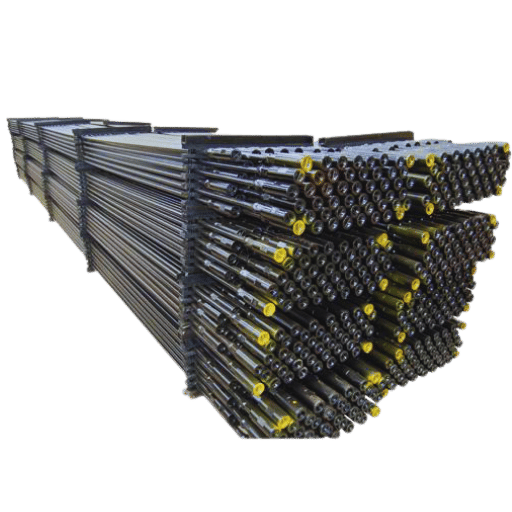

The oil business is perhaps the most sophisticated industry today, as its operations revolve around a highly interdisciplinary nature system. The sucker rods and rods strings, for example, are crucial for the artificial lifts used to withdraw oil from reservoirs. Other components work to boost productivity and operational efficiency as well. These systems of rods and pumps, which work hand in hand with surface mechanical devices, are designed for pumps to aid in extracting oil from the ground. In this guide I will discuss the components of sucker rods and rod strings covering their structure and processes as well as their role in oil extraction. After reading this guide, users will find out how these components assist in enhancing extraction efficiency, prolonging equipment life, and advancing technology for the sector.

What is a Sucker Rod and How is it Used in Pumping Systems?

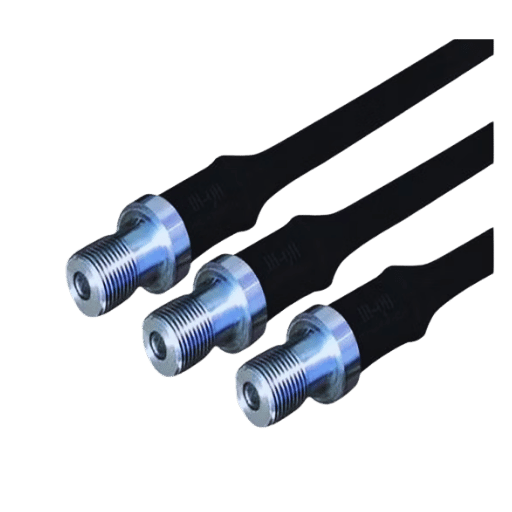

Used in rod pumping systems for oil retrieval, a sucker rod is an important component of the machine. It is a long, thin steel rod which links the surface pump jack with the downhole pump. This allows the mechanical energy needed to lift fluids to be transferred. The sucker rod enables fluid production to function uninterrupted by lifting the reciprocating motion provided by the pump jack. Sucker rods assist in the efficiency and reliability of pumping systems since they need to endure huge tensile loads and cyclic stresses throughout their operation.

