ASTM A500 Grade B is one of the most popular specifications used in construction and structural applications due to its optimal strength, cost, and ductility. Structural Engineers and Machine Designers are typically required to perform calculations according to these active rules, using cold-formed welded seams and hollow sections made of non-alloy carbon steels. In this context, the present article will analyze the basic features of the ASTM A500 grade B, the different applications within the sectors, and the principal advantages in terms of structural design and manufacturing. Both Industry Experts with an interest in the technical details, or any of the readers who may be simply interested in knowing more about the material, the contents of this text should clarify how and why it has remained at the core of many construction and engineering-related solutions.

Understanding ASTM A500 Grade B

Cold-formed welded or seamless carbon steel structural tubing for use in engineering and construction is manufactured to ASTM A500 Grade B specification. It covers hollow structural sections of various shapes, such as round, square, and rectangular. The high strength-to-weight ratio of this grade makes projects lightweight and more economical without sacrificing safety. Tubes provided under ASTM A500 Grade B are weldable and machinable, so they are highly recommended for certain jobs, including columns, trusses, bridges, and mechanical systems. Also, the long service life and cheap price enhance its suitability for contemporary developments.

Overview of ASTM A500 Standard

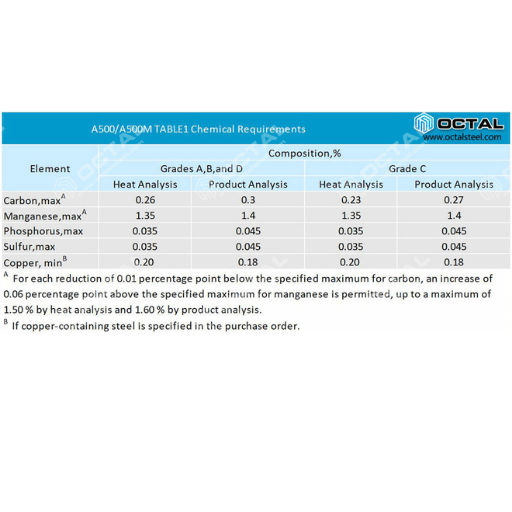

The ASTM A500 standard outlines the specifications for cold-formed, welded, and seamless carbon steel structural tubes for construction and mechanical applications. It provides information on mechanical properties such as minimum yield strength and tensile strength, including dimensional tolerances in order to guarantee uniformity and functionality. Structural tubing manufactured according to this standard is manufactured in different grades (A, B, C) and shapes, e.g., round, square, and rectangular sections. These detailed standards are aimed at facilitating the evolution of structures that are safe and trustworthy as well as efficient.

Key Specifications of A500 Grade B

- Content of the Material: Mostly composed of steel, ASTM A500 grade b seems to have a purpose and quality because it is an ideal material for structural applications.

- Elastic Limit: For astm a 500 grade b, it cannot elongate any further below 46,000 psi.

- Plastic Limit: Approximately 58000 psi is provided in the structure, which should not be broken.

- Deviation in Wall Thickness: There is a limit on the tolerance of wall thickness variation of not over +╳10% for conditions fixed such as instructing engineering.

- Geometric requirements: Nominal dimensions include those of the diameter, length and corners of the tube and mandatory ones.

Comparison with A500 Grade C

Comparing ASTM A500 Grade B and C in terms of yield strength, ability to stretch , tensile strength, cost, and availability, they are all different.

|

Parameter |

Grade B |

Grade C |

|---|---|---|

|

Yield Strength |

42,000 psi |

46,000 psi |

|

Tensile Strength |

58,000 psi |

62,000 psi |

|

Elongation (2″) |

23% |

21% |

|

Cost |

Lower |

Higher |

|

Availability |

Higher |

Lower |

Mechanical Properties of A500 Steel Pipe

Tensile and Yield Strength of A500 Grade B

For proper performance, it is necessary to consider the mechanical properties of ASTM A500 Grade B steel pipe. The following table summarizes the tensile and yield strength requirements for this grade:

- Yield Strength: 42,000 psi (290 MPa) minimum.

- Tensile Strength: 58,000 psi (400 MPa) minimum.

