Steel stands out as one of the most preferred materials utilized globally owing to its strength, versatility, and durability. Steel is not uniform in its magnetic properties, and different steel variants behave differently. The magnetic aspect of steel does beg the question of reasoning from where some variants get their magnetism, and others do not. The magnetic phenomena associated with steel and its behavior are essential to understand for industries dealing with construction, manufacturing, electronics, and even medical equipment. In this discussion, we will outline the science of magnetism, how and what steel’s magnetism depends upon, and its properties and possible applications. An engineer, designer, or a simple metal hobbyist, this guide explains many interesting things about steel and magnetism.

What Makes Steel Magnetic?

Steel is a magnetic material due to the presence of iron, which is a magnetic material itself. Iron has unpaired electrons, and their spins align with the direction of the magnetic field, giving rise to magnetism and contributing to the magnetism of steel. Also, the crystalline form of steel, particularly its ferritic form, supports the alignment of the magnetite; thus, it is receptive to magnetism and magnetically aligned. Nonetheless, the amount of magnetism in steel is not constant and depends on the steel’s composition and heat treatment. For instance, the stainless steels with the most chromium and nickel are non-magnetic because their structure is austenitic.

Ferromagnetism and Steel

The chemical composition and microstructure of steel greatly affect its magnetism. Magnetic steels commonly possess a ferritic or martensitic structure, where iron is present, and the atomic spins of the iron are orderly–aligned. On the other hand, austenitic stainless steels are non-magnetic because of their high chromium and nickel content. Furthermore, the magnetic properties of steel are changed by processes like heat treatment and cold working, which modify the internal arrangement of components, including the atomic structure, even more so in the ferrite phase.

The Role of Alloy Elements

The mechanical characteristics of steel, especially when considering diverse attributes, are significantly impacted by alloying elements. Adding carbon, manganese, chromium, and nickel furthers specific characteristics. As with most metals, steel’s hardness and strength increase with the addition of carbon. Manganese makes steel more challenging and more wear-resistant. Chromium is key for enhancing corrosion resistance and forming the protective oxide layer in stainless steel. Nickel increases strength and toughness and improves corrosion resistance, especially at lower temperatures. Steel can be manipulated to diverse performance requirements by meticulously selecting and combining alloying elements.

How Magnetic Fields Affect Steel

Magnetic fields affect steel by changing its internal organization and its magnetic properties. Steel is a magnetic metal and can become magnetized if placed within a magnetic field. This happens due to the magnetic field’s ability to brace domain structures, or magnetization zones, within steel. Steel’s phenomenon susceptibility is relative to its structure and the intensity of the magnetic field imposed. Furthermore, constant magnetization or strong fields, especially over extended periods, may alter function, best exemplified by permanent residual magnetism, the magnetization retained when the magnetizing field is removed. These considerations are critical in the case of dynamic applications where the material is subjected to magnetic fields.

Are All Types of Stainless Steel Magnetic?

Austenitic Stainless Steel and Magnetism

Austenitic stainless steels, like grade 304 and 316 stainless steels, are non-magnetic because of their face-centered cubic (FCC) crystal structure, which does not permit the magnet domains to align. However, some situations can change the magnetic characteristics of austenitic stainless steel.

For instance, cold-working deformation can convert some of the austenitic structures into martensite, a form capable of hardening steel and making it magnetic. This is known as strain-induced martensite formation. Under such conditions, 304 stainless steel, after being heavily cold-worked or welded, changes its properties to exhibit weak magnetic behavior. Here, increased magnetism results from structural changes due to mechanical or thermal stress.

Research indicates that the magnetism of cold-worked stainless steel is low when examined in the context of permeability values. For context, austenitic stainless steels have a relative magnetic permeability of nearly 1.0 in the annealed state. Still, in a processed state where martensite is formed, that value is expected to increase slightly.

Remember that nickel and chromium are essential to austenitic stainless steels because they stabilize the FCC structure and decrease the magnetic response. These aspects are relevant for engineers and material scientists when they choose materials for non-magnetic applications with rigid requirements.

