Pipes are considered an essential element that spans multiple industries, including construction, plumbing, and oil and gas transportation. Very important in the engineering of a given structure is the weight of a pipe per foot, which affects the structural integrity of said structure as well as any transporting logistics and the overall cost of the project. Being an engineer, contractor, or self-taught person means the knowledge of how pipe weight is calculated will enhance efficiency and safety in one’s respective endeavor. This tutorial will delve into the key factors affecting pipe weight, describe how to calculate it, and then explore practical insights to assist you in making well-informed decisions. Get ready to develop an appreciation for the science behind this vital matter: weight per foot of pipe!

Introduction to Pipe Weight

Pipe weight is a vital factor when deciding the requisite materials, the transportation requirements, and the installation planning. This is mostly figured based on the dimensions of the pipe, the density of the material, and wall thickness. The common formula in use is:

Pipe Weight per Foot (lbs) = 10.69 × (Wall Thickness − Wall Thickness²) × (Outer Diameter − Wall Thickness) × Material Density

After entering all appropriate values, the weight per unit length of the pipe can be calculated with accuracy. These values are necessary to guarantee safety, reduce expenses, and obey safety codes for many applications.

What is Pipe Weight Per Foot?

The unit of pipe weight per foot is the weight of one linear foot of pipe, which depends on its dimensions, density of the material, and wall thickness. This measurement enables one to assess how heavy a one-size pipe is for planning, safe handling, construction, plumbing, or engineering projects.

Importance of Knowing Pipe Weight

The weight of a pipe per foot is an important consideration in engineering, manufacturing, and construction. Accurate pipe weight calculations ensure that structures remain safe and do not overload their foundations, support systems, or transportation arrangements. For example, oil and gas, plumbing, and shipbuilding work with pipelines that are vast in distances, and a wrong solution in weight measurements could cause a catastrophe.

Optimizing costs is the other aspect correlated to pipe weight. For instance, a pound of steel pipe has a given price, so knowing the weight per foot enables businesses to estimate material costs and adjust their budgets accordingly. Moreover, weight calculations become paramount for transportation logistics under various considerations to ensure they do not waste fuel, comply with maximum load regulations, and maintain safety during handling and shipping.

Recent data reveals that weight per foot for a carbon-steel pipe 12 inches in diameter with 0.5-inch wall thickness approximates 47.41-pound. A bigger pipe, like a 24-inch one under similar specifications, can weigh over 189 pounds per foot! Therefore, such data are meant to highlight the importance of weight determinations for large-scale projects where weight varies reciprocally with size.

Aside from cost and logistics, pipe weight data is needed to comply with safety standards, such as those laid down by ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization). These standards often provide for particular limits and tolerances as is necessary for the material to meet performance requirements without compromising safety. In a nutshell, knowing pipe weight is indispensable for efficiency, safety, and practical application in many industries.

Applications in Construction and Engineering

Since pipes have yet to be the principal subject in construction and engineering, weight calculations and measurements must be performed accurately with respect to maintaining a structure intact, maintaining efficiency in operations, and managing the costs of projects. For example, in large construction and infrastructure projects, steel pipes tend to be used for structural supports, water distribution, and gas transportation because of its high strength and durability. In general, according to the industry data, steel pipes are mostly used in the structural framework of bridges and skyscrapers, as steel pipes are supposed to withstand compressive and tensile forces in both directions.

Similarly, for civil projects, underground utilities like water mains, storm drains, and sewage systems usually employ PVC pipe, HDPE pipe, and ductile iron pipe materials. This type of pipe ranges from being lightweight to strong and will last between 50 and 100 years. Hence, they are among the least costly and most durable options for long-term infrastructure investments.

Weight is also a matter of consideration in pipeline transportation; the oil and gas industry requires correct calculations of pipe weight to design pipelines capable of withstanding great pressure while restricting material use. For instance, in a typical onshore oil pipeline system, carbon steel pipes with different wall thicknesses may be required so that it can handle pressure within the range of 200 to 1,500 psi, ensuring the transfer happens safely with minimum chances of material failure.

Very basically, piping system selection and applications in construction and engineering are highly dependent on pipe manufacturing materials, weight of the pipe, and application requirements for performance and safety.

Factors Influencing Pipe Weight

1. Material Composition

The pipe’s weight ultimately varies with the type of material used in its manufacture. For example, pipes made of steel, copper, or concrete are heavier than those made of lightweight materials like PVC or aluminum.

