The use of lightweight metal pipe has impacted various sectors positively. These pipes have contributed to the growth of industries such as construction and automotive, aerospace and manufacturing, among others. The flexibility and, nevertheless, strength and lightness of these products make them a resource in high demand in the present day, where changes are quick and auxiliary structures are being made. This piece takes a look at the various ways that lightweight metal pipes can be used and also looks at the advantages that come with their use in business and consumer aspects of life. Whether you possess the capacity to envisage better ways of doing things or you have the power to choose what to purchase, lightweight metal pipes can indeed redefine modern infrastructure and design, and this copy aims to explain how and why to expect further changes in perspective.

What Are the Key Features of Lightweight Metal Pipes?

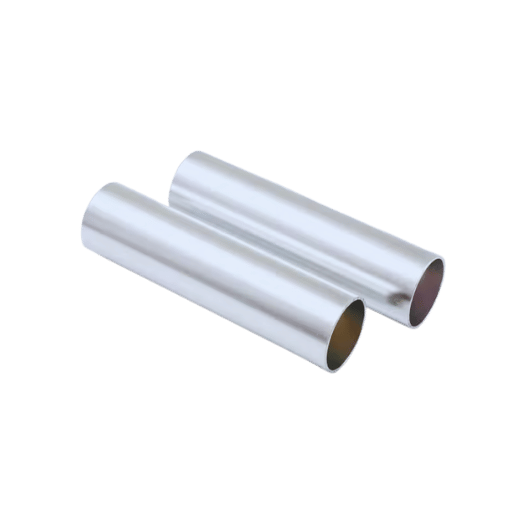

There are quite a few special properties of lightweight metal pipes that make them desirable for a lot of implementations:

- Low Weight-to-Strength Ratio: Such pipes are much higher than that in conventional materials with zero weight accumulated.

- Corrosion Resistance: A vast part of lightweight metals, e.g., aluminum, stainless steel, do not corrode easily and in fact they are inherently resistant to such processes, which increases their service time in severe conditions.

- Versatility: Most of them require little work to change their shapes and only need cutting and shaping them to certain shapes for specific uses, which makes these materials applicable to several uses such as construction, motor vehicle production, and aeronautics.

- Sustainability: A good number of lightweight metal pipe sheaths can be used again, and this helps in saving the environment as well as reducing the general costs.

- Thermal and Electrical Conductivity: Metals, namely aluminum and copper-based materials, give good heat and electrical conductivity, thereby extending the use of these materials.

In fact, Infrastructure requirements as well as the Designer’s creativity make the lightweight metal pipe indispensable.

Understanding Metal Pipe Material

Certain lightweight metal pipes may be more suitable for specific applications than others owing to their respective specifying requirements. Most used materials are steel, iron, and non-ferrous metals such as aluminum and copper. Steel pipes are likely to last long, and, therefore, they are used, but in many cases only for high-pressure systems. There is also the advent of aluminum as an alternative to steel, which, thanks to the low weight and corrosion factor of the material, is very attractive. Copper has good heat and electricity-conducting properties, and therefore it is widely used in plumbing and electrical work. Titanium is both strong and corrosion-free, and thus is used in, for instance, the aircraft industry. The characteristics of each material ensure the appropriate functioning in several sectors and structures.

Importance of Tube Diameter in Performance

The breadth of a cylinder becomes the contributing factor towards its efficacy. It changes the flow rate, pressure, and strength of a system. The greater the diameter, the more flow it allows, and less pressure is lost. Therefore, it fits well for high-volume usage. On the other hand, the smaller diameter need not be precise, and controllable flows are more common in systems with desired flows. Appropriately selecting cylinder size is necessary to accomplish the desired performance without any functional breakdown in the system, hence the highlighted aspects of designing in which the said aspects are also alluded to.