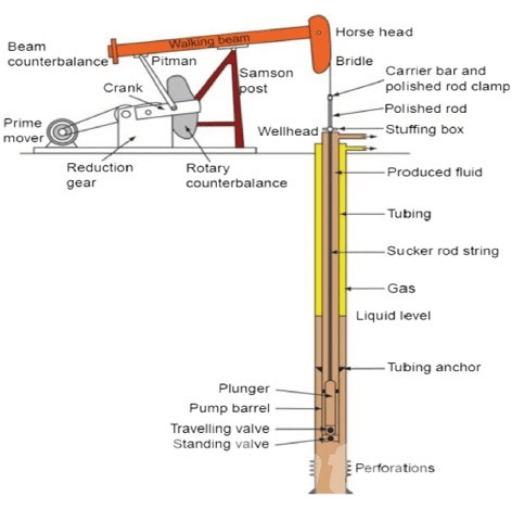

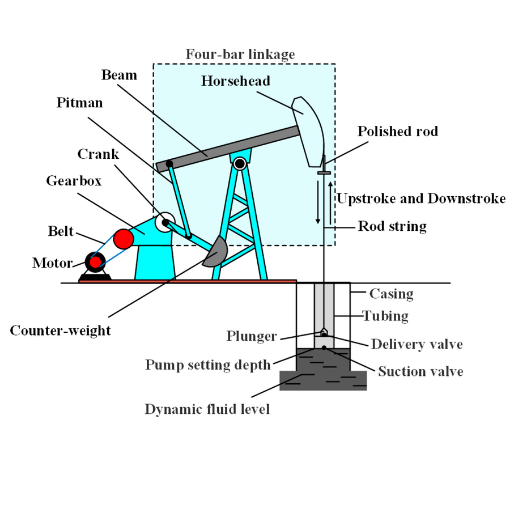

Components of a Sucker Rod System

A sucker rod system comprises of the following components: sucker rod string, pump jack, polished rod, stuffing box, downhole pump, and others. All these components work together for effective fluid extraction in an artificial lift method.

How Does a Sucker Rod Function in an Oil Well?

A sucker rod operates within an oil well by conveyancing the surface pump jack’s mechanical energy to the downhole pump, thus facilitating the extraction of fluids from subsurface reservoirs.

Common Rod String Configurations

| Configuration | Description | Key Features |

|---|---|---|

|

Straight |

Uniform rod size |

Simple, shallow wells |

|

Tapered |

Varying rod sizes |

Deeper wells, reduced surface load |

|

Continuous |

Single, unbroken rod |

No couplings, reduced wear |

|

Composite |

Fiberglass & steel |

Lightweight, corrosion-resistant |

How is a Sucker Rod Manufactured?

Materials Used in Rod String Manufacture

The production of rod strings needs raw materials with particular mechanical, structural, and subsurface characteristics. Listed below are the primary materials and their characteristics:

| Material | Key Use | Strength (psi) | Advantages | Applications |

|---|---|---|---|---|

|

Steel |

Sucker rods |

100,000-150,000 |

High strength, fatigue resistance |

Deep wells |

|

Fiberglass |

Corrosive wells |

60,000-100,000 |

Lightweight, corrosion resistance |

Medium-depth, corrosive environments |

|

Composite Materials |

High performance |

Varies |

Strength, reduced weight |

Challenging environments |

|

Coated Metals |

Enhanced durability |

N/A |

Corrosion, abrasion resistance |

Aggressive chemical wells |

Choosing a rod string material is influenced by a variety of factors, such as the well’s depth, temperature, pressure, and surrounding environment. To enhance rod effectiveness and dependability, precision machining and other advanced manufacturing methods like Pyrometry or heat treatment are used. Furthermore, the worldwide market for sucker rods is still changing as new approaches to design and materials are sought out, for instance, carbon fiber reinforced polymers which may serve the ever-increasing needs for oilfield operational effectiveness and reliability.

Steps in the Manufacturing Process

The construction of sucker rods involves manufacturing spans that are crucial to the efficiency of its use in oilfields:

Selection Of Materials

Materials needed for the rods’ construction require having corrosion resistance and tensile strength. Therefore, high grade steel and carbon-fiber reinforced polymers serve as good options.

Components And Processes

Excess material is added to the rod by heating the raw material to a specific temperature and using extrusion and rolling processes on it.

Heat Treatment

Undesirable variants of the rods which are sharpened into a more useful form by seasoning strengthen ribs and increase impact resistance. Heat cycles that are specifically quenched and evenly tempered provide these effects best.

Extrusion, Tools, and Finishing

Severe regarding pairs of rods outfitted with interleaving strands are precisely combined using CNC multicutter devices. During these operations, the accuracy of spacing is tightly controlled in order for a good fit to be achieved. Along with this, polish coating and other types of surface finishing treatment that lower friction and strengthen against deteriorating wear are applied.

Checking And Industries Standards

Before being classed as a full specimen, each rod must undergo ultrasonic checking, as well as verification of tensile strength and dimensional examination, ensuring proper compliance with industry standards. Check alternative options. Each validation ascertains each specimen’s integrity of no internal damage.

Storing And Deploying

Sucker rods are delivered to various oilfields and suppliers as demanded, after fulfilling the criteria of thorough strong anti-corrosion coatings.

Adopting these additional manufacturing processes is helping companies optimize the functional performance and maintenance cycles of sucker rods. Emerging market intel suggests a growing adoption of carbon-fiber reinforced polymers, which are anticipated to enhance productivity and minimize downtime, indicating an increasing focus on improvements in the sector.