The above limits are examples of structural strength and indicate that the material can withstand quite a high level of stress before stretching or breaking and thus is very applicable in construction work.

Impact Resistance and Ductility

The ASTM A500 grade b steel is characterized by impressive impact strength and ductility that remains adequate for withstanding fluctuating climates and handling dynamic loadings. As a result of the high impact strength, the steel can withstand any shock forces, and more so, ductility will enable the material to be shaped without fracturing. This is applicable in structures that are put under pressure, like bridges, buildings, or any other industrial constructs that have achieved these properties. In this case, the metal’s properties, namely, high temperature resistance and flexibility, become useful to a user as there is a lower risk of structural collapse taking place.

Corrosion Resistance Factors

The ability of materials to resist corrosion is highly affected by a number of principal factors, especially in steel, and it happens that:

- Material Composition – To resist corrosion, chromium, nickel, or molybdenum are added, and this helps in the formation of protective oxides. Essentially in steel, corrosion is avoided by the presence of chromium in its composition among other features.

- Environmental Conditions – The presence of moisture, temperature, salts or chemicals in the environment will have an impact on the corrosive attack. In environments rich in water or salts the rate of corrosion will be higher.

- Surface Coating – This involves painting or coating with different kinds of paints using epoxy, galvanizing or even anodizing which make the material impervious to corrosive elements.

- Maintenance Practices – This includes cleaning the surfaces regularly and inspecting them to avoid further coverage of the material with corrosive materials over a period. The use of inhibitors also minimizes corrosion of the material for the time being.

These will be the elements that most contribute to whether the material will last long before degrading, but also if it will withstand the threats posed by a given environment.

Applications of A500 Steel

Structural Applications in Construction

- Building Frameworks – ASTM A500 Grade B in steel roll form is a good option for structural frameworks in houses, business buildings, and manufacturing buildings as it offers good strength properties.

- Piles and Bridges – The loads which are major breakages and anchor stress are held by A500 steel perfectly, hence it is the preferred material for gratings in the bridges.

- Bolts, Fascia and Underdeck Cores – Because certain structural details such as cross earning, copes and bends are often easier and less expensive to fabricate in A500 rather than in A36 structural shapes, A500 is also used for these details.

- Structures Built for Civil Engineering Purpose – It is one type of material that finds application in the construction of highways, tunnels, and other massive structures and hence she is introduced in the long span because of the propensity to support greater weight.

- Industrial Facilities – Assembly plants, storage structures, and fabrication facilities can incorporate A500 steel plates as their cores to carry heavy machine and instrumentation infrastructure.

- Reinforcements and Retrofits– Steels of A500 grade are used as structural reinforcement and illotropic alteration of structures oblong objects in order to increase their structural efficiency and for an extended service life.

Use in Manufacturing and Fabrication

ASTM A500 grade B steel is an all-purpose steel that has a lot of uses. It is very affordable, rust-proof, and it has high tensile strength for its weight. This means hollow structural sections, HSS, are the popular products of this alloy in construction projects. In other words, the uniformity of this steel and its processability are good if it’s going to be scalped, welded, and even fastened. What is more, due to its different grades, it can also effectively be utilized in any of the fabrication works without much wastage.

Advantages in Cold-Formed Applications

- Durable Yet Light: Being in the form of steel offers remarkable strength in relation to its weight, which is quite advantageous, especially where structural strength is required, yet excessive weight is not.

- Dimensional Accuracy: Tight tolerances are adhered to in the manufacturing process which yields components that are manufactured with precision and are efficient at their allocated use without excessive material wastage.

- Protection Against Corrosion: Depending on the environment, most of the materials made from cold-formed structure materials are also protected through some enhancement technology in order to fight corrosion.

- Flexible Usage: Each of the materials can be shaped into various profiles to fit different types of architectural and structural needs.

- Cost-Effective: Thanks to rational use of resources and modern technology, reduced construction costs are one of the advantages and that is what attracts most of the builders.

