For industrial, commercial, and residential purposes, the 2-inch pipe is a great asset that is seriously incorporated into the system and structures. Whether you are coming up with plumbing designs, installing an irrigation system, or heating and ventilation air conditioning, it is important that you understand the scope of work for the 2-inch pipe to be effective. This section explains in detail the primary functions, strengths, and technological issues related to 2-inch pipe, which can be usefull not only for professionals but also for hobbyists. Through examination of its sources of material, strength, flexibility, and adaptability, you will come to fully appreciate how this very common yet very useful part can be true to the intents of your upcoming installation, whether it is a drain or a shop fitting.

The History and Evolution of 2 Inch Pipes

For several decades, the 2-inch pipe has been one of the basic components in plumbing, building, and industrial systems. Pipes in the past used materials such as cast iron and lead, which were long-lasting but were also susceptible to rust and corrosion, and so required a lot of care. The late nineteenth and early twentieth centuries brought most improvements in piping materials with the introduction of galvanized steel, as it offered better protection against corrosion and also increased the period of problematic piping replacement.

As history teaches us, with time, improved technologies facilitated the shaping of better materials several decades ago, PVC and other plastics among them. Such materials were easy to transport, relatively cheap, and corrosion-proof compared to metals. At the moment, however, 2-inch pipe might be made out of copper, stainless steel, or even high-density polyethylene (HDPE) without any difficulties, as there are specific applications and environments for each. How the industry shapes is concerned with the extension of the pipe, which involves remodeling the production and building of pipes in order to achieve better durability, performance, and eco-friendliness.

Early Uses of Steel Pipes in Construction

The use of steel pipes in the construction of buildings and bridges began in the last years of the 19th century. With them being strong and able to carry more loads, they became one of the first materials to provide the framework in the construction of buildings and bridges. The tough and flexible nature of these pipes proved beneficial in the making of basements, in plumbing, more particularly, where the concept of 2-inch pipe or schedules was developed. Then, they were used in the construction of high rises and factories because they withstand the nagging pressure and survive in varied weather conditions.

Technological Advancements in Pipe Production

Due to material science developments as well as developments in the methods of production, the process of manufacturing pipes has transformed a lot. For instance, any high-performance material like polyethylene and PVC, unlike the traditional bulky metal pipes, is much more flexible, resistant to corrosion, and appreciates a significant lifespan.

Exemplary application of mechanization, production processes such as extrusion, and special welding techniques have been enhanced to promote consistency and accuracy. The advent of 3D printing allows the ability to personalize pipe structures in a variety of settings for each specific application (for example, schedule 40 pipes can be manufactured for different purposes in different workshops). Incremental advances in current technologies have taken place regarding pipe production, making the whole exercise more flexible and cheaper while retaining the use of pipes for different industries.

Impact of 2 Inch Pipes on Modern Infrastructure

2-inch pipe is a component that is very useful when it comes to the construction of pipelines in modern structures. This vital component of piping can be utilized in plumbing systems, drainage systems, as well as other applications. The size of the pipe is moderate, and this makes it very attractive to homeowners and developers alike, for it can accommodate the flow of fluid that is reasonable without occupying so much space. This and other factors notwithstanding, the present state of materials and engineering techniques has played a role in increasing the cost-effectiveness as well as their ability to achieve 2-inch pipe among structures and projects.

Applications of 2 Inch Pipes Across Industries

Common Uses in Construction

- •Plumbing: Used for water supply and drainage systems in houses and commercial outlets.

- •HVAC: The conduit for coolants and other fluids within heating, ventilation, and air conditioning systems.

- •Irrigation: Good for conveying water for small to medium agricultural and landscaping projects.

- •Gas Lines: Convey rarely natural gas or propane for heating or cooking.

- •Electrical Conduits: Protect electric wiring from any construction activities.

Role in the Oil and Gas Industry

Pipes are the backbone of the oil and gas sector, as they provide a safe and efficient means of moving crude oil, gas, and finished goods. They are used in all phases of operations: the upstream, where they are used to carry resources from the well head, and also in midstream and downstream functions, where they act as transportation, for example, long-distance pipelines. These attributes ensure that the operations in the industry can be carried out without accidents or breakdown of equipment.

Emerging Applications in Renewable Energy

- Hydrogen Transportation: Pipelines are being converted to facilitate the hydrogen delivery, among the clean energy carriers, as the demand for green hydrogen grows with the renewable energy transition.

- Carbon Capture and Storage (CCS): Pipeline systems therefore make it possible for the CO2 captured from industrial plants and taken to storage sites for the large-scale CCS programs.

- Biogas Distribution: The existing natural gas pipeline system is being used in some instances to distribute biogas or biomethane from organic waste, as a green alternative to fossil-based products.

