Steel pipes are used in almost every industry because they are tough, strong, and sturdy enough to handle a variety of work. There are many kinds of steel pipes, but Schedule 80 pipes are especially notable because of the thickness, tolerance to increased pressure, and ability to withstand demanding conditions. This article contains the basic factors that justify the advantages of using Schedule 80 steel pipes for current construction and engineering processes.

What is Schedule 80 Pipe?

The schedule 80 pipe can be made using either steel or PVC. Its distinctiveness stems from the fact that its walls are thicker compared to those of schedule 40, lending it greater toughness or durability. Such pipes are ideally suitable for applications and processes that involve, among other things, high pressures in such sectors as construction, industry, and chemical processing. If thicker walls mean that an object is less likely to break, then the object in question stands as an excellent option where preservability and security high standards are expected.

Characteristics of Schedule 80 Steel Pipe

✓Resistant to High Pressures

Unlike standard schedule 40 pipe, schedule 80 pipe is meant to take very high pressures from within, hence why in such cases any tension on stress-bearing applications owing to pressure being applied on schedule 80 pipes is an important aspect.

✓More Wall Thickness

Stress deformation is considerably avoided by an increase in wall thickness, due to which the structure is strong.

✓Fight Corrosion

Based on the material type for use, for example, stainless steel, it means providing high tolerance to aggressive media, which makes the pipe extremely serviceable in aggressively reactive atmospheres.

✓Improved Thermoregulation

The structure of the pipe provides plasticity to work even at high or low temperatures.

✓Working with the Material

The Schedule 80 pipe is easily accommodated in almost all mechanical operations, thus making it very suitable for such needs.

Understanding Sch 80 Pipe Thickness

Schedule 80 pipes are a type of pipe that is thicker compared to schedule 40 pipes for the Same diameter. This additional thickness is for boosting strength and pressure withstandability, and since that is quite important in high-pressure applications, schedule 80 pipes are preferred. For instance, it is possible to find 1-inch schedule 80 pipe with a wall thickness of around 0.179 inches as per industry standards. The thicker walls also enhance dependability in harsh conditions by making the walls more resilient and tough to stress.

Applications of Schedule 80 Steel

Industrial Systems with High Pressure Levels

When there is a need for high pressure fluid or gas handling, schedule 80 pipes are many times applied in industrial systems such as chemical process plants and thermal power plants.

Pipes in the oil and gas industry

High pressure resistance and enhanced strength makes it suitable for such environments oil and gas transmission pipelines which are required to be in extreme pressure and conditions.

HVAC and plumbing systems

They are strong and therefore used in the HVAC systems as well as in the robust or heavy-duty plumbing systems, especially where great heat or mechanical effort is expected.

Constructive elements

According to the schedule 80 pipe, elements of the building, bridges, or any other structures will be supported by these pipes as they are a construction frame used in the construction that functions to carry heavy weights.

How Does Schedule 80 Differ from Schedule 40 Pipe?

Wall Thickness Comparison

The main distinction between different schedule pipes 80 and 40 is their wall thickness, which relates to their nominal size and varies among different schedule pipes. That is, the schedule 80 pipe has a relatively thicker wall compared to the schedule 40 pipe of the same nominal size. This additional thickness allows the system with schedule 80 to accommodate more pressure, thus these thicker pipes are used where they are required to cope with more stress. However, due to the increase in the thickness of the walls, the internal diameter decreases, which may lead to a reduction in the flow.

Pressure Rating Differences

Pipes made to rigorous standards, such as Schedule 80, are often in high demand because of their thicker walls and higher pressure limitation as compared to Schedule 40. In practical terms, pipelines that are anticipated to fall within the range of higher pressures are constructed with pipes as thick as the schedule 80 pipe. In other words, in a specific pipe diameter, more water pressure may be sustained without breaking in a schedule 80 pipe and not in a schedule 40 pipe that is used in applications with lower requirements but a high flow rate.

Where Each Type is Used

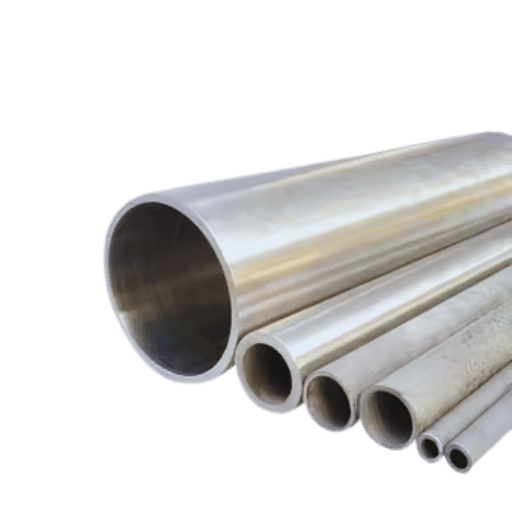

What are the Dimensions and Size Options for Schedule 80 Pipes?