Quality Control and Inspection Standards

| Key Point | Details |

|---|---|

|

ISO 9000 |

Quality Mgmt. |

|

ISO 9001 |

QMS Requirements |

|

ISO 14000 |

Env. Mgmt. |

|

ISO 14001 |

Env. Systems |

|

ISO 26000 |

Social Resp. |

|

ISO 31011 |

Risk Mgmt. |

|

ANSI/ASQ Z1.4 |

AQL Sampling |

|

ISO 2859-1 |

Sampling Std. |

What are the Advantages of Using Fiberglass Rods?

Comparing Fiberglass and Steel Rods

| Parameter | Fiberglass | Steel |

|---|---|---|

|

Weight |

Lightweight |

Heavy |

|

Corrosion |

Resistant |

Prone |

|

Tensile Strength |

High |

Moderate |

|

Load Capacity |

Moderate |

High |

|

Heat Resistance |

Low |

High |

|

Durability |

Long-lasting |

Requires Maintenance |

|

Cost |

Higher upfront |

Lower upfront |

|

Conductivity |

Non-conductive |

Conductive |

|

Flexibility |

Limited |

High |

|

Eco-Friendliness |

Moderate |

Recyclable |

Benefits of Fiberglass Rods in Corrosive Environments

- Corrosion Resistance: Glass fiber rods are fiberglass rods that possess remarkable resistance to corrosion, which makes them very useful in applications that are exposed to moisture, chemicals or salt water.

- Light Weight: Their light weight makes the transportation and installation easier as well as decreases the total structural weight.

- Durability: They are highly durable fiberglass rods and demand little maintenance from the user and so, can serve for longer periods of time under difficult conditions.

- Electrical Safety: Fiberglass rods are a safer alternative for use in employing near electrical equipment since they do not conduct electricity.

- Eco-friendliness: These rods are of moderate eco-friendliness since they are created using less energy-conserving methods and are made of recyclable materials.

- High Cost Profit Swings: Their maintenance requirements and lengthy operational lifespan cabinet lowers costs over time.

- Robotics Changes: Fiberglass rods can be crafted to the specifications of the ribs of certain projects, increasing the scope of these rods.

- Changes to structures cause these rods remain to be reliable along with the ability to withstand extreme and harsh weather conditions enables these rods fix themselves.

Understanding the Tensile Strength of Fiberglass

The fiberglass material is well known for its remarkable tensile strength, which makes it useful in construction, aerospace, and marine engineering. As for any material, tensile strength is its’ critical breaking point which it can bear tensile stress without succumbing to damage. Recent studies indicate fiberglass having a tensile strength between 345 and 3447 MPa, depending on the type of composition and manufacturing processes done. This adaptability makes fiberglass favorable in meeting the required demands for various applications where both strength and flexibility are needed.

The internal composition of fiberglass is what gives it such a high tensile strength, consisting of fine glass fibers bound together by a resin matrix. These glass fibers help counteract the fracture from tension by sharing the stress evenly. The amazing strength fiberglass composites exhibit, coupled with lightweight weight makes it favorable for diverse industrial applications, especially when demanding conditions are present. Other than the internal structure of the material, this is also supported by improvements in manufacturing processes, the efficiency, and the strength fiberglass produces has increased, giving industries additional reasons to trust the material further.

How to Ensure High-Quality Sucker Rod Performance?

Addressing Corrosion and Fatigue Issues

Protective Coatings Utilization

Applying protective coatings, notably epoxy or polyurethane, onto sucker rods can mitigate corrosion. Such coatings safeguard against moisture, chemicals, and other corrosive materials.

Implementing Corrosion-Resistant Materials

The use of stainless steel and fiberglass in sucker rod construction significantly reduces corrosion susceptibility due to the materials’ inherent anticorrosive properties.

Routine Maintenance and Monitoring

Establishing set intervals for suckers rods inspection aids in identifying surface damage and wear sooner. Timely maintenance helps curb minor problems from escalating into fatigue failure.

Cathodic Protection Systems

Engineering cathodic protection systems can mitigate electrochemical corrosion by diverting currents away from the rod and extending its life.

Minimizing Operational Stress

Avoiding excessive loads and optimal operational parameters helps reduce fatigue stress on sucker rods. Structural strain caused by overloading and nonconsistent load cycles must be curtailed.