- Geothermal Uses: Pipelines take geothermal fluids from the reservoir situated underground and give the geothermal fluids to the power plant for the generation of energy efficiently.

- Thermal Energy Transport: An alternative way of promoting the transmission of excess thermal energy generated by other renewable energy schemes, such as solar thermal plants, to a place where it can be utilized or stored is recently designed pipelines.

- Energy Storage with Ammonia Distribution: In the process of ammonia transport, pipelines are being developed. Ammonia is trending upward to being categorized as a renewable fuel and an energy storage medium.

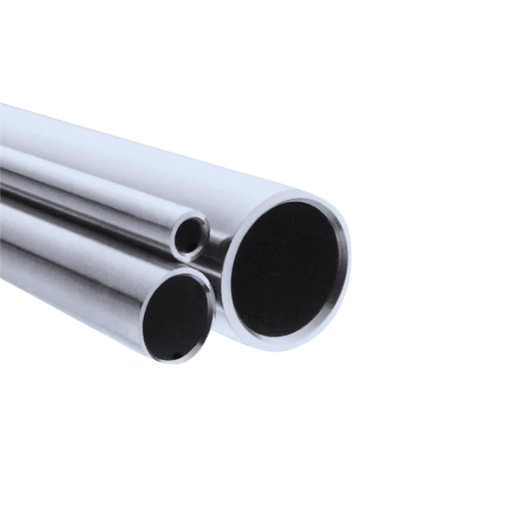

Comparing 2 Inch Pipes with Other Materials

Comparison with PVC and Other Pipe Materials

| Material | Cost | Durability | Flexibility | Thermal Res. | Env. Impact | Applications |

|---|---|---|---|---|---|---|

| PVC | Low | Medium | Low | Low | Moderate | Drainage, irrigation |

| PEX | Medium | High | High | Medium | Moderate | Indoor plumbing |

| Copper | High | Very High | Low | High | High | Potable water, heating |

| Galvanized Steel | Medium | Medium | Low | Low | Low | Older water systems |

| Cast Iron | High | Very High | Low | Low | Low | Sewage, drainage |

| HDPE | Medium | Very High | High | High | High | Industrial, municipal |

| CPVC | Medium | High | Low | High | Moderate | Hot water systems |

| ABS | Low | Medium | Low | Low | Moderate | Waste systems |

| Stainless Steel | High | Very High | Low | High | High | Industrial, potable |

| Ductile Iron | Medium | Very High | Low | High | High | Water mains |

Strength and Durability of Steel Pipes

- Excellent Tensile Strength of Steel: One of the features of steel pipes is that it has an exceptional tensile strength; this allows them to resist deformation under pressure, which consequently makes them best suited for use when transporting fluids or gases, especially under high pressure.

- Ability to counter External Forces: Steel pipes can also absorb a lot of force from the outside, for example, soil and even physical impact from outside, which contributes to the long life of the pipes in different conditions.

Environmental Impact and Recyclability

A 2-inch pipe can be called an ideal pipe in terms of sustainability because it is highly recyclable and cost-effective to produce. Steel is, in fact, fully recyclable with no loss of quality, thus greatly lowering the consumption of raw materials and waste produced. Further, due to the changes in technologies involved in creating modern steel, this product has also been refined so that much less energy is spent, and hence its emissions have reduced greatly. Thus it cannot be overemphasized how suitable and environmentally friendly steel pipes are for a wide number of industry and building purposes.

Installation Tips for 2 Inch Pipes

Essential Tools and Materials for Installation

Having the correct tools and materials will ensure that the installation of 2-inch steel pipes goes smoothly. Following is a comprehensive list of what is essential:

Pipe Cutter or Hacksaw

For 2-inch pipes, a sturdy pipe cutter or a good-quality hacksaw should be in good working condition to produce clean and straight cuts. Any uneven ends would make fitment during the assembly a bit difficult.

Measuring Tape

Accurate pipe measurements matter on-site for alignment and structural considerations. Use a good measuring tape, preferably one having the metric system on one side and the imperial system on the other.

Pipe Threading Machine

In the case where threaded joints are utilized, a pipe threading machine becomes necessary so as to cut uniform threads at the pipe ends, thus ensuring a secure mechanical connection.

Pipe Wrench

A good pipe wrench of optimal size (minimum 18 inches for 2-inch pipes) gives the best grip and torque on tightening the joints, having lesser chances of slipping or damaging.

Pipe Crease Compound or Thread Seal Tape

These sealing materials stay between the threads and avoid leakage. Manufacturers recommend thread seal tape, which generally refers to PTFE tape, for its heat resistance and chemical inertness.

Leveling Tool

Torpedo levels or bubble levels are absolute necessities for verifying the straight installation of horizontal and vertical pipe runs.