2. Pipe Dimensions

The weight of a pipe increases with the wall thickness and diameter. This is because, with thick walls, more material gets used, hence heavier.

3. Length or Run of the Pipe

The longer the pipe, the heavier it is. They weigh more due to the greater volume of materials contained.

4. Coatings and Linings

Conserving coatings, coatings or linings, and sometimes insulation make for added weight. While these features ensure durability and performance of the pipes, their presence does affect weight considerations.

5. Operating Conditions

The high-pressure or high-temperature piping will generally weigh more, as, for strength and safety, thicker-walled pipe is used.

Material Types: Steel vs. Stainless vs. Carbon Steel

Steel types differ in properties: stainless steel resists corrosion, carbon steel is stronger, and general steel offers versatility.

|

Key Point |

Details |

|---|---|

|

Corrosion |

Stainless resists corrosion |

|

Strength |

Carbon steel is stronger |

|

Versatility |

General steel is versatile |

|

Maintenance |

Stainless is easier to maintain |

|

Hardness |

Carbon steel is harder |

Pipe Dimensions and Their Impact on Weight

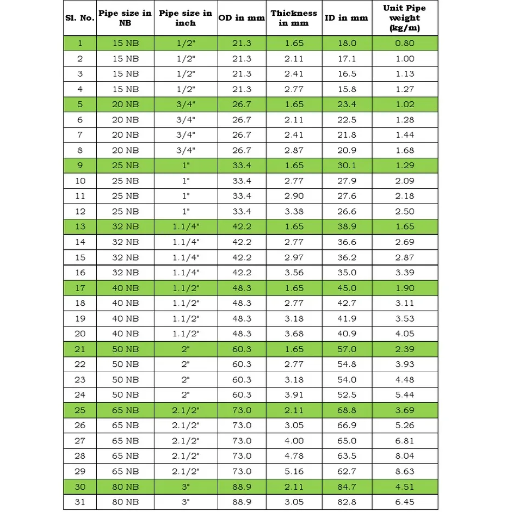

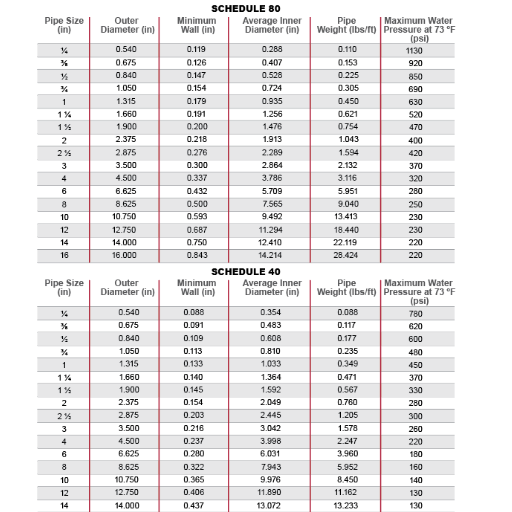

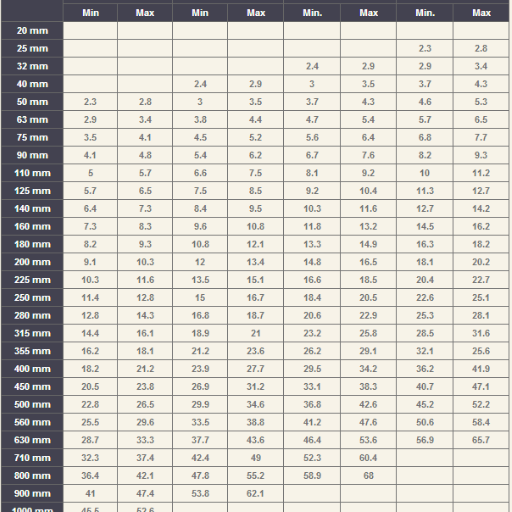

The dimensions of a pipe determine its weight; their diameter, wall thickness, and length are essential for weight calculations. The nominal pipe size or diameter directly determines the volume of material used, which in turn affects the weight of the pipe-so there is a closer relationship of sizes and weights. A standard 8-inch schedule 40 steel pipe with an outer diameter of 8.625 inches and wall thickness of 0.322 inches weighs approximately 24.97 pounds per foot.

