For accuracy and versatility in metal cutting, few tools can match the oxy-fuel torch in efficiency. This time-honored method has been famous in industries from manufacturing to construction because of its ability to cut through thick steel with speed and accuracy. But our question is: what makes oxy-fuel cutting so effective, and how does temperature affect the process? In this text, we will look into the science behind oxy-fuel cutting, analyze how the torch operates, and seek out its various uses. Consider this guide base knowledge for both seasoned professionals and new operators working with metal. All of this is to tell you what makes this tool a trusted selection amongst cataclysmic, cutting-edge operations.

Introduction to Oxy-Fuel Cutting

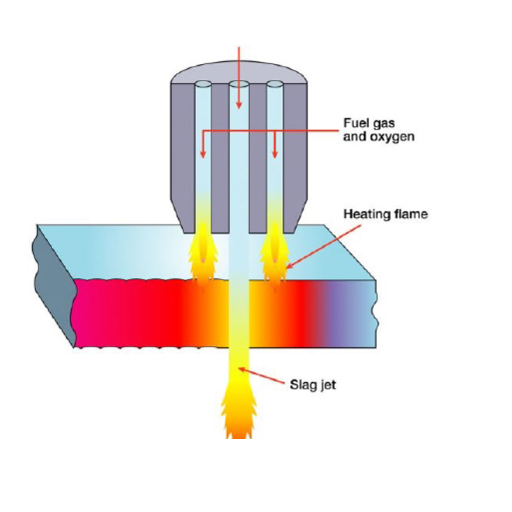

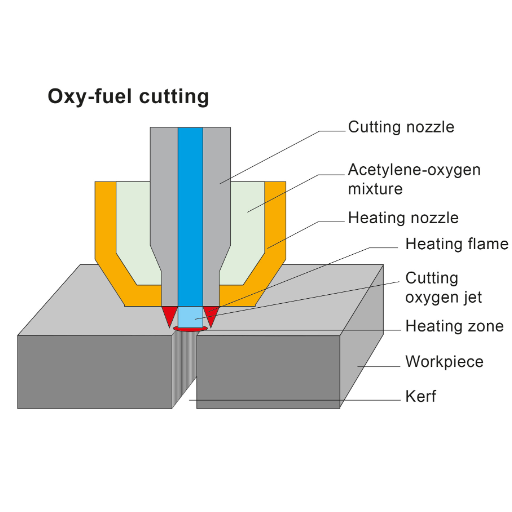

Oxy-fuel cutting is a process that is known for cutting metals using a high-temperature flame produced by oxygen and a fuel gas such as acetylene, propane, or natural gas. The flame preheats the metal to a certain critical heat, after which pure oxygen is directed to the area and causes the metal to oxidize or burn away to give a clean and precise cut. This process is very useful in cutting through thick pieces of ferrous metals, as well as in the building industry, shipbuilding, and metal fabrication. The reliability and versatility of oxy-fuel cutting make it an indispensable tool for many applications.

What is Oxy-Fuel Cutting?

Oxy-fuel cutting uses a straightforward but highly effective technique wherein the combustion process is utilized for making an accurate cut on thick metals. In this process, the metal surface is preheated to an ignition temperature that usually varies between 900°F and 1,600°F, depending on the material used. The fuel gas, commonly acetylene, propane, or natural gas, combines with oxygen to produce a flame of great temperature. Once the metal is heated sufficiently, a stream of pure oxygen equally concentrated is directed at the metal, which reacts with the oxygen to form iron oxide that melts and is then blown away from the cut area.

The oxy-fuel is now high-tech, far more precise, and efficient in capability. For example, automated oxy-fuel cutting machines realize a speed of more than 20 inches per minute on carbon steel plate up to 12 inches thick. Industry analysis says that oxy-fuel cutting is one of the most cost-effective solutions for heavy-duty cutting tasks, with operating expenses generally considered lower than other alternatives, including plasma or laser cutting. This method works best for industries engaged in fabrication or repair at a large scale, given it offers portability and efficiency besides accuracy.