The Magnetic Behavior of Ferritic and Martensitic Stainless Steels

The magnetic properties of ferritic and martensitic stainless steels are much more significant than austenitic grades. The primary difference between the two grades of stainless steel is based on their crystal structures. Ferritic stainless steels possess a body-centered cubic (BCC) crystal structure that is intrinsically ferrimagnetic, thus making the alloy easily capable of undergoing magnetization. Contrary to popular belief, martensitic stainless steels are also magnetic, but their magnetism is caused by the BCC or body-centered tetragonal (BCT) structures that form during heat treatment. The response these steels demonstrate to a magnetic field make them ideal for use in areas where magnetic abilities is a must, however, they must be careful with the low magnetic disturbance in constructions involving low magnetic fields. Regardless of the grade, these properties will remain true based on the alloying constituents in the composition and the heat treatment applied.

Why Some Stainless Steel is Not Magnetic

The non-magnetic attributes of some stainless steels stem mainly from their crystal structure. Austenitic stainless steels, 304 and 316 grades, for instance, mainly consist of a face-centered cubic (FCC) structure, which nullifies ferromagnetism. Magnetism is absent due to the lack of unpaired electrons in the atom’s FCC lattice, which causes magnetic behavior in other materials.

The chemical makeup of stainless steel considerably affects its magnetic response. For instance, large amounts of nickel and chromium stabilize the FCC structure in austenitic stainless steels, barring the development of ferromagnetic phases. These elements counteract magnetism in ferritic or martensitic stainless steels with body-centered cubic (BCC) or body-centered tetragonal (BCT) structures.

External factors, however, can manifest magnetic characteristics in austenitic stainless steels. Severe cold work for long durations or high deformation during production can alter the FCC structure to a magnetic phase, which is martensitic. This change, known as strain-induced martensite, tends to be more prevalent in leaner alloy grades like 301 stainless steel and is less pronounced in 316 grades due to molybdenum’s stabilizing influence.

Additionally, stainless steel’s susceptibility to magnetism can change based on how the alloy is composed and processed. Research shows that 304 stainless steel has initial magnetic susceptibility between 1.05 and 1.15, while 316 stainless steel, which has a higher molybdenum content, shows much lower numbers, often around 1.01. These differences are essential when selecting a particular stainless steel grade for applications with magnetic properties as a critical consideration.

To conclude, the lack of magnetism in some types of stainless steel can be attributed to their atomic structure and the alloys that make up the steel. Magnetism can also be influenced by external factors such as mechanical heating, which illustrates the importance of meticulous engineering design.

How Do Magnets Interact with Steel?

The Influence of Steel Grades on Magnetism

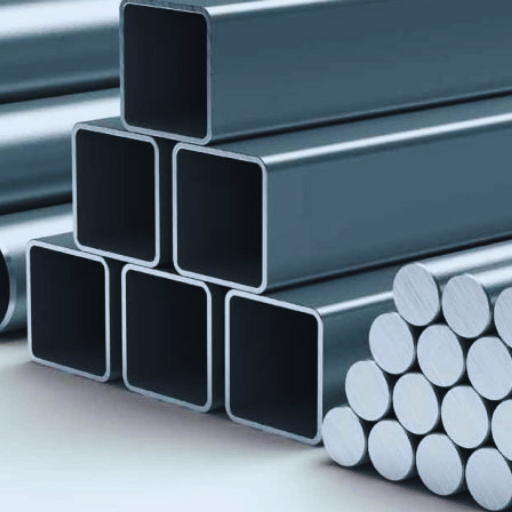

The composition and microstructure of steel determine its magnetic properties. Magnetic steel types include carbon steel due to its higher iron content, ferritic structure, and high magnetic properties. Meanwhile, austenitic stainless steels, such as the 300 series, are usually non-magnetic due to their crystal structure hindering magnetic domains from aligning. These materials can develop partial magnetism due to cold working or mechanical deformation. Understanding these characteristics is critical when selecting the appropriate steel grade for magnet applications.

