In fact, making use of seamless stainless steel pipes in industrial sectors and construction projects marks a paradigm shift with the paramount qualities of durability, multiplicity, and performance. What then renders it so special? How do these differ from normal pipe sets, and why are they important for processes ranging from oil and gas to pharmaceuticals? And in this detail-rich article, the author attempted to lay bare all the knowledge surrounding seamless stainless steel pipes. Including the manufacturing process, key advantages, myriad applications, and how to select the right type for your needs. Whether you are a seasoned expert or an initiate exploring the fields, get ready to learn why seamless stainless steel pipes are at the forefront of present-day engineering solutions.

What is Seamless Stainless Steel Pipe?

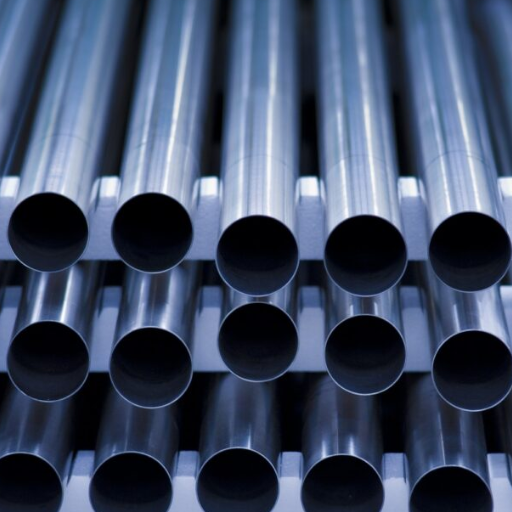

A seamless stainless steel pipe is essentially a pipe fashioned out of a single block of steel hollowed into a cylindrical shape without welding seams or joints. This type of manufacture makes it high in strength, durable, and resistant to pressure; hence, dishonest in scenarios where utmost reliability is required. Typical use scenarios include oil and gas, chemical processing, and construction treatments, whereby the pipe extends its resistance to corrosion and retains its integrity against environmental factors.

Understanding Seamless Pipe Manufacturing

Seamless pipes manufacture might be deemed a complicated yet efficient process, thus the best in quality and performance. Typically, this process starts with a solid steel billet that is heated to very high temperatures making it malleable. The heated billet is pierced with a mandrel to create the hollow shape, which is later rolled and stretched to obtain the required length, diameter, and wall thickness. Technologies such as rotary piercing and extrusion further improve the accuracy of the desired pipe specifications.

The evolution in manufacturing has since placed emphasis on sustainability and energy-efficient production. For example, energy reduction by up to 30% can be achieved in some modern plants using clean production systems and recycling of raw materials through the production cycle. The seamless pipes also go through stringent checks such as ultrasonic testing and hydrostatic pressure testing to ascertain their quality and compliance with international standards such as ASTM and ASME.

The measurements taken in these industries indicate that seamless pipes are prominent in oil and gas activities, where safety and reliability at extraordinary pressure hold extreme importance. Using higher grades of materials such as stainless steel and alloy steels for more corrosive or pressure-intensive applications has opened a pathway for innovation. By way of investing more in processes and materials, manufacturers are trying to meet the global demand for quicker and more durable piping solutions.

Characteristics of Stainless Steel Seamless Pipes

Stainless steel seamless pipes are renowned for their exceptional durability, high corrosion resistance, and versatility, making them a preferred choice in demanding industries. These pipes are manufactured without any welding or seam, which enhances their strength and ability to withstand high pressures.

- Corrosion Resistance

Stainless steel seamless pipes offer excellent resistance to corrosion from chemicals, moisture, and other environmental factors. Depending on the grade, they can endure exposure to acidic or alkaline environments, making them ideal for use in chemical processing plants and marine conditions.

- High-Temperature Strength

These pipes exhibit superior performance under extreme temperatures, maintaining their integrity and mechanical properties even in high-heat settings. For instance, grades like 316 and 321 are commonly used in applications requiring resistance to oxidation and heat.