Support Brackets and Anchors

Buy high-quality support brackets and anchors for a pipe, suited to the load and environmental conditions of the application.

Safety Gear

Personal protective equipment (PPE), such as safety goggles, gloves, and steel-toed boots, should always be worn during installation to prevent injury.

Lubricants

To facilitate assembly and prevent galling, apply lubricants on a pipe-friendly basis to threads or connections, particularly in drain installations where necessary.

💡 Pro Tip: Keeping these tools and materials at hand will definitely ensure a smooth, professional, and efficient process of installing the 2-inch pipe. Each element plays a crucial part in the maintenance of the performance and reliability of the final piping system.

Step-by-Step Guide to Fitting and Welding

- 1

Prepare The Work Area

Clear the workspace of any debris or obstructions to ensure a safe and efficient working environment. Also, verify that all tools and safety equipment needed for the operation are at hand.

- 2

Measure and Mark the Pipe

Measure in full to check the pipe length as required in the installation. Mark the pipe using either a pipe marker or chalk at the appropriate points for cutting or welding, descending to a precision level in orientation.

- 3

Cutting of Pipe

Use a pipe cutter, a reciprocating saw, or a grinder to cut the pipe to the mark, all with regard to its material type. Check the cut edges to ensure they are clean and burr-free.

- 4

Fit Pipe Joints

Interconnect pipe sections by fixing a proper fitting. Check for proper alignment and orientation to achieve a satisfactory and stress-free connection.

- 5

Tack Weld the Joints

Apply tack welds at critical points around the pipe joint to keep the sections in place, allowing for final adjustments to be made before the actual welding for maintaining perfect alignment and fit.

Safety Precautions During Installation

⚠️ Critical Safety Guidelines

PPE: The Must-Wear Apparel for Workers

The designated safety gloves and goggles shall be used to protect the worker in case there are showers of sparks; a welding helmet shall be used to guard against thermal radiation.

Maintaining Good Ventilation

Always do welding or cutting in a well-ventilated area so as not to accumulate toxic fumes.

Tools and Equipment Inspection

Check all tools and boating equipment to ensure they are in working condition before using them.

Elimination of Flammable Material

Remove any flammable liquid or material from the workspace and fire hazards.

Safe Working Environment Maintenance

Keep the area clean and orderly to prevent accidents and follow the safety requirements.

If these few steps are followed, installation risks can be greatly minimized.

Maintenance and Longevity of 2 Inch Pipes

Common Issues and Solutions

🔧 Corrosion and Rust

Issue: In the course of time, metal 2-inch pipes remain prone to corrosion and rusting, especially in circumstances involving humidity or harsh chemical exposure.

Solution: Clean the pipes to a certain degree; the pipes can either be given anticorrosion treatment or, better yet, corrosion-resistant pipes must be used; an example will be stainless steel or PVC.

🚰 Clogging or Blockage

Issue: Deposition of debris and sediments or fouling due to deposits may cause blockage to flow, partial or full.

Solution: Thorough cleaning and flushing of the pipe may be done from time to time, while strainers or filters are also recommended to be installed for the drainage system to keep away debris.

💧 Leakages and Cracks

Issue: The causes of leakages are extraneous mechanical stresses, temperature variations of any kind, or improper installation methods.

Solution: Have regular checks on their integrity so any weak points could be detected early, and remedial action should be taken to address any defective pipe. Methods applied in remediation could be either welding or replacement of pipe sections.

Tips for Cleaning and Inspection

- Regular Inspection Schedule: Maintain a consistent schedule for inspection. Inspections catch problems early to facilitate maintenance and, thereby, impair a system failure.

- Clean Properly: Use cleaning tools that match the pipe material and size, otherwise, they may create damages.

- Check Accumulation of Residue: Investigate those parts that usually host residue build-up, such as bends or joints on pipes, particularly on drain systems, and treat them at once against blockages.

- Get Into Documentation: Document all actions for cleaning and inspections with detailed give-and-take about dates, findings, and actions held. This is necessary for knowing how well the system is doing.

- Consider Accessibility: Make sure critical inspection points are easy to find and access to ease routine maintenance and keep downtimes short.

When to Repair vs. Replace

A repair or replacement must be decided upon considering the actual condition, cost, and expected lifetime of a system component.

✅ When to Repair

- The problem is small and localised

- Costs less than 50% of replacement value

- The system can work efficiently for a long time

- Safety standards can be maintained

🔄 When to Replace

- Component is outdated

- Phase of repairs and are becoming more costly

- System performance can be significantly affected

- Safety standards cannot be met

- Energy-saving options offer long-term savings

The Future of 2 Inch Pipes in Sustainable Construction

Innovations for a Reduced Carbon Footprint

Advancements in 2-inch pipe fabrication and fittings are playing their part in strategies for smart building development. They have implemented modern materials like plastic and composite materials, which help in waste reduction by using the so-called non-virgin resources.