Structural Strength and Durability Factors

A system can only be relied upon and expected to last as long as its structural robustness and capacity to withstand wear are ensured. The choice of material is at the heart of this; materials such as steel and aluminium have high strengths and good corrosion resistance, whereas artefacts of composite construction can be a lightweight metal pipe with sufficient strength in appropriate situations. More so, it is also necessary that the design takes into consideration the loads that will be applied during service, mostly static but also environmental dynamic loads, which can cause deformations or failure. It is also crucial to conduct maintenance and examination to maintain both the structure and its functions in the long run.

How to Choose the Right Tubing Size for Your Project?

Assessing Pressure and Load Requirements

- Determine Operation Pressure Limits – An assessment involving the maximum and minimum pressures the operating condition subjects the tubing to so that it can survive within the prescribed range without failure.

- Consider Burst Pressure Rating – The tubing burst pressure shall need to be checked against the highest pressure expected, to keep some safety margin from catastrophic failure.

- Consider Axial and Radial Loads– Both axial tensile/compressive forces and radial loads may act upon the tubing, which has to be checked for deformation under said loads.

- Consider Pressure Surges– Pressure surges and spikes shall be accounted for within the operating system, and one shall select tubing capable of withstanding such transient conditions, damage-free, without loss of performance.

- Consider Environmental Stresses– External stresses such as periodic temperature variation, vibration, and corrosion should be considered. These external stresses may affect the ability of the tubing to handle pressure and load effectively through time.

Determining Wall Thickness for Optimal Performance

It is essential to take into consideration the aforementioned major factors, when choosing the appropriate wall thickness to ensure effective operation:

- Working Pressure – Choose the wall thickness that can withstand the maximum working pressure without any chance of breakage. Consult relevant pressure classes, such as those contained in ASME or ASTM, for exact specifications.

- Material Capability – Check the tensile and yield strength of the material to ensure that it is within the pressure requirements of the particular function, especially in cases where the hydraulic systems are high-powered.

- Safety Margin– A sufficient safety margin is provided in case of any unforeseen changes and strains when the system is operating. This is the range from 1.5 to 3, i.e., one and a half to twice or thrice the maximum pressure of the system.

- Useful Dimension – Check the fitting with other areas of the system; the wall thickness should ensure the proper enclosing and secure attachment.

By taking into account these factors, you are able to guarantee the wall thickness of the tubing is efficient and is likely to last long enough with regard to its function.

Selecting the Appropriate Length and Shape

It is necessary to bear in mind the appropriateness of the length and the type of tubing in reference to the factors characterizing the given scope, say, the availability of the desired interior space, among others. The optimum length should be enough to link up components in the existing setup and avoid the unnecessary twists, which otherwise call for extra lengths that, in the long run, cause prohibitive pressure drops between the components, thus hindering productive performance of the system. The delivery of the respective tubes may include a straight, coiled, or designed shape that optimizes the arrangement of the system and meets the space constraints while preserving the function. It should be ensured that the pipe is always in conformity with the international standards, or else the system will fail and have a short life, which is not the expected outcome.

In What Applications Are Lightweight Metal Pipes Most Commonly Used?

Exploring Industrial and Construction Uses

- HVAC System Components: Lightweight metal pipe placements are utilized widely in heating systems, ventilation systems as well as air conditioning systems to aid in the flow of air, water and refrigerant.

- Plumbing Facility: The pipes are often seen within houses, buildings and industrial corresponding plumbing applications as a means of containing water or even draining waste water as they do not rust nor break.

- Constructive Supports: Compact pipes are also applied in construction activities that require struts, framework or even grids, and pipelines.

- Gas & Oil Transportation: Metal pipes are applicable in the construction of pipelines, so as to enable the transportation of oil, gas and any other fluids at high pressure, either in industrial applications or in an outdoor situation.

- Cars and Aircraft Manufacture: The principle of lightweight pipes is applied in some fundamental applications, especially exhaust systems, pipes that deliver fuel, and any structural parts where there is a need to reduce weight but maintain enough strength.

