Piping systems serve as the central nervous system for many industries in construction, plumbing, manufacturing, and transportation of oil and gases. With several varieties in existence, two of the most commonly found, yet very different, types of pipes are black steel pipes and HDPE (High-Density Polyethylene) pipes. Yet, do these pipes differ in terms of durability, performance, price, or fields of application? This article looks closely into distinguishing black steel pipe from HDPE pipe so that you can form the right decision that suits your particular project needs. Whether you are involved in designing a high-pressure water system or a structural frame, knowing the contrasts serves you in the long run toward choosing the right material for success.

Introduction to Pipe Materials

The differing material characteristics give Black Steel and HDPE pipes different purposes in practical applications. Black steel pipe is renowned for its strength and ability to withstand tremendous pressure; hence, it finds applications in gas distribution, fire sprinkler systems, and structural supports. Being highly durable, it needs a protective layer of paint to be applied to prevent corrosion.

While HDPE pipe is lightweight, corrosion-resistant, and flexible, making it suitable for water and sewage systems, cable protection, and impact-resistant applications. Installation could be made quite simple due to its flexibility, even in terrains. When used in very high-temperature and high-pressure conditions, HDPE will undoubtedly fail; however, under many situations, it proves to be a cost-effective solution due to its low maintenance and long life expectancy.

While considering these two pipe types, one needs to analyze environmental considerations, loading factors, and budget restrictions carefully.

Overview of Pipe Materials

Pipe materials are selected based on the nature of their applications, durability, and the cost of installation in a given environment. The standard pipe materials considered are HDPE (High-Density Polyethylene), PVC (Polyvinyl Chloride), and steel pipes.

HDPE pipes are most popular due to their flexibility, chemical resistance, and ability to resist impacts, and are therefore most suitable for pressure systems, water distribution, and wastewater services. Their lightweight and corrosion-resistant nature lessens the inadequacies related to installation and maintenance.

PVC pipes are also commonly used wherever rigidity, affordability, and resistance to rust or chemicals are required. They are suitable for plumbing, irrigation, and low-pressure systems. However, they are fragile at very high or low ambient temperatures and must be handled with great care.

Steel pipes, including those made of stainless and carbon steels, which are generally preferred in environments of high pressure and high temperature, offer high strength and durability to withstand the industrial environment of gas and oil transportation. Despite their durability, steel pipes are vulnerable to corrosion in the absence of protective measures and are also expensive.

All these materials have advantages while also facing some limitations. Several key considerations, including the load to be carried, the environment in which it will be installed, and the long-term cost of pipes, must be taken into account when selecting a piping system.

Importance of Choosing the Right Pipe

The proper choice of pipes is the efficiency, safety, and longevity of any system. This choice should be made considering the mechanical properties of the material, its compatibility with the material being transported, and other environmental considerations, such as temperature, pressure, corrosion resistance, and external stress factors. Take PVC pipes for example: They are light, cheap, and used for low-pressure applications; on the other hand, steel pipes are high strength and durable under extreme conditions at a considerably higher cost and subject to corrosion if not coated appropriately. Next to these, the maintenance and lifespan of the operation must be weighed against the initial investment cost, thereby making the solution cost-effective in the long run.

Select the best pipe that minimizes the probability of leakage, structural failure, and unexpected repairs, thereby optimizing the system’s working life and return on investment.

Key Definitions: Black Steel and HDPE

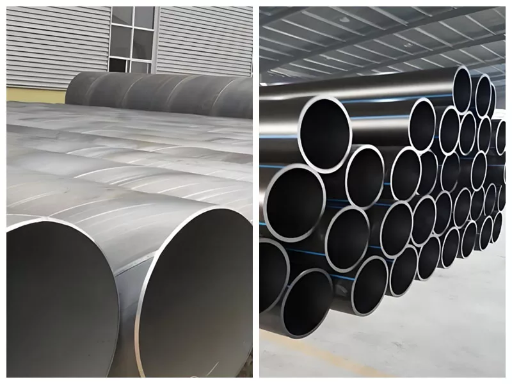

Black Steel Pipes

Black Steel pipes are steel pipes without any coating, with traces of dark-colored iron oxide formed during the manufacturing process. These pipes are generally used for applications such as gas transportation and fire sprinkler systems. Black steel pipes, like their counterparts, are characterized by their very high tensile strength and durability. Their susceptibility to corrosion limits their application to the conveyance of potable water without proper treatment or to other places where water is present unless treated or properly coated. They find their use in areas where the pressure is very high, primarily for industrial applications, and demand maintenance-wise, though they must be well-monitored.

