Blind flanges serve a unique but important function in several industries that involve setting up pipe work. So whether you are a technocrat, project officer or a mere enthusiast of technical aspects of equipment, blind flanges are concepts that have to be fully understood in order to run a safe, efficient and regulatory compliant business. The purpose of this manuscript, therefore, is to unravel the speculative connotation of blind flanges since it contains details of their description, classification, preparation and use methods. This paper will help you understand some of the things you want to know concerning blind flanges right from why they are installed down to how they work. It even includes the secrets patterns and information that will enhance your proficiency in generating piping systems. Let us take the first step!

What is a Blind Flange and How Does It Work?

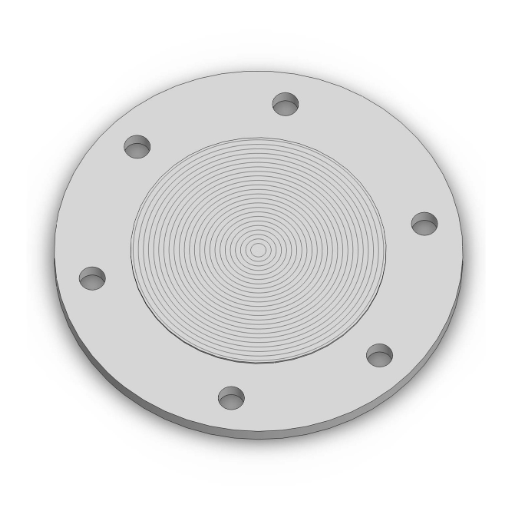

A blank (or blind) flange is a solid, round plate typically used to close the end of a piping system. When comparing it with other types of flanges which link parts of a piping system or it is attached to a device, a blank flange is meant to stop the flow of the gas or liquid altogether. It is usually connected to the piping with the help of bolts and bolted joints with holes that have been precisely drilled, so the connection between pipes remains reliable and free of any leaks. In most cases, they are used to prevent the flow of medium through pipes when the procedure is supposed to be specified or a given pipe loop needs fixing. The simplistic nature of blind flanges and the manner in which they are used in engineering has earned them a key spot in the design of piping systems, because their design is simple but their application is quite essential in safety of the system.

Definition and Function of a Blind Flange

Improvements in technology used in gases and liquids moving equipment, which involves pipes, blind flanges are considered indispensible in pipe work, able to operate without, gases, fluids and high pressure motivates the use of blind flanges in industrial and other applications. One of the most outstanding aspects of blind flanges is the absence of additional devices whereas as a blind they are effectively sealed the end of a pipeline. It means that operations such as maintenance service or testing a system or laying it means they are being extended. And there will be very little or no disturbance to the current system.

In addition, blind replacement cost is very high current days, as blind is offered in different materials which include stainless steel, carbon steel as well as alloy steel. This high level of versatility makes them effective to use in spite of the unfavorable operating environments like high temperatures, high pressures and the humidity caused by corrosion. For instance, in instances where the levels used for pressure piping operations are more than 100 bar, blind blinds are expanded to endure that high pressure cannot leak out and also they resist being pushed out by the same force.

Furthermore, blind flanges have also been developed for global businesses, and hence, are available in accordance with many such codes as ANSI/ASME B16.5 or ISO 7005 with the advantage of regulations throughout the world. Such requirements encompass for instance flange size, class designation and matching norms as well as the nature, testing and qualification of the blank.

In addition, blind pipes indisputably make an impact on the strength and long-term operation of the pipelines, managing to ensure protection, insurance, and adaptive opportunity. They are an integral element of various heavy industries, thanks for their aggressive designs and the adherence to essentially strict guidelines concerning materials and building of these industrial components, right from the oil and gas industry, to reasons such as petrochemical industries and water filtration plant.

How a Blind Flange Seals the End of a Pipe

A blind flange is a solid barrier that is mounted at the pipe end to obstruct the flow of gas or fluid. Provided that its design is plain like a flat plate that has no ‘bore’ at the centre, it is possible to make a radius tight joint with the blind panel. This is done by fixing the blind flange at the end of the pipe with nuts and bolts where the gasket also in fixed between the flange face and the opening of the pipe in order to ensure sealed tight.