Role in High Strength Structural Applications

High-strength structural applications require exceptional toughness, load-bearing and stress-bearing properties, and durability against environmental conditions of metal pipes, and this is one of their primary applications. Bridges, skyscrapers, and industrial buildings are often designed with metal pipes given the materials’ endurance and the structures’ lifespan. Furthermore, because these materials are able to absorb considerable stress and pressure, they are the most suitable material for building safe systems. These qualities of metal pipes make them remain a favorite material in most difficult construction and engineering works.

Application in the Machinery and Transport Sectors

- Hydraulic Systems: Metal pipes constitute another major item in hydraulic systems, wherein fluids move under high pressure while transmitting mechanical energy towards the operation of machines. These are made strong and capable of high-pressure resistance and hence are suitable for heavy-duty use.

- Exhaust Systems: Vehicles, both in the automotive and industrial sectors, use metal pipes in their exhaust systems, as it helps in the safe and proper removal of all the waste gases from the engine, such that it functions correctly and there are no emissions beyond what is allowed.

- Fuel Transport: Inside engines as well as between external tanks and industrial equipment, metal pipes carrying fuel like gasoline or diesel are used because they are strong enough and do not easily oxidize.

- Cooling and Refrigeration Systems: These are present in the systems that require coolant transfer, such as pipes, which are stable enough at a given temperature and strong enough to operate within the system for a long time without any problems.

Comparing Aluminum and Stainless Steel Tubes

Weighing Corrosion Resistance and Longevity

Aluminum tubing and stainless steel tubing both have their place in many industries, depending on the task at hand, especially where corrosion resistance and service time are concerned, but the former is much more advantageous than the latter, particularly when placed in different conditions. This is due to the fact that it possesses a protective layer formed from oxides, which makes it usable in applications meant for hostile or more aggressive or corrosive environments like the marine or industrial sectors among others. While aluminium has good corrosion resistance, it can’t be used permanently on acidic or saline conditions as it is corrosive. However, aluminum is a much lighter material in comparison to stainless steel. This would be very suitable, especially in construction, where the weight of materials is of utmost importance. Stainless steel, in cases of aggressive environments and heavy use where maintenance is a challenge, is in most cases an option in preference to other metals, so as to enhance durability.

Evaluating Weight and Strength Attributes

Aluminum provides help in every event for lightweight metal pipes, which are used for rolls or constructions. When it is necessary to choose a metal that has high tensile stress and the ability to work with high loads or is elastic, stainless steel is appropriate, since despite its weight, it is a lot stronger than aluminum. And, of course, its downside is that it weighs more, and this is, of course, a disadvantage where a low weight and good design are a priority. Ironically, the aluminum is the opposite of steel since its strength or tensile stress is less, yet it offers a higher weight efficiency and is most effective in such light structures, when motion or transportation is required, and weight limitation would become a problem. There can be no ‘this or that’ strategies in the circumstances, forcing one between the usefulness of durability as against the odds of weight with respect to that particular situation.

Cost Efficiency and Availability for Projects

When refined or manufactured, the cost of aluminum is often higher compared to that of steel. Nevertheless, it appeals, especially in several instances. For instance, reduced weight and resistance to rust simplify certain surfaces, hence the use of the material in the long term for certain projects that require little maintenance or fuel consumption. Conversely, since steel is a much more common and cheaper material to produce, it is most often the least expensive solution for the construction of massive structures or situations where lightweight metal pipe does not matter. Therefore, one has to determine whether any of these materials is worth the expenditure based on the allocated funds for the project, the availability of these materials in that specific environment, and the expected costs in recent times.

| Comparison Factor | Aluminum | Stainless Steel |

|---|---|---|

| Corrosion Resistance | Okay (can deteriorate in an acidic/saline environment) | Great (native oxide layer) |

| Weight | Really light | Really heavy |

| Strength | Great strength-to-weight ratio | Best strength |

| Cost | Gets expensive at first | More economical |

| Best Applications | Transportation, aerospace, weight-critical projects | Marine, industrial, high-load applications |

| Long-term Value | Cost saving on maintenance and fuel efficiency | Almost no maintenance in harsh environments |

What Are the Benefits of Custom-Fabricated Steel Tubes?