Standard Schedule 80 Pipe Dimensions

Information regarding dimensions of a schedule 80 pipe regarding wall thickness and diameters is as follows:

- Normal Pipe Size (In NPS) in Range: From 1/8 inch to 24 inches.

- The external diameter (OD): Changes depending on the NPS; for example, a 1-inch pipe has an OD of about 1.315 inches.

- Thickness of the Walls: Greater than that of Schedule 40 pipes, in the case of NPS 1 inch Schedule 80, wall thickness is 0.179 inches.

- Internal Diameter (ID): Smaller than that of Schedule 40 pipes because of the greater thickness of the walls. In NPS 1 inch Schedule 80 , it is about 0.957 inches, showing how the thickness was over-designed .

Note: Exact dimensions may sometimes change slightly per the material and the manufacturer in question. Please check the required dimensional tables in these cases.

Exploring Schedule 80 Steel Pipe Sizes

An implicit idea concerning the topology is that it is classified as a thick-walled member having a schedule 80 pipe design; this makes it suitable for high-duty stresses. A good example of this is in the following:

Note that actual dimensions may vary marginally due to manufacturing and material, so always check the relevant up-to-date industry standards to confirm exact measurements.

How ANSI Specifications Apply

ANSI specifications assist in streamlining production processes by harmonizing the dimensional, material, and performance characteristics of piping systems. This gives manufacturers and engineers a common ground and an agreed set of rules to achieve certain levels of safety, reliability, and performance. The ASTM standard covers critical aspects such as wall thickness, diameter, and grade of materials and plays a big role in the selection of components for α particular application or the selection of components for meeting compliance requirements, when either schedule ‘4o’ or schedule ’80’ comes into play. Hence, industries that adhere to ANSI specifications with regard to their systems are able to secure uniformity and decrease the chances of any malfunctions or incongruities.

Why Choose Schedule 80 Steel Pipe for High-Pressure Applications?

The Advantage of Increased Wall Thickness

- More Considerable Withstanding to Pressure: More wall thickness of schedule 80 pipe steel permits more internal pressures, thus being used in appropriate applications of high-pressure delivery systems in commercial and industrial purposes.

- More Durable: Thicker walls offer better mechanical strength against certain forces, thus preventing deformation or damage that can result in excessive use.

- Better Corrosion Protection: Because of additional material between the internal and external surfaces, the pipe is able to reabsorb damage from corrosivity and environments by increasing its life span.

- Lower Likelihood of a Leakage Occurrence: The construction is firm enough to decrease the possibility of any leaks and ruptures from happening, and therefore works well for systems where fluid retention is essential.

- Capability for huge conditions: As for sending cold or hot footage, conditions schedule 80 pipes are applicable with such thicker walls, therefore increasing thermal resistance of structures.

Durability and Longevity Considerations

Schedule 80 pipes are constructed in a marginally larger wall size than their schedule 40 counterparts, for better endurance against various weather conditions that make them the materials of choice in a schedule 40 metal pipe replacement. Moreover, these materials provide reliable services over time in the presence of mechanical forces, temperature fluctuations, and aggressive media to. Before sourcing materials, the environmental conditions where the material will run, including the temperature and chemical conditions, need to be considered to perform and last correctly. However, such ambitious applications can be met only with the strength and endurance installed in a schedule 80 pipe.

Sustainability in Structural and Mechanical Applications

- Use of Recycled Materials: Involving recycled materials like steel, aluminum, or plastics lowers demand for virgin materials and the wastes and energy consumed during processing.

- Energy-Efficient Systems: Energy conservation is ensured within building design through advanced means such as installing a heat recovery system or enhancing insulation.

- Durability and Longevity:By using durable materials and long design and engineering, the need for frequent replacement of components and the associated resource consumption is reduced.

- Modular and Reusable Design: Use of modular systems aids in fast repairs, upgrades, and reuse of components, thus limiting the production of waste and aiding its sustainable management during the lifecycle.

What Factors Influence the Pricing of Schedule 80 Steel Pipes?

Material and Manufacturing Costs

Schedule 80 Pipe material and manufacturing costs depend mainly on the steel used for its production and the cost of human resources and energy in manufacturing. Superior steel and excellent manufacturing methods tend to increase costs. In addition, there are other costs associated with the availability of raw materials, the cost of transportation, as well as the demand for steel in the market.

Impact of Schedule 80 Pipe Thickness on Costs

If dredging is done with schedule 80 pipe, then production cost increases because the amount of steel is high, which is why thicker poles mean more quantity of steel and a higher production cost. Also, schedule 80 pipes are heavier, so the transportation of the same amount is weaker than moving schedule 40 pipes; this is also another reason for increasing cost. In pipes with higher thickness, more milling and cold work operations are required, which in turn has an impact on labor and production cost. That’s why schedule 80 AR girl-walled pipes are more expensive than those with smaller walls relatively.

