Steel is the backbone of a number of industries, and for special applications, API steel becomes a must-have material that meets high-performance environment demands. But: what is the meaning of API steel, and why is it of major importance to the oil and gas, construction, and transportation sectors? This guide intends to explore the Steel APIs in its depths while getting into their properties, classifications, and understanding why they are considered essential in industries demanding strength and precision. Whether you’re an experienced professional looking for ways to use the right materials for your projects or simply want to learn about all those different roles API steel plays in our world, consider this complete guide your partner with clues. Basic understanding of their characteristics leads to detailed applications, so start your exploration of the API steel working world here.

Introduction to Steel APIs

Steel APIs, or steel parameters set up by the American Petroleum Institute, set specifications for materials used in more industry types such as oil and gas, construction, and manufacturing. These standards certify that steel meets very high standards concerning strength, durability, performing in extreme conditions, to name a few. API steel grades are generally to be found in pipelines, pressure vessels, and structural applications; that is why these are high-priority requirements in any project concerning safety and reliability. The API standards ensure manufacturers that produce consistent-quality products suited for critical industries.

What is an API Steel?

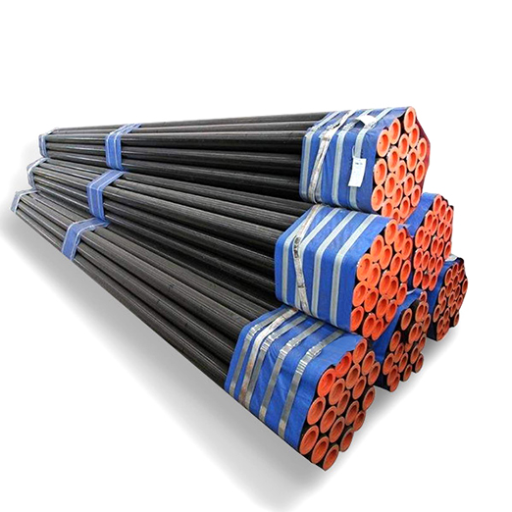

API steel refers to steel that meets the strict requirements and standards set by the American Petroleum Institute (API). These steel grades are designed to meet the complex demands of the oil, gas, and energy industries, affording excellent performance and reliability in severe environments. The API steel grades, like API 5L and API 5CT, allow for the construction of pipelines, pressure vessels, casing, and tubing for the reliable and efficient transport of energy and energy storage.

Enhanced mechanical properties are one of the main aspects of API steel. For example, API 5L steel has two product specification levels, PSL1 and PSL2, which differ in their performance and testing requirements. PSL1 is a standard quality level, whereas PSL2 imposes tighter specifications for toughness, chemical composition, and mechanical properties. Another high-grade API steels of great tensile strength, corrosion resistance, and weldability are X42, X52, X60, etc., making them appropriate for high-pressure and long-distance pipeline systems.

API specifications also stress impact testing and fracture toughness, which are an essential consideration in challenging environments where steel is subjected to low temperatures or high stresses. Modern manufacturing of API steels uses state-of-the-art metallurgical methods, including microalloying and controlled rolling, to make the steels able to bear the dynamic loads and rigors of operating conditions.

By complying with API standards, these steel products stand on the world’s infrastructure in some of the most demanding industries, ensuring safety, efficiency, and durability.

Overview of the American Petroleum Institute (API)

The American Petroleum Institute (API), on a broader spectrum, is a trade association that has historically provided its users with inputs into optical strategies, safety regulations, and technical developments. Established in 1919, API widely enjoys more than 100 years of expertise in writing standards that explain operational excellence and pride themselves equally on environmental sustainability. Presently, it represents more than 600 member companies spread across industries such as exploration, production, refining, and distribution.

The API serve as the real backbone to promulgating industry standards through the more than 800 technical codes and standards that are in use, not only across North America but basically by every energy producer across the globe. The range of standards covers practically all relevant aspects, from equipment and offshore safety to operational efficiency and emission controls. In this direction, the API 610 standards have become universally accepted for centrifugal pumps in refineries and other heavy-duty industrial processes.

