What is Black Iron: Understanding Black Iron Pipe and Its Applications

Overview: The dark iron pipe is an era-tested, durable, and versatile material that stands as one of the basic elements in several industries. It being wrought strength, payment worthy, and reliable has made it commonly employed in plumbing, natural gas distribution, industrial sites, and even home applications of modern design. This guide will take you through an overview of black iron pipe and its exclusive advantages, and applications where black iron pipe excels.

Introduction to Black Iron

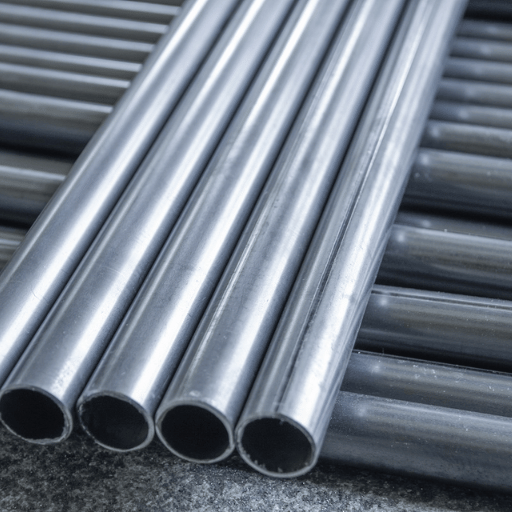

The black iron pipe represents a robust and flexible material mainly used in piping, building, and industrial applications. It has very good strength and resistance to high temperature, thus suitable for harsh environments. It is formed by coating steel with a dark-colored iron oxide layer in the manufacturing process to increase strength and offer an average level of corrosion resistance.

Key Advantages:

- Reliability: A trusted material for critical infrastructures

- Cost-effective: The most economical solution for commercial and residential projects

- Durability: Does not fail under pressure and temperature

- Versatility: Has a diversified nature with applications in various industries

Definition and Composition of Black Iron

Black iron finds extensive use in industrial applications and heavy construction due to its unique properties. The composition consists essentially of steel with a dense layer of iron oxide formed on its surface, providing exceptional mechanical wear resistance even under extreme temperature fluctuations.

This characteristic makes black iron particularly suitable for:

- Gas transmission lines

- Water heating systems

- Industrial frameworks

- Fire sprinkler systems

⚠️ Important Note: Black iron offers good structural characteristics but is not recommended for use as a drinking water conduit because of the possibility of rusting with time. With modern production processes, corrosion resistance has improved, so much emphasis is being laid on the selection of its application.

Historical Significance of Black Iron

Black iron materials had served as a workforce for infrastructure development and industrialization since their creation. In the times of the Industrial Revolution, it was extensively used for the construction of pipelines and railways, and machines, as it was durable and cheaper to manufacture. The material was also used for steam engines and large-scale manufacturing that could withstand extreme temperatures and mechanical stress.

Applications of Black Iron in Various Industries

Construction & Infrastructure

Extensively utilized in building construction, bridges, and heavy infrastructure due to its strong structural integrity in high-load situations.

Manufacturing

They are essential in machinery manufacture and heavy-duty industrial operations because of their requirement for reliability or durability.

Transportation

Applications involve the automotive segment, railway luggage, and the vessel manufacturing, where strength and resilience are the key requirements.

Energy Distribution

Pipelines and storage tanks are essential for supplying oil, gas, water, etc., to distribution systems with the necessary resistance of high.

Additional Applications:

- Heavy Industry: Tools and machinery manufacturing

- Agriculture: Farm equipment and irrigation systems

- Utilities: Light posts, fencing, water treatment plants

- Fire Safety: Sprinkler system installations

Characteristics of Black Iron Pipe

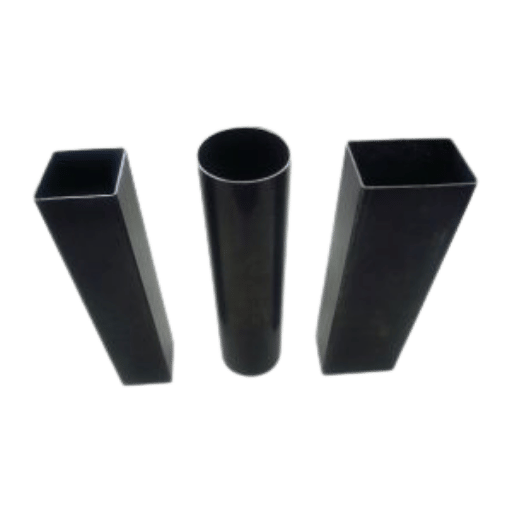

What is a Black Iron Pipe?

