When it comes to reliable and strong solutions for construction projects, U-shaped hot rolled steel sheet piles are the best choice for engineers and developers worldwide. They are the most popular among the steel profiles as they are the most versatile in the creation of durable retaining walls, revetments, and other foundation structures in various industries. However, what is it that really makes U sheet piles a must-have in the modern world of construction? This article scrutinizes the main traits, advantages, and usages of the product, thus providing the reader with a thorough understanding of the steel sheets’ vital role in the construction field and power. Be it that you are updating your knowledge of construction materials or looking at ways to optimize project efficiency with the use of innovations, this book will give you a helping hand in making an informed decision by giving you valuable insights.

Introduction to Sheet Piles

Sheet piles are long, distinct sections made of steel, concrete, or vinyl, intended to offer support and hold back the soil or the water. They are widely present in the building of walls, seawalls and water breakers, excavation supports, flood control systems. The locked segments are hammered into the ground, thus forming a sheath of continuous length, their great firmness and stability being guaranteed owing to a special provision in the design for that purpose. At the same time, the quality and other features such as resistance to various things like rotting result in sheet piles being one of the most efficient means of dealing with infrastructural and environmental problems.

What are Sheet Piles?

Sheet piles are the long and thin types of steel, concrete, or timber sections that interlock to form a solid barrier. They find their way in the construction work mainly for the backing, prevention of soil or water movement, and reinforcing the structure side in projects like retaining walls, seawalls, and excavation sites.

Importance of U Sheet Pile

U sheet piles are one of the most important items in a construction project due to their high strength, durability, and flexibility. Their design with locking ensures there will be no space between them, thus, they are very suitable for lateral forces and have great soil and water retention capacity. The cost of U sheet piles is proportionate to their strength; they are also quick to fix and be removed, thus, being one of the only earth retaining solutions that are environment-friendly.

Applications of Hot Rolled Steel Sheet Pile

Hot-rolled steel sheet piles are extensively utilized in different construction works as they have the power and capability. They are most suitable for the making of retaining walls and bridge abutments but also flood defenses, and sea walls. Moreover, they are the most effective way of constructing cofferdams and underground structures for the reason that they make the soil solid and do not allow water to go through. They are the right things also because of their lastingness and the ease of handling to be used for either temporary or permanent solutions.

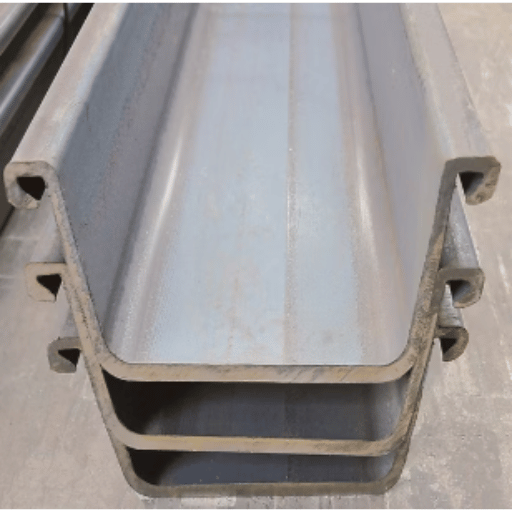

Understanding Hot Rolled U Sections

Hot-rolled U-sections are a type of steel sheet pile in the shape of the letter “U” that is specially treated, uptaken by their great power, suppleness, and the easy job of placing. Such sections are made by the process of hot rolling that makes the steel stronger and harder with the advantage of uniformity. The major usage of hot-rolled U sections is in creating structures that need earth retraction like, for example, retaining walls, bridge abutments, and waterfront structures. The interlocking system that the piles possess allows the seamless connecting of the piles, thus improving the total stability of the structure and, consequently, reducing the infiltration of water. The very fact that they have been in use for a long time and have shown no signs of wear and tear due to the heavy loads they can carry, makes them a first-rate choice for providing and maintaining the integrity of the structure in a very harsh environment at the same time.