In the front line of the Institute is sustainability and emission reduction. The Institute was involved in defining the carbon capture, utilization, and storage (CCUS) framework and has been a major advocate for methane emission reduction schemes for oil and gas operations. Measurable results have been brought about in reducing greenhouse gas emissions, especially in industry projects run under API standards, as recent studies and data suggest.

API also presses considerable importance on development of the workforce, so that with training and certification programs it ensures that industry personnel can face the challenge of change. The API Individual Certification Programs (ICP) is an example of an initiative focused at upgrading the skills and knowledge of people in vital operational functions.

By virtue of the API’s leadership in innovation, safety, and sustainability, it remains a fundamental pillar on the road to achieve global energy excellence.

Importance of Steel APIs in the Industry

Steel APIs (Application Programming Interfaces) have become increasingly critical to industrial processes these days, accelerating processes to improve efficiencies and allowing innovations to take place in diverse fields such as construction, manufacturing, and energy. These interfaces provide standardized systems for the smooth communication among various machines, systems, and software applications promoting interoperability and reducing operational silos in operations.

Steel APIs are highly relevant when it comes to the application areas of quality assurance and testing. In real-time data exchange, Steel APIs enable automated assurance of requests such as measurement of properties on raw materials and materials like tensile strength, hardness, corrosion resistance, and ensuring that the product conforms to industry standards like ASTM International and ISO certifications. Industry reports revealed that the metalworking market, including API-supported businesses, is expected to rally in prominence, driven by the increasing demand for precision and high-grade materials in aerospace and renewable energy fields.

Steel APIs also support sustainability efforts and improved resource management. The use of data analytics allows organizations to maximize their processes, minimizing waste production, which is in alignment with sustainability programs and reducing its carbon footprints. The steel-making industry itself accounts for nearly 7% of all global greenhouse gas emissions, underscoring the need for increased use of Steel API technologies for improved efficiencies and greener practices.

Enhanced predictive maintenance, inventory management, and supply chain visibility enabled by Industry 4.0 technologies now see dynamic assistance from Steel APIs, facilitating innovations and competitiveness of stakeholders in the treacherous global market, where such actors, from manufacturers to end users, need to swim side-by-side together.

Types of Steel and Their Grades

Steel is categorized into four main types: carbon, alloy, stainless, and tool steel, each with specific grades for various applications.

| Type | Grades | Use | Strength | Cost |

|---|---|---|---|---|

|

Carbon |

Low/Med/High |

Construction |

Moderate |

Low |

|

Alloy |

Various |

Machinery |

High |

Moderate |

|

Stainless |

304/316 |

Corrosion Res |

High |

High |

|

Tool |

HSS/D2 |

Cutting Tools |

Very High |

High |

Carbon Steel and Its Applications

Carbon steel, one of the most commonly used steels, is basically made out of iron and carbon, with other elements being added in varying quantities to get the required properties. It is divided into three classes according to the carbon content: low carbon steel (mild steel), medium carbon steel, and high carbon steel.

Low Carbon Steel (Mild Steel): With a carbon percentage of 0.05 to 0.25, it is very malleable and ductile and thus can be used for pipes, body panels for automobiles, and structural shapes, among others. It is preferred to be welded and relatively cheaper for industries where large value of materials is being used.

Medium Carbon Steel: Having a carbon content between 0.25 and 0.60, this steel has an intermediate balance between strength and ductility. Due to its strength and wear resistance, medium carbon steel is often used for forging machine parts and gears as well as for train rails.

High Carbon Steel: With carbon content from 0.60 to 1.25%, high carbon steel is hard and resistant to abrasions. It is used for cutting tools and blades, springs, and high-strength wires, where it is important to maintain rigidity and durability.

In the world, more than 70% of total steel production is carbon steel, with usage in areas such as construction, transport, and energy. The latest data from AISI seems to suggest that steel production continues to follow infrastructure due to its cheap and versatile nature. Carbon steel is recyclable, thus being very important for constructing sustainable solutions in the future.