Wall thickness also remains as a factor that determines various weights. Thicker-walled pipes, generally indicated by higher schedule numbers (Schedule 80 or Schedule 160), are used where the highest pressures apply and are therefore heaviest. For example, a similar size 8-inch steel pipe in Schedule 80 weighs about 37.72 pounds per foot due to an increase in material for the thick construction.

Length is simple, yet important. More length in a pipe means more weight proportional to it. A 20-foot section of the 8-inch Schedule 40 pipe would weigh just under 500 pounds, whereas the 20-foot length of Schedule 80 is more than 750 pounds.

These concepts of pipe dimensions in effect on weighing are quite critical to design optimization, handling logistics, and accurate costing for transportation and installation.

How Wall Thickness Affects Pipe Weight

Wall thickness is an essential factor in determining pipe weight since higher thickness means more material volume per unit length. This is very much so with typical pipe schedules such as Schedule 40 and Schedule 80. For example, Schedule 80 pipes are designed with thicker walls than Schedule 40 pipes of the same diameter, thus making Schedule 80 pipes heavier and able to resist higher pressure.

Consider an 8-inch steel pipe with a length of 20 ft. Schedule 40 pipes weigh approximately 500 lb, whereas Schedule 80 pipes weigh over 750 lb, the weight difference being primarily due to more material incorporated into the thick walls. The material of the pipe also contributes to the total weight of the pipe, owing to different materials having different densities.

Beyond influencing weight, the wall thickness also determines the pipe strength and pressure rating. With thicker walls, pipes are capable of resisting higher internal pressures; thus, they are used in high-demand industrial applications such as transport of oil and gas, chemical handling, and high-pressure extension of fluids. The added weight of thicker pipes requires stronger support structures during installation, not to mention the increases in transporting and handling costs. Knowledge of such considerations helps engineers and designers weigh the right pipe specifications synonymous with a project’s practical needs and performance requirements.

Calculating Pipe Weight Per Foot

To calculate the weight of a pipe per foot, use the following formula:

Pipe Weight (lbs/ft) = 10.69 × (Wall Thickness − Wall Thickness²) × (Outer Diameter − Wall Thickness)

Steps for Calculation:

- Identify the pipe’s outer diameter (OD) and wall thickness (WT). These are standard measurements provided by pipe manufacturers.

- Substitute the values into the formula above.

- Perform the calculations to determine the weight per foot.

This formula applies to steel pipes and is widely recognized for its accuracy. Always ensure the measurements are in inches for consistency and correct results.

Formulas for Weight Calculation

When calculating the weight of a pipe, it’s essential to consider both the material density and geometric dimensions to ensure accuracy. Below are some commonly used formulas for pipe weight calculations alongside explanations and examples for clarity:

1. Standard Weight Formula for Steel Pipes

The weight per foot of a steel pipe can be calculated using the following formula:

Weight (lbs/ft) = 10.69 × (Outer Diameter – Wall Thickness) × Wall Thickness

- Outer Diameter (OD): Measurement across the greatest exterior width of the pipe.

- Wall Thickness (WT): Difference between the outer and inner diameter divided by 2.

Example Calculation:

For a steel pipe with an OD of 10 inches and WT of 0.5 inches, the weight is calculated as:

Weight = 10.69 × (10 – 0.5) × 0.5 = 10.69 × 9.5 × 0.5 = 50.78 lbs/ft.

2. General Pipe Weight Formula

For materials other than steel, the following formula applies:

Weight (lbs/ft) = (π × (OD² – ID²) × Material Density) / 144

- Outer Diameter (OD): Outer width of the pipe.

- Inner Diameter (ID): Inner width of the pipe (OD – 2 × WT).

- Material Density: Typically measured in lbs/in³ and varies depending on the pipe material (e.g., aluminum, PVC, etc.).

Example Calculation (Aluminum Pipe):

An aluminum pipe with an OD of 6 inches, WT of 0.25 inches, and a material density of 0.0975 lbs/in³:

- ID = OD – 2 × WT = 6 – (2 × 0.25) = 5.5 inches.

- Weight = (π × (6² – 5.5²) × 0.0975) / 144

= (π × (36 – 30.25) × 0.0975) / 144

= (π × 5.75 × 0.0975) / 144

= 0.0122 lbs/ft.