Blind flanges are a mix of all grades of materials, which are different from stainless steel or even carbon and a wide variety of alloys. This means that these sentence can be tailored depending on the special pressures and temperatures of a given system. For instance, in harsh working environments such as oil and gas and petrochemicals, blind flanges have a pressure range from 150 to 2500 pounds per square inch (PSI) hence making them appropriate for demeaning operating conditions.

Surface finish of a flange is another factor in its sealing capability. The high-pressure flanges are usually with the ring type joint flange finish and the raised face flanges (Rf) can be modified according to the media and the place of the fusion faces. With all this in mind, it can thus be depicted that flanges are frequently and rigorously tested and proven to meet the ANSI/ASME standard when they are made.

In strict adherence to this enhanced sealing protocol, then it can be concluded that blind flanges do not only maintain their configuration but allow for easy disconnection or addition of new components such as piping without costs of changing the existing infrastructure, hence making it convenient to be used in very many industrial applications.

Typical Uses of Blind Pipe Flanges in Piping Systems

Devoid of sight pipe flanges are extremely versatile and sturdy thus they have been employed across different industrial sectors. Many individuals utilize these flanges for one of their intended purposes, which is closing the pipe means in the piping arrangement through which flow could be changed or stopped and enables their location. As an example, within the environment of any chemical or petrochemical plant where there are several piping expansions, blind flanges will be used to block off or isolate that particular whole stretch of the pipework to be inspected. This will not only ensure safety but it will also help in reducing the total downtime downtime.

In addition, blind flanges also have application in systems that are designed at high pressure and high temperature because the blind flanges act as the last line of defense in preventing any kind of leakage in the live systems. Blind flanges are used in industries like oil and gas for the systems that have fluids or gases under pressure. Some designs of these products are made to withstand a pressure of over 10,000 PSI and can be very useful particularly in such harsh conditions.

Also, blind flanges help in carrying out the expansion or modification of systems without impacting on all operations. These are used to fit the additional piping or the new machinery simply by providing a temporary shut down which prevents the restart. Therefore, these became a choice especially for sectors involved with expansion such as power generation and water treatment plant to promote scale.

Works have shown that applying blind flanges cuts the installation and maintenance cost by almost a third compared to the other techniques for sealing. The sustainability of such advantages has been aided by the employment of such methods hence its sustainability in terms of material and technology integration since some uses such as in the use of stainless steels or alloy pipelines have enhanced the durability of pipes particularly blinflanges.

Types and Materials of Blind Flanges

In the market, there are countless different types and species of blind flanges for different system types and service conditions. Raised face (RF) blind flange, flat face (FF) blind flange, ring type joint (RTJ) blind flange are three most common types suited to specific pressure and sealing requirements.

In terms of the most common materials, the blinds mainly usually stainless steel, carbon steel, and alloy steel because of their high tensile strength and corrosion resistance properties. However, where there can be the necessity to use the product in extreme conditions specialized materials such as nickel alloys and plastic-based materials may be used. The traders of these goods would require that the material used for the blind conforms to the pressure, temperatures and nature of fluids in question.

Common Types of Flange Used in Industry

Flanges are critical components in piping and pipeline systems, enabling the secure connection, safety, and efficient operation of industrial processes. Below are some of the most common types of flanges used in various industries, along with their specific applications and characteristics:

- Weld Neck Flange (WN)

Weld neck flanges are designed with a long tapered hub that is welded to a pipe. They provide excellent support for high-pressure applications and are ideal for environments with fluctuating temperatures. Their structure ensures a smooth transition from flange to pipe, reducing turbulence and erosion. These flanges are widely applied in chemical plants, oil and gas systems, and high-pressure pipelines.

- Slip-On Flange (SO)

Slip-on flanges are easy to install and weld, requiring the pipe to be slid through the bore before welding is performed on both the inside and outside. They are best suited for low-pressure applications where cost-efficiency and moderate sealing are paramount. Typically, these are used in water treatment systems and low-pressure fluid transport systems.