Understanding API 5L and its Variants

API 5L includes seamless and welded pipes, categorized into PSL1 and PSL2, with variants like X42, X52, X60, X65, and X70 for oil, gas, and water transportation.

| Aspect | PSL1 | PSL2 |

|---|---|---|

|

Type |

Basic |

Advanced |

|

Grades |

X42-X70 |

X42-X70 |

|

Process |

Seam/Weld |

Seam/Weld |

|

Use |

Oil/Gas/Water |

Oil/Gas/Water |

|

Strength |

Standard |

Higher |

Key Steel Grades: API 5L X52 and API 5L X65

API 5L X52 and X65 are steel grades used in pipelines, with X65 offering higher strength and alloy content compared to X52.

| Aspect | X52 | X65 |

|---|---|---|

|

Strength |

Moderate |

High |

|

Alloy |

Lower Content |

Higher Content |

|

Use |

Standard Pipelines |

High-Pressure Use |

|

Cost |

Lower |

Higher |

Corrosion Resistance in Steel APIs

Corrosion-resistant steels, such as API 5L grades, must be durable and perform well in harsh atmospheres. They are usually treated and coated to defend against moisture, chemicals, and temperature extremes. Various alloying elements, including chromium, molybdenum, and nickel, also enhance their corrosion resistance. Improvements in protection technology, such as polyethylene coatings and fusion epoxy coatings, add a longer life to steel pipelines. Corrosion-resistant steel has proved to be a more dependable and cost-efficient solution to critical infrastructure and industrial applications.

Factors Contributing to Corrosion

Corrosion is a complex process influenced by various environmental and material-based factors. Understanding these factors can help in mitigating the risks and prolonging the lifespan of materials like steel. Below is a detailed list of significant factors contributing to corrosion:

- Environmental Conditions

- Moisture and Humidity: High levels of moisture in the air accelerate the oxidation process, particularly in environments with prolonged exposure to water or high humidity.

- Temperature: Extreme temperatures, whether excessively hot or cold, often increase the rate of chemical reactions. Elevated temperatures can especially speed up corrosion in metals.

- Pollutants: Industrial areas with high concentrations of sulfur dioxide or chlorides in the air, such as near marine environments or factories, contribute heavily to corrosion.

- Material Composition

- Surface Condition: Imperfections on the material’s surface, such as scratches or poorly treated coatings, create vulnerable points for corrosion to initiate.

- Chemical Properties: The composition of the metal, including the presence of impurities or lack of protective alloying elements, impacts its resistance to corroding agents.

- Electrochemical Factors

- Electrolytes: The presence of conductive substances like saltwater provides an effective medium for electrochemical reactions to occur, accelerating corrosion.

- Galvanic Coupling: When two dissimilar metals are in contact in the presence of an electrolyte, galvanic corrosion may occur, with one metal corroding faster than the other.

- Design and Construction

- Poor Drainage: Structures that trap water or allow stagnant pools to form increase the risk of corrosion.

- Welded Joints: Improperly treated welds can be susceptible to higher corrosion rates due to structural inconsistencies.

- Operating Conditions

- Chemical Exposure: Pipelines, tanks, or industrial equipment that transport or store corrosive chemicals are at higher risk.

- Mechanical Stress: Combined mechanical and corrosive forces, such as in stress corrosion cracking, can lead to material failure.

Understanding these contributing factors is crucial for implementing effective strategies such as protective coatings, controlled environments, or advanced corrosion-resistant materials to mitigate risks. Statistical studies show that corrosion-related damages account for approximately $2.5 trillion annually worldwide, underscoring the importance of proactive measures.

Comparative Analysis of Corrosion Resistance in Steel Grades

Grades of steel exhibit varying degrees of corrosion resistance depending on chemical composition, surface treatment, and environmental exposure. From its chrome content of at least 10.5%, stainless steel earns the highest corrosion resistance; the chromium forms an oxide film on the surface and acts as a barrier against oxidation. Amongst stainless steels, austenitic types 304 and 316 are well known for corrosion resistance. Because of the presence of molybdenum, Type 316 withstands pitting due to chlorides better than others and is therefore frequently chosen for marine or high-salinity environments.