History and Evolution of Oxy-Fuel Cutting Techniques

The genesis of oxy-fuel cutting goes back to the late 1800s, with the evolution of practical welding and gas-cutting systems. In 1903, Edmond Fouché and Charles Picard introduced the oxy-acetylene torch in metalworking. By burning oxygen and acetylene gas to produce flame hot enough to melt and sever steel, it permitted precise cutting and welding processes at astonishing efficiency.

Through the years, oxy-fuel cutting has garnered massive improvements. Its first applications were limited by very simple equipment and working range limitations, so these improvements greatly enhanced their execution. For example, multi-gas setups now allow users to switch fuels, such as propane or natural gas, which also opens up other applications and reduces cost in some.

Technological advancements have integrated oxy-fuel cutting setups into automated systems. Most CNC (Computer Numerical Control) machines are currently integrated with oxy-fuel cutting heads to allow more precise largescale operation. According to some recent industry intelligence reports, the mix increases productivity by up to 40% while retaining rigorous tolerance levels essential for heavy industrial applications. Further, improvements in nozzle design are helping improve fuel efficiency, slash oxygen consumption by up to 25%, and thus enhance the sustainability of the method.

The very adaptability and strength of the oxyfuel keep it relevant with modern-day industries like shipbuilding, construction, and manufacturing, notwithstanding newer technologies like lasers and plasma. Its historical evolution stands as proof that it is a progressive solution to an industry need that merged innovation with practicality to remain the basic instrument of metal fabrication.

Applications Across Industries

The oxygen-fuel cutting process continues to be a critical technology owing to its multipurpose nature and efficiency. In construction, it is mostly utilized for cutting structural steel with precision to allow immediate assembly of building or bridge frameworks. Some other heavies in the shipbuilding…industries rely on oxy-fuel cutting for its ability to cut thick steel plates, thereby greatly shortening the production time. The manufacturing operations then adopt the process to carry on fabrication for the production of components and parts for machinery, household appliances, and tools.

In recent times, numerous innovations have been brought into the oxy-fuel cutting arena to make it even better-the gas mixtures have faster cuts with all the newer and better nozzles that perform smoother cuts simultaneously with laser-perfect accuracy. Studies emphasize that this technique can be utilized on steel thicknesses greater than 12 inches, primarily for very heavy-duty applications. Further studies reveal that this method is cost-effective compared to other methods, with costs being up to 50% less than the more advanced methods such as lasers cut, making the whole procedure more portable and handy to use, which position oxy-fuel cutting as one of the primary toolboxes for this life-worthy industrial activity.

The Science Behind the Oxy-Fuel Flame

The oxy-fuel flame gets created by mixing oxygen with a fuel gas such as acetylene or propane in a controlled way. Oxygen supports combustion, letting the fuel gas burn at very high temperatures. This intense heat is enough to melt metal, making it suitable for cutting and welding processes. The flame consists of two zones: the inner cone, where partial combustion of fuel gases takes place, and the outer envelope, where combustion completes. Depending on the oxygen-fuel ratio, the flame can be made to perform the task it is intended for, i.e., to cut or join.

Understanding Oxygen and Acetylene Combustion

The fusion of acetylene and oxygen combustion furnishes the very focal point of gas welding and cutting methods because it gives rise to almighty temperature. Oxygen and acetylene react chemically by combustion to give a flame temperature of about 3,480°C (6,296°F), making it among the highest flame temperatures encountered in the usual industrial practice. Such heat has the ability to weld and cut metals in a nutshell, including steel and iron.

The combustion, thereafter, begins with molecules of acetylene C2H2 that are mixed with oxygen O2 to produce heat due to rapid oxidation. The reaction for complete combustion takes the form:

2C2H2 + 5O2 → 4CO2 + 2H2O + Heat

This reaction represents an ideal state of combustion, where sufficient oxygen is present. But any irregularity in the oxygen-acetylene ratio value can change the character of the flame. A reducing, or carburizing, flame has extra acetylene and is used, for instance, for annealing or creating fillets in welding, depositing soot and reducing oxidation; on the other hand, a neutral flame is used for balanced combustion in general welding, and an oxidizing flame with surplus oxygen provides the maximum heat for cutting.

