Top 15 Steel Casing Pipe manufacturers to Watch in 2025: Updated List

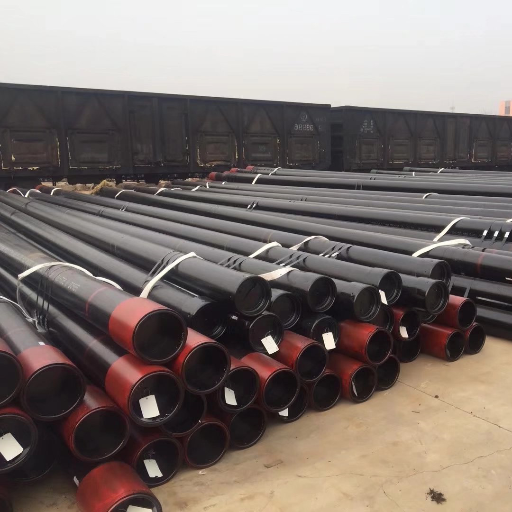

Steel casing pipes are fundamental components across various sectors, providing essential support and protection for numerous applications. Their role in industries such as construction, oil and gas, and water well drilling cannot be overstated. These pipes serve as protective barriers, encasing utility lines and providing structural integrity. Choosing the right steel pipe manufacturer will make all the difference for projects that need precision and reliability. This guide details the best steel casing pipe suppliers in the market.

Introduction to Steel Casing Pipes

Importance of Steel Casing in Various Industries

The steel casing pipes find application in many fields as they can withstand environmental challenges or physical stresses. They are mainly used in the following industries:

- Oil and Gas Industry: Casing pipes are run to encase pipelines and to protect them during drilling operations.

- Construction: Steel pipes are used to reinforce structural foundations, and in pile installations, they support large-diameter steel pipes.

- Water Well Drilling: They preserve the bore integrity and guard against contamination.

Their versatility and sturdiness have earned them a preference worldwide among contractors and engineers.

Role of High-Quality Manufacturers in Project Success

The steel casing pipe is a product manufactured by the company. Quality at this stage is acclaimed for success in any project involving steel casing pipes. A good-quality manufacturer ensures that products adhere to very stringent specifications and quality standards, guaranteeing durable and efficient constructions. To achieve such results, advanced fabrication techniques, including precision welding and custom pipe processing, are employed to manufacture products that effectively meet the specific needs of various projects. Having reputable manufacturers of steel pipes ensures increased safety, longevity, and overall project efficiency, further reducing the likelihood of costly failures or delays.

Overview of Applications and Specifications

The steel casing pipes are used for various applications, ranging from structural supports to utility protection. The specifications can vary according to the use of each casing pipe, diameter, length, thickness, and other wall thickness measuring factors, each playing a dangerous role in its operation. For instance, large-diameter steel casing pipes are required in projects where such installations need to bear much weight, while a thinner casing would be an option for lighter loads. Split casings with free coatings and precision-welded for further functional application-fitting in all areas from underground utilities to fiber optic cable encasements.

Detailed Profiles of the Top 15 Steel Casing Pipe Manufacturers

| Rank | Company | Founded | Key Advantages | Disadvantages |

|---|---|---|---|---|

| 1 | BalingSteel | 1998 | Extensive product range, international standards, customization | Limited global distribution |

| 2 | Tenaris | 2002 | Advanced R&D, global presence, high-spec products | Premium pricing |

| 3 | Metal Zenith | 2000s | Customization, strict quality control | Limited global brand recognition |

| 4 | Vallourec | 1899 | Expertise in extreme conditions, high-performance | High costs |

| 5 | Pittsburgh Pipe | 1977 | Extensive customization, 24/7 support | Focused on U.S. market |

| 6 | JFE Steel Corporation | 2003 | Superior quality, advanced technology | Limited customization |

| 7 | U.S. Steel | 1901 | Extensive distribution network | Focused on North America |

| 8 | Pipe Industries | 1979 | Expertise in large-diameter pipes | Limited product range |

| 9 | Nippon Steel | 1950 | Advanced R&D, global reach | Premium pricing |

| 10 | TMK | 2001 | Expertise in high-specification pipes | Focused on energy applications |

| 11 | Fengbao Steel | 2008 | Flexible sourcing and logistics | Limited global presence |

| 12 | Joho Steel Co., Ltd | 1988 | Competitive pricing, integrated production | Limited product diversity |

| 13 | Hengyang Valin | 1958 | High-quality seamless pipes | Limited customization |

| 14 | TPCO | 1989 | Large production capacity | Focused on energy markets |

| 15 | Baosteel Group | 1978 | Extensive product range | Limited focus on casing pipes |

💡 Quick Reference Guide

Each manufacturer listed above has been evaluated based on their product quality, market presence, technological capabilities, and customer service standards. The ranking considers factors such as innovation, reliability, and industry reputation.