Additionally, there is a reduction in heat loss, and energy efficiency is enhanced. These are improvements that upgraded pipes have brought about. The use of pipes in prefabricated and modular buildings reduces waste in the form of materials and emissions during the construction process.

This could result in offsetting the carbon footprint, but also the adherence to the sustainability requirements of the entire construction industry.

Contribution to Green Building Projects

Mechanical work through pipe systems plays a huge role in promoting energy-efficient and environmentally friendly buildings, given its application in water management systems, such as in drain systems. Good designs in piping help reduce unwanted losses, such as heat losses, improve thermal efficiencies, and provide better water supply and adherence to the limits of water use, among others.

Moreover, certain materials used in pipe manufacturing have negligible energy consumption, while production also helps control the waste generated due to construction. Such aspects facilitate meeting the requirements of accreditation systems such as LEED and BREEAM, which promote ecological development.

Lifecycle and Recyclability of Steel Pipes

Steel tubes are considered environmentally friendly due to their durability and the ability to recycle them after they serve their initial purpose. They are durable and can be used for a long time without compromising their performance, which can be several decades, if not more.

Besides, steel can be reused 100% which means there is no loss of fiber at the end of the life of the product. In addition to waste reduction, inherent recyclability curbs the extraction of fresh resources, thereby facilitating the concept of sustainable development as a circular economy and promoting eco–friendly practices.

Frequently Asked Questions (FAQs)

Q: What can be the common applications of a 2-inch PVC pipe?

A: A 2-inch PVC pipe is commonly employed in a variety of construction tasks such as drainage construction, domestic water piping, and even water irrigation components. The diameter of the pipe allows for efficient transportation of fluids.

Q: What makes schedule 40 pipes different from schedule 80 pipes?

A: Schedule 40 pipes are suitable for use in plenty of applications, but for drain applications, Schedule 80 pipes provide a thicker wall. Besides, the number of layers of wall these pipes have makes a huge difference. As such, a schedule 80 pipe has a thicker wall than a schedule 40 pipe, and as such, the schedule 80 pipe is more durable and applicable where high pressure is to be resisted.

Q: Is it possible to use 2 2-inch pipe, such as a black pipe, in drainage systems?

A: Yes, it is possible to use a 2-inch black pipe for drainage systems. However, check that the black pipe that you are using is designated for drainage systems because there are types of black pipes that are only meant for use as gas lines and not as water lines.

Q: What are the available types of joints and connections that can be used with a 2-inch pipe?

A: The various types of joints and connections applications that can be used with a 2-inch pipe include coupling, cap, union, tee, and even 90 90-degree elbow. These couples allow the pipe with another to be joined or the pipe to be turned into this orthogonal shape.

Q: What is the actual nominal diameter of a two-inch PVC pipe?

A: In general, the exact inner diameter (ID) of a two-inch pvc pipe is around 2.067 inches, which is very important, especially when installing pipes with certain flow requirements.

Q: Can you talk about how a two-inch pipe can be coupled together?

A: Joining two 2-inch pipes with a coupling is quite simple: just stick each end of the pipe in the coupling and glue it using PVC cement or a particular sealant. Make sure the pipes are cut properly, as they should not overlap or go beyond the fitting over the pipe wall.

Q: What makes a 2-inch pipe union different from a coupling?

A: Water courses because of the fitting called a coupling. Pipes are joined permanently using this fitting, while unions are used for easy disconnection. This aids in maintenance, where the fitting has to be removed quite often.

Q: Am I allowed to use a 2-inch pipe in the making of furniture?

A: Certainly, a two-inch pipe can be used in making furniture due to its resourcefulness in many do-it-yourself projects involving metal or PVC tubes, the construction of frames or supports, and even as a drainage pipe in specific designs. Its robustness makes it ideal.

Q: How is a 90-degree elbow useful when using a 2-inch pipe?

A: Inserting a plain bend helps to adjust the course of the flow when using a 2-inch pipe. Such a fitting is used to change the direction of water or fluid since flow is not interrupted considerably, and these kinds of fittings are commonly used in plumbing to bypass structures within the piping plan.

📚 Reference Sources

- Low Pressure Pipe (LPP) – Texas A&M University: Reviews the use of 2-inch PVC pipe for low-pressure systems.

- Approved Pipe Materials – Tillamook County Government: A listing of approved materials and specifications for various types of pipe, including gradient requirements for 2-inch pipes.

- Steel

- Pipe (fluid conveyance)

- Metal

- Black Steel Pipe Supplier In China