Once refined, oxygen and acetylene are packed and safed to harness the utmost performance from the duo. Acetylene, for example, is inherently unstable at pressures exceeding 15 psi (103 kPa) and has to be regulated to prevent unsafe decomposition; notwithstanding, its explosive range in air is between 2.5% and 100%, and therefore, all possible steps require monitoring and control during application.

Flame Temperature and Its Importance in Cutting

Being a sublime stone in the arts of cutting and industrial processes, the flame temperature is an indicator of industrial cutting processes efficiency and accuracy. Given the 1:1 mixture proportions of oxygen and acetylene, the oxy-acetylene flame reaches a temperature of around 5,572°F (3,090°C). In such high temperatures, steel can be quickly taken to its ignition point, whereby the cutting is performed swiftly and efficiently.

Another important aspect besides the temperature is the nature of the flame, which may be neutral, oxidizing, or reducing. The performance of the cut and the state of the product are subject to the influence of the flame. Normally, the neutral flame would yield the best-quality cuts since the ratio of oxygen to acetylene is balanced, while the oxidizing flame would cause excessive oxidation that could show up as surface defects.

Another important aspect: Heat distribution. The flame concentrates the heat in a small area such that the heat gets away while spreading on the surface with thermal stress on the surrounding material, thus risking warping or structural damage. This also emphasizes choosing the right fuel combination and proper equipment calibration.

Together with modern cutting techniques like automated torch systems and gas mixing controls, these high-temperature flames provide some exceptional accuracy for a multiplicity of industrial purposes, occurring anywhere from the fabrication of almost artistic designs to the beveling of thick steel plates. Flame temperature has been a considerable factor for industries to coordinate their activities even for strenuous cutting works.

Factors Affecting Flame Characteristics

Several key factors influence flame characteristics, including temperature, fuel-to-oxygen ratio, gas purity, and environmental conditions. Understanding how these variables interact is essential for achieving precise flame control and optimizing industrial processes.

- Fuel-to-Oxygen Ratio

The ratio of fuel to oxygen plays a pivotal role in defining the flame’s behavior. A balanced ratio produces a neutral flame, ideal for many industrial applications. Too much oxygen creates an oxidizing flame, which may promote metal oxidation, while excess fuel results in a reducing flame, which can reduce oxides and minimize scaling.

- Gas Purity

The purity of fuel gases, such as acetylene, propane, or natural gas, directly impacts the flame’s stability and heat output. Impurities or inconsistent gas quality can lead to fluctuating temperatures and uneven cutting or welding performance. For instance, acetylene with a purity grade of 99.6% or higher ensures a hotter, more consistent flame compared to lower-grade alternatives.

- Ambient Temperature and Pressure

Environmental factors such as temperature, atmospheric pressure, and humidity alter flame characteristics. For example, higher altitudes—where air pressure and oxygen density are lower—require adjustments in fuel and oxygen flow settings to maintain efficient combustion.

- Nozzle Design and Maintenance

The design of the torch nozzle influences flame size, shape, and heat distribution. Regular maintenance, like clearing nozzle blockages and replacing worn-out components, ensures uniform gas flow and optimal flame output.

- Advancements in Automation

Modern automated systems allow for precise adjustments in variables like gas flow and combustion settings. This level of control not only enhances repeatability but also improves energy efficiency. For example, automated oxy-fuel cutting machines can fine-tune the flame to match the material thickness being processed, reducing waste and increasing productivity.

By accounting for these factors, manufacturers and operators can fine-tune flame characteristics to meet the exact requirements of their tasks, ensuring efficiency, safety, and high-quality outcomes.

Oxy-Fuel Cutting Process

In oxyfuel flame cutting, solid metal is heated with a flame up to the ignition temperature and a jet of pure oxygen is then used to oxidize and cut through the material. The oxy-fuel cutting technique works well mostly on ferrous metals such as steel since they are capable of cheap oxidation methods. After the metal has been preheated, the flame is fed by a fuel gas, such as acetylene, propane, or natural gas, and oxygen. At about the ignition temperature, a strong jet of oxygen is flushed against the workpiece, and in an instant, it oxidizes and cuts. This technique is a versatile, fast method to accurately cut thick metals.

