Carbon steel pipes are the life artery of various industrial sectors, being valued for their strength, durability, and adaptability. Among these, seamless carbon steel pipes occupy a place of pride by virtue of their special manufacturing process where welding or joints are not necessary, thereby giving superior structural strength. But what are seamless carbon steel pipes, really? And why are they preferentially used in applications from energy infrastructure to automotive manufacturing? The article goes into a detailed analysis of the characteristics, benefits, and applications of seamless carbon steel pipes, giving you an all-around appreciation of their very important role in modern industries. Whether you are a professional in the industry or are simply casual about the engineering of essential materials, you will have the required insight from this guide.

What is CS Pipe?

CS pipe is a kind of pipe made mainly from carbon and iron. It is a durable, strong pipe, and a pipe that resists high pressures and, thus, finds wide usage in the industries of basic construction, energy, and transportation. These pipes would traditionally be set in environments where they need to endure harsh conditions such as super high temperature or corrosive environment, hence an assurance for critical application. Carbon steel pipes are quite versatile and come in many sizes and grades to match other project requirements.

Definition of Carbon Steel Pipe

Carbon steel pipes are hollow-cylindrical structures mainly made of carbon and iron, having various functions for industrial and commercial purposes. “Carbon steel” is a generic term used for an alloy that derives strength and durability from the controlled addition of carbon between 0.04% and 2.0%, depending on the specification required. This alloy thus strikes a balance between hardness, ductility, and tensile strength, all of which are sorely needed on many occasions.

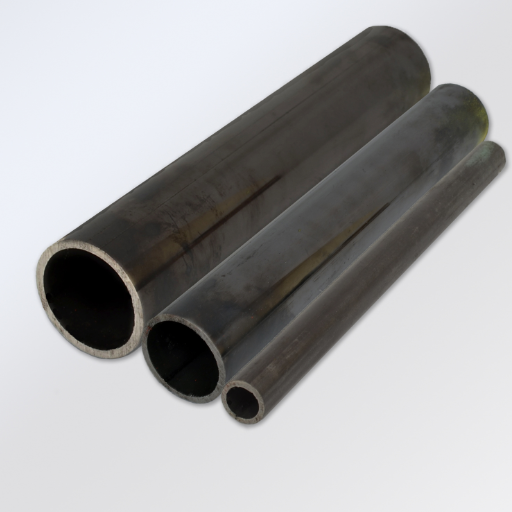

From a current industry perspective, carbon steel pipes are classified differently with regard to their manufacturing processes, namely, seamless, welded, and ERW pipes. Seamless pipes are used in applications where high pressure is involved. Less resistant welded joints would otherwise be weak points. Welded pipes are economical and can be used in applications where low pressures are involved.

According to industries, depending on their grades, carbon steels can withstand pressures up to 10 MPa and may work at temperatures above 400°F. Against shock and vibration, these carbon steel pipes offer better resistance, which attributes to their stability in dynamic systems like oil gas pipelines, transmission of steam, and transport systems. Material investigators brought forward examples where the tensile strength of carbon steel pipes varies from 400 MPa to 550 MPa, appearing competitive to many other materials at the same time being economically attractive.

Another important fact is the sustainability of carbon steel pipes – they are recyclable! Then come the varieties from grades ASTM A106 to A53, which allows for particular requirements for mechanical properties, corrosion resistance, and bearing capacity to be met; thus, these pipes can be customized for areas of construction, shipbuilding, and chemical processing, among others. This has made them important tools used across industries worldwide.

Composition and Carbon Content

Carbon steel pipes derive their strength and versatility from their distinct composition, which primarily consists of iron and carbon, along with trace amounts of other elements like manganese, silicon, and sulfur. The carbon content plays a pivotal role in determining the properties of these pipes, with classifications generally divided into low, medium, and high-carbon steel.

- Low-carbon steel (often referred to as mild steel) contains approximately 0.05% to 0.25% carbon by weight, offering excellent ductility and weldability, making it ideal for bending and fabrication applications.

- Medium-carbon steel typically contains 0.25% to 0.60% carbon, providing a balanced combination of strength and toughness suitable for shafts, axles, and structural components.

- High-carbon steel features carbon content ranging from 0.60% to 1.5%, delivering superior hardness, wear resistance, and tensile strength, which is essential for tools and cutting materials.