- Enhanced Pressure Tolerance

With no weak welded joints, seamless pipes are structurally robust and capable of withstanding higher internal and external pressures. This characteristic makes them suitable for applications such as oil and gas pipelines, high-pressure boiler systems, and hydraulic systems.

- Dimensional Accuracy

Advanced manufacturing processes result in seamless pipes with precise dimensions and uniformity. This accuracy is crucial in industries where tight tolerances and exact specifications are required, such as aerospace and medical applications.

- Longevity and Cost-Effectiveness

While the initial cost of stainless steel seamless pipes can be higher, their longevity and reduced need for maintenance provide significant cost savings in the long term. They retain their performance and appearance, even after years of use.

- Versatility Across Industries

These pipes are utilized across a broad range of industries, including construction, automotive, energy, and food processing, due to their adaptability to varied operational conditions. For example, they are frequently used in hygienic environments like dairies and breweries due to their non-reactive and easy-to-clean surfaces.

- Environmental Benefits

Stainless steel seamless pipes are recyclable and environmentally sustainable. At the end of their lifecycle, they can be melted and reprocessed without any loss in quality, reducing waste and supporting eco-friendly initiatives.

Applications of Seamless Stainless Steel Pipe

Seamless stainless steel pipes are widely utilized across multiple industries due to their strength, durability, and corrosion-resistant properties. Below are some key applications:

- Oil and Gas Industry

Seamless stainless steel pipes play a critical role in the transportation of oil, gas, and other hydrocarbons. Their ability to withstand high temperatures and pressures makes them ideal for pipelines. Additionally, their corrosion resistance ensures longevity, even in harsh environments like offshore drilling sites. According to recent industry data, the demand for seamless pipes in this sector is projected to grow at a CAGR of over 5% in the next five years.

- Chemical and Petrochemical Industry

These pipes are well-suited for handling aggressive chemicals and high-risk substances without degrading. Their seamless structure ensures no weak points, reducing the likelihood of leaks or failures in processes involving high-pressure steam, acids, or alkalis. Stainless steel pipes in this industry are often crafted to comply with stringent safety regulations, boosting their reliability.

- Healthcare and Pharmaceutical Production

The healthcare and pharmaceutical sectors rely on seamless stainless steel pipes for ultra-hygienic applications, including drug production and medical equipment manufacturing. The non-porous nature of stainless steel prevents bacterial growth, and its ease of cleaning ensures sanitary conditions are maintained. Demand for high-grade stainless piping systems has surged in pharmaceutical production facilities globally, driven by advancements in precision medicine and vaccine production.

- Automotive and Aerospace Industries

Stainless steel seamless pipes are integral in the fabrication of exhaust systems, structural components, and hydraulic lines. Their lightweight strength ensures fuel efficiency while maintaining safety standards. The aerospace sector, in particular, benefits from these pipes’ ability to withstand extreme altitudes and temperatures. Market reports reveal an increasing shift toward the use of stainless steel seamless pipes in innovative electric vehicle (EV) designs.

- Water Treatment and Desalination

The desalination process, which converts seawater into potable water, heavily utilizes stainless steel pipes resistant to both corrosion from saltwater and chemical treatments. Water treatment facilities depend on these pipes for their durability and low maintenance costs, ensuring efficient operations over extended periods.

- Construction and Architecture

Seamless stainless steel pipes are used for constructing modern buildings and infrastructure, including bridges and high-rise towers. Their combination of aesthetic appeal and structural integrity makes them a popular choice for exposed architectural elements. The stainless steel market in construction is anticipated to experience steady growth, driven by a rising focus on sustainable and long-lasting materials.

By catering to these diverse applications, seamless stainless steel pipes continue to drive innovation and efficiency across industries while aligning with global goals for sustainability and high-performance standards.

How is Seamless Tubing Made?