HDPE Pipes

The High-Density Polyethylene (HDPE) pipes are thermoplastic polymer-based pipes, with flexibility, chemical resistance, and lightweight properties esteemed for making water distribution, sewerage, and irrigation systems. Given their best resistance to corrosion and environmental stress cracking (ESC), they are the most suitable types of pipes in those fields, with the added capability of resisting high temperature and being hard and withstand impacts under normal operating conditions that sometimes make them most cost-efficient and low-maintenance solutions for piping over the long run. Another liability of HDPE pipes is that they have a seamless construction, thereby reducing the likelihood of leakages and enhancing the performance and reliability of pipe systems. Some technological developments, such as the use of UV-stabilized versions of HDPE, have further extended the potential applications of HDPE pipes in outdoor environments.

The various priorities derived from these parameters will enable an engineer to make a data-driven choice related to specific project requirements, thereby achieving optimum performance and long-term economic efficiency.

Composition and Physical Properties

Being a thermoplastic polymer derived from petroleum, HDPE pipes have an extremely chemical-resistant nature against any kind of substances, thereby allowing its use in corrosive areas. The material is non-corrosive, highly flexible, and resistant to considerable thermal and pressure variations, with a low coefficient of friction. This ensures fluid flow within the pipeline with minimal energy loss. Additionally, the material’s inertness makes it suitable for potable water systems and other environmentally sensitive applications.

Black steel pipes are manufactured from mild steel, which is primarily composed of iron with trace amounts of carbon, thereby enhancing strength and rigidity. It does not have that much protection from corrosion when exposed to moisture, unlike galvanized steel. Being strong and good withstanding load, it is mainly used in gas transport and as a structural framework application. Black steel pipes are heavier and much less flexible than HDPE pipes, and limited smoothness increases surface resistance to fluid motion. It is well-suited for industrial environments with high pressures, given its strong and thermally tolerant nature.

Material Composition of Black Steel Pipe

They are primarily made from mild steel, a low-carbon steel variant. Typically, the base metal consists of iron that is combined with carbon in concentrations ranging from 0.05 since 0.25%. Tiny amounts of other elements like manganese, silicon, and sulfur might also be present because of the manufacturing processes, which aid in strengthening and hardening of the material. The absence of any alloying elements, such as chromium or molybdenum, distinguishes black steel from other types of pipe materials and gives rise to its uncoated, dark surface.

Material Composition of HDPE Pipe

High-Density Polyethylene (HDPE) pipe is primarily composed of thermoplastic polyethylene resin, known for its high strength-to-density ratio. HDPE pipes are produced from polymerization processes that result in a material with a density in the range of 0.93-0.97 g/cm3. This material composition offers pipes an excellent degree of flexibility, chemical resistance, and durability, making them suitable for a wide variety of applications. HDPE pipes typically incorporate trace amounts of various additives, such as stabilizers, antioxidants, and UV inhibitors, to enhance their stability and weather resistance over extended periods. With the advent of recent developments, research into HDPE gives rise to the use of precision-grade resins and advanced extrusion processes, thereby making it even more reliable for high-performance applications such as gas distribution, potable water transport, and industrial piping systems.

Physical Properties: Strength and Flexibility

Black steel pipes are renowned for their high tensile strength and are therefore utilized in applications that require strong structural support, including gas transportation, fire sprinkler systems, and heavy-duty mechanical uses. However, since they are rigid, they cannot be used where substantial flexibility is required. In certain environments, they begin changing to rust unless coated or treated in some other way.

On the other hand, HDPE (High-Density Polyethylene) pipes are among the most flexible pipes available, allowing them to accommodate shifting soil conditions and dynamic loads such as pressure surges. They have a lower tensile strength compared to that of black steel; however, they are superior in impact resistance and environmental stress cracking and as such are considered the optimum choice for long-life transport of fluids, particularly in systems for water and gas distribution. Both materials have their advantages, and the selection will depend on the individual application requirements.