3. Nominal Weight for Standard Pipes (Quick Reference)

For quick reference, standard weights for common pipe sizes and materials are often provided in tabular form. Below is an example for steel pipes:

|

Pipe Size (inches) |

Wall Thickness (inches) |

Weight (lbs/ft) |

|---|---|---|

|

4 |

0.25 |

10.79 |

|

6 |

0.375 |

22.58 |

|

8 |

0.5 |

40.67 |

Key Considerations While Using Formulas

- Ensure all measurements are consistent (e.g., converting from feet to inches if required).

- Account for the material’s density, as it significantly impacts the weight calculation.

- Always cross-check your calculations for accuracy and reliability.

These formulas and approaches provide a comprehensive guide for determining pipe weight across a variety of materials and applications.

Using a Pipe Weight Per Foot Calculator

A pipe weight per foot calculator is very easy to use, and it can streamline the planning of any project. I usually feed it the original pipe specifications, such as material, outside diameter, wall thickness, and length. The calculator returns the weight per foot, which helps in estimating the total weight more efficiently. This tool saves time and provides accuracy while considering the handling, transportation, and structural support requirements when working on design and implementation.

Example Calculations: Steel and Carbon Steel Pipes

To calculate the weight of steel and carbon steel pipes, it’s essential to use the formula:

Weight (lbs/ft) = [OD – Wall Thickness] × Wall Thickness × 10.69

Where:

- OD is the outside diameter of the pipe (in inches).

- Wall Thickness is the thickness of the pipe’s walls (in inches).

- 10.69 is a constant that accounts for the density of steel (approximately 490 lbs/ft³).

Example 1: Steel Pipe Calculation

Consider a steel pipe with:

- OD = 6 inches

- Wall Thickness = 0.5 inches

Using the formula:

Weight (lbs/ft) = [6 – 0.5] × 0.5 × 10.69

Weight (lbs/ft) = 5.5 × 0.5 × 10.69

Weight (lbs/ft) = 2.75 × 10.69

Weight (lbs/ft) = 29.9 lbs/ft

For this particular pipe, the weight is approximately 29.9 lbs per foot.

Example 2: Carbon Steel Pipe Calculation

For a carbon steel pipe with:

- OD = 8 inches

- Wall Thickness = 0.25 inches

Using the formula:

Weight (lbs/ft) = [8 – 0.25] × 0.25 × 10.69

Weight (lbs/ft) = 7.75 × 0.25 × 10.69

Weight (lbs/ft) = 1.9375 × 10.69

Weight (lbs/ft) = 20.7 lbs/ft

Thus, this carbon steel pipe weighs approximately 20.7 lbs per foot.

By applying the above formula, users can efficiently estimate the weight of steel and carbon steel pipes of various dimensions, ensuring precision and suitability for different applications.

Practical Applications of Pipe Weight Calculations

Depending upon the industry, pipe weight calculations ensure safety, efficiency, and economy of the project. It calculates the materials required for construction, transportation, and installation based on the load-bearing capacity of the pipe. A more precise weight calculation enables engineers to design safer systems that comply with standards and project specifications. Pipe manufacturers can calculate pipe weights to save on raw material usage, minimize waste, and thus save on production cost. Hence the knowledge of pipe weights during planning, fabrication, and installation ensures rational decisions.

Choosing the Right Pipe for Your Project

In making the right pipe choice for your project, the efficiency, performance, and cost factors should all weigh into the decision-making process. There are several parameters to consider:

1. Material Type

The material type greatly affects the longevity, weight, and resistance to environmental factors. Common materials are:

Steel: With its strength and versatility, steel pipe suits cases like high-pressure application in industries. Carbon steel are commonly used in oil-and-gas pipeline works for their strength.

PVC: As PVC pipes are light and corrosion resistant, they find uses in plumbing or drainage works. Generally, PVC finds high application in cheap residential and commercial buildings.

Copper: Due to its bactericidal nature, copper is preferred for potable water systems, smooth and durable but may require a higher upfront consideration.

2. Pipe Dimensions

Acceptable diameter and wall thickness must be selected for a pipe in order to ensure proper flow rate and pressure handling. Standard pipe sizes are generally within ⅛ inch for small applications to greater than 24 inches for industrial purposes. Not fitting in correct size would reduce flow and may overburden it.