- Socket Weld Flange (SW)

Socket weld flanges are inserted into a recessed area of the flange, ensuring a strong connection through a single fillet weld. These are suitable for small-diameter, high-pressure pipelines, offering excellent leakage prevention. They are commonly found in steam, gas, and hydraulic systems.

- Blind Flange (BL)

Blind flanges are used to seal off a pipeline or create a termination point. Unlike other types, they do not have a bore and are ideal for applications requiring inspection and maintenance shutoff. Blind flanges are heavily utilized in oil and gas refinery settings, as well as in high-pressure vessels.

- Lap Joint Flange (LJ)

Lap joint flanges are paired with stub end fittings, making them easy to assemble and disassemble, which is useful in systems requiring frequent maintenance. They are commonly made from stainless steel to provide resistance against corrosion. These flanges are widely used in chemical processing and pharmaceutical industries.

- Threaded Flange (TH)

Threaded flanges are unique in being compatible with systems where welding is not possible. They possess an internal thread that matches the pipe’s external thread, ensuring a secure connection. These flanges are ideal in low-pressure and non-critical applications, such as plumbing and drainage systems.

- Orifice Flange

Orifice flanges are used in conjunction with orifice meters to measure fluid flow accurately. These flanges come with pressure taps to facilitate connection to flow measuring devices. They are particularly essential in industries like natural gas production and chemical processing, where precise flow measurement is required.

Materials: From Carbon Steel to Stainless Steel Blind

Selecting the ideal flange for your piping system requires evaluating several critical factors to ensure safety, efficiency, and long-term performance. Below are important considerations to guide your decision:

- Pressure and Temperature Ratings

Different flanges are designed to handle specific pressure and temperature ranges. For example, ASME B16.5 flanges are categorized into pressure classes such as 150, 300, 600, and above. Stainless steel flanges are often preferred for operations with high temperatures or corrosive environments, while carbon steel flanges may suffice for lower-pressure systems. It’s vital to ensure that the flange material matches the operational requirements.

- Material Compatibility

The choice of material plays a significant role in the compatibility and durability of the flange. For instance, corrosive environments may require stainless steel or alloy-based flanges, whereas less demanding systems could work well with ductile iron or carbon steel. Proper material selection prevents system failure and ensures compliance with industry standards.

- Pipe Size and Design

Flanges must match the specific dimensions of the piping system, including outer diameter (OD), inner diameter (ID), and bolt patterns. ANSI or ASME standards establish these dimensions to maintain consistency across applications. Additionally, the selection of weld neck, slip-on, or threaded flange types often depends on the pipe design and how the flange will be attached.

- End Connection Type

The type of flange connection impacts ease of installation and maintenance. Popular options include slip-on, blind, socket weld, and threaded varieties. For high-pressure applications, weld neck flanges are preferred due to their robust construction, whereas slip-on flanges are cost-effective for low-pressure scenarios.

- Corrosion Resistance and Environmental Factors

Environmental conditions such as humidity, chemical exposure, or seawater contact necessitate flanges with excellent corrosion resistance. Coated carbon steel or high-alloy materials may enhance longevity in such settings. Additionally, periodic inspections and maintenance can play a critical role in extending the lifespan of the flange.

- Standards and Certifications

Ensure that the flange adheres to recognized industry standards, such as ASME B16.5, API 6A, or ISO certifications. These ensure the flange has been rigorously tested for quality and performance, minimizing risks in critical applications.

Emerging Trends and Data in Flange Selection

Recent industry reports highlight advancements in flange technology aimed at improving operational safety and reducing costs. For example:

- Advanced Coating Technologies: New coatings, such as fusion-bonded epoxy (FBE), are being implemented to increase resistance to extreme environments, particularly in the oil and gas sector.

- Material Innovations: High-performance alloys such as duplex stainless steels are gaining traction due to their superior corrosion resistance and mechanical properties.

- Digital Integration: Modern piping systems are increasingly integrating smart flanges equipped with sensors for real-time monitoring of temperature, pressure, and flow rates, enhancing overall efficiency.