The seamless tube is manufactured in a manner that does not entail welding or joints and produces a smooth and uniform structure. First, a solid cylindrical piece of steel known as a billet is blasted with heat and softened. In the next step, the billet is pierced by a mandrel or piercing rod to produce a hollow tube. The tube is then elongated further and shaped under rollers or by drawing to the required dimensions and finish. The lack of seams makes the tubing very strong, thereby suitable for pressure and precision applications.

From Steel Billets to Finished Product

With the advent of modified methods of seamless tube production, new avenues have opened up for improved operational efficiency and precision amounts, ultimately yielding products of superior quality. One common method is rotary piercing, where a hot billet rotates between angled rollers to develop a hollow shape with fairly uniform wall thicknesses. This technique contributes to tight control on wall thickness and dimensional accuracy, especially critical in highly demanding industries such as aerospace and energy.

Moreover, the controlled heating and controlled cooling stages, which constitute thermomechanical processing, adjust the grain structure of steel to produce an improvement in mechanical properties such as tensile strength, ductility, and fatigue resistance, thus rendering the tubes workable in extreme environments. Seamless tubes manufactured through thermomechanical processing, for example, can resist pressures well beyond 20,000 psi, required in high-pressure hydraulic applications.

Industry reports indicate the growing trend for seamless tubes in oil and gas. Global demand for seamless pipes is forecast to increase, showcasing a CAGR of nearly 5% over the next 10 years, owing to their unmatched intrinsic quality of durability and reliability. Incorporation of modern technology coupled with rigorous quality testing thus ensures producers maintain international acceptance of seamless tubes as per standards like ASTM and API.

The application of such technologies in practice thus shows the intent of the industry to manufacture parts that fulfill, and far exceed, performance criteria posed by today’s modern engineering demand.

The Role of Alloy in Seamless Tube Production

Alloys constituted in seamless tube production are necessary to provide the strength, flexibility, and corrosion resistance required in highly demanding end-use applications. Most commonly, alloy steels, basically a combination of iron and other elements such as chromium, molybdenum, and nickel, are used in manufacturing seamless tubes. The requirements are such that the alloying elements are always kept under very strict control to enhance certain properties of the tubular steel.

Chromium provides corrosion resistance enough to be used in tubes that are exposed to wet or chemical environments. Molybdenum increases strength at high temperature and pressure-highly required in the oil and gas industries where seamless tubes are most exposed to these severe conditions. Nickel increases the toughness of the metal in cryogenic conditions. Another important motive defining the alloy compositions is the end-use specifications in the construction, automotive, and energy sectors. Hence, variants of alloy compositions can be made depending on the specifications for an end-use.

A recent analysis of the market reveals the onset of increased demand for high-performance alloy seamless tubes to support modern infrastructural projects and energy systems. For example, seamless tubes with nickel-chromium-molybdenum alloy compositions are extensively used in renewable energy projects such as geothermal power plants, as they are capable of sustaining corrosive and high-temperature environments. It is reported that HSLA steels in seamless tubes have shown up to 20% enhancement in strength than their conventional low carbon steel counterparts while maintaining equal or better durability.

The evolution of alloy-related aspects ensures that seamless tubes fulfill the requirements of the present-day industries along with sustaining the future demands of sustainability and advanced engineering applications. By manipulating the alloy compositions, manufacturers bring about products that lead the path of performance and efficiency and hence have their footprints in almost every global industry.

Ensuring Specification Compliance

In industries such as energy, automotive, and construction, the first and foremost requirement for the production and application of seamless tubes is the need to meet extreme specification requirements. This compliance starts with an immense quality assurance process in manufacturing. For instance, commonly accepted non-destructive testing methods are ultrasonic testing and eddy-current testing to pinpoint any defect and authenticate structural integrity.