Components of the Oxy-Fuel Cutting System

The components of an oxy-fuel cutting system include cylinders, regulators, hoses, torch, and safety valves.

| Key Point | Details |

|---|---|

|

Cylinders |

Oxygen and fuel gas storage |

|

Regulators |

Control gas pressure |

|

Hoses |

Transport gases to the torch |

|

Torch |

Mix and ignite gases |

|

Valves |

Ensure safety and flow control |

Choosing the Right Cutting Tip

Selecting the cutting tip for oxy-fuel should be done with care to reap maximum performance and get actual cuts from an oxy-fuel cutting system. Several factors influence the choice for a cutting tip: type and thickness of the material being cut, kind of fuel gas used, and the quality of the cut desired. Cutting tips are manufactured to have variable orifice sizes and fine-tuned configurations dependent on flame and oxygen flow rate.

For example, small orifice tips supplying a comparatively narrow yet concentrated flame are generally used for thinner metals because such manufacturers thin the flame too far, and there is the burning out of the material or waste. Large orifice tips should be used for thicker materials since their oxygen flow allows for deeper and cleaner cuts. Industry-standard tip charts customized for each application are usually supplied by the manufacturers; these charts include information for setting the tip size, speed of cutting, gas pressures, and preheats required for the flame, providing the operator with information to perform cuts efficiently and accurately.

Other advantages include the correct tip being more efficient in gas consumption and less dangerous in terms of backfires or flame disturbances. Regular cleaning of the tips and checks for wear and tear form an important part of good tip maintenance and will guarantee the consistent performance of cutting operations. When choosing tips, one should make note of the tip type compatible with the torch model used and whether the tip material is adequate for long exposure to a high-temperature environment.

Step-by-Step Oxy-Fuel Cutting Technique

1. Prepare the Equipment

Make sure all your equipment is in good working order. Give your torch, hoses, and regulators the once-over for any signs of damage or wear. Ensure the oxygen and fuel gas cylinders are firmly fastened and that the pressure levels are suitable for operations.

2. Adjust Gas Pressure

Regulate the pressure for oxygen and fuel gas on their respective regulators to exact specifications according to your torch and cutting tip. For instance, oxygen pressure is normally higher (20-40 psi for cutting) compared to fuel gas pressure (5-10 psi for acetylene, depending on the actual use).

3. Ignite the Torch

Open the fuel gas valve slightly and use a spark lighter to ignite the gas. Then slowly open the oxygen valve to form a neutral flame. A neutral flame will have a sharply defined inner cone and is necessary for good cutting.

4. Preheat the Material

Position the cutting torch at the start point of the material. Hold the flame steady to preheat the area to a bright red color indicating that it is ready for cutting. Preheat to make sure of a clean cut.

5. Open the Cutting Oxygen Valve

Once the material is hot, release a stream of highly pressurized oxygen by pressing the cutting oxygen lever. Hold the torch steadily and move it slowly along the line of the cut, keeping the flame in line with the material.

6. Watch the Cutting Speed

Fine-tune the cutting speed to suit the thickness of the material and the quality desired. For instance, steel plates up to 1/2 in. thick are cut slower, and thinner material has a faster cutting speed.

7. Clean the Kerf

Upon finishing the cut, check the kerf (the gap made by the cut) to make sure it is clean and free of slag. Too much slag may show improper settings or could mean you need to adjust your technique.

8. Shut Down Safely

To shut down the torch, close off the fuel gas valve first, then the oxygen valve. Close cylinder valves properly and release any remaining pressure in the system. Inspect the equipment for wear and clean if necessary.

With these detailed steps, one can assure precision, safety, and efficiency to oxy-fuel cutting across applications.

Factors Affecting Cutting Efficiency

1. Material Type

Cutting efficiency largely depends upon material composition and thickness. Softer metals and less-thick materials are easier to cut than hard or thick ones.