On the other hand, the lower-intermediate range of steel grades, such as carbon steel, lack the protective features of stainless steel and tend to rust and wear unless treated by paints or inhibitors. Data reveal that corrosion of untreated carbon steel can go up to 250 µm per year, and on the contrary, stainless steel was almost unaffected by similar conditions due to the existence of a passive layer on the surface.

More recently arisen duplex stainless steels are the one that resides between austenitic and ferritic microstructures. With hybrid microstructures, improved strength and corrosion resistance, and resistance to stress corrosion cracking, duplex steels are gaining more importance in oil and gas industries. For example, grade 2205 duplex offers almost twice the strength of standard austenitic stainless steels whilst retaining the highest resistance to pitting and crevice corrosion.

Bringing together these performance-based differences, it is obvious that the selection of materials is highly dependent on the working environment intended. For cost-savings, durability, or even-for hard service, bothering about such little differences existing in steel grades is necessary for long-term performance and asset protection.

Importance of Corrosion Management

Corrosion management is one of the major factors for the preservation of infrastructure and operational assets and maintaining their integrity and safety. Every year, industries on every continent suffer huge economic losses due to corrosion endangering infrastructure, with the global cost of corrosion estimated to exceed $2.5 trillion per annum or about 3-4% of global GDP. Apart from alleviating this financial burden, effective corrosion management also guarantees environmental sustainability and operational reliability.

One significant dimension of corrosion management involves strategies to prevent corrosion, including the use of protective coatings, cathodic protection, or corrosion-resistant materials like duplex stainless steels. If applied correctly, these measures lead to fewer maintenance requirements as fewer equipment and structure failures are considered within the design life. By way of illustration, it is reported that maintenance arising from corrosion can be reduced by 40% with the application of either advanced protective coatings or one of the cathodic protection systems.

Also, real-time monitoring and analysis techniques are now at the heart of corrosion management with a proactive tilt. Modern monitoring systems that use sensor networks together with artificial intelligence and data analytics help detect the onset of corrosion so that remediation measures can quickly be applied. Oil and gas, marine, and chemical processing industries have thereby adopted these technologies for enhanced asset performance and reduction of unexpected failures.

The corrosion management system also protects the infrastructure from breaking down and becoming unsafe due to potential failures or unsafe breaches in the containment of materials. A combined approach applying advanced materials, technologies for monitoring, and preventive measures can, under good service life design practices, lead to huge cost savings while giving long-term durability and environmental protection.

Applications of Steel APIs in Pipeline Construction

Steel APIs are primarily used in pipeline construction for transporting oil, gas, water, and other fluids in onshore, offshore, and distribution networks.

| Application | Details |

|---|---|

|

Oil Transport |

Onshore/Offshore |

|

Gas Transport |

Distribution |

|

Water Transport |

Power Systems |

|

Fluid Transport |

Industrial Use |

Role of API Steel in Oil and Gas Pipelines

API steel is an integral material in building and sustaining oil and gas pipelines, in effect forming the backbone of energy transportation infrastructure. These materials stand apart due to a high strength-to-weight ratio that makes them relevant in handling pipeline stresses that involve high pressure and environmental effects. Hence, the grades such as API 5L X42, X52, X60, and X70 have been widely used for their better mechanical properties and ability to withstand extreme working conditions, including high pressure, temperature variation, and corrosive environment.

These modern types of API steels have metallurgic properties so carefully designed to achieve a reasonable balance between toughness and weldability, thereby eliminating cracking and fractures. For example, studies reveal that high-strength steel pipelines are able to transport hydrocarbons at pressures upward of 2,000 psi, much more efficiently than traditional materials. Among other TMCP-related innovations are those that permit the production of thinner but stronger steel plates, thus helping to lower materials and transportation costs.

API steel also has corrosion resistance properties. Coating systems and advanced corrosion-resistant metal claddings may extend the life of pipelines by decades. For example, pipelines of API 5L grades with protective coatings have been said to operate safely for over 30 years in severe environments, offshore or arid regions, with little to no maintenance.

Building of specific pipelines with API steel supports other sustainability targets. Lightweight but durable steels cut down carbon emission from transport and reduce material wastage, hence leading towards greener energy projects. As the global oil and gas activity continuously moves to harsher and relatively remote locations, API steel ensures that the pipelines are still efficient, safe, and environmentally friendly.