Material properties are thoroughly tested, with particular attention paid to determining the chemical composition through spectroscopy analysis to confirm alloy consistency. For example, seamless tubes operating under pressure in high-pressure environments are often required to comply with standards such as ASTM A213 or EN 10216-2, which govern the mechanical properties and dimensions specific to these components.

Also, dimensional tolerances approach extremely tight accuracy, with typical deviations capped at just a fraction of a millimeter, quintessential for precision applications such as hydraulics. Studies have shown that better calibration instruments and newer standards have led to an improvement of up to 15% in consistency, highlighting the engineering advances of the day. Consequently, seamless tubes remain highly reliable to face challenging operating environments while complying with client and statutory requirements.

Why Choose Seamless Steel Pipe Over Welded Pipe?

Seamless steel pipes offer superior strength and durability compared to welded pipes, as they lack weld seams that can be potential weak points. Their uniform structure ensures better resistance to pressure, making them ideal for high-pressure applications. Additionally, seamless pipes provide enhanced corrosion resistance and consistent performance in extreme temperatures and harsh environments. Their precision and reliability make them a preferred choice for critical applications in industries such as energy, automotive, and construction.

Differences Between Welded and Seamless Pipes

Seamless pipes are stronger, more pressure-resistant, and corrosion-resistant but costlier, while welded pipes are economical, widely available, and suitable for low-to-medium pressure applications.

|

Parameter |

Seamless |

Welded |

|---|---|---|

|

Strength |

High |

Moderate |

|

Pressure |

High |

Low-Medium |

|

Corrosion |

High |

Moderate |

|

Cost |

High |

Low |

|

Surface |

Smooth |

Seam visible |

|

Size Range |

Limited |

Wide |

|

Applications |

Critical |

General |

|

Production |

Complex |

Simple |

|

Availability |

Limited |

High |

|

Durability |

High |

Moderate |

Advantages of Seamless Pipe in Corrosive Environments

- Superior Corrosion Resistance

Seamless pipes are manufactured without any welds, which eliminates potential weak points where corrosion often begins. This makes them highly resistant to uniform and localized corrosion, even in harsh chemical environments.

- Uniform Structure

The absence of welds in seamless pipes creates a consistent structure, enhancing their durability and reliability when exposed to corrosive substances such as acids, alkalis, and saltwater solutions. This uniformity ensures long-term functionality.

- High-Pressure Compatibility

Seamless pipes can handle higher pressure without deformation, which is essential in corrosive conditions where added pressure from liquid or gaseous materials might occur. Their robust design minimizes instances of leaks or structural failure.

- Enhanced Longevity in Extreme Conditions

Seamless pipes exhibit excellent resistance to pitting, crevice corrosion, and stress corrosion cracking when used in environments with high humidity, extreme temperatures, or fluctuating chemical exposure. For instance, in petrochemical and marine industries, their lifespan surpasses that of welded alternatives.

- Improved Material Integrity

The seamless manufacturing process ensures that the pipe material retains its natural strength and composition. This integrity makes seamless pipes suitable for use in transporting aggressive chemicals or hazardous materials.

- Compliance with Industry Standards

Seamless pipes are designed and tested to meet stringent industrial standards for corrosion resistance, such as ASTM and ASME specifications. Such compliance ensures their effectiveness in critical applications like offshore drilling, energy production, and chemical processing plants.

By choosing seamless pipes for corrosive environments, industries can ensure better safety, reliability, and cost-efficiency over the long term, particularly in applications where material performance is non-negotiable.

Cost Considerations for Seamless Steel Products

When evaluating the cost of seamless steel products, several factors come into play that impact their pricing structure. One of the primary contributors to cost is the manufacturing process. Seamless pipes are produced through advanced methods that eliminate the need for welding, resulting in a higher-quality product but with greater production expenses. This precision contributes to their elevated price compared to welded pipes.

Material costs also significantly influence pricing. Seamless steel products are often made from premium-grade alloys to enhance durability and resistance to challenging conditions. The type of steel, such as carbon steel, stainless steel, or high-alloy variations, can lead to variations in cost.