By carefully considering these factors and leveraging modern advancements, you can select a flange that aligns with your specific application requirements while optimizing performance, cost, and longevity.

Installation and Use: How to Fit a Blind Flange

- Preparation: Ensure the piping system is depressurized and free from any hazardous materials. Inspect all components, including the blind flange and gasket surface, for cleanliness and defects.

- Alignment: Position the gasket on the pipe end, ensuring it is properly seated. Align the blind flange with the pipe flange, matching the bolt holes accurately to prevent misalignment.

- Bolting: Insert the bolts through the aligned holes and hand-tighten the nuts, securing the blind flange in place. Make sure the gasket remains in position during this step.

- Tightening: Using a torque wrench, tighten the bolts in a crisscross or star pattern to ensure even pressure on the gasket. Follow the specified torque values provided by the manufacturer for optimal sealing.

- Final Check: Inspect the assembly for proper alignment and tightness. Confirm that the system is securely sealed before reapplying pressure.

Steps for Proper Fitting of a Blind Flange

Below are the steps and guidelines to observe so that the flange is installed properly and the possible difficulties are avoided.

1. verify flange compatibillity

Make sure that the blind flange fits the pipe construction including dimensions, pressure rating, and the material of the flange. For example, carbon steel Class 150 flange may differ from a stainless steel Class 300 flange depending on the system requirements.

2. look at the sealing face

Make sure that the surfaces of the flange and the pipes that are in contact are smooth and free from dust, rust, or scratches. Even the smallest imperfection can lead to failure of the seal. Wipe the surface clean with a lint-free cloth soaked in the recommended cleaning solution.

3. choose the correct gasket

Select a gasket that is compatible with the fluid being transported and the temperature and pressure of operation of the system. For example, PTFE gaskets are suitable for chemical resistance, while spiral-wound gaskets are used for high-pressure applications.

4. check the fuckin’ torque

It is necessary to determine the torque to apply for tightening the bolts, which must be done not exceeding or going below the tightening curves specified by the manufacturer. Torque values across the bolts differ and among others, such torque would differ depending on the material, size, and type of flange. As an example, in a Class 150 flange case, a ½ inch bolt needs 40 ft-lbs approximately whereas in a larger bolt, the torque must be significantly higher.

5. apply solution lubrication to the bolts and nuts

Slipper Software has engineered a thread lubricant that enhances overhaul accuracy by reducing the friction along the assembly increases the accuracy of up-tighten torque. This is also important to prevent thread boundness, enabling easier disassembly during inspections.

6. tighten the bolts in the order in which they are arranged

It is also important to tighten bolts while making sure that ’s cross or star system is applied so that there is no unbalance in the applied force on the flange face. The correct way of doing this is: tighten all the bolts up to the point whereby they hold the flange securely, then begin torquing the bolts in phases, say 30%, then 60%, and finally 100% of the torque as required.

7. check for uniformity

Measure the distance between the two flanges of the pipe using a feeler gauge, once a hole is tightened up to the required values. This is done to ensure that the compressive stress on the gasket remains that way in the absence of any clearances and that such gaps will not become leaks.

8. hydrostatic test

After every detail has been followed, the last step in flange installation is the hydrostatic test which helps confirm there will be no leakages in the created piping system. In particular, pay attention to the visible signs of leakage or reduction in pressure as this would ascertain that the flanges are still sealed.

The Role of Gasket and Bolt in Ensuring a Secure Seal

The safe operation of pipeline systems is ensured or rather dependent on the proper assembly and tightness of gaskets on flange connections with special importance of bolts. The gasket performs the core function of sealing by filling any microscopic gaps or raised surfaces between the flanges to make the joint watertight. The material of the gasket is usually composed of storage materials depending on the pressure and temperature and compatibility with the chemical of the concerned system rubber, thermoplastic, graphite, or metal. Such gasket will withstand no problem the given service conditions respectively.

