The steel plate industry plays a pivotal role across the global economy in furnishing essential raw materials for many applications. In construction, manufacturing, energy, and transportation, steel plates go into innumerable applications in other fields.

Key Insights from This Guide:

- The innovations brought by these manufacturers to the industry

- The unique offerings of each supplier that cater to different business needs

Introduction to the Steel Plate Industry

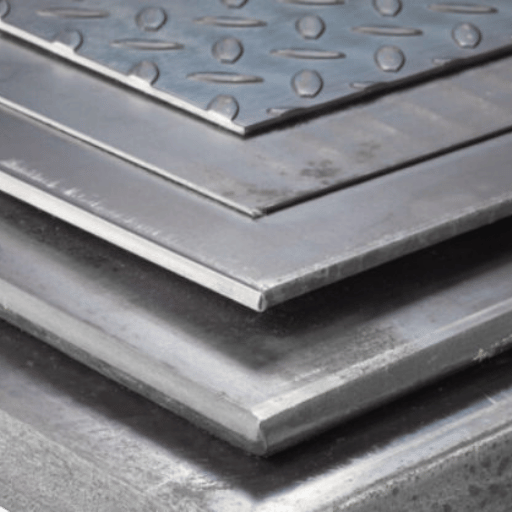

Steel making is the foundation for modern infrastructure, enabling the creation of everything from spectacular skyscrapers to bridges. It is stated by way of exposition that steel plates are available in various grades, characterized by their strength and durability, including carbon steel, alloy steel, and stainless steel. The plate industry has undergone significant evolution in recent years, particularly in terms of plate processing and production. As a result, specialized products such as abrasion-resistant plates and pressure vessel steel are now in high demand. Keeping in view the requirement for rugged and reliable materials, steel suppliers are at the forefront and continually take one step forward with advanced technology.

Overview of Steel Plate Applications

Steel plates are materials that possess a high degree of versatility in their applications. A few household industries that profane the use of steel plates include:

🏗️ Construction Sector

They serve as structural steel products, which possess excellent yield strength and corrosion resistance.

🚗 Transportation Industry

These are heavy steel plates, also referred to as stainless steel plates in some nomenclatures, and are used in vehicle manufacture, emphasizing both safety and performance.

Steel plates are widely used in various energy fields, particularly in the manufacture of pressure vessels and pipelines. These areas demand exceptional plate grades and thickness, making the availability of the right steel plate supplier quite crucial, who can provide the apt plate rolling and processing facilities.

The Role of Steel Suppliers in the Industry

Steel suppliers play a crucial role in bridging the gap between steel production and end-users. As distributors and processors, they offer a diverse range of steel plate products. Some of the main functions of steel suppliers include the following:

- From hot-rolled carbon steel plates to highly specialized alloy steel plates, they provide everything

- They also provide heavy processing, including plasma and welding processing services, to prepare steel products according to specific needs

Additionally, prominent steel supply companies have a broad geographical reach, enabling them to serve markets efficiently and effectively.

Current Trends in Steel Production

In recent years, the steel production landscape has been witnessing trends, primarily shaped by technological advancements and shifting market demands. Increasing importance is hence placed on sustainable development and the adoption of environmentally friendly practices by manufacturers, who strive to supply steel plates with minimal environmental impact. There appears to be a demand for high-strength steel and stainless steel plates, which offer better performance and longevity. Plate processing is being computerized in broad terms, with several players investing in new technologies to improve efficiency and product quality. These trends are beginning to shape the future of the steel plate industry, where innovation will be considered the cornerstone.

Importance of Selecting Top Manufacturers

Quality Assurance in Steel Products

Selecting manufacturers in the steel plate industry plays a crucial role in ensuring the quality of steel products. With leading steel suppliers, quality control is closely monitored, where steel plates are carefully controlled to conform to or exceed the industry standards, such as ASTM specifications. Manufacturers market a wide range of plate materials, from carbon steel plates to stainless steel plates, designed for high strength and reliability. By dealing with reputable suppliers, project firms have access to steel with consistent performance, enhancing project integrity.

Impact on Project Success

Selecting a steel plate supplier plays a crucial role in the success of any project, especially in industries that heavily rely on structural steel products. The quality of plates greatly determines the yield strength and corrosion resistance needed in construction, transportation, and energy projects. The supplier must collaborate with the end user to provide specialized plate grades, such as abrasion-resistant plates and pressure-vessel steel, tailored to the specific application requirements, in accordance with plate services. Being top-of-the-line also means that the supplier will prove essential for the timely and cost-effective delivery of projects.

