest research and latest industry inputs, structural tubing has been increasingly used for construction. For instance, the global structural steel market is set to scale up approximately 5% CAGR between 2023 and 2030, highlighting the ever-growing dependence on tubing solutions such as A500 Grade B for infrastructures of great importance.

Furthermore, their resistance against torsional stresses and adaptability toward configurations within tight spaces make them suited for use in machinery enclosures, conveyor belt systems, and agricultural equipment. For all modern engineering requirements, precision in fabrication is necessary for fair compromises made concerning dimensions and performance. These attributes give it the edge as a versatile and most vital component in present engineering and industrial projects.

Advantages in Construction Projects

The integration of advanced materials and components has been revolutionizing modern construction practice. Among the major advantages is the adaptability of construction materials, such as modular steel panels that shorten project times and reduce labor costs. For instance, some studies suggest up to 50% reduction in construction time when using prefabricated materials, thus enabling quicker project completion without compromising the work quality. Further, lightweight and sufficiently durable materials aid in load management and structural integrity, making them ideal choices for high-rises and bridges.

Another critical advantage is in sustainability. New construction components are often designed from an energy-saving point of view, using recyclable materials and minimizing wastes. For example, certain types of steel are made with a large percentage of recycled content, which helps reduce carbon emissions from the overall construction activities. According to recent industry reports, innovations and developments made in the area of recyclable materials have contributed to reducing waste generation by more than 30% in large-scale projects.

These improvements also speak of enhanced safety and conformance to stringent industry regulations and standards. Fire-resistant, earthquake-resistant, and weather-resistant materials are some key selling points these days that lead to the creation of an infrastructure that will stand the test of time. It demonstrates how, in terms of construction materials, modern approach contributes toward efficiency, sustainability, and reliability in today’s construction projects.

Comparison: A500 Grade B vs. Grade C

A500 Grade B and Grade C differ in tensile strength, yield strength, carbon content, and cost, with Grade C offering higher strength and tighter tolerances.

|

Aspect |

Grade B |

Grade C |

|---|---|---|

|

Tensile |

58,000 psi |

62,000 psi |

|

Yield |

46,000 psi |

50,000 psi |

|

Carbon |

Higher |

Lower |

|

Cost |

Lower |

Higher |

|

Tolerance |

Tight |

Tighter |

Key Differences Between A500 Grade B and Grade C

A500 steel is widely used in structural applications, with notable differences between Grade B and Grade C primarily focused on their mechanical properties and performance under various conditions. Below is a detailed breakdown:

- Yield Strength

One of the primary distinctions lies in the yield strength of the two grades. A500 Grade B has a minimum yield strength requirement of 46,000 psi, while Grade C offers a higher yield strength of at least 50,000 psi. This makes Grade C more suitable for applications requiring increased load-bearing capacity and resistance to deformation under stress.

- Tensile Strength

Tensile strength, another critical factor, refers to the maximum load a material can bear before fracturing. A500 Grade B requires a minimum tensile strength of 58,000 psi, whereas Grade C must meet or exceed 62,000 psi, indicating its superior strength and durability.

- Applications and Usage

Due to the higher strength-to-weight ratio of Grade C, it is often preferred in high-stress environments such as bridges, structural supports, and columns in tall buildings. Meanwhile, Grade B is commonly used in applications where moderate strength is sufficient and cost considerations are a factor.

- Chemical Composition

Though both grades share a similar base composition, Grade C typically undergoes more stringent manufacturing processes, ensuring enhanced performance characteristics. This includes greater consistency in its microstructure, contributing to its superior mechanical properties.

- Weldability and Ductility

Both grades offer excellent weldability; however, Grade C’s increased strength does not significantly compromise its ductility, allowing it to maintain adequate flexibility during fabrication and under stress.

- Cost Implications

Due to its enhanced properties, Grade C generally costs more than Grade B. Structural engineers typically weigh these costs alongside the performance benefits to determine the optimal material for a given project.

These distinctions highlight how A500 Grade C is designed for more demanding structural applications, while Grade B remains a reliable and cost-effective option for general-purpose use. Understanding these differences is essential for selecting the right material to meet specific project requirements.

Performance Metrics and Strengths

When we assess the performance parameters and strengths of the different grades of A500 Steel, few factors come into play: tensile strength, yield strength, and elongation properties. A500 Grade C has a guaranteed minimum yield strength of 50,000 psi, and Grade B has only a minimum of 42,000 psi. Hence, Grade C is obviously preferable in high-stress applications where structural integrity is essential. At the same time, the tensile strength is also higher in Grade C than in Grade B, measuring at 62,000 psi against 58,000 psi, respectively, thus making it the stronger material.