Casing and Tubing: Specifications and Uses

Integral elements of well integrity and fluid transportation, casing and tubing are fundamental to the oil and gas industry. Casing stabilizes the wellbore, preventing its collapse as the drilling progresses, while tubing provides a safe and efficient conduit for hydrocarbons to reach the surface. Both are rigorously specified to meet industry demands and safety standards.

Casing is manufactured in several grades such as H40, J55, N80, and P110, with each set to more specific parameters of depth, pressure, and environment. For example, the P110 casing is usually used in HPHT wells because of its high strength and corrosion resistance. The outside diameter of casing varies according to the well design, with standard sizes starting around 4 ½ inches to well above 20 inches- effectively providing a wide range of options for various applications.

Tubing receives a somewhat smaller diameter between 1 ¼ inches and 4 ½ inches, and usually the optimum diameter is selected to match the production flow rate or the pressure in the well. The selection of tubing material may be based, among other aspects, on the type of reservoir and possible exposure to corrosive media; carbon steels and high chromium alloys are among the materials in most common use. Threading with very good precision is likewise a key factor to ensuring tightness and system integrity, either API round threads or premium thread connections being used.

The further evolution of casing and tubing reliability and performance arose from new materials and manufacturing technologies. Microalloyed steels and high-tech protective coatings brought casing and tubing to new levels of corrosion, wear, and environmental resistance. These developments help in deepening and making wells more complex with safety and operational efficiency.

Advantages of Using Steel Pipe in Pipeline Infrastructure

Pipe Steel is a foundational structure for modern pipeline infrastructure, endowed with supreme durability, versatility, and cost-effectiveness. They are capable of withstanding extremely high pressure, temperature, and harsh environmental conditions in order to safely transport oil, gas, water, or other materials of importance over long distances.

A notable advantage of steel pipes is that they have an excellent ratio between strength and weight. Steel pipes can withstand enormous pressure exerted internally without breaking or compromising their structural integrity. Hence, they leak less or not at all, thus averting any hazardous situation. For instance, high-strength steels grades X70 and X80 were determined by research to show a yield strength ranging from 70,000 to 80,000 PSI, thereby making them suitable for high-pressure applications for the so-called energy transportation.

Steel also offers resistance to impact from external forces, which may comprise ground shifts, or seismic activities, hence safeguarding and enhancing the longevity of the system. Also, with modern coatings and treatments available for steel, such as epoxy coatings and cathodic protection systems, its resistance is even greater against corrosion. These kinds of engineering extend the life of pipes greatly, with many pipeline systems designed to operate at a satisfactory efficiency for at least 50 years.

Concerning economics, these steel pipelines render value for life. The installation cost would normally be more compared to other materials; however, due to less maintenance required by steel pipes and longer service life, it costs less in operational aspects in the course of time. In addition, steel pipes are very recyclable, so their environmental impact is minimal, which goes hand in hand with sustainability goals.

In addition to this, steel pipes allow for design and construction flexibility. They can be produced in an array of sizes, diameters, and wall thicknesses, allowing them to be tailored to the specifications required for a specific project. This flexibility assures that steel construction can maintain even complex networks that involve deepwater and cross-country systems, thus cementing their role within global infrastructure.

Last but not least, the worldwide availability of steel, coupled with the continuous innovations in steel pipe technology, ensures steady supply chains and better performance to cater to the changing industrial requirements worldwide. Putting all these factors together means that steel pipes make an unrivaled option for dependable, efficient, and green pipeline solutions.

Benefits for Developers and Businesses

Steel pipes grant developers and businesses the reliability, operational and time efficiencies, and durability needed for long-term projects. Their strength and resistance to corrosion ensure minimal maintenance and project downtime, which is just another name for operational costs. The versatility of steel pipes across so many different industries, including construction and energy, makes it possible for companies to address various project requirements on time. Moreover, new developments in steel pipe technologies mean that steel pipes meet contemporary safety and sustainability requirements, encouraging environmentally friendly practices without sacrificing functionality. The above benefits highlight the fact that steel pipes present an attractive, pragmatic, and economic proposition for both developers and business entities.