Using Advanced Surface Treatments

Treatments like shot peening and ion implantation bolster the sucker rod surface by applying compressive stresses that resist crack formation and propagation due to fatigue cycles.

Proper Maintenance and Inspection Techniques

Thorough maintenance and inspection procedures for both proactive and reactive measures about the operational life of sucker rods are essential to mitigating failures and unplanned inefficiencies. As per the regulatory standards, checkpoints for condition monitoring and diagnostics are foundational in the prevention of operational injuries. Outlined below are foundational checkpoints to inspection and maintenance:

Visual Inspections and Nondestructive Testing (NDT)

Continuously visually inspecting the rods aids in capturing wear, rust, and impact marks across surfaces. Subsurface cracks and material defects can also be captured through NDT techniques such as dependent ultrasonic testing (UT) and magnetic particle inspection (MPI). These techniques have been shown to greatly enhance detection accuracy, with ultrasonic testing boasting accuracy performance metrics in the range of 90% to 95% for internal flaw detection.

Corrosion Management

The harsh environments associated with sucker rods are continuously degrading, impacting the suckers rods operational life due to corrosion. Protective coatings and inhibitors, along with cathodic protection methodologies, can stave off the impact certain corrosive elements would have. Recent studies have shown that epoxy-based coatings are capable of providing corrosion resistance in the range of 80%. By applying these coatings, rods can expect enhanced operational life.

Load and Stress Monitoring

Cutting-edge real time sensors with advanced load monitoring systems enable effortless tracking of all presented mechanical stressors to sucker rods. Overloaded conditions account for approximately 60-70% of fatigue-related failures in sucker rods, thus making stress analysis critical.

Consistent Lubrication

Efficient lubrication lessens wear and friction, facilitates more work performed over some time, and maintains a smooth operation throughout. Based on recent studies, use of high-grade lubricants increases efficiency by decreasing friction up to 40%, which mitigates the chances of pitting and galling.

Replacement Schedules and Record Keeping

An inspection and operational data driven predefined replacement schedule should be followed strictly. Well-kept records of the maintenance history and material costs against inspections bolster strategies based on predictive maintenance which, in turn, reduces spontaneous downtimes by 25% at most.

As of now, the performance dependability and cost-effectiveness of sucker rod operations can be considerably augmented by the use of advanced maintenance and inspection protocols and technologies juxtaposed with newer industry tools.

Innovations in Rod Pumping Systems

Being in this area professionally, I know that innovations within rod pumping systems are important for improving operational effectiveness alongside reliability. Important advancements include the use of systems that monitor operational parameters in real time, which enable identification of issues before they pose a problem, and the implementation of modern materials such as composite rods, which reduce wear and prolong service life. Moreover, automation, as well as machine learning, is being used to fine-tune pumps and improve maintenance scheduling to reduce costs during sustained periods of low productivity. All these innovations mark a remarkable improvement in the functionality of rod pumping systems.

What Challenges Do Rod Strings Face in Different Well Conditions?

Dealing with Friction and Torque

Francois,’ said Eugene, forcing himself to breathe steadily even as he clenched his fists and strained to remain still. Frances– she could be Frances now. The tricky one was interested in the furtive gleam of the eyes which were not used to the twist in the roads. Working on friction and torque means knowing how their relationship works—what decreases friction (for example, lubrication) also decreases the torque needed for a mechanical advantage.”

Impact of Load Variations on Rod String

Operational loads greatly affect the performance and life span of rod strings in different well conditions. An increase in load leads to an increase in stress for the rod string parts, which may lead to material fatigue, mechanical failure in worst cases. Vertical changes of liquid and well pressure changes can also make cyclic loads, which lead to wear.

As noted by Google recently, new concepts such as VSDs and real-time monitoring systems seem to effectively solve load variation problems. With the use of VSDs, pump rates can now be increased or decreased up to 100 % based on the load, hence relieving unnecessary tension on the rod string. On the other hand, real-time monitoring systems analytically process system data and allow operators to anticipate irregular load shifts, thereby eliminating odd patterns and improving systems’ overall stability and efficiency.