The gasket, on the other hand, is pressured by the bolts or nuts to create tightness. With ease using ultrasonic strain gauges the system can be monitored. Moreover, the bolts must hold the gasketing such that the stress applied is uniformly distributed. Indeed, the group will identify and discuss possible is bad played bolting is evenly placed and non raised. Moreover, the group will discuss subjecting the bolt joints to uniform bolt loads under what circumstances that is applicable.

For further reading, we find out that as much as 85% of flange joint deficiencies can be blamed on aspects of fitting like overtightening or use of the wrong bolt material and gasket density. Because of this, the do’s and don’t’s set forth by ASME such as, in the case of ASME B16.5 and similar ones, assist in flange, bolt and gasket utilization which will be safer and more cost-effective. Furthermore, it has been possible to improve the sealing function by the use of new products in the market such as Pyroseal spiral wound gaskets and ultrahigh strength bolts hence very high pressure or external temperature sealing is possible.

Common Mistakes When Using a Blind Flange

Apart from for the usual role of sealing piping components, blind flanges play a crucial role since they enclose a larger space and also help isolate the end ears of pipelines or various components. Nonetheless, they may lead to critical situations due to misusage or the incorrect manner of installation. In the text below, find some pitfalls to avoid when in use, as well as a way to ease their operational use in practice:

False Flange Sizing and Ratings

One other reason for flange defects in blind applications is when wrong sized blind flanges or flanges with incorrect pressure ratings of the system are chosen. Using a flange that is incompatible with the system’s specifications sometimes causes poor sealing which may result in loss of equipment and material. Among the other reasons for failure of flange components with time is the citing of flange sizes and ratings differences as a leading cause.

Bolt Over Tightening and Different Bolt Torque

Applying too much bolts tightness or different torque to the nor flange or the gasket material can ruin the flange sealing. The use of calibrated torque wrench is essential to avoid such problems Primary torque patterns like the star pattern must be followed. These patterns have proven that even distribution of the torque enhances the sealing performance up to 30%.

Inappropriate Choice of Gaskets

In service fluid-tightness of the flange joint requires the sealant to be compatible with the fluid as well as with the related service conditions i.e. temperature and pressure. For instance, the failure of a low temperature rated gasket at super high temperatures may result in a blowout. It has been observed through various researches that close to 20% of the failures of flange results from using the wrong material for the gasket.

Not Looking for Defects on the Flange Face

In cases of a flange, surface marks, rust, or even substances on its face could result in leakage and wastage. It is established that making detailed antecedent audits and preparation of the flange combats fixing issues during the sealing. It was also figured out that making sure that the system is free of such problems can increase the service life of the flange by 40 percent.

Extending the life of its blind flange requires that the occasional check up be done not only for wear and corrosion resistance but also for the degradation of the gasket. It is very serious that such simple practices are often ignored and it may be cost effective in the long run. One such various statistics illustrate that a planned maintenance scheme can halve the outages of plants.

Applications of Blind Flanges in Various Industries

Blind flanges are widely used in various industries due to their ability to provide a secure seal, block off unused pipe ends, and allow for easy future access.

- Oil and Gas: Blind flanges are critical for capping high-pressure pipelines during testing or maintenance, ensuring system integrity and safety.

- Chemical Processing: These flanges provide a safe barrier for handling hazardous chemicals, preventing leaks and contamination.

- Water Treatment: Blind flanges seal pipe ends in filtration systems or during system upgrades, maintaining operational efficiency.

- Power Generation: They are used in boiler systems and pressure vessels to close off openings while sustaining high-temperature conditions effectively.

Their versatility and reliability make blind flanges indispensable for maintaining secure and efficient operations across these industries.

Critical Role in Oil and Gas Sectors

Blind flanges find their application in the oil and natural gas sectors where safety, accuracy, and productivity are at the core of the business. These parts are used to close the high-pressure and high-temperature pipelines, vessel surfaces as well as orifices of other process apparatuses while achieving the desired operating safety. They are commonly employed during pipe breakout operations within the confines of the pipeline and equipment to temporarily create a leak free enclosure in order to avoid contents loss and danger.