3. Pressure and Temperature Ratings

They have to withstand the operating condition in your system. For example, for high pressure systems in chemical plants, pipes with higher strength like Schedule 80 or 160 pipes are selected. If working in environments with high temperature, materials that are resistant to this condition should be taken into consideration, like stainless steel or special alloys.

4. Corrosion and Chemical Resistance

Consideration must be given to the external and internal environmental conditions in which the pipe is expected to operate. In a coastal or highly acidic atmosphere, one may have to look for coated or stainless steel pipes to avoid corrosion, while transporting chemicals require materials really meant to resist chemical reactivity, such as HDPE or fluoropolymers.

5. Budget and Lifecycle Costs

Life-cycle cost evaluation is leaned on more for optimizing values over a period of time, and pipe purchasing that connects with maintenance, repair possibilities, and energy to pump fluid are considered in some respect.

6. Industry Standards

It is essential that the pipes comply with industry-level certifications and regulations such as standards from ASTM, ASME, or ISO to guarantee their quality and applicability for intended usage. Verifying compliance guarantees safety as well as performance reliability.

By developing these factors in priority, project managers and engineers will be able to make an informed decision that enables the selected pipe to maximize on both the technical as well as the financial requirements.

Impact on Structural Integrity and Safety

The procedure of pipe selection sustains common structural integrity for safety in carrying out application situations. In the application realm, pipe materials and designs pose pros and cons with respect to a structure’s ability to withstand certain stresses and environmental factors. Steel pipes are known for their tensile strength and can operate under high pressure and temperature, making them very suitable for industrial and heavy-duty applications. Recent evidence suggests that carbon steel pipes, if well coated, possess a long life span of more than 50 years, hence further making such infrastructure sustainable and cost-efficient.

Corrosion resistance, therefore, remains another parameter concerning safety and longevity. Corrosion undermines the pipeline’s structural integrity and may cause leakage or near-failure events. Materials like stainless steel, PVC, and HDPE maintain a reasonably good resistance against corrosive elements and thus lower maintenance requirements and assure longevity. Studies have shown that HDPE pipes, for example, have excellent resistance to chemicals and can flex easily, thus proving reliable in aggressive soil conditions and other harsh environments.

More so, the right design particulars and specifications of pressure rating, pipe wall thickness, and suitable joint design greatly enhance the prevention capability against structural issues. For instance, good joint design with well-fitted joints and adequately rated fittings reduces chances of mechanical failures during application. Innovative solutions to further reduce risks of degradation and external load-induced damages have recently entered into the marketplace, including flexible composite pipes and improved coatings.

In a practical sense, by choosing materials and construction methodologies ensuring structural soundness, project stakeholders assure safer operations while also upholding arduous industrial and environmental standards. Having balanced these factors, one achieves further longevity and a reduction in chances for costly repairs or replacements.

Cost Implications Related to Pipe Weight

The weight of a pipe is critical in being a factor in the cost of the materials as well as the great factor that, in the long term, affects the operating cost of a project undertaken for industrial purposes or infrastructural development. Heavier-weight pipes usually require greater raw material input in manufacturing, thus increasing upfront costs. For example, steel pipes, an accepted option, would cost anywhere close to about $900 to $2,500 per ton, depending upon grade and market demand. Additionally, from the age of heavier pipe, transport costs will also rise. Freight charges may get an increase of 10-20% due to vitality spent on extra handling and fuel consumption.

Being operative, heavier pipes will cause more support costs as they require reinforced supports and stronger installation equipment, thus increasing construction costs and labor. On the other hand, considering the use of lighter alternatives such as composites or thermoplastics will reduce those extra costs while also providing corrosion resistance and ease of handling. For example, comparatively lightweight HDPE pipes hold many benefits, with fairly low installation and maintenance costs compared to steel, in terms of durability over time.

By putting the pipe weight and its material against the project requirements, one can easily manage costs. Hence, it is very important that one predicts beforehand and carries out a life-cycle cost analysis to decide on the solution that delivers the best value and is operationally reliable throughout the system’s lifecycle.

Tools and Resources for Accurate Calculations

Correct calculations form the basis for project planning and execution. Some important tools and resources for precision are:

- Pipe Flow Software: Tools like Pipe Flow Expert are used to analyze flow dynamics, pressure loss, and flow rates for pipe systems.

- Cost Estimation Tools: Platforms such as RSMeans provide reliable cost data for materials, installation, and maintenance pertinent to project-specific data.