Adapting to Various Well Environments

Rod strings operate in a range of well conditions from shallow and low-pressure to high-temperature and high-pressure wells. One of the main problems to overcome is their working life in a multi-temperature and multi-pressure environment, and in the presence of corrosive agents such as hydrogen sulfide or carbon dioxide, which are characteristic of some reservoirs. To counteract these environmental factors, advanced metallurgy and protective coatings are used more often. In addition, the latest advancements in data technologies, as well as search engine algorithms like Google’s, have made available predictive analytics and simulation tools designed for optimally tailored configurations for specific challenges, which give operators out-of-the-box designs. While ensuring and leveraging the rod string systems’ performance, along with their robust performance and wear-free operation, the observer systems’ wear and operational longevity can be achieved.

What Role Does the Beam Pump Play in Oil Extraction?

Understanding the Beam System Mechanism

Sucker rod pumps, or beam pumps, are crucial in the artificial lifting mechanisms for oil extraction, particularly in old wells with diminishing reservoir pressures. Its action principle is a reciprocating motion driven by a beam mounted on the surface, which is connected to the underground pump by several sucker rods. That is the method used to elevate oil from the bottom of the well.

Using sophisticated data analytics and the latest insights from Google search algorithms, beam pump operation can be optimized. These algorithms facilitate precision adjustments to be made not only to the stroke length, but also to the pump’s rate of work and load balancing, thus worsening fluid extraction and increasing the failure rate of the equipment. Moreover, data-driven predictive monitoring enables the detection of planned maintenance activities, thereby optimizing system downtime. Advanced analytics will improve the accuracy of operational forecasting, ensuring strategic planning and improved reliability of pumping systems. Integrating these algorithms into the beam pump operation enables smarter and more environmentally friendly oil extraction.

Integration of Downhole Pumps with Beam Systems

The incorporation of beam systems with downhole pumps utilizes sophisticated data evaluation and oil extraction tracking technologies to improve efficiency. These hybrid systems continuously monitor crucial parameters like fluid levels, pump strokes, and motor activity using sensors and IoT devices. With such information, predictive algorithms can pinpoint operational shortcomings or possible mechanical issues and offer proactive solutions to modify pumping tasks. In addition, new developments in machine learning, especially when trained with extensive datasets available on Google, improve estimation and evaluation accuracy. The seamless integration of these tools greatly refines the coordination of downhole pumps and beam systems, leading to enhanced energy efficiency, longer operational life, and lower maintenance costs. Integrating such tools signifies the transition from conventional to modernized, optimized oil production.

Efficiency of Beam Pumps in Oil and Gas Extraction

Operation settings tend to have an influence on beam pumps used in oil and gas extraction, achieving operational efficiencies of 48-58%.

Frequently Asked Questions (FAQs)

Q: What is the main purpose of a sucker rod in the oil sector?

A: The main purpose of a sucker rod in the oil sector is to convey the mechanical work performed by a surface pumping unit to the downhole pump, thus permitting the artificial lift procedure to lift the oil from the well.

Q: What are sucker rods composed of to guarantee strength?

A: In order to withstand harsh oil well conditions and ensure these rods have an extended service life, sucker rods are made of high tensile alloy steel, carbon steel, or other corrosion resistant materials.

Q: Why is the rod and coupling important regarding the efficiency of a rod string?

A: The issued rods and couplings serve as a vital connection that allows the individual rods to be assembled into a continuous rod string. The thread and diameter specifications are set in a way that secures together while minimizing energy loss during the reciprocating motion.

Q: What function does the polished rod perform in the pumping unit?

A: The polished rod is part of the rod string which was withdrawn from the well and passes through the stuffing box at the wellhead. Thus, the polished rod provides the seal which assists the leak proofing and ensures no energy is lost during the transferring process.

Q: In what way does the weight of the rod string influence the pumping procedure?

A: The rod string weight greatly affects the operational efficiency of the pumping process. Proper weight optimizes the balance necessary to avoid problems such as excessive wear, rod failure, or overheating and helps streamline efficient reciprocation.

Q: Which factors come into consideration when determining the length of a sucker rod?

A: In deciding the length of a sucker rod, an operator’s input with regard to their well depth, well pumping capacity, and optimum stroke length for effective pumping is critical as it helps in accommodating varying sizes of wells.

Q: In what ways does a walking beam improve the effectiveness of a pumping unit?

A: A surface pumping unit’s walking beam assists in the effective reciprocation of the rod string. Its construction assists in proper load transfer distribution and block system overload, therefore lowering system stress and improving efficiency and durability.