Furthermore, advanced manufacturing techniques now allow for precise control of these compositions, leading to specialized grades tailored for specific needs. For example, certain grades may include added chromium or nickel to enhance rust resistance or withstand extreme temperature conditions. Such meticulous attention to the carbon content and overall composition ensures that carbon steel pipes meet modern industry standards, offering unparalleled performance across a spectrum of challenging environments.

Types of Carbon Steel Pipes

Types of carbon steel pipes include seamless, welded, ERW, LSAW, and fabricated pipes, each designed for specific applications and conditions.

|

Parameter |

Type |

Key Features |

|---|---|---|

|

Seamless |

No welds |

High strength, stress-resistant |

|

Welded |

Welded joints |

Cost-effective, versatile |

|

ERW |

Electric resistance |

Lightweight, corrosion-resistant |

|

LSAW |

Longitudinal welds |

Seamless finish, rustproof |

|

Fabricated |

Custom-made |

High durability, tensile strength |

Manufacturing Process of Seamless Carbon Steel Pipe

Seamless carbon steel pipe manufacturing entails several meticulous operations to ensure high quality and accurate specifications.

- Preparation of Raw Material: A steel billet is selected with due consideration of quality check and grading according to requirements.

- Heating: The billet is heated in a rotary hearth furnace, up to a malleable temperature, for the eventual shaping process.

- Perforation: The billet, after heating, is pierced by a mandrel or a rotary piercing tool that provides it with a hollow center and basic pipe form.

- Elongation: The hollow shell is elongated and rolled to the required thickness and dimensions.

- Sizing and Shaping: Additional processing stages are employed to size the pipe and improve its diameter, wall thickness, and surface finish to tight specifications.

- Cooling and Inspection: The pipe is cooled off and subjected to rigorous quality control inspection methods before being released, so as to detect any possible flaws or irregularities.

Thus, in this way, a high-quality seamless carbon steel pipe offers undwind defects or oil joint, hence rendering the product durable, sturdy, and efficient for the heavy duty operations.

How Seamless Pipes are Made

Seamless pipes are designed to offer utmost strength, reliability, and performance in different areas of application. The seamless configuration allows the pipes to be free from the weak joints of seams and welds present in other pipes. Consequently, the absence of seams makes these pipes resist further cracking or failure under very high pressures, temperatures, and other rigorous conditions.

The worldwide market for seamless pipes has been growing at a fast pace and shall exceed $97 billion by 2031 due to their great use in the oil and gas industries, chemical, automotive, and power generation. In oil and gas, for example, they are used in seamless pipes for transporting fluids and gases under extreme conditions to maintain the integrity and ensure the safety of the structure. Their smooth inner surfaces reduce friction, thereby saving operating costs.

With changes in manufacturing technologies, seamless pipes have been developed so as to be produced with increased precision and consistency, thereby suitable for the exact specifications required by special applications. These facilitates have made seamless pipes an important constituent of modern industrial infrastructure.

Comparison with Welded Pipes

Seamless pipes offer higher strength, pressure capacity, and corrosion resistance, while welded pipes are more cost-effective, versatile, and suitable for larger sizes.

|

Parameter |

Seamless Pipes |

Welded Pipes |

|---|---|---|

|

Strength |

Higher |

Moderate |

|

Pressure |

High capacity |

Lower capacity |

|

Corrosion |

Resistant |

Seam prone to corrosion |

|

Cost |

Expensive |

Cost-effective |

|

Size Range |

Limited |

Wide, including large |

|

Applications |

High-pressure, critical |

General, construction |

Quality Control in Manufacturing

Quality control in the manufacturing of seamless pipes represents one of the key processes that ensure products meet the industry standards and satisfy customer requirements. Thorough inspection and testing are performed during the process at various stages to ensure the highest performance and reliability levels. Key methods include non-destructive testing, dimensional inspection, and analysis of chemical composition.

Non-destructive testing methods possibly detect any internal or surface defects without causing damage to the pipe. These are primarily important for energy, automotive, and aerospace applications, where safety cannot be compromised. Dimensional inspections test if the pipe conforms to the requirement of precise measurements, i.e., the diameter, wall thickness, length, as per international standards like ASTM and ISO. For example, pipes must be maintained within tolerance limits of ±0.5 mm for critical applications.

Analysis of chemical composition ensures that the material conforms to the specified grades such as carbon steel or alloy steel, which enhances the mechanical properties of strength and corrosion resistance. Data show that pipes that possess consistent chemical composition reduce possible occurrences of failures by even 30% by thereby augmenting their service life in arduous environments.