2. Torch Settings

Correct fuel and oxygen ratios make for a clean and efficient cut. Any deviation from this can go to produce cuts with too jagged edges or excessive slag.

3. Nozzle Condition

A clean and undamaged nozzle is preferred for precision. If a nozzle is clogged or damaged, the gas flow will be obstructed off, hampering cutting efficiency.

4. Operator Technique

Performance depends on good technique: consistent speed, good torch angle, steady movement. Bad practices will imply imprecise, not good cuts.

5. Gas Quality and Flow Rate

Good cutting needs good gas, and good gas needs its flow rate to be adequate. Any contamination or inadequate gas flow will not let it pass smoothly.

Efficiency and quality in oxy-fuel cutting can be improved by attending to these factors.

Oxygen and Fuel Gas Ratios

The right oxygen and fuel gas ratio is a balancing act that results in attaining optimum cutting performance during the oxy-fuel cutting process. The flame must efficiently burn to provide the screen heat needed for cutting. Usually, a neutral flame is hit for most operations-this is the flame generated when oxygen and fuel gas are combined in the right ratios.

For example, acetylene, being one of the most widely used fuel gases, has a ratio of oxygen-to-acetylene of about 1.2:1 for neutral flame production. This means that strictly for each unit of acetylene, 1.2 units of oxygen should be supplied. The ratios will change for certain applications, the gas types, and the equipment being used. Propane and natural gas, which are also more commonly used, may especially see different ratios higher than those required for acetylene, from 4:1 to 5:1.

Just maintaining the correct ratio will reduce soot formation, incomplete combustion, and ensure clean and sharp cuts. Repeat calibration of the equipment and watching those gas flow rates will keep those ratios just where you want them, efficiently working and wasting little. Manufacturer suggestions should always be looked into for the specific ratio setups that would best fit the particular cutting jobs at hand and the respective material properties.

Material Thickness and Type

The thickness and type of material used during flame-cutting processes are two factors tending to influence the efficiency of the cutting process and, consequently, the quality of the cut. This also means that cutting of thin materials, such as sheets less than 6 mm thick, requires a very low flame intensity and exact gas ratio to prevent warping and excessive heat-affected zones. With the cutting of thicker materials, such as steel plates of above 20 mm, gas flow rates will have to be higher, with increased oxygen pressure while using special torches suited for heavy applications.

Different metals will react differently to the cutting process. For instance, low carbon steel is preferred with oxy-fuel cutting because it has such compositions and melting points that are quite predictable; however, with such material types as stainless steel and aluminum where the oxide layer and reflection properties interfere with the processes, it is usually indirectly dependent on the technique. Stainless steel is often best plasma or laser cut, and aluminum may require further modifications to prevent thermal distortion.

As a result of the development of new cutting methods, the materials and thicknesses that can be feasibly processed have become far more numerous. The cutting tool has automated settings for precise, repeatable cutting according to a given task specification. For industrial purposes, material-reference charts bearing specific recommendations of pressure settings and cutting speeds will ensure that a cutting process is optimized for the material to be cut. To ensure the best results, it is essential to make sure that the cutting machine is compatible with the material specifications.

Environmental Conditions and Their Impact

Cutting processes present a different and unique set of variables that can affect their efficiency and precision. Temperature, humidity, and airflow are perhaps the most effective elements dismantling equipment performance and behavior of the material. A humid atmosphere can introduce moisture into the cutting environment, and this kind of environment may bring about oxidation or corrosion for certain materials, mostly metals. Cut quality is hindered under these conditions, and problems arise in maintaining the machining equipment for the quality environment.

Temperature changes affect the cut in other ways. At very low temperatures, metals will become brittle, and at higher temperatures, they will lose strength and become susceptible to thermal warping. All these changes in the properties of the material affect cut accuracy and require operators to alter their operational settings either to compensate for expansion or contraction of the material.

Air currents, which conceptually embrace proper ventilation and wind direction, are equally important to heat and residue management in various cutting processes. Adequate ventilation removes particulate matter and gases produced by the cutting, thereby ensuring safety and maintaining an unobstructed view of the cut along with an assured degree of precision.