- Standardized Calculation Templates: Calculation templates supported by the industry from organizations like ASME provide for uniformity and adherence to the technical standards.

- Material Selection Guides: Information provided by manufacturers and industry associations helps in selecting the most appropriate material.

- Training and Certification Programs: Courses conducted by institutions such as AWWA or local engineering associations certify good calculation procedures through proper technical training.

Based on these calculations, a project can be successfully put together by balancing budget and performance criteria.

Online Calculators and Software

The importance of online calculators and software cannot be overstated-given the many options available today, these tools provide exact computations and save a lot of time. They assist professionals with complex equations, material selection, and efficiency in project flow. To illustrate, Pipe Flow Expert or Bentley Systems software are capable of modeling piping systems with all required accuracy in areas such as pressure drop analysis and flow rate calculations. Online beam calculators are also available for engineers.)

A review of leading tools in 2023 noted the ever-increasing accuracy of these instruments and their functions. Current programs take into account things like environmental considerations, material properties, and real-time data analytics. Conversion of units, auto-detection of errors, and visual simulation are just some of the functions that aid in decision-making processes. Integrating these tools into projects enables professionals to considerably increase their time while ensuring enhanced project reliability and sustainability.

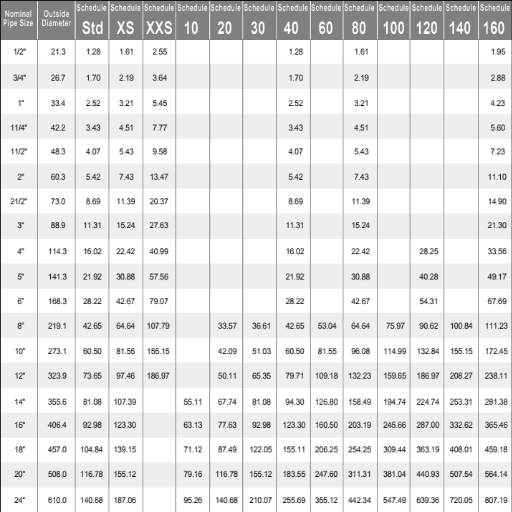

Reference Tables for Steel Pipe Dimensions

Reference tables for steel pipe dimensions include data on sizes, diameters, wall thickness, and schedules.

|

Key Point |

Details |

|---|---|

|

Sizes |

Nominal pipe sizes (NPS) |

|

Diameter |

Outer diameter (OD) |

|

Thickness |

Wall thickness (WT) |

|

Schedules |

Pipe schedule numbers |

|

Length |

Standard lengths (20ft, 40ft) |

Industry Standards and Guidelines

Adhering to industry standards and guidelines is imperative to ensure safety, efficiency, and quality in the development of engineering projects. The various standards pertaining to steel pipe dimensions mostly belong to ASTM International (e.g., ASTM A53 and ASTM A106), with API 5L laying down specifications for line pipes and ASME B36.10M and B36.19M specifying standards for welded and seamless wrought steel pipes.

For instance, ASTM A53 specifies the requirements for black and hot-dipped, zinc-coated, welded, and seamless steel pipe for mechanical and pressure applications. API 5L, on the other hand, specifies the requirements for pipelines used for the transportation of oil, gas, and other fluids in terms of strength, toughness, and resistance to adverse environmental conditions. ASME B36.10M specifies the nominal pipe sizes and wall thicknesses for the welded and seamless wrought steel pipes for various kinds of applications, maintaining a standard for interchangeability.

Also, with the advancement of material technology, various modern pipes in these standards have been designed with much higher pressure ratings and corrosion resistance. Correct specification meansthat the pipe will comply with the applicable mandatory standards; but more importantly, it will also meet performance standards consistently, thereby reducing incidences of failure within the system and promoting sustainability in the long run.

Reference Sources

1. Volumetric Capacity of Drill Pipe using an Enhanced Method of Dimensional Measurement

- Authors: A. C. Rodriguez et al.

- Publication Date: 2024-02-12

- Journal: All Days

- Citation Token: (Rodriguez et al., 2024)

- Summary:

- This study addresses the volumetric capacity of drill pipe, which is crucial for optimizing drilling operations. The authors highlight that current estimations based on nominal product dimensions do not account for manufacturing variations or material loss after use. They present a method using non-destructive data capture to determine the volumetric capacity more accurately, focusing on fluid capacity, fluid displacement, and adjusted weight per foot.