Cost-Effectiveness of Using API Steel

API steel is famous for its high strength and durability property prices, which count against industries. Since it possesses relatively higher mechanical properties, less steel is ordinarily sufficient to deliver the required performance, thus saving procurement costs without compromising safety or quality standards. Furthermore, high corrosion resistance leads to a decrease in periodic maintenance and renewals, thereby reducing operational and repair costs over the years.

According to industry reports, API steel-A-grade oil and gas materials have longer usage lives and, therefore, lead to much savings in terms of lifecycle costs. For instance, the greater service life of pipelines made from API 5L-grade steel helps in optimizing operations by reducing downtime and repair requirements, which is translated into the operating cost reduced by 20 to 30% over a number of years.

Apart from this, production and design flexibility of API steel also leads to resource optimization. In short, with improvements in manufacturing methods-from high-frequency welding to new thermal treatments-there is now a guarantee that a high-grade product will be produced at a reasonable cost while adhering to industry intervals. All these factors tone API steel as an environmentally friendly and economically feasible option for numerous applications.

Enhancing Pipeline Integrity with API Standards

When it comes to pipeline integrity, API standards serve an equally important function as a thorough set of norms concerned with safety, reliability, and efficiency. From my perspective, adherence to these standards ensures that pipelines are designed, built, and maintained with the utmost precision and quality. When there are problems about the best materials to be used, the suitable welding techniques to be applied, or how to prevent corrosion, I always refer to API standards for solutions to ensure optimum pipeline performance and long operational life. These standards are key; they become my tools in pursuit of pipeline safety and durability.

Long-Term Benefits of API Compliance

Long-term reliability and safety in pipeline operations are achieved when API compliance is met. By following the regulations, I minimize risks while saving on the maintenance of infrastructure and extending the overall life of the infrastructure. This assurance of operational efficiency enhances my ability to confidently adhere to industry standards while protecting the environment and its resources.

Future Trends in Steel APIs

The future remains bright for steel APIs in sustainability, performance, and adaptability. On the innovation side, advanced alloys are being developed that increase strength while reducing weight in accordance with energy efficiency. From here, installation of sensors for real-time monitoring of operational performance is increasingly considered with the aim of achieving a safe and efficient working environment. Other sustainability initiatives are targeting a green manufacturing process from a viewpoint of reduced carbon footprint in steel production. Hence this set of trends is meant to have stepped in to serve the ever-changing demands of the industry while concurrently addressing emerging environmental and operational levees.

Innovations in Steel Production and Technology

Steel production remains subject to deep changes due to the dual imperatives of performance optimization and environmental sustainability. Among these changes, perhaps the most dramatic one has been the development of hydrogen-based direct reduction (H2-DR) technology. This method replaces the carbon-intensive processes with the use of green hydrogen as a reducing agent, thus greatly reducing CO₂ emissions from steelmaking. Studies suggest that this in itself can account for up to a 90% decrease in emissions with respect to the blast furnace approach.

AI and machine learning-based solutions are another big area of development for incorporation inside steel plants. From an operational point of view, this involves real-time data analysis for process controls, predictive maintenance, and quality control. For example, AI can now be deployed in production to optimize furnace operations or to identify a hardware failure long before it actually occurs; thus, significant reductions in downtime and operational costs can be realized.

Much progress is being made in the field of electric arc furnaces to improve energy efficiency and recycling capacity. The advances in EAFs now allow for scrap steel recycling more efficiently with less energy consumption to produce high-quality steel, thereby rivaling virgin material. This change has helped further global initiatives toward enhancing the circular economy in the steel industry.

Material science development has also unlocked advanced grades of steel like high-strength steel alloys with improved strength and toughness. These materials are especially critical in automotive industries where manufacturers want to cut down on vehicle weight yet provide the safety standards.

Taken together, these innovations represent the steel industry’s commitment to advancement on the sustainability, efficiency, and technological excellence fronts. Every leap has given this industry a more competitive edge and has aligned it for a greener and sustainable future.