Long-term Supplier Relationships

Long-term relationships with major steel plate suppliers yield lots of benefits for businesses. These relationships foster trust and reliability, ensuring a consistent supply of products, such as steel. These suppliers also offer advanced plate processing capabilities, including plate rolling, plasma cutting, and welding services. Equally, long-term relationships enable the company to reap benefits from the supplier’s innovations and presence in various geographical markets, which in turn encourages smooth operations across diverse markets. Continuous cooperation with a trusted supplier enables the business to stay informed about industry trends, thereby maintaining an edge in a rapidly evolving marketplace.

Factors to Consider When Choosing a Steel Plate Supplier

✓ Geographical Presence and Distribution

Geographical presence and distribution capabilities are key factors to consider when selecting a steel plate supplier. Suppliers with a wide reach, which includes some of North America’s top steel companies, can ensure that product deliveries, in this case, steel plate products, are made from various regions on time. This presence typically indicates a well-established distribution network, which is essential for developing uninterrupted supply chains and avoiding logistical challenges. Being widely located geographically, the supplier can provide plates in various grades, allowing companies to have a full range of steel products suitable for their respective needs, such as ASTM-compliant carbon steel plates or stainless steel plates.

✓ Innovations in Manufacturing Processes

Modern advancements in manufacturing processes form another essential criterion for selecting a steel plate supplier. Plasma cutting and plate rolling are examples of advanced plate processing technologies that prominent manufacturers invest in to increase their production efficiency and the quality of the work done. Thanks to such innovations, a supplier can offer a variety of plate products, including high-strength alloy steel plates and customized structural steel products. When businessmen choose a supplier equipped with advanced processing capabilities, they can obtain value-added steel plates that are engineered to exact dimensions, affording them the best operational performance and reliability in their applications.

✓ Sustainability Practices in Steel Production

Sustainability practices are becoming increasingly important for the steel industry, making it essential to choose a steel plate supplier that aligns with these practices. Top manufacturers have begun applying their eco-friendly engineering principles to reduce emissions and waste, resulting in steel plates and steel products with smaller environmental footprints. These programs are vital in aligning themselves with global sustainability goals and in response to growing demands for environmentally friendly materials. Commercial units would enhance both their corporate social responsibility profiles and their sustainability efforts by choosing suppliers committed to sustainable practices. Besides such ventures, these companies could also secure some of the finest-grade steel products, such as abrasion-resistant plates and pressure vessel steel.

Top 15 Steel Plate Manufacturers of 2025

1. Baling Steel

Year Founded: 1998

Introduction: This is a leading steel factory worldwide, renowned for producing high-quality steel plates and for its innovative production techniques.

Main Products: Steel plates for construction, automotive, and heavy machinery.

Key Advantages: High production capacity, advanced technology, and a strong global distribution network.

Disadvantages: Limited information on specific certifications.

Website: Baling Steel

2. China Baowu Group

Year Founded: 2016 (merger of Baosteel and Wuhan Iron & Steel)

Introduction: The largest steel producer globally, headquartered in China.

Main Products: High-strength steel plates, automotive steel, and construction materials.

Key Advantages: Massive production capacity and advanced research and development.

Disadvantages: Environmental concerns due to large-scale operations.

Website: China Baowu Group

3. ArcelorMittal

Year Founded: 2006 (merger of Arcelor and Mittal Steel)

Introduction: A global leader in steel production with operations in over 60 countries.

Main Products: Steel plates, automotive steel, and structural steel.

Key Advantages: Strong global presence and innovative solutions.

Disadvantages: High operational costs.

Website: ArcelorMittal

4. Nippon Steel Corporation

Year Founded: 1970

Introduction: A Japanese steel giant known for its high-quality products.

Main Products: Stainless steel plates, automotive steel, and construction materials.

Key Advantages: Advanced technology and intense focus on sustainability.

Disadvantages: Limited production capacity compared to Chinese competitors.

Website: Nippon Steel

5. HBIS Group

Year Founded: 2008

Introduction: One of China’s largest steel manufacturers.

Main Products: Steel plates, automotive steel, and construction materials.

Key Advantages: Large production capacity and diverse product range.

Disadvantages: Environmental impact concerns.

Website: HBIS Group

6. POSCO

Year Founded: 1968

Introduction: A South Korean steel manufacturer known for its innovation.

Main Products: Steel plates, automotive steel, and high-strength steel.

Key Advantages: Advanced technology and strong R&D.

Disadvantages: High competition in the Asian market.