Definition of Hot Rolled U Sheet Pile

U sheet piles that are hot-rolled are essentially steel structures created by hot-rolling, each with the shape of a U as a characteristic cross-section. They are the type of piles utilized in soil retention and load-carrying cases with the convenience of locking connections for the pile-to-pile joints which add to the overall rigidity and water-tightness of the wall. They are equally strong and adaptable for any situation thus putting them in the Great Wall of China’s category of constructually challenging jobs alike and not far from sea projects achievable.

Benefits of Hot Rolled U Sections

1. High Strength and Durability

Their sturdy design guarantees great load capacity and their performance is resistant to extreme conditions for a long time.

2. Water Resistance

The locking connections are designed in such a way that they are ideal for applications that need water-tightness, making a water negative pressure system thorough with the connections.

3. Versatility

They are perfect for making different structures like waterfront, underground or earth retaining walls, shoreline protections and flood control projects.

4. Ease of Installation

Less time and less money should be the main result of using efficient methods in the installation.

5. Recyclability

Being made of structural steel, they hold good for the environment and can be recycled or reused.

Comparing Hot Rolled and Cold-Formed Steel Sheet Pile

Hot rolled and cold-formed steel sheet piles differ mostly from one another in their manufacturing process, material properties, and applications. Hot rolled sheet piles are made at high temperatures which gives them much better strength, tighter interlocks, and higher durability, thus making them to be the best fit for the heavy-duty and critical infrastructure projects while cold-formed sheet piles offer cost-effective solutions for the not-so-demanding but lighter weight and the flexibility of manufacturing are the paramount advantages. It is common to see hot rolled piles being used in projects that want the structure to perform the best and to be waterproof, but a few of them are sometimes not quite sufficient and the cold-formed piles are the right choice where the versatility and being economical are the key points of consideration.

Characteristics of U Sheet Piles

1. Durability

U sheet piles are made from very strong steel, so the piles have a very good resistance to such environmental factors like corrosion and weathering.

2. Interlocking System

They have very precise interlocking designs that will make for a very tight and secure connection, and also, they will greatly contribute to the stability of the construction or any other application in which these piles are used.

3. High Load Capacity

U sheet piles can bear heavy loads and hence they are one of the best options for big construction projects as well as for different marine structures.

4. Versatility

These piles would suit any kind of project, whether it is a foundation or a project requiring soil reinforcement.

5. Ease of Installation

U sheet piles are finished with a high-quality steel sheet that makes the installation process quick and therefore cost-effective.

6. Sustainability

U sheet piles are very green due to the fact that they are made of 100% recyclable material.

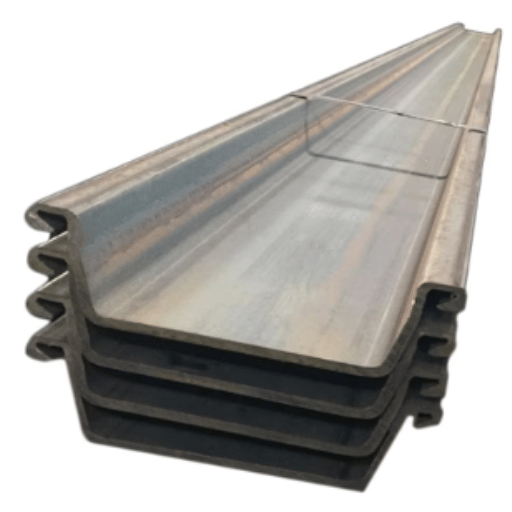

Typical Pile Profiles

U sheet piles are available in various profiles which are made differently depending on the project requirements. The profiles can be light for small and heavy for big infrastructure projects. These profiles are different in their width, height, and thickness so they can give the necessary strength and flexibility, thus the best performance in any construction zone where the diversity of scenarios is considered.

Corrosion Resistance of Hot Rolled U Sheet Piles

The hot-rolled U-sheet piles have a better resistance to corrosion, which permits the piles’ life span and dependability to be guaranteed in the different environments. The material structure of the piles is compact and uniform, due to the hot rolling process, and this gives them a greater resistance to corrosion by water, chemicals and soil. Moreover, the piles can be given an even longer life by providing them with some suitable coatings, e.g., galvanization or a special type of painting, which will continue to be advantageous even under the conditions of marine or industrial application that are highly aggressive.