Impact of Environmental Regulations on Steel APIs

Environmental policies affected drastically the shaping of the establishment and provisions for steel application programming interfaces (APIs) that allow the industry to align with sustainability requirements. Hence, these laws provide impetus for steel manufacturers and software developers to focus on processes that reduce carbon emissions, energy consumption, and waste. For instance, with the adoption of the European Union’s Carbon Border Adjustment Mechanism (CBAM) and the further refinement of emission control standards, the practice has been directed toward including green features for steel APIs. Such APIs are now being deployed to track material use efficiency and other environmental impact parameters as well as wire energy use effectiveness into the production process.

Decarbonization on a global scale has also brought further innovation. Recent studies describe the steel industry as responsible for around 7-9% of total emissions of CO2 worldwide; hence the dire requirement for better methods and tools. APIs have been positioned at the forefront, increasingly enabling data-driven decisions aimed at supporting the assessment and measurement of the consequences of strict environmental regulations. Manufacturers use APIs for real-time data reporting of their main areas of operation to better optimize operations in meeting their emissions reduction targets. Also, the adoption of digital twin technology through steel APIs is creating proxies for actual happenings to a higher degree of forecasting accuracy in the assessment of environmental impact.

The industry-response here has been promising, with heavy investments in API-supported collaborative platforms that promote transparency in environmental reporting. A prime example is the ever-growing integration of blockchains within APIs to pave the pathway for carbon accounting transparency across the steel supply chain. Through such tools, companies are able to brand their sustainability data in a verifiable manner, an imperative step for partnership solicitation and remaining competitive.

Having said that, with the synthesis of environmental regulations and technological innovation in steel APIs, the scene has been set for a major shift toward sustainable industrial practices. These digital solutions are nudging the world toward a cleaner future, balancing their existential functionalities with compliance requirements and maintaining an industry-efficient organization in the steel domain.

Predictions for the Future of Pipeline Steel

The future pipeline steel will increasingly be concerned with sustainability, resilience, and advanced technology integration. One important trend is the continuing development of HSLA steels. They are designed to resist heavy operating pressure and harsh environmental conditions while conserving energy and cost in materials. It has been found from studies that HSLA steels potentially provide better pipeline performances and favor greener practices since less energy is required when they are produced and transported.

One key development in this regard is the installation of more advanced monitoring systems. At the forefront is the upscaling of smart pipelines with IoT-enabled sensors giving health status updates relating to structural integrity, flow rates, and leakages in real time. Such an approach also enhances from a safety perspective and operational efficiency. For instance, an advancement in AI-driven predictive maintenance programs could reduce the number of failures by 30% at least, which would in turn reduce both operational downtime as well as potential environmental hazards.

There is also an increased focus on hydrogen-compatible pipeline materials. Hydrogen is often seen as an essential player in the renewable-energy transition, and it offers special challenges-a very notable one being material embrittlement. Advanced pipeline steels that could safely transport hydrogen will be a crucial factor in ensuring its large-scale commercial application. According to recent studies by the industry, by the year 2030, it is expected that hydrogen pipelines could constitute most of new infrastructure investments, mark a key transition in energy transportation.

Also, stricter environmental regulations will fuel the pursuit of carbon-neutral steel production. Increased development will take place in DRI processes using green hydrogen and harnessing CCUS technologies. Industry report data indicate the will to strongly establish these approaches could reduce CO2 emissions in steel production by up to 90%, greatly contributing to global decarbonization goals.

The pipeline steel industry will thus be shaped by these technological developments, material innovations, and sustainability efforts, ensuring it remains a viable option to take care of challenges posed by a rapidly unfolding energy landscape, thus affirming its environmental and economic priority.

Reference Sources

1. Effect of High-Frequency Electric Resistance Welding (HF-ERW) Parameters on Metallurgical Transformations and Tensile Properties of API X52 Microalloy Steel Welding Joint

- Authors: M. Sabzi et al.

- Published: July 20, 2023

- Journal: Archives of Metallurgy and Materials

- Key Findings: This study investigates how different parameters of the HF-ERW process, such as frequency, compression force, and Vee angle, affect the mechanical properties and metallurgical transformations of API X52 microalloy steel welding joints. The optimal parameters were found to yield the best mechanical properties.