Post-manufacturing checks usually include hydrostatic-testing procedures, wherein the pipes are filled with water under pressure to detect leaks if any exist. With such rigorous quality control, seamless pipes offer superior reliability and hence find their place in heavy-duty industrial applications of the modern era.

Applications of Seamless Carbon Steel Pipe

The seamless carbon steel pipes find widespread application in various industries because of their strength, reliability, and resistance to very high pressure and temperature. The key areas of application include:

- Oil and Gas Industry: To transport crude oil, gas, and refined products, thanks to its durability and leak-proof features.

- Power Generation: Employed in boilers, heat exchangers, and other high-pressure apparatuses.

- Construction: Perfect in structural applications requiring construction frameworks and support systems to assure stability and safety.

- Automotive: Utilized in producing vehicle parts, including exhaust systems and suspension components.

- Chemical and Petrochemical Industry: Conveying corrosive fluids under extreme conditions.

Use in Structural Steel Applications

Structural steel pipes have always been at the core of the modern construction projects due to the undisputed strength, durability, and versatility they offer. These pipes find applications in social infrastructure and construction work, including high-rise buildings, bridges, industrial frameworks, and residential structures. One most relevant aspects of these pipes is that they take in extremely huge loads while being fairly light, thus making an important consideration concerning stable yet efficient designs in construction.

There have been further modifications to manufacturing technology to improve the performance characteristics of structural steel pipes. New developments in high-strength alloys and fabrication processes for structural steel pipes allow structural steel pipes to bear higher loads, resist corrosion better, and resist a wider range of environmental conditions. For example, exposure to international data shows that high-strength structural steel can carry over 50% more load than conventional materials, thereby providing higher safety margins and a longer life to the structures.

The other trend that is gaining momentum is the use of hollow structural sections (HSS) by architects and engineers for design efficiency and cost-effectiveness. In fact, they now stand as worthy peers to cast-in-place concrete for well over thirty years, optimizing material use and offering aesthetic values. With the beginning of modular construction and an increasing precedence on sustainability, structural steel applications are leading the way for two greener and novel building options around the world.

Industrial Applications of CS Pipe

Carbon steel pipes find applications in various industries across the industrial sectors owing to their strength, durability, and cost-effectiveness. Their versatility enables them to be used in numerous industries, including oil and gas, chemical, energy production, and construction. To cite an example, crude oil, natural gas, and refined products require the very mechanisms of CS pipes subjected to high pressures and extreme temperatures over long distances.

CS pipes are also used in the chemical industry for the transfer of corrosive and non-corrosive substances, aided by the fact that they can be lined or coated with surface treatments. Other energy production facilities such as thermal and nuclear power plants use CS pipes in high-pressure steam and water systems thanks to their heat resistance. On the other hand, in the construction industry, CS pipes are used structurally in supports and foundations and for plumbing and HVAC systems.

The global market for CS pipes is forecast to undergo a substantial growth, which is further augmented by the developments in manufacturing technologies that allow customized pipe designs to cater to specific industrial applications. For example, high-grade CS pipes with enhanced corrosion resistance and service life are now promoted to meet stringent operational requisites. Considering their dependability, least-cost production, and sustainability features such as recyclable material, carbon steel pipes are indispensable across different industrial applications.

Common Pipe Products and Fittings

When it comes to pipe systems, selecting the right products and fittings is crucial for ensuring efficiency, durability, and safety in various applications. Below is an overview of common pipe products and fittings along with their typical uses:

- Seamless Pipes

Seamless pipes are highly sought after for their strength and ability to handle high-pressure applications. Manufactured without a weld seam, these pipes are ideal for industries such as oil and gas, chemical processing, and power generation. They also come in a range of materials, including carbon steel, stainless steel, and alloy steel, catering to specific industry standards.

- Welded Pipes

Welded pipes, created by welding sheets or plates of steel, are preferred for their cost-effectiveness in medium- to low-pressure applications. They are widely used in water treatment systems, structural applications, and fluid transportation pipelines. Modern welding techniques ensure stronger joints, making them a reliable option in less demanding environments.

- Flanges

Flanges are critical pipe fittings that allow for easy assembly and disassembly of piping systems. Available in various types—such as slip-on, weld-neck, socket-weld, and blind flanges—they play a significant role in maintenance and repairs. Their use is especially prevalent in industrial facilities where routine inspection is needed.