The black iron pipe is a resilient and flexible conduit that is manufactured from mild steel with an iron oxide coating on the surface, which brings out its black appearance. Contrary to the name, these pipes are not manufactured of pure iron but are, indeed, steel pipes. The black iron pipe is hence ideally suited for applications involving natural gas and propane transport on the commercial and residential side, being able to withstand sometimes extreme temperature and pressure conditions without bending or warping.

Application Area:

- Natural gas distribution: Gas lines for residential and commercial use

- Propane systems: Transportation of propane at high pressure

- Fire sprinkler systems: Situations requiring corrosion resistance under conditions of non-exposure

- Industrial pipework: High temperature and pressure applications

Corrosion Resistance of Black Iron Pipe

The black iron pipe will merely resist corrosion moderately in environments in which it does not undergo direct moisture contact or corrosion agents. Thus, in indoor uses or any dry environment, it retains durability and reliability over time.

Important Considerations: Black iron pipe is not considered to be highly corrosion-resistant, as moisture or humidity would start an oxidation process. The pipe must either be coated or treated to protect it against corrosion when used in wet applications so that its lifetime may be extended.

Comparison with Galvanized Pipe

| Feature | Black Iron Pipe | Galvanized Pipe |

|---|---|---|

| Coating | None (uncoated) | Zinc coating |

| Corrosion Resistance | Low to moderate | High (initially) |

| Cost | Lower | Higher |

| Best Use | Gas lines, dry environments | Water lines, outdoor applications |

| Maintenance | Regular inspection required | Lower maintenance initially |

Installing Black Iron Pipe

Tools and Materials Needed

Essential Tools Checklist:

- ✓ Black iron pipes (various sizes)

- ✓ Pipe fittings (elbows, tees, couplings)

- ✓ Pipe wrench

- ✓ Pipe cutter or hacksaw

- ✓ Threading machine or pre-threaded pipes

- ✓ Pipe thread sealant or Teflon tape

- ✓ Measuring tape

- ✓ Marker or pencil

- ✓ Safety gloves and goggles

Step-by-Step Installation Guide

Common Mistakes to Avoid When Installing Black Iron

| Key Point | Common Mistake | Proper Solution |

|---|---|---|

| Material Quality | Using low-quality materials | Choose durable, compatible types |

| Tightening | Over/under-tightening connections | Follow proper torque guidelines |

| Cleaning | Skipping cleaning procedures | Clean pipes thoroughly to prevent corrosion |

| Sealant | Ignoring thread sealant | Use Teflon tape or pipe dope |

| Planning | Poor planning/measurement | Measure and plan meticulously |

| Support | Insufficient pipe support | Secure every 6-8 feet |

| Expansion | Ignoring temperature changes | Account for expansion/contraction with joints |

| Testing | Skipping leak tests | Test with air and soap solution |

Differences Between Black Iron and Other Pipes

Black Iron vs. Carbon Steel Pipe

| Parameter | Black Iron Pipe | Carbon Steel Pipe |

|---|---|---|

| Material | Malleable iron | High carbon steel |

| Corrosion Resistance | Moderate | Lower |

| Strength | Less brittle | Harder, more brittle |

| Welding | More challenging | Easier to weld |

| Applications | Gas lines, fire systems | Water systems, structural use |

| Cost | More economical | Higher cost |

| Fire Resistance | High | Moderate |

Choosing the Right Pipe for Your Project

Selection Guidelines:

When selecting pipes for a project, conduct a detailed assessment of specific application requirements:

- Indoor/High Heat Applications: Black iron pipes are ideal due to cost-effectiveness and easy welding properties

- Outdoor/Wet Environments: Galvanized pipes provide superior corrosion defense, though at a higher initial cost

- Consider Long-term Factors: Maintenance requirements, expected lifespan, and workability should guide selection

- Environmental Matching: Ensure pipe choice aligns with both technical and environmental project requirements

Fittings and Accessories for Black Iron Pipe

Types of Fittings Used with Black Iron

Elbows

Essential for redirecting pipeline flow and changing direction in piping systems.

Tees

Connect main lines with branch lines, allowing for system distribution and splitting.

Couplings

Join two pipes together in straight-line connections for system continuity.

Unions

Provide easy connection and disconnection capabilities for maintenance access.