Advantages of Custom Design and Specifications

- Exact Fit for Applications: Like fabricated steel tubes custom made to design and dimension specifications, they must be compatible with their project needs and require less installation adjustment.

- Bettering Structural Integrity: Since tubes are manufactured to fine tolerance, it is possible to optimize structural performance for greater resistance to imposed loads.

- Improved Efficiency: The custom-made procedures prevent wastage of materials and hence support better production processes that can lead to reduced costs and save time during fabricating and construction phases.

- Complex Project Versatility: It allows for the creation of unique shapes, sizes, and configurations for custom uses that cannot be satisfied by standard tubes.

- Aesthetics and Functional Flexibility: Custom solutions avail the opportunity to see the structural elements through an aesthetic view or via some functional peculiarity relevant to the final product.

Impact of High Quality Fabrication on Performance

High-quality fabrication plays a crucial role in performance as it guarantees structural integrity, precision, and durability. There are minimum defects for superior craft, such as weak euphoric junctions and fluctuations in dimensions, which threaten reliability. Also, precise methods of construction eliminate low output while eliminating any requirement for assembling repairs, and the products last longer before they break down. Higher performances are consequently achieved while at the same time saving costs, ultimately resulting in the initial and long-term benefits of such a material.

How to Maintain and Order Lightweight Metal Pipes?

Proper Maintenance for Longevity

Best Practice: Regular visual inspections and checks of any lightweight metal pipe are necessary to ensure that the structure can be used for an extended period of time without premature wear, corrosion, or damage.. Wash the pipes using suitable cleaning solutions free of abrasives that may cause surface degradation, and try to reduce exposure to chemicals that are highly corrosive or extreme temperature levels which may compromise the structural integrity of the material in question. It is possible to extend their retention of usefulness and effectiveness by maintaining them in accordance with the guidelines provided by the manufacturer and ensuring that any problem that arises is dealt with on an urgent basis.

How to Contact Manufacturers and Suppliers

- Research Contact Information: Look up the manufacturer’s or supplier’s website for contact details such as phone numbers, emails, and addresses. There might be a separate customer-service division or sales department.

- Use Contact Forms:A lot of suppliers will give you the convenience of an online form for making inquiries. Fill out such a form carefully with your requirements or queries.

- Calls or Emails Directly: Use phone or email contacts for direct communication. Make sure the message we send contains the necessary details such as product specifications, quantities, and deadlines.

- Utilize Online Directories: An online directory for industry suppliers or any other legitimate platform might have verified contacts for manufacturers and suppliers.

- Meetings If Required: In case detailed order checking or agreements are involved, set up a meeting or consultation to discuss projects clearly and ensure smoother cooperation.

Optimizing Order and Delivery Process

- Ensure Smooth Communication: The orders must be communicated informally and appropriately, with an emphasis on preventing any misconceptions. Ideally, all particulars might need to be confirmed, such as product specifications, quantities, and when things would be delivered.

- Put Tracking Systems into Effect: Use a tracking system to do away with any opacity and sometimes, address delays before time.

- Source from Reliable Suppliers: Work with dependable suppliers who can always deliver on time with good quality.

- Combineable Shipments: Combine shipments wherever possible, so orders can be shipped less frequently, thereby cutting shipping time and cost.

- Regular Evaluations of Performance: The performance of the supplier and deliveries has to be regularly evaluated by using key indicators such as on-time delivery rate and the product condition on arrival, and then take any required actions needed.

Frequently Asked Questions (FAQs)

Q: What benefits does lightweight metal piping offer in industrial settings?

A: A lightweight metal pipe of aluminum or steel offers various benefits such as easy transportation, reduction of shipping expenses, and facilitation of operational efficiency in industrial or heavy machining activities. From an industrial point of view, Andreas further commented that these lightweight metals have longevity and take pressure, hence being able to be utilized for many industrial purposes without contending with heavy steel pipe disadvantages.