- Elbows

Pipe elbows are used to change the direction of flow between two pipes, typically available in 45-degree and 90-degree options. They enable smooth transitions in complex piping networks, ensuring minimal pressure drop and efficient flow management. Elbows are commonly utilized in plumbing, heating, and industrial piping systems.

- Tees and Crosses

Tees and crosses allow for the branching of pipes in multiple directions. Tees split flow into two separate directions, while crosses provide four outlets. These fittings are indispensable within distribution systems and networks, such as those found in water supply or natural gas distribution.

- Reducers

Reducers can either increase or decrease pipe size within a system, maintaining consistent flow between different diameters. Available as concentric or eccentric reducers, they are essential for adapting pipes to equipment with varying dimensional requirements, such as pumps and valves.

- Couplings

Couplings are small fittings used to join two pipes together, often employed to repair damaged pipe sections or extend pipe runs. With both threaded and non-threaded varieties available, couplings add versatility to piping systems.

- Valves

Valves govern the flow of liquids or gases within a pipe system, offering control, regulation, and shut-off capabilities. Common valve types include gate valves, ball valves, and butterfly valves, each designed to meet specific operational needs. Industries like chemical manufacturing and power plants rely heavily on advanced valves for safety and efficiency.

By integrating these essential pipe products and fittings, industries can achieve optimized performance across their piping systems. Material selection, industry standards, and application-specific requirements are key factors to ensure the longevity and reliability of these critical components.

Benefits of Using Carbon Steel Pipe

Produced with steel, carbon steel offers several advantages, which make it preferred for industrial piping applications:

- Durability: Since steels are known for their strength, carbon steel pipes hold internal pressure and adverse environmental effects without deformation or rupture.

- Cost-Effectiveness: It considers a very cheap piping material, and low maintenance costs make for a good investment over time.

- Versatility: Carbon steel piping serves any application for conveying water, gases, oils, etc.

- Corrosion Resistance: When good anti-corrosive coatings are applied, it becomes corrosion-resistant in many environments.

- Eco-Friendly: Steel being highly recyclable, choosing carbon steel is one way for greener solutions in conserving other resources.

These are some features that make carbon steel piping a worthy consideration for fulfilling diverse industrial needs.

Durability and Strength

Carbon steel pipes are known for their extraordinary durability and strength and find application in industry after industry. Being strong, carbon steels can survive high-pressure environments, extreme temperatures, and heavy loads without damage to structural integrity. In the contemporary age, with advancements in material science, the mechanical properties of carbon steel have been improved further, with tensile strengths touching 70,000 psi for certain grades such as ASTM A106 Grade B.

This strength-to-weight ratio has ensured the pipes remain strong against mechanical stress with lesser chances of deformation or failure in use. Under wear-and-tear conditions, think construction or chemical processing plants, the carbon steel pipes will enjoy a longer life. Performance data and their testing provide evidence that they do perform for decades with very few interventions for replacement and repairs.

The steel is further toughened by heat treatment and modern fabrication processes that improve the grain structure of the steel. For this reason, carbon steel pipe offers an economical solution where massive and durable piping systems are required.

Cost-Effectiveness

Carbon steel pipes are well-known for providing good value due to a number of factors that make these pipes an attractive option for users. Lesser cost of initial material, the durability and the life of a pipe save great amounts of money for the user. Other materials like cast iron or PVC tend to require heavier maintenance, as studies reveal. It is suspected that properly installed carbon steel systems ought to last for about 50 years, reducing replacements costs considerably.

On the flip side, the abundance and recyclability of carbon steel stand for environmental consciousness, which simultaneously leads to cheaper upfront costs. Production efficiency has gotten a step up by newly discovered manufacturing processes, and thus faced by carbon steel pipes to remain the cheapest yet top-quality. On the other hand, their application compatibility, such as oil and gas, water distribution, and structural engineering, adds another dimension to their economic value for projects with diverse requirements. Thus, such factors render carbon steel pipes as a financially sound and strongly performing option for long-term infrastructural and industrial requirements.

Versatility in Applications

In the sense of being adaptable, carbon steel pipes render themselves indispensable in many industries. They nevertheless present high robustness requirements in oil and gas pipeline construction companies that install them for transporting crude oil, natural gas, and other petrochemical products across long distances under conditions of high pressure and challenging environment. Water distribution maintains its descriptor because of the usage of carbon steel pipes, in making sure that water is delivered from urban to rural areas with time.