Common Applications of Black Steel and HDPE Pipes

As a black steel pipe, it is most often employed in high-pressure environments, such as gas and oil transmission, fire sprinklers, and specific structural applications where the pipe’s properties of toughness and heat resistance are desired. On the other hand, due to their flexibility, corrosion resistance, and resistance to chemicals they may encounter, HDPE pipes find applications in water distribution systems, sewage systems, irrigation systems, and natural gas pipelines. The choice of materials depends on specific operational requirements, such as pressure, environmental factors, and design longevity.

Typical Uses for Black Steel Pipe

- Transportation of natural gas and oil in the energy sector is due to its strength and pressure tolerance.

- Fire sprinkler systems, where its high heat resistance and durability are critical for safety.

- Industrial piping systems for steam, water, and air transport under high-pressure and high-temperature conditions.

- Construction frameworks, such as scaffolding or structural supports, are used due to their rigidity and load-bearing capabilities.

- Hydraulic systems in heavy machinery offer robust performance and minimal leakage under demanding conditions.

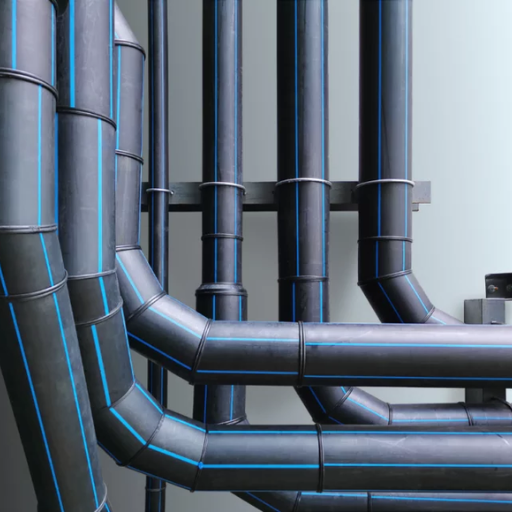

Typical Uses for HDPE Pipe

- Water distribution systems, due to their excellent corrosion resistance and long service life.

- Sewage and wastewater pipelines offer reliable performance in underground applications.

- Agricultural irrigation networks provide flexibility and durability in varied terrain.

- Gas distribution pipelines utilize their impermeability and strength under pressure.

- Cable protection conduits ensure secure and long-lasting housing for electrical and communication cables.

Comparative Analysis of Application Suitability

Black steel pipes and HDPE pipes differ in terms of cost, corrosion resistance, durability, weight, flexibility, pressure rating, and ease of installation, making them suitable for various applications.

Durability and Performance in Various Environments

Black steel pipes excel in high-pressure applications but are prone to corrosion, while HDPE pipes are corrosion-resistant, lightweight, and perform well in diverse environmental conditions but are limited by lower pressure tolerance.

Performance of Black Steel Pipe Under Different Conditions

Black steel pipes work well where durability, strength, and resistance to high pressure are paramount. Their seamless nature makes them ideal for carrying water, gas, and oil in industrial and commercial infrastructures. Nevertheless, black steel, being moisture-sensitive, corrodes and is therefore not suited for environments that demand prolonged water exposure unless the pipes are properly painted or coated. Installation-wise, their design and considerable weight make the procedure a bit complicated. In any case, Black steel pipes found their niche in applications where corrosion was not a consideration and where environment control measures guaranteed longevity.

Performance of HDPE Pipe Under Different Conditions

In my analysis, HDPE pipes are fantastic performers under different conditions due to their flexibility, high chemical resistance, and durability. They work well in temperature-varying environments, as they are capable of resisting both extremely high and extremely low temperatures with minimal degradation. HDPE pipe systems have an excellent corrosion-resistant nature, bringing advantages in carrying water, chemicals, and gases. On the plus side, their weight reduction and ease of installation reduce both labor and transportation expenses. Despite this, HDPE pipes may require additional bracing or anchoring when placed in high-pressure scenarios or locations with high soil movement. Ultimately, how they perform depends on adhering to good installation norms and following their respective material guidelines.