It is wise to monitor and work around these environmental parameters for maximum performance. Research has shown that keeping the working environment regulated between 60-75°F and maintaining relative humidity at 40-50% can help in minimizing the adverse effects of these external variables. Once maintained, environmental controllers such as dehumidifiers or enclosures with humidity controls can help maintain these parameters, ultimately improving the output and quality of the cutting operation.

Safety Precautions in Oxy-Fuel Cutting

Safety precautions in oxy-fuel cutting include wearing protective gear, inspecting equipment, and avoiding flammable materials.

| Key Point | Details |

|---|---|

|

Gear |

Wear protective clothing |

|

Inspection |

Check cylinders and torch damage |

|

Valves |

Use flashback arrestors |

|

Flammable |

Avoid cutting near flammable items |

|

Transport |

Secure cylinders during transport |

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is vital in ensuring the safety of workers involved in oxy-fuel cutting operations. The process generates high temperatures, sparks, and fumes, which can pose significant risks if adequate precautions are not taken. Key PPE items include:

- Welding Helmets and Goggles: Eye protection is essential to shield against intense light, ultraviolet (UV) radiation, and flying debris. Welding goggles or helmets with lenses featuring a shade range suitable for oxy-fuel cutting (typically shade 4-6) are recommended according to ANSI Z87.1 standards.

- Flame-Resistant Clothing: Operators should wear flame-resistant clothing made of materials such as treated cotton or leather to prevent burns from sparks and molten metal splatter. Loose-fitting garments should be avoided to minimize fire risks.

- Respiratory Protection: Oxy-fuel cutting produces fumes that may contain harmful substances such as carbon monoxide or metal oxides. Depending on the material being cut and the ventilation of the workspace, respirators compliant with NIOSH-approved standards may be necessary to protect against inhaling dangerous particles.

- Heat-Resistant Gloves: Thick, heat-resistant gloves are essential to protect operators’ hands from exposure to extreme heat and accidental burns caused by molten materials.

- Steel-Toed Boots: Foot protection is crucial to guard against heavy falling objects and drops of molten metal. Boots should also feature heat-resistant soles to withstand contact with hot surfaces.

- Hearing Protection: Oxy-fuel cutting operations can generate significant noise levels, particularly when paired with additional equipment like grinders or drills. Earplugs or earmuffs compliant with OSHA noise exposure guidelines help reduce the risk of hearing damage.

By integrating these essential PPE components into daily operations, workers minimize potential hazards and create a safer working environment. Proper training on the use and maintenance of these protective measures further enhances safety and operational efficiency. Ensuring compliance with regulatory safety standards not only protects personnel but also reinforces workplace productivity and morale.

Fire Safety Measures

With fire safety measures, I look at things from a prevention angle while mitigating all possible risks and preparing for emergencies. That includes keeping the exits clear, inspecting fire extinguishers at regular intervals, servicing them from time to time, and routinely carrying out fire drills to remind and prepare everyone for emergencies. It also includes instructing people on how to handle and respond to fires and the proper use of equipment to ensure everyone’s safety and readiness.

Proper Equipment Handling and Maintenance

Whenever handling or working with any tool, one has to realize that safety and efficiency are paramount. Hence, I make sure to always follow manufacturers’ instructions for operating the equipment. I mean, I am checking in regularly to find faults that could arise and deal with them early. This way, I counteract the situations that would lead the equipment to malfunction, which creates a place that could be hazardous to all.

Comparing Oxy-Fuel Cutting with Alternative Methods

Oxy-fuel cutting is widely utilized for its ability to efficiently cut thick steel and other ferrous metals. The oxygen and fuel gases combine to provide a flame with very high temperature that is capable of melting the material. Cost-wise, this is the cheapest method available; it is portable, and perfect for heavy-duty application.

On the other hand, other methods such as plasma cutting are faster and more precise when it comes to cutting thin plates and non-ferrous materials such as aluminum. Plasma produces cleaner edges with less slag. Laser cutting is absolute precision for those with complex designs; however, it is costly to run and needs far more equipment.