Q: In what way does the size of the inner diameter of a lightweight steel pipe affect its function?

A: It is correct to assume that the inner diameter of a lightweight steel pipe matters quite a great deal, and more so because it has an implication on the flow of fluids and gases where the diameter is large. An increase in the inner diameter means that more material can be passed through, which improves the effectiveness of the systems that use those pipes to transport materials.

Q: Could lightweight rectangular tubes serve a structural function?

A: Yes, structural applications often involve the use of rectangular tubes with reduced weight. There are light and strong construction projects with weight constraints that can use them with ease. Square and rectangular shapes also have the advantages of stacking and are used extensively for framework purposes.

Q: Which type of finishing is applied to lightweight metal pipes?

A: Lightweight metal pipe is available in many finish types, such as powder coating, galvanized, or polished. These finishes enhance the public appearance of the product, but at the same time enhance corrosion resistance, thus increasing the service life of such a pipe in challenging conditions.

Q: In what way are on-sale lite steel tubes, and which materials are common constituents of these tubes’ accommodation?

A: Maintaining low-priced aluminum pipes ensures that these tubes are applicable to most low-cost projects. As one considers the available resources, one should also consider the issues relating to price, durability, weight, and specific purpose as these may arise when one is using the available tubing and how they influence the final benefit.

Q: Are there particular instances where hollow lightweight tubes are preferable?

A: Hollow lightweight pipes are more specifically used in areas where less weight means more advantage, mostly in automotive and aerospace industries, where burst pressure ratings have to be developed. These structural properties make them easier to use as they will be subjected to stresses against a decrease in the total weight as compared to other solid versions.

Q: Why is the schedule important in lightweight metal pipe design?

A: When talking about lightweight metal pipe dimensions, sch is a term that determines the wall thickness of the pipe for a certain piping system. Its use and adoption is aimed at facilitating the correct performance of the pipe under the envisaged weight and pressure.

Q: What are the advantages of the roll forming process in the manufacturing of lightweight metal tubing?

A: Gone are the days when the only option for producing lightweight metal tubing was either to incur high costs or compromise on the quality. The roll forming technique has helped in this regard as it allows for seamless production of tubes where these tubes can be round, square or oval in shape, but this time, within appreciable limits. As an additional benefit, the technique can be adapted for different sizes and shapes, thereby ensuring that specific requirements can be fulfilled.

Q: Is there something that has to be taken into account in relation to the length of lightweight steel pipes on the construction plan?

A: Measuring the length of a lightweight metal pipe for construction might require additional factors such as tolerance limits, pipe usage and the possible presence of additional joints. Taking the right measurements helps in the fitting and functioning of the component in relation to the complete design.

Q: Why should industries consider using flexible lightweight metal hoses?

A: The ability of the flexible lightweight metal hoses to provide increased maneuverability for the installer and follow the routing required without affecting the fluid dynamics is of particular significance. Such hoses are resilient and can contain pressures from either vibrations or moving parts within the industry.

Reference Sources

1. Experimental investigation of the behavior of the steel-reinforced high-density polyethylene and corrugated metal pipe

- This study aims at the flexibility and lightweight properties of HDPE materials, as opposed to corrugated metal pipes, which often require welding for assembly.

- Read more here

2. Composite Pipe Design And Analysis

- This paper discusses the analysis of composite pipes with metal liners, concentrating on their structural behavior under different conditions.

- Read more here

Additional Resources

Key Takeaways

The lightweight metal pipe industry is a major intervention of modern-day engineering and construction. Their high strength-to-weight ratio, corrosion resistance, and more or less versatility make these high-engineered structures very popular amongst many industries. Be it working on HVAC, structural buildings, or airplanes, a well-constructed knowledge of using these materials is very crucial to making the best out of a project. Also, there are certain variables, such as material, diameter of the pipe, thickness of the wall, and very good housekeeping practices, among others, which are to be considered for purposes of enhancing performance, durability, and cost of completion of the project from the lightweight metal pipe application.