- Key Findings:

- The fluid capacity for a 15,000 ft drill string comprised of 5.5 in OD and 0.415 in wall thickness is found to be 304.5±8.5 bbl.

- The fluid displacement is 156.0±1.5 bbl, and the adjusted weight per foot is 28.6±0.3 lb/ft.

- Methodology:

- The study employs enhanced dimensional measurement techniques and non-destructive testing methods to gather data on the drill pipe’s dimensions and weight characteristics.

2. Aluminum Drill Pipe Fatigue Analysis

- Authors: Guilherme Farias Miscow et al.

- Publication Date: 2004 (not within the last 5 years but relevant)

- Citation Token: (Miscow et al., 2004, pp. 919–926)

- Summary:

- This paper discusses the fatigue analysis of aluminum drill pipes, which are considered as alternatives to conventional steel pipes due to their lower weight per foot. The study investigates the fatigue damage that occurs under cyclic loading conditions, particularly in curved sections of wells.

- Key Findings:

- The study identifies that failures often occur in the transition region of tool joints, influenced by geometric discontinuities and metallurgical factors.

- Methodology:

- The authors conducted experimental tests on small-scale coupons and full-scale fatigue tests on aluminum drill pipes to assess their fatigue life.

3. Pyro Technology for Cutting Drill Pipe and Bottomhole Assemblies

- Authors: J. F. Cole

- Publication Date: 1999 (not within the last 5 years but relevant)

- Citation Token: (Cole, 1999)

- Summary:

- This paper introduces new technology for disengaging drill pipe using pyro technology, which can be relevant for understanding the weight and handling of drill pipes in various conditions.

- Key Findings:

- The technology provides a safe method for cutting drill pipes, which can impact the overall weight management during drilling operations.

- Methodology:

- The study discusses the application of pyro technology and compares it with traditional methods of pipe disengagement.

Frequently Asked Questions (FAQs)

How to Calculate the Weight of a Pipe with Any Wall Thickness?

To calculate the weight of a pipe with any wall thickness, you need to know the dimensions of the pipe, including its outer diameter, wall thickness, and material density. The formula can be used to determine the weight by calculating the volume of the steel used in the pipe and then multiplying it by the density of the material.

What is the Weight per Foot for Any Size of Pipe?

The weight per foot for any size of pipe varies based on the diameter and wall thickness. For instance, a larger diameter pipe with a thicker wall will weigh more than a smaller, thinner pipe. You can use a pipe weight per foot calculator to quickly find this information based on the specific dimensions.

How to Use a Pipe Weight per Foot Calculator?

A pipe weight per foot calculator is a tool that allows you to input the size of pipe, wall thickness, and material type, such as carbon steel. The calculator will then output the weight per foot, making it easier to determine how much material you will need for your project.

What Formula Can Be Used to Calculate the Weight of Steel Pipe?

The formula to calculate the weight of steel pipe involves using the dimensions of the pipe and the density of the material. The weight can be calculated as follows: Weight = (Outer Diameter – Wall Thickness) x Wall Thickness x Length x Density. This formula helps you determine the weight per foot for accurate measurements.

What is the Unit Weight of Carbon Steel Pipe?

The unit weight of carbon steel pipe varies depending on the size and schedule. For example, a standard sch 40 carbon steel pipe has a specific weight per foot that can be found in manufacturer specifications. Understanding the unit weight helps in selecting the right pipe for your needs.

How to Determine the Weight of a Valve?

The weight of a valve can be determined by using the same principles as calculating pipe weight. By knowing the dimensions and material of the valve, you can use the appropriate formula to calculate its weight per foot, allowing for better planning in your piping system.

How Does Wall Thickness Affect the Weight of a Pipe?

The wall thickness significantly affects the weight of a pipe. A thicker wall increases the volume of the material, leading to a higher weight per foot. This is important to consider when selecting pipes for structural or fluid transport applications, where weight may impact the overall design.

How to Calculate the Weight in Kg per Meter?

To calculate the weight in kg per meter, first find the weight per foot using the appropriate dimensions and formula. Then, convert the weight per foot to kg per meter by multiplying the weight per foot by 3.281, which accounts for the conversion from feet to meters. This provides a more global measurement that can be useful in international projects.