Each has their pros and cons, so the deciding factor comes down to the type and thickness of material, budget, and project needs. Oxy-fuel cutting is still one of the best options for heavy, industrial applications due to its simplicity and dependability.

Oxy-Fuel vs. Plasma Cutting

Oxy-fuel cutting is cost-effective and ideal for thick materials, while plasma cutting offers superior speed, precision, and versatility.

|

Key Point |

Details |

|---|---|

|

Thickness |

Oxy-fuel for thick materials |

|

Precision |

Plasma is more precise |

|

Speed |

Plasma is faster |

|

Cost |

Oxy-fuel is more affordable |

|

Versatility |

Plasma handles thin materials better |

Oxy-Fuel vs. Laser Cutting

Oxy-fuel cutting excels in thick steel and cost-efficiency, while laser cutting offers superior precision, speed, and versatility.

|

Key Point |

Details |

|---|---|

|

Thickness |

Oxy-fuel for thick steel |

|

Precision |

Laser cutting is superior |

|

Speed |

Laser is faster |

|

Cost |

Oxy-fuel is more cost-effective |

|

Versatility |

Laser is more versatile |

Advantages and Disadvantages of Each Method

1. Oxy-Fuel Cutting

Advantages

- Versatility: Oxy-fuel cutting is highly effective on a wide range of ferrous metals and allows for cutting thicker materials, often up to 24 inches or more.

- Portability: The equipment is relatively lightweight and does not require an external power source, making it ideal for fieldwork or remote locations.

- Cost-Effective: The initial investment and operational costs are lower compared to plasma or laser cutting systems.

Disadvantages

- Limited to Ferrous Metals: This method is not suitable for cutting non-ferrous metals such as aluminum or stainless steel.

- Slower Speed: The cutting speed is considerably slower compared to plasma and laser cutting, particularly on thinner materials.

- Heat-Affected Zone (HAZ): The high heat intensity can lead to a larger heat-affected zone, which may compromise material integrity near the cut edge.

2. Plasma Cutting

Advantages

- Versatility Across Materials: Plasma cutting can effectively handle a variety of conductive metals, including steel, stainless steel, and aluminum.

- Faster Cutting Speeds: This method outperforms oxy-fuel cutting in terms of speed, especially on thinner materials, improving overall productivity.

- Precision: Plasma cutters produce cleaner cuts with minimal slag, reducing the need for post-processing work.

Disadvantages

- Cost: The initial investment in plasma cutting equipment is higher, and operational costs can increase due to the need for electricity and consumable components like electrodes and nozzles.

- Thickness Limitation: While exceptional for cutting thin and medium-thickness materials, plasma cutting is less effective for extremely thick metals compared to oxy-fuel cutting.

- Dependence on Power Source: Plasma cutters require a stable power supply, which limits their portability compared to oxy-fuel systems.

3. Laser Cutting

Advantages

- High Precision and Detail: Laser cutting excels in achieving intricate designs and precise cuts, making it ideal for projects requiring tight tolerances.

- Speed with Thin Materials: For thinner metals and sheet materials, laser cutting can achieve very rapid processing.

- Minimal Waste: The narrow kerf width and high precision reduce material waste significantly.

Disadvantages

- High Cost: Laser cutting machines come with a substantial upfront cost, along with ongoing maintenance expenses.

- Material Limitations: While effective on most types of metals and even non-metals, laser cutting struggles with extremely thick materials.

- Safety Concerns: The use of lasers requires stringent safety controls to protect operators from potential hazards, including exposure to high-powered light.

Reference Sources

- Heated temperature and Range of the Oxy-acetylene Cutting Reinforcing Bar by Simulation and Experiment

- Authors: Bong-Joo Kim et al.

- Publication Year: 2008

- Summary: This study investigates the heated temperature and range during the oxy-acetylene cutting of reinforcing bars. It employs both simulation and experimental methods to analyze the thermal effects during the cutting process. The findings indicate that the temperature distribution is critical for optimizing cutting efficiency and quality.

- Methodology: The research utilized simulation techniques alongside experimental setups to measure temperature variations during the cutting process, providing a comprehensive understanding of the thermal dynamics involved(Kim et al., 2008, pp. 1–5).