Demand and supply dynamics within the global steel market further shape prices. Geopolitical factors, raw material availability, and market fluctuations can cause price surges or reductions. For example, as of recent data, global steel prices have experienced volatility due to shifts in production rates and international trade policies.

However, while upfront investment may appear higher, seamless steel products tend to offer long-term savings. Their reliability and reduced risk of failure in critical applications translate to lower maintenance and replacement costs over time. Industries dealing with high-pressure and high-temperature environments, such as oil and gas or power generation, find these attributes particularly cost-effective.

Additionally, bulk purchasing, supplier partnerships, and selecting the right specifications for your application can aid in optimizing costs. By carefully assessing project requirements and considering supplier quality certifications, industries can strike a balance between cost-efficiency and performance.

What are the Key Specifications for Seamless Stainless Steel Tubing?

When selecting seamless stainless steel tubing, the key specifications to consider include:

- Material Grade: Common grades such as 304, 316, and 321 offer varying levels of corrosion resistance, strength, and temperature tolerance suitable for different applications.

- Outer Diameter (OD) and Wall Thickness: Precise sizing ensures compatibility with your system and supports pressure handling requirements.

- Surface Finish: Options like polished or pickled finishes are chosen based on cleanliness and corrosion resistance standards.

- Tensile Strength and Pressure Rating: Ensure the tubing can withstand the demands of your specific operating environment.

- Standards and Certifications: Compliance with standards such as ASTM A213 or A269 guarantees material quality and performance consistency.

Selecting the proper specifications ensures durability, efficiency, and safety in industrial applications.

Understanding ASTM Standards for Seamless Tubes

ASTM standards for seamless tubes define specifications for material composition, mechanical properties, and applications, ensuring quality, safety, and compatibility across industries.

|

Standard |

Material |

Temp. Range |

Applications |

Key Feature |

|---|---|---|---|---|

|

ASTM A53 |

Carbon |

Moderate |

Structural |

Versatile |

|

ASTM A106 |

Carbon |

High |

High-temp |

Durable |

|

ASTM A333 |

Carbon/Alloy |

Low |

Cryogenic |

Cold-tolerant |

|

ASTM A500 |

Carbon |

Moderate |

Structural |

Shaped |

|

ASTM A672 |

Carbon |

Moderate |

High-pressure |

Welded |

The Importance of Wall Thickness and Outside Diameter

Wall thickness and outside diameter are considered some of the most limiting design parameters relating to the performance, durability, and safety of seamless tubes in industrial applications. The wall thickness of tubes determines how much of internal and external pressure it could resist. For example, larger wall thickness withstands higher pressure, thus used for heavy-duty operations, such as oil and gas industries or high-pressure hydraulic systems. Low wall thickness walls may be preferred where weights are considered, such as aerospace or automotive manufacturing.

Outside diameter relative to the value of thickness will also suggest the structural integrity of the tube and the flow situation. Get very good control on specs so as to fit into any conjunction and remain uniform in the process. Being a standard outside diameter with the proper wall thickness will assure constant fluid flow rates within a given system and lessen irregular pressure drops.

Data are compiled from the recent industry standards on the tolerances of seamless tubing. For wall thickness, standards set safe limits for deviation in most industrial-grade tubes within ±10–12%, as per ASME or ASTM specifications, for example. For outside diameter, tolerances for commonly used sizes of 1-10 inches would go from ±0.005 to ±0.020 inches based on grades.

The safety applications portfolio that requires high precision will surely have to study the relationship between the two. An engineer or designer must carefully consider the service requirements and the properties of materials for all performance criteria and the tubes that generally create compliance.