Q: How does the use of corrosion-resistant materials affect sucker rods?

A: Protective materials must be used on sucker rods to ensure that mercaptan and other corrosive materials found in petroleum do not react and lead to chemical damage. Rods would have to be maintained and repaired frequently if safeguards are not put in place to extend rod life.

Q: Why is it important that sucker rods adhere to API standards?

A: API standards guarantee that sucker rods have gone through proper quality and performance evaluations, thereby assuring dependability and safety risks during oil extraction operations. It is critical for effective and efficient pumping to comply with such standards.

Q: In which ways could engineers and operators maximize the performance of a rod string?

A: Performance optimization in rod strings is achieved by attentive monitoring of equipment wear, crack detection, material selection, appropriate design lengths, diameters, and quality couplings, which further enhances performance.

Reference Sources

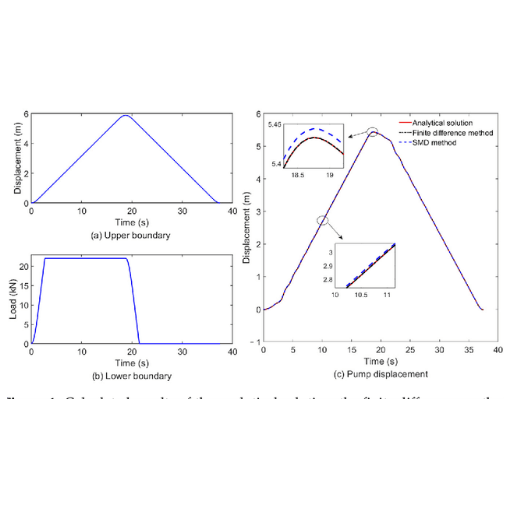

1. A Novel Approach to Behavioral Prediction of a Sucker Rod Pumping Unit Using Polished Rod Velocity Data

- By: Jiaojian Yin, Hongzhang Ma

- Published In: Mathematics

- Publication Date: April 25, 2024

Summary of Findings:

- This work proposes a polynomial model for forecasting fault dynamometer cards as a function of polished rod velocity.

- An accurate iterative prediction algorithm is described, achieving a peak relative error of 0.10% for simulated cards and 1.45% for measured cards.

Research Design:

- This study uses an analytical solution of the wave equation for a sucker rod string system together with model validation against classical finite difference method simulated cards and actual surface dynamometer cards (Yin & Ma, 2024).

2. A Mixed Approach for the Solution of the One-Dimensional Wave Equation of Tapered Sucker-Rod Strings

- Authors: Jiaojian Yin, Hongzhang Ma

- Published in: Axioms

- Publication Date: June 20, 2024

Highlights:

- It is emphasized in the study that a hybrid method, which included analytical and finite difference methods yielded high accuracy simulations.

- Testing the technique on two different oil wells confirmed the method’s accuracy with a maximum relative area error of 0.09% when compared to results obtained from traditional finite difference methods.

Methodology

- The authors create a recursive matrix form within the scope of the Fourier series for the analytical solution, along with constructing a generalized model of the pumping condition (Yin & Ma, 2024, p. 414).

3. Advanced Reliability Maintenance Intervals of Downhole Sucker Rod Strings About Sperical PCP In-line Pump Systems Operating in Extreme External Conditions

- Authors: Vora, Degtyarov, Liushev, Sh\”Shliasheva

- Published in: 14-13-2024

Takeaways:

- Enhancement of sucker rod strings in PCP systems focuses on solving numerous issues concerning MTBF, with one of the approaches achieving a two hundred percent increase over a single year.

- Altering the standards of sucker rods’ deployment and handling significantly improves machine interface interactions are vital in achieving the desired outcomes.

Research Ethodology:

- The cases studied combine qualitative interviews with quantitative surveys focusing on failure analysis and its mitigation within the components of the devices studied (Vora et al., 2024).

4. How a Sucker Rod Pump (Oil Well Pump) Works – MIT: The functioning and uses of sucker rod pumps are detailed on this MIT page.

5. A Comprehensive Review of Sucker Rod Pumps’ Components – Harvard ADS: An overview of the components of sucker rod pumps with emphasis on their related functions within the oil industry.

6. PTRM 115 – Sucker Rod Pumping – WVNCC: Course objectives from West Virginia Northern Community College on the operation of sucker rod pumping systems.