Dimension and Specifications of U Sections

U steel sections, commonly known as U-shaped channels, are offered in a broad range of sizes to accommodate numerous structural and engineering requirements. Typically, their specifications cover the width of the flange, the height of the web, and the steel material thickness. The actual sizes are in millimeters or inches, with measurements being in the range from small profiles like 50x25x4 mm to large ones such as 400x100x13 mm. The material grade, weight per unit length, and adherence to industry-specific standards (like ASTM, EN, or JIS) are the main factors that affect their selection for certain projects. Comprehensive information can usually be given in manufacturers’ catalog or technical datasheet, which are specific for various applications.

Applications of U-Type Sheet Piles in Shore Construction

These are the applications where U-type sheet piles are usually of primary importance for being a substantial part, mainly in terms of durability and strength in shore construction. Some of the common scenarios these are used in are:

1. Seawalls and Bulkheads

For the tough protection against wave and current action and coast erosion prevention.

2. Berths and Harbor Walls

For the establishment of stable docking areas that are critical for the functioning of marine infrastructure.

3. Flood Defense Systems

For the provision of floodwater level control and the prevention of flooding in high-risk areas through the use of the piles as flood barrier structures.

4. Revetments and Embankments

For the reinforcement of slopes, banks, and the enhancement of overall structural stability.

These applications indeed are a testament to the fact that U-type sheet piles are multi-talented in the fighting of critical challenges faced by coastal and marine infrastructure projects.

Shoreline Protection and Restoration

The primary function of U-type sheet piles is to protect and restore the shoreline by the stability of eroded beaches and coastlands and the reduction of the damages caused by wave actions and tides. With their robustness and longevity, they are an ideal choice for building fences to protect habitats, prevent soil loss, and help with ecosystem rebuilding projects. Furthermore, they could serve as the transfer point of sustainable structures that would harden the site, so it better withstands the climate changes and extreme weather events.

Use in Waterfront Structures

Riprap, bulkheads, and revetments are the most typical means of shoreline erosion prevention and protection against wave impact in coastal areas. These constructions help protect coastlines, keep slopecollapse under control, and endure the effects of tidal forces for years. Also, they are ecologically friendly, which mean they add the double benefit of not only being maintenance-free but conserving, allowing them to adapt to varying climate conditions without any other structures or foundations.

Case Studies of U Sheet Pile Applications

🌊 Coastal Protection in Japan

One technique to deal with the rising sea level and coastline order in Japan was the use of U sheet piles. The structures were made with a continuous interlocking system that made the whole thing like a massive wall, keeping out the eroding forces of the sea. This simultaneous safeguarding and operation was incorporated with the following processes: giving public services for safety food and medical emergencies from the nearest centers.

💧 Urban Flood Control in the Netherlands

In the Netherlands, U sheet piles have been combined with urban flood control systems. The riverbanks and canals have been made solid through sheet piles and big rocks so that the water collection and drainage system would not become faulty. The water storage would thus be an overload to the capacity, leading to floods, and the road and traffic hazards would materialize owing to damaged infrastructure.

🚢 Port Infrastructure Development in the United States

A number of U. S. ports chose U sheet piles as they developed their quay walls. Being very strong and easy to put in place, they helped make the construction of the shipping hub faster and thus more cost-effective. This process could be made the best in the terms of durability and cost efficiency to deal with the increasing trade and shipping needs.

📚 Reference Sources

- LinkedIn – North America U Steel Sheet Piling Market: The text states the usage of U steel sheet piles in commercial construction and highlights their attributes like strength, flexibility, and recyclability.

- LinkedIn – US Steel Sheet Pile Market: By Type: The text mainly focuses on steel piles being the material of choice in the case of commercial and industrial activities because of the former’s high strength-to-weight ratio and the latter’s easy availability.

- Pile Buck – 2025 Buyer’s Guide: Steel Sheet Pile: The text compares U-type sheet pile with Z-type sheet pile for efficiency and applications and discusses the use of U-type sheet piles, and hence the focus of the whole report/text other applications and utilities.

Frequently Asked Questions (FAQs)

Choose U Sheet Piles for Your Next Project

Experience unmatched strength, durability, and versatility with hot rolled U sheet piles. The perfect solution for retaining walls, marine structures, and foundation support in demanding construction environments.