In civil engineering, they are employed in greater volumes and for applications that demand loads from the fabrication of buildings, bridges, and industrial structural frameworks. According to current data from industry analyses, the global carbon steel pipes market will maintain steady growth, with considerable demand generated mainly from the construction sector in places working infrastructure developments. Their resistance to adverse temperatures and deformation makes carbon steel pipes preferred again for high-stress applications like power generation and manufacturing.

In addition, modern developments in manufacturing technology, including those that have embraced seamless pipe production methods, have allowed for improvements in quality and reliability to ensure that carbon steel pipes meet modern industrial standards. Combining modern technological enhancements with good material properties has clearly established the role of carbon steel pipes as indispensable to different industries.

Industry Trends and Future Outlook

Growth has been imminent in the carbon steel pipe industry, with increasing infrastructure developments, energy projects, and manufacturing working as the thrust. One major trend being followed is sustainability: practicing recycling of materials and implementing energy-efficient methods into production. Integration of technology, such as real-time monitoring systems for operational efficiency and consistent product output, can pay further dividends.

At the same time, the global trend towards investment in renewable projects and urbanization is expected to benefit the pipe industry. With a marked inclination towards green, this can fuel the innovation of corrosion-resistant and lightweight pipe designs. Collectively, these open up interesting prospects for innovation and expansion in a bitterly competitive fast-growing market.

Emerging Technologies in Pipe Manufacturing

Considerable transformation awaits the pipe manufacturing sector through the adoption of technology to enhance efficiency, sustainability, and performance. One major development is the integration of smart manufacturing techniques like IIoT and automation. Such innovations put an end to downtime by allowing production-line monitoring in real-time along with predictive maintenance and resource optimization, slashing costs by as much as 30%.

Another big breakthrough is in the creation of new materials, including composite and thermoplastic pipes. These alternatives have better corrosive properties, they are lighter in weight, and they are more durable, which increases their applications to oil and gas, chemical processing, and water management industries. For example, composite pipes are now considered the best replacement for metal ones given their capacity to withstand harsh environmental conditions without diminishing performance.

3D printing is still a way to redefine the pipe manufacturing landscape. With the design time minimized by rapid prototyping and customization, 3D printing works with minimum waste of material. Now manufacturing intricate geometries with pinpoint accuracy opens new avenues of tailored applications in niche markets.

Sustainability has become the driver for innovation in the sector. Green manufacturing initiatives, such as using recycled materials and energy-efficient production methods, are on the rise. A recent report revealed that companies with eco-friendly solutions saw demand jump by about 20% due to mounting pressure from consumers and governments in favor of responsible products.

In ending, newer advancements in digital twins and simulation technologies will help manufacturers model and optimize their pipe systems even before production takes place, thereby improving quality assurance, minimizing downtime, and reducing risks that result from trial-and-error.

Together, these emerging technologies show how the pipe industries have embraced innovation and attempt to solve some of the current challenges while laying down efficient, sustainable, and adaptable alternatives.

Shifts in Market Demand

Market demand for pipe manufacturing is set into great flux by several factors worldwide. One noteworthy trend is that of Green undertones. Due to multiple restrictions on carbon emissions and increasing awareness about sustainability, pipes manufactured from recycled materials or through environmentally friendly processes are in demand. On a global scale, markets for green or sustainable pipes are expected to register a CAGR of over 5% during the next five years, driven by construction and water management projects focusing on sustainability.

Also, urbanization and infrastructure development activities in emerging countries generate demand for durable yet cost-effective piping solutions. With such countries pouring immense investments into smart cities and large infrastructure projects, including China, India, and Brazil, there has been a greater push towards innovative piping systems that can meet the demands of modern construction.

In contrast, developed economies continue to reinvent their aging infrastructure, thereby encouraging suitable adoption of materials such as polyethylene (PE) and cross-linked polyethylene (PEX), known for their very long life and high corrosion resistance. The data also indicate an increased demand for specialized pipes for particular use cases like health care, oil and gas, and renewable energy, underscoring the diversification of demand.

Changes in market forces are reflective of the critical importance of being able to adapt versus rigid manufacturing approaches with companies leaning toward both sustainability and technological advancement in meeting the shifting priorities of consumer and industrial applications.