Market Trends and Availability

A particular type of piping, namely the schedule 80 pipe, has become increasingly popular across sectors where its enhanced strength and robustness, against pressures greater than any other, is required; see the oil or gas industry or chemical processing industries, which inevitably require the use of such schedule pipelines. However, they might not be readily available in certain cases due to the market conditions of the area or the supplier. No business would mind spending a few more coins on a schedule 80 pipe; these pipes are where performance and endurance are above cost in the long run.

Frequently Asked Questions (FAQs)

Q: How is the method of making schedule 40 pipes different from the method of making schedule 80 pipes?

A: The biggest distinction between a schedule 40 pipe and a schedule 80 pipe is the wall thickness of each one. The wall in a schedule 80 pipe is thicker than the wall in a schedule 40 pipe, which can withstand more pressure for the pipe. Such a function makes it more useful in high-pressure or corrosive chemical applications where schedule 80 pipe needs to be used more.

Q: How thick are schedule 80 pipes?

A: The wall that protects a schedule 80 pipe is not of the same thickness throughout. The diameter of the wall will differ based on the pipe and how it is made. Nonetheless, for a wider pipe schedule, there is a thicker wall, which explains the extra stiffness provided by a schedule 80 pipe compared to a schedule 40 pipe. This thickness is very important because the pipe must be strong enough to withstand the pressure for which it is intended.

Q: Describe the pressure rating of the schedule 80 steel pipe – is it substantial or average?

A: Schedule 80 steel pipes have an enhanced pressure rating than Schedule 40 steel pipes because their walls are way thicker. Consequently, schedule 80 pipe can withstand more pressure per square inch and is often quite apt for beverage and food, energy, and other industries where fluid flow may be a huge part of the operation.

Q: Can schedule 80 pipes be used for plumbing?

A: Yes, schedule 80 pipes are an excellent solution when it comes to plumbing, especially where there is high pressure or aggressive chemicals in use, due to the more durable nature of the pipes. They are tolerant of high heat and are commonly applied in industrial operations.

Q: What is the criterion for selecting the pipe among schedule 40 and schedule 80?

A: The answer lies in the pressure requirements for the application and what type of medium will be conveyed through the pipeline. If it is to be a high-pressure application where the fluid is corrosion-resistant, schedule 80 would suffice for its additional thickness.

Q: What uses do schedule 80 pipes have?

A: Schedule 80 steel pipes are recommended in varied practical sectors like the construction industry, the manufacturing industry, and even in the plumbing industry. These pipes can function in high pressures and temperatures, thus making them suitable in places where gases are distributed or even chemicals are used.

Q: In what ways do the schedule 80 pipe fittings differ from the schedule 40 pipe fittings?

A: Fittings for schedule 80 pipes have been made in such a way that they accommodate the higher thickness of the pipe in order to prevent any form of leakage. This size increase and the dimensions of these fittings follow the schedule 80 standards and are therefore demanded for installing them appropriately.

Q: How would you describe the benefits of Sch 80 pipes?

A: Sch 80 pipes are advantageous over schedule 40 pipes for a number of reasons, including greater resistance to impact and corrosion, and higher maximum pressure ratings and strength. The characteristics above make these types of pipes valuable for the situations that involve demanding working conditions while still being machinable without fear of breakage.

Conclusion

The modern industrial development cannot do without such an important element as steel pipes of schedule number 80. They are known to be suitable for the most challenging operations due to their enhanced properties, which include strength, durability, and resistance to pressure. Once you do any kind of engineering work, construction work, or work in any industry, you would get to know the uniqueness and the benefits that a schedule 80 pipe provides. This will help you make decisions that will ensure the safety of these processes while enhancing the effectiveness of their processes as well as their longevity.

Schedule 80 pipe finds extensive use in a number of high-demand projects around the world, esp. due to the fact that they come with thicker walls and higher pressure capacity. Although they require more financial outlay in the beginning, as compared to Schedule 40 pipes, their enhanced hardness, low maintenance, and longer longevity result in assurance of return on invested capital under stress or harsh conditions. There are ANSI standards regarding the sizing of pipes available for your particular application, so you may help to maximize the effective use of any project.

Reference Sources

1. Standard Pipe Schedule and Spec

- Standard Pipe Schedules include Schedule 80. The said documents are provided by South Dakota State University.

- Link to source

2. Standard Pipe Sizes

- Academia.edu hosts a paper that deals with standard pipe sizes and dimensions, Schedule 80 being one of them.

- Link to source

3. AIS Waiver Decision Memorandum for Schedule 80 Pipe

- The use of Schedule 80 pipe in certain applications is discussed by the EPA.

- Link to source

5. Pressure