Blind flanges are also increasing due to the increased activities in oil finding as well as unconventional means of drilling resulting to increased consumption as indicated in the industrial statistics. These measures are in lined with the increased development of the oil and gas pipeline market as the use of these flanges is also expected to increase throughout the niche of the upstream, midstream, and downstream. For example, blind flanges are particulary used during the offshore floating drilling procedures execution as they retain the pipes which are not in use perfectly and safely ends made under non-liquid condition。

Blind flanges are also used in ensuring cimpliance of the systems with the regulations, as some of them are designed to meet the high standard safeties such as those required by american petroleum institute (API), and occupational safety and health administration (OSHA). As the oil and gas industry advances in the direction of more environmentally friendly practices, the use of materials which are resistant to corrosion in the production of blind flanges , such as stainless steel, and the alloy types, ensure that they will last and will not be detrimental to the environment. These developments highlight the essential function that blind flanges still perform in fostering efficient and secure energy production on the global scale.

Applications in Water Treatment and Pressure Vessel Openings

Blind flanges serve a critical purpose in water treatment systems and pressure vessel openings by ensuring the secure closure of pipelines and storage tanks. Used extensively in desalination plants, wastewater management facilities, and municipal water treatment systems, blind flanges act as both safety and functional components by sealing off unused pipeline sections or access points. This prevents potential leaks and contamination, which is particularly vital for protecting water quality and meeting stringent regulatory standards.

In pressure vessel systems, blind flanges withstand extreme conditions, including high pressures and temperatures, to seal openings securely during maintenance or operational downtime. Advanced materials such as duplex stainless steel or high-alloy compositions are increasingly utilized in blind flanges for these applications, offering enhanced resistance to corrosion, chemical exposure, and mechanical stress. For instance, certain grades of stainless steel can resist pitting corrosion at temperatures as high as 500°F (260°C), ensuring exceptional performance in aggressive environments.

Statistics indicate that the global water treatment market was valued at over $263 billion in 2021, and blind flanges are essential components supporting its infrastructure. Their durability and adaptability make them particularly vital in bolstering system integrity while accommodating increasing demands for clean and accessible water. Similarly, in pressure vessels, advancements in material science have allowed for the designing of blind flanges that meet even stricter ASME (American Society of Mechanical Engineers) and ANSI (American National Standards Institute) codes, ensuring operational safety under the most challenging circumstances.

Advantages and Limitations of Blind Flanges

Advantages of Blind Flanges

- Enhanced Safety: Blind flanges effectively seal off pipe ends, preventing leaks and ensuring safe operation in high-pressure systems.

- Ease of Maintenance: Their design allows quick access for cleaning, inspection, and system modifications without extensive dismantling.

- Versatility: Blind flanges can be used in a variety of industries and systems, accommodating different pressure and temperature requirements.

- Compliance Standards: Manufactured to meet stringent ASME and ANSI standards, blind flanges reinforce operational reliability and safety.

Limitations of Blind Flanges

- Installation and Removal Effort: Due to their role in sealing, removing and installing blind flanges may require significant manual effort or specialized tools.

- Material Cost: High-grade materials needed for durability under extreme conditions can contribute to increased costs.

- Size and Weight Considerations: Larger blind flanges can be heavy and cumbersome, potentially complicating handling, especially during maintenance or replacement.

Benefits of Blind Flanges in Preventing Leaks

Blind flanges are among the essential elements to consider in a piping system for ensuring tight leak-proof seals. They help close off pipe ends also known as pressure vessels, offering protection within thick walls to contain high pressure and withstand wide range of temperatures. In industries like oil and gas, petrochemicals, and water treatment, such abilities are crucial due to the fact that any leakage occurs could result in significant cost, hazards to human beings or the environment.

Nowadays high class blind flanges are made up of strict safety objectives having in mind modern engineering characters. Was developed using formation of some very tough materials, such as stainless or carbon steel, that tackle severe operating conditions. Among the materials used are stainless steel blind flanges that both possess nearly entirely do not require such high maintenance, failure or leakage counts.