Environmental Considerations and Sustainability

My brand of environmental considerations has sustainability at its core. The use of eco-friendly materials and processes to minimize waste and lessen the environmental footprint is something I hold in the highest esteem. My practices have to evolve with the shifting goals of sustainability while upholding stringent production standards for quality and environmental integrity. The solution addresses present environmental qualms and transitions toward preparing for the sustainability pathway.

Reference Sources

- Research on the Project Management of Thermal Pipe Network Engineering Based on Cs Mode

- Authors: J. Zhan et al.

- Publication Date: October 29, 2021

- Summary:

- This study discusses the optimization of urban central heating systems through the development of thermal pipe networks using a CS mode architecture. The authors emphasize the importance of modern project management concepts in enhancing operational efficiency and resource utilization.

- Methodology: The research includes a multi-stage analysis covering project preparation, implementation, completion inspection, and evaluation, demonstrating how advanced management concepts can improve project outcomes in thermal engineering(Zhan et al., 2021).

- Comparison of CS, CGM and CS-CGM for Prediction of Pipe’s Inner Surface in FGMs

- Authors: Haolong Chen et al.

- Publication Year: 2018

- Summary:

- This paper compares different modeling techniques (CS, CGM, and CS-CGM) for predicting the inner surface of pipes made from functionally graded materials (FGMs). The study highlights the effectiveness of these methods in accurately predicting surface characteristics, which is crucial for the design and maintenance of pipes.

- Methodology: The authors employed computational simulations to analyze the performance of each modeling technique, providing insights into their applicability in engineering contexts(Chen et al., 2018).

- Thermal Stress Analysis of High Temperature Pipe Using Cell-Based Smoothed Point Interpolation Method (CS-PIM)

- Authors: Lu Huan Zhang Gui et al.

- Publication Date: November 1, 2016

- Summary:

- This research focuses on the thermal stress analysis of high-temperature pipes using a novel computational method (CS-PIM). The findings indicate that the CS-PIM method offers improved accuracy in predicting thermal stresses compared to traditional methods.

- Methodology: The study utilized numerical simulations to evaluate the thermal stress distribution in pipes, demonstrating the advantages of the CS-PIM approach in engineering applications(Zong Zhi Liu Yi jun, 2016, pp. 2113–2119).

Frequently Asked Questions (FAQs)

What is a CS pipe and its typical applications?

A CS pipe, or carbon steel pipe, is a versatile material widely used in various industries due to its incredible strength and durability. It is commonly utilized in construction, oil and gas, and water transportation applications because of its ability to withstand high pressure and corrosion.

What are the differences between seamless steel pipes and welded steel pipes?

Seamless steel pipes are manufactured without welds, providing a stronger and more reliable option for high-pressure applications. In contrast, welded steel pipes are created by joining steel plates or strips, making them more cost-effective but potentially less robust under extreme conditions.

What are the standard carbon steel pipe specifications?

Standard carbon steel pipe specifications include various industry standards such as ASTM A106 and ASTM A53. These specifications define the chemical composition, mechanical properties, and dimensions of the pipes, ensuring they meet performance requirements for specific applications.

How is a106 pipe different from other carbon steel pipes?

A106 pipe is specifically designed for high-temperature services and is made from carbon steel. It is available in seamless forms and is known for its strength and ability to be used in power generation and chemical processing applications, setting it apart from other types of carbon steel pipes.

What are the types of carbon steel pipes available?

There are various types of carbon steel pipes available, including low carbon, medium carbon, and high carbon steel pipes. Each type has different carbon content, affecting its strength and ductility, making them suitable for specific applications.

What does the carbon content in carbon steel mean?

The carbon content in carbon steel refers to the percentage of carbon present in the steel. It significantly impacts the strength and hardness of the material. Generally, higher carbon content results in increased strength, while lower carbon content provides better ductility and weldability.

Why is black carbon steel used in construction?

Black carbon steel is frequently used in construction due to its strength, affordability, and ease of availability. It is often utilized for structural applications such as beams and columns, where high strength is critical.

What are the advantages of using seamless carbon steel pipes?

Seamless carbon steel pipes offer several advantages, including higher pressure tolerance, superior strength, and reduced likelihood of leaks. They are ideal for high-stress applications, making them a preferred choice in industries such as oil and gas and chemical processing.

What is the significance of steel grades in carbon steel pipes?

Steel grades in carbon steel pipes indicate the quality and characteristics of the pipe material. Different grades denote variations in chemical composition and mechanical properties, ensuring the pipe is suitable for its intended application, whether it’s low carbon, medium carbon, or high carbon steel.