Website: POSCO

7. Tata Steel

Year Founded: 1907

Introduction: An Indian multinational steel-making company.

Main Products: Steel plates, automotive steel, and construction materials.

Key Advantages: Strong presence in emerging markets.

Disadvantages: Limited global reach compared to larger competitors.

Website: Tata Steel

8. JFE Steel Corporation

Year Founded: 2003

Introduction: A Japanese steel manufacturer with a focus on high-quality products.

Main Products: Steel plates, automotive steel, and construction materials.

Key Advantages: Advanced technology and intense focus on quality.

Disadvantages: Smaller production capacity compared to Chinese manufacturers.

Website: JFE Steel

9. Shagang Group

Year Founded: 1975

Introduction: A leading private steel manufacturer in China.

Main Products: Steel plates, construction steel, and automotive steel.

Key Advantages: High production capacity and competitive pricing.

Disadvantages: Environmental concerns.

Website: Shagang Group

10. Ansteel Group

Year Founded: 1916

Introduction: One of China’s oldest and most established steel manufacturers.

Main Products: Steel plates, automotive steel, and construction materials.

Key Advantages: Long history and strong reputation.

Disadvantages: Limited innovation compared to newer companies.

Website: Ansteel Group

11. Outokumpu

Year Founded: 1910

Introduction: A Finnish company specializing in stainless steel.

Main Products: Stainless steel plates and specialty steel.

Key Advantages: High-quality products and a sustainability focus.

Disadvantages: Limited product range.

Website: Outokumpu

12. Jindal Stainless

Year Founded: 1970

Introduction: An Indian company specializing in stainless steel.

Main Products: Stainless steel plates and specialty steel.

Key Advantages: Strong presence in the Indian market.

Disadvantages: Limited global reach.

Website: Jindal Stainless

13. Nucor Corporation

Year Founded: 1940

Introduction: A leading American steel manufacturer.

Main Products: Steel plates, construction steel, and automotive steel.

Key Advantages: Strong focus on sustainability and innovation.

Disadvantages: Limited presence in the Asian market.

Website: Nucor

14. ThyssenKrupp

Year Founded: 1999 (merger of Thyssen AG and Krupp)

Introduction: A German multinational conglomerate.

Main Products: Steel plates, automotive steel, and construction materials.

Key Advantages: Advanced technology and strong R&D.

Disadvantages: High operational costs.

Website: ThyssenKrupp

15. Metal Zenith

Year Founded: 2000

Introduction: A Chinese company specializing in high-quality steel products.

Main Products: Steel plates, automotive steel, and construction materials.

Key Advantages: Competitive pricing and strong global presence.

Disadvantages: Limited focus on sustainability.

Website: Metal Zenith

Future Trends in the Steel Plate Industry

🚀 Emerging Technologies in Steel Manufacturing

Emerging technologies have been the driving force in the technical advancement of steel manufacture, promoting efficiency, while innovations occur in the production of steel plates. With developments in automation and digitalization,-plate processing by AI, and intelligent manufacturing systems are now becoming means of streamlining production processes and improving product quality. This has given steel manufacturers greater leverage in producing steel products that meet the ever-changing needs of industries requiring materials that are high-performance and sustainable via customization and precision.

📊 Shifts in Global Demand for Steel Plates

Global demand for steel plates has fluctuated due to varying economic conditions and changing industrial requirements. An infrastructure setup with renewable energy projects and improved transportation keeps the demand for high-strength steel products and specialized types high. The manufacturers, who must deal with these changes, will need to enhance their production technologies and expand their product range to meet the increasing and diversified demands of global markets.

🌱 Predictions for Sustainability in Steel Production

Sustainability in steel production is expected to take center stage in the near future, with predictions stressing green practices and green innovations. Manufacturers must therefore reduce their carbon footprints, use resources efficiently, and develop recyclable steel plate products. These green measures aim to meet global environmental objectives transparently, ensuring this industry secures a sustainable future while maintaining the quality standards and performance of its products.

Final Thoughts

The steel plate industry is a continuously evolving one with spectacular innovations and sustainability initiatives. By associating the peculiar forces and services from these top 15 manufacturers to their project specifications and eventual objectives, businesses can yield a working decision. If quality standards, geographical reach, technology, or environmental consciousness are essential to you, then the selection of a steel plate supplier remains imperative to your success in this competitive world.

💡 Pro Tip: When choosing a steel plate manufacturer, besides the sheer product needs, the buyer must consider the innovation premise, the supplier’s sustainability practices, and the extent to which it will contribute to the long-term survival and growth of your business.