Research has shown that spending money on durable and quality blind flanges can help in cost savings pertaining to pipelining maintenance delivery by about 25 percent especially because they are not prone to faults and hence not much embarked in and time. On another note, improving the performance of blind flanges comes with highly improved sealing methods such as the incorporation of O-ring grooves and using specific compatible gaskets. In particular, these act as effective means of preventing system malfunction and inefficiency in extreme applications.

Understanding Pressure Ratings and Durability

As far as the question of tolerances, tensile strength and wear and tear are concerned, I am mostly concentrated about the performance of the blind flanges within the system they will be implanted. I mostly consider the adequacy of the reviewing process adopted on codes for fittings, to ensure that they are within operational pressure limits set by standards such as ASME or ANSI. Further, according to the situation at hand, I look at the adopted materials such as stainless steel or carbon steel that is hard and most resistant to wearing off. This way, of all fingers, I am able to put the two together, pressure ratings of components and suitable wear resistant material hence ensuring no objects fail or wear out prematurely.

Limitations and Considerations for Specific Pressure Applications

When addressing limitations and considerations for specific pressure applications, I always account for factors like temperature fluctuations, potential chemical interactions, and environmental conditions. For instance, extreme temperatures can impact material integrity, while certain chemicals may cause corrosion or degradation. Additionally, I remain mindful of connection types, ensuring they are suitable for the pressure ranges and fluid types involved to prevent leaks or failures. By assessing these elements thoroughly, I can tailor my approach to meet the unique demands of each application.

Reference Sources

-

Finite Element Modeling of Welded Thick Plates for Bonneville Navigation Lock – Discusses factors contributing to failure in steel-rolled shapes, including flange intersections.

-

Blind bolted collar plate connections to unfilled hollow section columns – Explores blind bolted connections and their structural implications.

-

Behaviour of headed anchor blind bolts embedded in concrete filled circular hollow section column – Examines the interaction of blind bolts and flanges in structural applications.

Frequently Asked Questions (FAQs)

Q: What is a blind flange?

A: A blind flange is a solid disk used to block off a section of a pipe or a nozzle on a vessel that is not in use. Blind flanges are typically installed at the ends of pipes where a valve or another pipe system is expected to be added later.

Q: How does a blind flange differ from a spectacle blind?

A: A blind flange is a solid disk that serves to block off the end of a pipe, while a spectacle blind consists of two disks connected by a small section of metal. One disk is solid, and the other is a ring that allows flow when placed in the pipeline. Spectacle blinds are typically used when frequent isolation is required.

Q: What materials are blind flanges commonly made from?

A: Blind flanges are commonly made from various materials, including carbon steel, stainless steel, and alloy steel. The choice depends on the application and environmental conditions.

Q: How are blind flanges installed?

A: Blind flanges are typically installed by bolting them onto the pipe system. They can be welded for a more permanent installation, often using a butt weld for a secure fit.

Q: What industries commonly use blind flanges?

A: Blind flanges are commonly used in industries such as oil and gas, chemical processing, and water treatment. They are essential for systems that require maintenance or expansion.

Q: Can blind flanges handle high pressure?

A: Yes, high-quality blind flanges are designed to handle high-pressure applications. The material and design of the flange must be chosen based on the pressure requirements of the system.

Q: What is the function of a gate valve in relation to blind flanges?

A: A gate valve is used to control the flow of fluid through a pipe. In systems with blind flanges, a gate valve can be used to isolate the section of the pipe where the blind flange is installed, allowing for maintenance or system changes without disrupting the entire pipeline.

Q: How do I choose the right supplier for blind flanges?

A: Choose a supplier that offers a wide range of options, high-quality materials, and meets industry standards. It’s also important that they provide technical support and have a reputation for reliability and customer satisfaction.

Q: Are blind flanges used in both high and low-temperature environments?

A: Yes, blind flanges can be used in both high and low-temperature environments. The material selection is crucial to ensure the flange performs effectively under the specific temperature conditions of the application.

Q: What is the relevance of a solid disk in a blind flange?

A: The solid disk in a blind flange is crucial as it completely seals off the end of the pipe, preventing any flow through that section. This is essential for system maintenance, testing, and expansion.