Common Pipe Sizes and Fittings

When talking about pipe sizing and fittings, there exist general standards that oversee compatibility for specific use cases and industries. Usually, pipe sizes are as per the Nomi pipe size (NPS) system or by the outer diameter. These sizes vary greatly based on what they are used for. Smaller pipes with outside diameter of 1/2-inch to 2-inch are employed for residential plumbing services, while bigger ones with outside diameter ranging anywhere between 4 inches to 24 inches or larger serve industrial pipeline construction and infrastructure development.

Fittings come into use to interface pipes and alter flow paths; for example, elbows, tees, couplings, reducers, and so on. Typically, a 90-degree or 45-degree elbow is fitted in a pipeline system to change the direction of flow, whereas reducer fittings serve to change pipe diameters. They are of standardized dimensions such that fittings are made to conform to the pipe sizes they serve along the lines of ASTM or ANSI standards.

The most prominent industrial trend is the growth in use of stainless steel and PVC for corrosion resistance, durability, and cost-effectiveness. The thickness of the pipe wall according to schedule (for example Schedule 40, Schedule 80) will also affect its ability to withstand pressure. Generally, Schedule 40 is employed for low pressure and general usage purposes and Schedule 80 is employed in high-pressure purposes.

The right combination of pipe sizes and fittings must be chosen to make any system-from water distribution to industrial chemical transport-efficient, safe, and long-lasting.

How to Maintain Superior Corrosion Resistance in Seamless Stainless Steel Pipe?

To maintain superior corrosion resistance in seamless stainless steel pipes, follow these key practices:

- Choose the Right Grade: Select a stainless steel grade that matches the environmental conditions. For example, grades like 316 or 316L offer enhanced corrosion resistance in chloride-rich environments.

- Ensure Proper Cleaning and Maintenance: Regularly clean the surface of the pipe to remove debris, contaminants, or corrosive substances that can compromise its resistance over time.

- Avoid Surface Damage: Minimize scratching, gouging, or other damage that can disturb the protective chromium oxide layer and lead to localized corrosion.

- Control Environmental Exposure: Limit exposure to harsh chemicals or extreme temperatures that can accelerate corrosion processes.

- Apply Protective Coatings if Necessary: Use specialized coatings or treatments in highly aggressive environments to add an extra layer of protection.

By employing these practices, you can extend the lifespan of seamless stainless steel pipes while maintaining their structural integrity and resistance to corrosion.

Choosing the Right Stainless Steel Alloy

In choosing the proper stainless steel alloy, it is paramount that I take into account all requirements of the given application. For example, if the best corrosion resistance is required, I tend to favor 316 or 317 grades in the harsh environment. If strength and durability are considered, my choices often tend to include 304 stainless steel, also for its versatility. On the other hand, when very high temperatures are in question, I check available heat-resistant types such as 310 or duplex. At the end of the day, I always check to make sure the right alloy is selected in accord with the environmental conditions, cost, and intended use so as to complement performance and value.

Surface Treatments and Finishing Techniques

Surface treatments and finishing techniques that I use are mostly aimed at improving and refining the material’s performance and appearance. Thus, usually, with stainless steel, I would either electro-polish for a lacquer finish that is corrosion-resistant, or bead blast for a matte appearance. Of course, I also use passivation to rid the steel of contaminants and promote corrosion resistance. The type of finishing method I wish to go for finds the final word in being dictated by the application’s need, both functionally and aesthetically.

Regular Maintenance and Inspection Protocols

Effective maintenance and inspection protocols are vital to ensure the longevity and optimal functionality of materials and equipment. For stainless steel, regular cleaning with warm water and a mild detergent is essential to remove surface contaminants and prevent the buildup of debris that could lead to corrosion. Additionally, scheduling periodic inspections helps identify surface irregularities, scratches, or cracks that might compromise the integrity of the material over time.

Recent advancements suggest that integrating non-destructive testing (NDT) methods, such as ultrasonic testing and visual inspections using endoscopic tools, can significantly enhance the accuracy of assessments. These techniques can detect subsurface defects and early-stage wear without causing damage to the material itself. Data from industry studies indicate that equipment subjected to consistent maintenance experiences a lifespan increase of up to 30%, highlighting the importance of routine care.