Longevity and Maintenance Requirements

HDPE pipes are long-serving pipes lasting more than 50 years when used under appropriate conditions. Corrosion is virtually unknown in HDPE, as are chemical reactions and environmental stress cracking, allowing for a longer life phase than conventional steel or concrete. Maintenance requirements for HDPE pipes are minimal due to their non-corrosive nature and smooth interior surfaces, which reduce the potential for scaling and improve hydraulic resistance. However, regular inspections must be carried out in high-pressure and other dynamic soil environments to monitor possible stresses or displacements. Sound installation, in terms of correct jointing and conformity to relevant standards, enhances the long service life. Advanced monitoring techniques, such as ultrasonic testing or pressure sensors, could be used to improve maintenance schedules and detect these problems before they escalate.

Cost-Effectiveness and Economic Factors

Both black steel and HDPE pipes offer distinct cost-effectiveness benefits depending on factors such as material cost, installation expense, maintenance, durability, and operational efficiency.

Initial Costs of Black Steel vs. HDPE Pipe

The initial costs of black steel pipe are generally higher due to the demands for materials and labor, while HDPE pipe is more affordable due to its lightweight nature and simpler installation.

Long-Term Cost Considerations

When considering the long-term costs of black steel and HDPE piping, several factors must be taken into account: durability, maintenance, and operational efficiency. Black steel pipes, while sturdy and suitable for high-pressure systems, are prone to corrosion over time, resulting in higher maintenance and replacement costs. Being heavier than most pipes, the black steel is also considered less suitable for mining operations in scaling conditions, primarily due to the higher costs associated with maintaining pumping systems or other liquid flow systems.

In contrast, HDPE pipes resist corrosion, scaling, and chemical attacks the best; hence, they are another fine long-term investment. The lightweight nature of HDPE pipes allows for savings in transportation, and the flexibility of the pipe reduces the number of fittings needed, further lowering costs during installation, with minimal yearly maintenance costs. When all factors, such as maintenance life span and costs, are considered, HDPE piping stands out with the lowest cost of ownership compared to black steel piping, especially when the project requires continuous exposure to moisture or chemicals.

Cost-Effectiveness in Different Industries

Black steel and High-Density Polyethylene (HDPE) pipes are used in various industries, depending on which one offers better cost-effectiveness for a specific application. The black steel pipe is preferred in industries that require high tolerance to pressure, structural strength, and the ability to withstand high temperatures. For instance, the higher price is justified for oil and gas pipeline construction and purchase of fertilizers, water, and fire sprinkler equipment. However, they require higher maintenance as the days go by, as they are prone to corrosion, and their lifecycle costs are higher in areas with high moisture or chemical exposure.

HDPE pipes are best suited for industries that value flexibility, chemical resistance, and low maintenance costs, such as water distribution, irrigation, and wastewater treatment. Their resistance to corrosion and long lifespan greatly reduce operational costs. Moreover, because HDPE pipes are lightweight, transportation becomes quite inexpensive, making great economic sense for large-scale projects.

Ultimately, deciding between black steel and HDPE pipes is mainly dependent on the specific needs of an industry, the environmental conditions, and the priorities regarding costs, where each material offers certain advantages for specific applications.

Reference Sources

- HDPE vs. Steel Pipe: Why HDPE Wins – Discusses the advantages of HDPE over steel pipes, including corrosion resistance and lifespan.

- HDPE vs Steel Pipes: The Green Infrastructure Shift – Highlights the differences in construction and environmental benefits of HDPE and steel pipes.

- HDPE pipe terminology – everything you need to know– Explains terminology and market applications for HDPE and steel pipes.

- What Is The Difference Between HDPE And Steel Pipe? – Compares the flexibility, strength, and durability of HDPE and steel pipes.

- Top Black Steel Pipe Supplier In China

Frequently Asked Questions (FAQs)

Conclusion

The choice between black steel and HDPE pipes depends on your specific project requirements, environmental conditions, and budget considerations. While black steel excels in high-pressure, high-temperature applications, HDPE offers superior corrosion resistance, flexibility, and long-term cost-effectiveness. Consider all factors carefully to make the best decision for your piping system.