Plugs

Seal pipe ends effectively, preventing leaks and maintaining system pressure.

Bushings

Reduce pipe diameter for connecting pipes of different sizes in the system.

Caps

Close pipe ends permanently, providing secure termination points for system branches.

How to Select the Right Fittings

Maintenance Tips for Black Iron Pipe Fittings

🔧 Essential Maintenance Practices

Inspection

Occasional visual inspection for rust, corrosion, or leakage would be preferred since early detection avoids great damage and expensive repairs.

Cleaning of Plant Equipment

Keep fittings clean to prevent direct dirt, grease, or debris deposits that might accelerate corrosion. Ensure the use of cleaning materials that will not harm the pipe material itself.

Prevention of Corrosion

Apply anti-corrosion paint or coating to fittings if the environment is humid or in the presence of chemicals.

Monitoring of Connections

Check all pipe and fitting connections for remaining tight or cannot vibrate or pressure change, loosen them or cause leakage.

Pressure Considerations

Excess pressure or stress on the fitting through misalignment can allow cracking or failure of the system.

Replacement of Parts

Replace the fittings that are too worn, cracked, or badly corroded before they can compromise the integrity or safety of the system.

Frequently Asked Questions (FAQs)

Q: What is black iron, and what are its uses?

A: Black iron pipe is the steel pipe type that is left uncoated. It is typically used for the conveyance of natural gas and propane. Being of mild steel, it is therefore considered to be strong and durable. These are black pipes used for residential and commercial gas lines and other situations where a backing pipe system is required.

Q: How do black iron pipes differ from galvanized pipes?

A: The basic difference lies in the coating. While black iron pipe has no coating and will rust, galvanized pipe has a coating of zinc to prevent corrosion. The zinc coating will, thus, prevent it from rusting and increase its lifespan, which is why it is preferred for use outdoors or in places with high moisture content.

Q: How do you install black iron pipes?

A: At the time of installation, pipes are measured and cut to size, always ensuring the ends are threaded, and then connected to the proper fittings. All connections must be tightly secured to avoid any leaks. Teflon tape can also be applied to threaded connections to achieve better sealing. Correct installation of such fittings is crucial to the safety of their application, more so if the installation in question pertains to gas systems.

Q: Are black iron pipes safe for gas lines?

A: Black iron pipes are accepted to be a safer option for gas lines when installed properly. They are the most widely used gas pipes for both residential and commercial gas systems, mostly for discharging natural gas and propane. However, all connections must be tight, and pipes shall be inspected on a regular basis against corrosion or leakage to ensure safety.

Q: How long does a black iron pipe last?

A: Life expectancy is subject to environmental and application conditions. Properly installed and maintained black iron pipes can stand for several decades. If they remain exposed to varying degrees of moisture, the pipes may rust with time. Timely inspection and appropriate maintenance are among the best steps to extending the time they function well.

Q: Can black iron pipes rust or corrode?

A: Yes, black iron pipes may rust and corrode because they do not possess any protective coating, leaving them exposed to moisture and oxygen. The consequent formation of iron oxide (rust) diminishes the pipes’ efficiency, thus potentially giving way to leakage. Maintenance should include regular inspections and treatments, like painting or coating of the pipes to keep them intact.

Conclusion

Black iron pipe is the very essence that keeps infrastructures modern, as it offers a strategic combination of strength, affordability, and reliability in a diverse range of applications. Whether it is home gas lines or industrial frameworks, a local contractor, engineer, or homeowner will all agree that it is a valuable material with proven performance.

Depending on the installation requirements and maintenance, performance, and safety issues are taken into account. One major shortcoming of black iron is that it will have to be watched out for, should it be installed in moist environments, unlike galvanized iron. Otherwise, its cheap rates and equally great performance in dry applications with high temperature are reasons enough to let it take precedence in critical infrastructure applications.

Lessons to Remember:

- Versatility: Suitable for gas lines, fire systems, and industrial applications.

- Cost-Effective: Provides excellent value for strength and durability.

- Installation: Requires proper techniques and regular maintenance for optimal performance.

- Safety: Well-maintained service life can be guaranteed when properly installed.

Reference Sources

- Iron indices, what do they really mean?

This article is about iron mobilization and its indices and represents a reflection from a scientific perspective on iron-related topics.

Read more on ScienceDirect - On iron

This source discusses various types of iron, including black iron and its compositions, and is available on JSTOR.

Read more on JSTOR - Black Steel Pipe Supplier In China