Another factor that stands to be considered is the elongation at break. A500 Grade C shows slightly lower elongation percentages than Grade B, with typical values of around 21% versus 23%. The trade-off here is reflected in the strength-to-ductility ratio. Moreover, Grade C gives a better resistance to environmental stresses of a buckling or warping nature when overloaded, making it ideal for critical infrastructure projects like high-rise buildings, bridges, and industrial frameworks.

Again, it is worth remembering that A500 Grade B remains an excellent option for projects that do not require such advanced load-bearing capabilities. It is comparatively cheaper and satisfies the performance requirements for general-purpose projects. What really matters in deciding between these two grades is the specific requirement of the project and the cost constraints with which the decision for strength and performance can be balanced.

Choosing the Right Grade for Your Project

When picking a grade suitable for my project, I try to evaluate the particular requirements, such as strength, durability, and budget. If the project requires high structural performance and resistance, I take A500 Grade C into consideration as it can resist high loads. For large applications where cost considerations become important, I prefer A500 Grade B since it has proved reliable and effective all through. In the end, the criteria on which I base my decision lie between meeting the practical constraints of the project and achieving the best result.

Benefits of Using ASTM A500 Steel

1. High Strength-to-Weight Ratio

ASTM A500 steel has exceptional structural strength, but it is lightweight; thus, it is highly efficient for a variety of applications.

2. Economical

Cheap to make, it enhances the value, making it highly cost-friendly to a number of construction and engineering applications.

3. Versatility

Being available in different grades and shapes (square, rectangular, round), an ASTM A500 steel may be easily conformed to meet design details.

4. Protection from Damage

Quality steel ensures long-term performance against wear and tear, ensuring livelihood for the lives it supports.

5. Easy to Fabricate

ASTM A500 steel is easy to cut, weld, or form and further facilitates the fabrication process itself by reducing construction time.

By balancing strength, fidelity, and flexibility, ASTM A500 steel stands as a universal option for many structural uses.

Durability and Strength of ASTM A500 Grade B

ASTM A500 Grade B stands out for its durability and strength, thus affording it the ability to be used in structural applications. This steel grades to at least 46,000 psi in yield strength and at least 62,000 psi in tensile strength, conferring upon it the ability to sustain heavy stresses and loads. It is an ideal material for highly demanding construction projects due to its high deformation resistance under heavy use and weather changes.

ASTM A500 Grade B also holds huge corrosion resistance properties, especially when used with some sort of protective coating, which will only enhance its longevity under harsh weather. Its uniformity and consistent structural integrity allow it to be used advantageously in the fabrication of structural loads, framework, columns, and other significant facets of any infrastructure. Put together, ASTM A500 Grade B stands out as the best construction material for modern-day projects when it comes to performance and reliability.

Cost-Effectiveness in Structural Steel Applications

For the highest level of cost efficiency, both in terms of material purchase and maintenance over time, structural steel such as ASTM A500 Grade B is used. Steel is stronger than any other building material for its weight, so lighter weight constructions can be designed, and thus it helps in reducing the materials used without posing a risk in terms of strength. Studies indicate that steel is usually between 30 and 50 percent cheaper than concrete for comparable load-bearing capacity, particularly when labor and construction time are taken into account.

Additionally, an additional feature of sustainability is the recycling of structural steel, with 93% of steel used for construction being recovered and recycled globally. This contributes to their cost savings, since the use of recycled steel substantially reduces the costs of raw materials and energy in production. This is the efficiency until it gets into the prefabrication aspects. Pre-cut and pre-engineered steel components mean less labor and less construction time at the site by definition, resulting in enormous savings upfront to a project developer.

Combined with versatility, recyclability, and an integrated supply chain, structural steel continues to take the lead as far as initial construction costs and long-term economic value are concerned. Due to modern steel manufacturing and coating technologies, the position of steel as an economical choice for a wide range of applications bridges to tall buildings-has been dramatically enforced.

Environmental Considerations and Sustainability

Structural steel is the chief material in sustainable construction due to its recyclability and sustainable life cycle. Incredibly, steel remains one of the most recycled materials worldwide, with approximately 90% of the steel being recycled. Steel production follows the principles of a circular economy where scrap steel is melted and reprocessed into various products without loss in quality or performance, which in turn reduces the use of virgin raw materials and conserves natural resources.