- Methodology: The authors conducted experiments by varying welding parameters and prepared samples for tensile and Charpy impact tests to evaluate the mechanical properties of the welded joints(Sabzi et al., 2023).

2. Electrochemical Frequency Modulation, Electrochemical Noise, and Atomic Force Microscopy Studies on Corrosion Inhibition Behavior of Benzothiazolone for Steel API X100 in 10% HCl Solution

- Authors: I. Danaee, P. Nikparsa

- Published: August 14, 2019

- Journal: Journal of Materials Engineering and Performance

- Key Findings: The study evaluates the corrosion inhibition efficiency of benzothiazolone on API X100 steel in hydrochloric acid. The results indicate that benzothiazolone effectively inhibits corrosion, with the adsorption process following the Langmuir isotherm model.

- Methodology: The authors employed electrochemical techniques, including potentiodynamic polarization and electrochemical impedance spectroscopy, to assess the corrosion behavior and inhibition efficiency(Danaee & Nikparsa, 2019, pp. 5088–5103).

3. Hydrogen-Accelerated Fatigue of API X60 Pipeline Steel and Its Weld

- Authors: Lorenzo Etienne Faucon et al.

- Published: March 10, 2023

- Journal: Metals

- Key Findings: This research investigates the effects of hydrogen on the fatigue life of API X60 pipeline steel and its welds. The study found that hydrogen significantly reduces the fatigue life, particularly in weld metal, and highlights the importance of assessing existing defects in pipelines intended for hydrogen transport.

- Methodology: The authors developed an in situ testing setup to measure crack initiation and growth under hydrogen charging conditions, using direct current potential drop (DCPD) techniques(Faucon et al., 2023).

Frequently Asked Questions (FAQs)

What is the API 5L X52 Steel Specification?

The API 5L X52 steel specification outlines the requirements for line pipes used in the transportation of oil and gas. This grade is known for its excellent mechanical properties, including high yield strength and good weldability, making it suitable for various pipeline applications.

How Does Corrosion Affect Pipeline Steel?

Corrosion can significantly impact the integrity of pipeline steel, leading to reduced lifespan and potential leaks. Proper selection of materials, such as using API steel grades with corrosion-resistant properties, is essential for maintaining the safety and functionality of pipelines in harsh environments.

What Are the Mechanical Properties of API 5L X70?

The mechanical properties of API 5L X70 steel include high tensile strength and yield strength, which make it ideal for high-pressure applications in the oil industry. This steel grade is designed to withstand severe conditions while maintaining structural integrity.

What is the Importance of Heat Treatment in Steel Pipe Production?

Heat treatment plays a crucial role in enhancing the mechanical properties of steel pipes, including API X52 and API 5L X80 grades. It helps to improve the hardness, strength, and ductility of the steel, resulting in better performance in pipeline applications.

What Types of Casing and Tubing Are Used in Oil and Gas Wells?

Casing and tubing used in oil and gas wells typically include API 5CT steel products, which are designed for durability and resistance to corrosion. These materials are essential for maintaining well integrity and ensuring safe extraction of resources.

How Do Seamless Pipes Compare to Welded Pipes?

Seamless pipes are manufactured without any welds, providing better resistance to pressure and corrosion compared to welded pipes. This makes seamless pipes, particularly those conforming to API standards, preferred for critical applications in the oil and gas industry.

What Grades of Steel Are Commonly Used in Pipelines?

Common grades of steel used in pipelines include API 5L Grade B, API 5L X65, and API 5L X80. Each grade has specific mechanical properties and applications, ensuring optimal performance based on the pipeline’s requirements.

What Is the Role of ASTM Standards in Steel Manufacturing?

ASTM standards play a pivotal role in steel manufacturing by providing guidelines for the quality, performance, and testing of steel products, including API steels. Adhering to these standards ensures that materials meet industry requirements and safety regulations.

How Do Hydrogen Gas Effects Impact Pipeline Steel?

Hydrogen gas can cause embrittlement in pipeline steel, particularly in grades not designed to handle such exposure. Understanding the effects of hydrogen on steel, including those specified by API standards, is crucial for maintaining pipeline integrity in environments where hydrogen is present.