- Experimental investigation and optimization of Oxy-Acetylene assisted machining parameters for Nickel based alloy Inconel — 718

- Authors: O. G. Sonare et al.

- Publication Year: 2017

- Summary: This paper focuses on optimizing the machining parameters for oxy-acetylene cutting of Inconel 718, a nickel-based alloy. The study highlights the importance of temperature control in achieving desired machining outcomes, such as surface finish and tool wear.

- Methodology: The authors conducted a series of experiments to evaluate the effects of various cutting parameters on the performance of the oxy-acetylene process, analyzing the results to identify optimal settings for temperature management(Sonare et al., 2017, pp. 1–7).

- An Experimental Investigation of Hot Machining Performance Parameters using Oxy-Acetylene gas setup

- Authors: Venkatesh Ganta, D. Chakradhar

- Publication Year: 2014

- Summary: This study examines the performance parameters of hot machining using an oxy-acetylene gas setup. It emphasizes the role of temperature in enhancing machining efficiency and reducing tool wear.

- Methodology: The research involved experimental setups to measure the impact of temperature on various machining parameters, providing insights into the benefits of hot machining techniques(Ganta & Chakradhar, 2014).

Frequently Asked Questions (FAQs)

What is the oxy-fuel cutting process?

The oxy-fuel cutting process involves using a torch that mixes oxygen and a fuel gas, typically acetylene, to create a high-temperature flame. This flame is used to heat the metal until it reaches its ignition temperature, allowing for a cutting technique that effectively pierces through various types of materials.

What are the maximum flame temperatures in oxygen cutting?

The maximum flame temperature in oxygen cutting can reach up to 3,500 degrees Celsius (6,332 degrees Fahrenheit) when using an oxy-fuel torch. This high flame temperature is essential for effective cutting, allowing the flame to melt the metal and produce a clean cut.

How does the oxygen to fuel gas ratio affect cutting quality?

The oxygen to fuel gas ratio is crucial in achieving optimal cutting quality. A higher ratio leads to a hotter flame, which can improve cutting speed and quality. Conversely, a lower ratio may result in slower cutting speeds and a less effective cutting process, potentially leading to slag formation on the cut edge.

What types of fuel gases can be used in oxy-fuel cutting?

Common fuel gases used in oxy-fuel cutting include acetylene, propane, and MAPP gas. Each gas has unique properties; for instance, acetylene produces a higher flame temperature compared to propane, making it more suitable for certain cutting applications.

How does pierce time affect the cutting technique?

Pierce time refers to the duration it takes to create an initial hole in the metal before cutting. A shorter pierce time typically indicates a more efficient cutting technique, allowing for faster piercing and cutting. Factors like flame temperature and oxygen flow play a significant role in determining the pierce time.

What is the role of the inner cone of the flame in oxy-fuel cutting?

The inner cone of the flame is the hottest part of the oxy-fuel flame and is essential for effective cutting. It is where the oxygen jet mixes with the fuel gas, creating a high-temperature area that melts the metal. For optimal results, the cutting process should focus on maintaining this inner cone at the correct position over the material being cut.

Can natural gas be used in oxy-fuel cutting?

Yes, natural gas can be used in oxy-fuel cutting, although it generally produces a lower flame temperature compared to acetylene. While it may not be as efficient for cutting thicker metals, it is a commonly used fuel for lighter applications due to its availability and cost-effectiveness.

What are the safety precautions for using an acetylene cylinder?

When using an acetylene cylinder, it is essential to follow safety precautions such as ensuring that the cylinder is stored upright, away from heat sources, and in a well-ventilated area. Regularly checking for leaks and ensuring that the valve on the torch is functioning correctly can help prevent accidents during the cutting process.

How does using less oxygen affect the cutting process?

Using less oxygen in the cutting process can lead to a lower flame temperature, which may result in slower cutting speeds and less effective piercing of the metal. It can also increase the likelihood of slag formation, negatively impacting the quality of the cut. Maintaining the correct oxygen and fuel lines is crucial for optimal performance.