For environments exposed to harsher conditions, such as high humidity or saltwater, applying protective coatings or sealants on stainless steel surfaces can offer additional resistance to corrosion. Tracking maintenance schedules through digital software solutions has emerged as a dynamic approach, enabling automated reminders and comprehensive record-keeping to streamline inspections. By combining these practices, maintenance protocols not only ensure reliability but also substantially reduce long-term repair costs.

Reference Sources

-

Springer: Production of seamless steel pipe for oil and gas extraction in challenging conditions – Discusses new compositions and standards for seamless stainless steel pipes in demanding environments.

-

CED Engineering: Process Piping Fundamentals, Codes and Standards – Covers standards and pressure ratings for stainless steel seamless pipes.

-

ScienceDirect: Analysis of the failure causes in the flattening test of 2205 duplex stainless steel seamless tubes – Provides insights into testing and standards compliance for duplex stainless steel seamless pipes.

Frequently Asked Questions (FAQs)

Q: What is a stainless steel seamless tube, and how is it different from welded tubing?

A: A stainless steel seamless tube is made from a solid stainless steel billet that is extruded and drawn to create a tube without any welds. In contrast, welded tubing is made by curling a steel strip and welding the seam. Seamless tubes typically offer higher strength and better corrosion resistance compared to welded tubing.

Q: What are the benefits of using high-quality stainless steel seamless pipes?

A: High-quality stainless steel seamless pipes offer enhanced strength and corrosion resistance, making them ideal for high-pressure applications. They provide consistent performance and longevity, reducing maintenance needs and ensuring safety in critical applications.

Q: How do I choose the right pipe supplier for my project?

A: When selecting a pipe supplier, consider their experience, reputation, and range of stainless steel products. Ensure they provide pipes that meet industry standards like ASTM A269 and ASTM A511, and offer a variety of nominal pipe sizes and pipe schedules to suit your needs.

Q: What are the common applications for seamless stainless pipes?

A: Seamless stainless pipes are commonly used in industries that require high-pressure and high-temperature tolerance, such as oil and gas, petrochemical, and power generation. They are also used in construction and automotive industries due to their strength and versatility.

Q: What factors determine the outside diameter and wall thickness of a stainless steel seamless tube?

A: The outside diameter and wall thickness of a stainless steel seamless tube are determined by the specific requirements of the application, including pressure, temperature, and structural considerations. These factors ensure the tube can handle the operational stresses it will encounter.

Q: How does seamless and welded tubing differ in terms of manufacturing process?

A: Seamless tubing is created by extruding and drawing a solid stainless steel billet, while welded tubing is made by rolling a flat strip of steel and welding the seam. Seamless tubing often provides higher strength and better integrity due to the absence of welds.

Q: What are the advantages of using stainless seamless pipes over other materials?

A: Stainless seamless pipes offer several advantages, including superior strength and corrosion resistance, versatility across various applications, and longevity. They are also available in a range of sizes and finishes, making them adaptable for different industrial uses.

Q: What standards should high-quality stainless steel seamless pipes comply with?

A: High-quality stainless steel seamless pipes should comply with industry standards such as ASTM A269 and ASTM A511. These standards ensure the pipes meet specific requirements for strength, corrosion resistance, and dimensional accuracy.

Q: Can pipe fittings be used with stainless steel seamless pipes?

A: Yes, pipe fittings can be used with stainless steel seamless pipes to connect sections, change direction, or regulate flow. It is important to select fittings that match the pipe’s material and specifications to ensure compatibility and performance.

A: Related products often used alongside stainless steel seamless tubes include pipe fittings, welded tubes, and other stainless steel products. These components are used to complete piping systems and ensure efficient fluid or gas transport.