Comparative Analysis of Manufacturers

Key Differences in Product Specifications

Each purchaser will need to consider these specification differences when choosing among steel casing pipe manufacturers, as the specifications significantly affect project outcomes. The specifications shall consider critical diameter, wall thicknesses, and material compositions. Some manufacturers are using large-diameter steel pipes for large-scale structural engineering projects. Some others manufacture precision-engineered pipes for underground utilities, as well as for other specific applications. Furthermore, various coatings and proprietary manufacturing processes may be employed to differentiate between product lines, thereby distinguishing their durability and optimal use in diverse environments.

Geographical Service Areas and Market Focus

The geographical service areas and market focus of steel pipe manufacturers are essential criteria for ensuring timely project completion. Some companies enjoy a firm foothold in select regions, which allows for faster delivery and installation of casing pipes. Others may extend beyond regional borders, serving international markets with applications that span from residential to industrial projects. Often, such distribution capabilities reflect their expertise in specific sectors, such as oil and gas, construction, or water utilities, allowing them to provide specialized solutions to local market demands.

Price Points and Value Proposition

The price points and value propositions presented by steel casing pipe manufacturers vary according to factors such as production costs, international customization, and technical advancements. Some manufacturers may instill price competition with their product; however, they present the efficiency that primarily envisages a short lead time as the core value proposition. Others might then venture into high-end markets, emphasizing high-grade materials, advanced fabrication, and product customizations that are affordable to a large extent. These price and value differences affect the cost-effectiveness of the entire project, making it consequential for contractors to consider these issues when choosing a supplier.

How to Choose the Right Steel Casing Pipe Manufacturer

1

Evaluating Quality Standards and Certifications

While quality standards and certifications should be given paramount consideration when selecting a steel casing pipe manufacturer, pipes that have undergone stricter quality control are generally made to exact specifications regarding thickness and diameter. International standards, such as ISO and ASTM, define the requirements under which products should be manufactured so that they can withstand severe applications, including pipeline installation and bore drilling. Contractors should prefer suppliers with proven track records in quality assurance, as quality assurance directly affects the safety and longevity of the steel casing installed.

2

Importance of Customer Service and Technical Support

Customer support and technical support are indispensable when selecting a steel casing pipe supplier. Good manufacturers should maintain robust support systems and ensure that contractors receive installation guidance, specification clarifications, troubleshooting assistance, and other forms of support. This service should then be used as a tool to ensure that any given project does not experience delays and other impediments. From their own ability to find technical support the instant it is needed, as well as the giving of custom solutions, on the other hand, basically communicate-out from the respect they hold for customer satisfaction and ensuring the successful completion of their projects that require technical know-how, most especially in application areas such as pipe ramming and auger boring.

3

Assessing Lead Times and Inventory Management

Proper inventory management and the availability of products constitute major time windows that are crucial in maintaining project schedules. Having a manufacturer with a vast inventory is always essential, so that both standard and uncommon pipe solutions can be quickly delivered to minimize their waiting time. This is of utmost importance when the project is time-sensitive and involves the installation of large-diameter steel pipe or split casing. Evaluating a supplier’s capacity to maintain an adequate inventory and adhere to a reliable delivery schedule can significantly improve project efficiency, as materials are readily available when needed, thereby minimizing downtime and its associated costs.

Conclusion: Insights and Future Trends in the Steel Casing Pipe Industry

📋 Summary of Key Points

In short, selecting an appropriate steel casing pipe manufacturer means carefully considering what quality standards they abide by, their customer service, and their inventory handling practices. The right vendor will be able to supply top-quality products and assemblies to meet exact project specifications while providing great service and honoring time schedules as promised. These factors together ensure quality installation and the durability of steel casing applications-from utilities to large-scale industrial works.

Market Trends and Innovations

The steel casing pipe industry is undergoing a primary innovational phase, including in fabrication methods and material coating. Manufacturers are using more modern technology, which include precision welding and custom processing, to enhance product performance. Eco-friendly and corrosion-resistant coatings have also gained popularity as pipe linings to extend the pipe’s lifespan in harsh environmental conditions. These events are a testament to the growing need for sustainability and durability in modern infrastructure projects.

🔮

Final Thoughts for Informed Purchasing Decisions

To successfully grasp the steel casing pipe market and complete a purchase, one must comprehend the vendor’s capabilities and the trends impacting the industry. Contractors and engineers should opt for suppliers that offer custom solutions with excellent technical support and efficient logistics. Thus, the project further benefits from recent innovations, combining tried and tested performance with successful and durable installations. Such a strategy gives the stakeholders because of the steel casing pipe industry.

This comprehensive guide provides you with the essential information needed to make an informed decision when selecting steel casing pipe manufacturers for your next project.