Benefits of Using ASTM A500 Grade B

Cost-Effectiveness in Projects

The reason why ASTM A500 Grade B is very affordable is that it is efficiently manufactured, and the process involves cutting back on wastage while ensuring high quality. The use of strong structural materials also ensures that there is no need to change the structure often because of wear and tear, and this reduces the maintenance cost over time. Furthermore, it is a highly flexible material with simple designs that do not cost a lot of money when it comes to construction labor. All these features make it possible for it to be put into practice without straining financially in many situations.

Performance Benefits over Other Steel Grades

- Brought about a Better Specific Strength: The specified steel is characterized by an amazing strength despite being lightweight, which comes in handy when there is performance delivery at a high level with as minimal weight in materials logistics.

- More Enhanced Resistance to Corrosion: New age paints, as well as alloying, help achieve higher corrosion and environmental resistance, thus becoming quite convenient in trying situations.

- Growth in Tensile Strength: The tensile strength of this material is higher than that of other steel grades found in the market hence helping it survive higher loads without deforming or breaking.

- Better Responsiveness to Welding Techniques: Perfect metallurgical properties have greatly improved the weldability of this steel, such that there is very little or no pre-weld preparation, and the post-welds become strong and neat.

- Resistance to Thermal effects: This material has good resistance to temperature fluctuation, which ensures exhaustion in extremes of temperature.

- Longer Service Life: Thanks to the reliability of this steel and its resistance to wear and tear, the steel is covered under service for longer periods of time, thus reducing the replacements as well as the costs of replacements.

- Economic Energy Utilization Processing: The processing process developed for its manufacturing reduces energy use, which benefits the environment and helps lower production expenses.

All these factors combined make this steel grade, ASTM A500 Grade B, suitable for a number of uses in different industries, including engineering.

Durability and Longevity in Various Environments

- Substance Corrosiveness: This type of metal has a number of great features, the most significant being the fact that it is highly resistant to corrosion, allowing it to be used in marine environments, among others. Substances like aggressive chemicals, and also water, can enter any porous structure.

- High Working Temperatures: Due to the highly heat-resistant material, it works very well in high temperature environments, including power stations and a number of aerospace usages.

- Low Operating Temperatures: Structural steel also presents excellent mechanical properties at very low temperatures, factors that are enhanced by this property, enabling its use in cryogenic and arctic–class equipment.

- Rough Environment: This is very strong and does not wear easily, therefore it is a great material in industries that encounters a lot of wear, abrasiveness like mining, construction and handling of different materials.

- High Pressure Applications: Being a strong material in terms of tensile strength enables the use of ASTM A500 Grade B in very high-pressure pipelines, hydraulic applications, and also high-pressure vessels.

Comparative Analysis of A500 Steel Grades

Differences Between A500 Grade B and Other Grades

A500 Grade B, on the other hand, is distinct from the rest of the grades insofar as it concerns the yield strength, the tensile strength, the elongation, the percentage of carbon, the economical issue, and the application of use in a moderate-strain range without too-compromising the aura of power.

| Parameter | Grade A | Grade B | Grade C | Grade D |

|---|---|---|---|---|

|

Yield (psi) |

33,000 |

42,000 |

46,000 |

36,000 |

|

Tensile (psi) |

45,000 |

58,000 |

62,000 |

58,000 |

|

Elongation (%) |

25 |

23 |

21 |

23 |

|

Carbon (%) |

≤0.26 |

≤0.26 |

≤0.23 |

≤0.26 |

|

Cost |

Low |

Moderate |

Higher |

Highest |

|

Applications |

Light-duty |

Moderate |

Heavy-duty |

Critical |

Industry-Specific Preferences for A500 Grade B

Most of the engineers utilize ASTM A500 Grade B steel in the construction and structural engineering fields as it is simple to weld, uniform, and relatively cheap. Uses include building load bearing structures like bridges, buildings and foundations which require stable structural performance- to – strength ratio. Moreover, it is lightweight and corrosion resistant, hence incorporates aluminum structures such as industrial frameworks, transport systems, and agricultural structures made out of structural tubes. High strength and flexibility provide durability in use without increasing the cost of the system.