The other aspect is that modern steel production is energy-efficient. For instance, improvements in electric arc furnace (EAF) technology have led to energy use and greenhouse emissions significantly below that of conventional methods such as blast furnaces. Industry figures reveal that EAF-based production is capable of containing more than 85% recycled content, thus demonstrating its green potential.

The sources of steel are also earth energies. Supple and lasting, they act for the sustenance of durable steel structures that require little maintenance and hence fewer replacements. Once the steel components of a structure acquire their end life, their reuse is outrightly encouraged, which in turn is big in minimizing landfill dumping. The benefits speak for themselves, making structural steel an important material in green building certification such as LEED that promotes energy efficiency, waste reduction, and carbon neutrality.

When combined with its long-term performance, recyclability, and relatively low carbon footprint, structural steel is one of the most promising contenders in the sustainable construction sphere that supports industries in their collective pursuit of worldwide environmental goals.

Reference Sources

- Title: KAJIAN KEKUATAN RANGKA MESIN PENGGILING PADI DENGAN MATERIAL ASTM A500 MELALUI SIMULASI FEM

Authors: D. Tsamroh et al.

Publication Date: 2025-06-03

Citation Token: (Tsamroh et al., 2025)

Summary:

This study evaluates the performance of a rice milling machine frame made from ASTM A500 Grade B material using Finite Element Analysis (FEA). The research involved collecting technical data, modeling geometry using CAD software, and applying static and dynamic loads to assess the structural integrity. Key findings indicate that the frame exhibits sufficient stiffness and structural resistance to operational loads, with a safety factor significantly above the minimum required standards. - Title: Investigations on mechanical and metallurgical properties of ASTM A106 grade B pipes by automated MIG welding process

Authors: R. Sudhakar

Publication Date: 2018

Citation Token: (Sudhakar, 2018)

Summary:

This paper investigates the mechanical and metallurgical properties of ASTM A106 Grade B pipes, which are often compared with ASTM A500 materials in terms of welding and structural applications. The study focuses on the effects of the automated MIG welding process on the properties of the pipes. Key findings include the impact of welding parameters on tensile strength and ductility, highlighting the importance of optimal welding conditions to maintain material integrity.

Frequently Asked Questions (FAQs)

What are the mechanical properties of ASTM A500 Grade B pipe?

ASTM A500 Grade B pipe exhibits high strength and good weldability, with a minimum yield strength of 46,000 psi and a minimum tensile strength of 58,000 psi. These properties make it suitable for structural applications.

What is the difference between ASTM A500 Grade B and Grade C?

The primary difference between ASTM A500 Grade B and Grade C lies in their yield strength. Grade C has a higher minimum yield strength of 50,000 psi compared to Grade B’s 46,000 psi, making Grade C more suitable for applications requiring greater strength.

What are the dimensional tolerances for A500 carbon steel?

Dimensional tolerances for A500 carbon steel are specified in the ASTM A500 standard. These tolerances ensure that the steel pipe and tubing meet industry standards for size and shape, which is crucial for structural integrity.

What are the applications of ASTM A500 Grade B steel structural tubing?

ASTM A500 Grade B steel structural tubing is widely used in construction, manufacturing, and structural applications. It is commonly found in buildings, bridges, and other infrastructure due to its strength and durability.

How does the chemical composition of A500 Grade B affect its properties?

The chemical requirements of ASTM A500 Grade B include specific percentages of carbon, manganese, phosphorus, and sulfur, which contribute to its mechanical properties and overall performance in structural applications.

What are the benefits of using steel structural tubing?

Steel structural tubing, particularly ASTM A500 Grade B, offers various benefits including high strength-to-weight ratio, ease of fabrication, and versatility in design, making it ideal for a wide range of structural applications.

What is the significance of the ultimate tensile strength of A500?

The ultimate tensile strength of A500 indicates the maximum stress that the material can withstand before failure. This property is critical for ensuring that structures made from A500 steel maintain their integrity under load.

How do the tolerances for square and rectangular A500 tubing compare?

Tolerances for square and rectangular A500 tubing are specified to ensure consistency in dimensions. These tolerances help maintain the structural integrity and performance of the tubing in various applications.

What is the role of seamless steel in ASTM A500 applications?

Seamless steel is often used in ASTM A500 applications for its strength and reliability. It is favored in high-pressure applications where welded seams could be potential failure points.