Limitations and Considerations

While there are many positive aspects to the material, there are also a few downside aspects that have to be taken into account. To begin with, the material can be susceptible to rust if it does not undergo adequate maintenance, especially in humid conditions or wherever industrial chemicals have been used. Also, the production processes are all about using a lot of energy, which can otherwise negate the aim of sustainability. The cost-benefit analysis can differ to the extent that changes in the cost of raw materials may bring about ‘subsidizing’ aspects. For these qualities to be made available for application, they have to be given a critical appraisal.

Frequently Asked Questions (FAQs)

Q: What is the ASTM A500 Grade B standard, and what is the composition of Grade B?

A: The steel referred to as ASTM A500 Grade B is cold-formed, welded, and seamless carbon steel structural tubing. This cold-formed steel has a certain chemical composition containing carbon, manganese, phosphorus, sulfur, and silicon to ensure that it fulfills the required mechanical properties for structural purposes.

Q: How is ASTM A500 steel used as a thick-walled, high-capacity structural section?

A: Building frames, communication masts, bridge elements, etc., are often made of ASTM A500 steel, which has been mentioned already for its favourable mechanical properties and load tolerance. Therefore, structural integrity is present under all sections employed, whether thin or heavy.

Q: Why is the diameter and wall thickness of the steel tube important to know?

A: The outside diameter and the wall thickness of the steel tubing define its structural integrity and performance accordingly in terms of the loads it has to bear. Appropriately sized tubes blend engineering and structural properties that are considered for any purpose.

Q: What are the advantages of cold forming of ASTM A500 steel?

A: The use of cold-formed ASTM A500 steels has many benefits, such as strength, weldability, and the ability to fabricate in a range of sizes and thicknesses, making it the ideal steel for applications where structural integrity is a must.

Q: Is there any explanation of the role of the steel tubing seam of ASTM A500 Grade B?

A: The seam of the weld plays an important role in ensuring the structural integrity of the ASTM A500 Grade B steel tubing. Well-done welds increase the rigidity and the carrying of the tube’s load, which is just what is needed during bolted assembly or in places of considerable weight.

Q: What is the specification of ASTM A500 concerning the use of steel pipe in construction?

A: The ASTM A500 Standard covers the tube-shaped design, the chemical as well as mechanical, and the specified wall and outside dimensions for the attributed steel pipes. These stipulations aim at the efficiency of the staff in its application.

Q: How does one assess the strength of ASTM A500 Grade B as compared to other grades?

A: The strength of ASTM A500 Grade B is found to be higher than that of the lower types in general. The standards of its performance are such that they can meet the most demanding structural uses, and in this regard, the grade is well suited for its project activities.

Q: What dimensions are obtainable for ASTM A500 steel tubes?

A: ASTM A500 tubes are produced in different lengths and wall thicknesses to suit a broad range of structural conditions. Because of this, it is feasible for the engineers to choose suitable tubing for the precise conditions of use in which it will be applied.

Q: Which construction sectors employ ASTM A500 Grade B most commonly?

A: The Grade B ASTM A500 is mostly used in the construction of the internal and commercial buildings and other infrastructure works. This form of concrete structures is widely used and also helps when constructing bolted assemblies and handling heavy loads.

Reference Sources

1. Metal Inert Gas (MIG) Welding of ASTM A500 Grade B Steel Pipes: Thermographic Imaging and Examination (Higgins, 2005)

- Significant Results:

- The paper gives insight into how the welding of ASTM A500 Grade B steel pipes using the Metal Inert Gas (MIG) technique is analyzed using thermal imaging.

- Approach:

- For this research, infrared thermography was adopted to monitor the temperature pattern and profile while carrying out MIG welding on ASTM A500 grade B steel pipe.

2. ARE YOU PROPERLY SPECIFYING MATERIALS? – A paper elaborates on the specification of different materials, such as ASTM A500 grade B.

3. ASTM A36, Fy = 36 ksi, Fu = 58 ksi C- and MC-Shapes – Prepared by the University of Maryland, that specifies design values and other portions, including ASTM A500 grade B.

4. STRUCTURAL STEEL – Objectives relevant to construction provided by Pacific Lutheran University, which even mentions ASTM A500 grade B.

5. ASTM A500

6. Steel

7. Carbon steel