External Magnetic Fields and Steel

The external magnetic field interactions with steel highly depend on the composition and internal structure of the steel. Ferritic and martensitic steels have a higher iron content. Thus, they are strongly attracted to magnetic fields due to the alignment of magnetic domains. On the other hand, austenitic stainless steels like the 300 series are primarily non-magnetic and do not respond strongly to magnetic fields. However, some mechanical deformation or cold working imposes local magnetism on austenitic steels. For these cases, where steel is subjected to magnetic fields, the fully austenitic stainless steel would be more suitable as it contains lower magnetic permeability. This type of steel would provide less interference on magnetic-caused disturbances.

Magnetic Permeability of Different Steel Types

Different steel types have variants in magnetic permeability depending on their composition and microstructure. Generally, ferritic and martensitic stainless steels have higher magnetic permeability, making them more susceptible to magnetic fields. In comparison, fully austenitic stainless steels, like grade 316L, have very low magnetic permeability, which makes them helpful in guarding applications with minimal magnetic interference. Austenitic, fully non-magnetic grades after processing are preferred for maximum efficiency in magnetically sensitive environments.

Can Steel Become Non-Magnetic?

The Process of Demagnetizing Steel

To demagnetize steel means to disrupt its existing magnetic alignment, which can be done in three ways. First, applying heat beyond the steel’s Curie temperature will eliminate any magnetic properties since the material’s internal structure is reset. Second, an alternating magnetic field can gradually reduce residual magnetism by realigning the domains. The last method is physically hammering or bending, which changes the alignment of magnetic domains, although this technique is not very accurate. Although these methods are correct, they must be tailored to the application due to the materials involved and their mechanical properties.

Factors That Lead to Loss of Magnetism in Steel

The following are primary reasons which can lead to loss of magnetism in steel:

- Heat Exposure: High temperatures can disorder the internal structure of magnetic domains in steel, resulting in loss or total loss of magnetism. This is common when the material is raised above the Curie temperature.

- Physical Impact: Physical impacts, such as dropping or bending the material, increase mechanical strain and dislocate the internal magnetic domains, causing a loss of magnetism.

- Prolonged Alternating Magnetic Fields: Repeatedly applying alternating magnetic fields to steel for prolonged durations can disorient the domains and cause the material to lose its magnetism.

- Corrosion: Changing environmental conditions, such as oxidation, lead to corrosion of the material’s structure, reducing its ability to induce the structure magnetically.

These described facts should, within all other considerations, permeate the design of devices employing permanent magnets.

Applications of Magnetic and Non-Magnetic Stainless Steel

Industries Using Magnetic Stainless Steel

Magnetic stainless steel is widely used in industries that find its corrosive resistance and magnetism useful. The most important sectors are:

- Automotive: Used in some parts like sensors, fuel injectors, and exhaust systems due to the strength and magnetic nature of the material.

- Electronics: Important for transformers, solenoids, and magnetic storage media.

- Appliances: These are found in magnetic washer drums, refrigerating machines, and kitchen implements where strength and magnetism are helpful.

- Construction: Used for architecture and fasteners with strength and magnetism.

All these industries use magnetic stainless steel for its practical usefulness, dependability, and adaptability in different environments.

Advantages of Non-Magnetic Metals in Technology

Non-magnetic metals are legal but require stable magnetic fields for use in technology. The non-magnetic property makes such metals worthwhile in precision electronic devices, MRI machines, and modern semiconductor elements in other sensitive electronic appliances. Also, these metals are often used in aerospace and military technology because non-magnetic materials are constantly exposed to critical performance conditions without reliability issues. Non-magnetic materials also serve well in obtained environments because these metals are worn and corrosion-resistant. Thus, these non-magnetic metals significantly contribute to the development of technology today.

Frequently Asked Questions (FAQs)

Q: Is steel magnetic?

A: Steel is a magnet, although its magnetism is conditional on the type of steel. Certain types of steel, like ferromagnetic steel, are strongly magnetic because of the iron and the crystal structure they possess.

Q: Why are some types of steel, like 304 and 316, not magnetic?

A: 304 and 316 stainless steels are not magnetic due to their high quantity of chromium and nickel. These two elements promote an austenitic crystal structure that does not favor magnetic moments’ alignment. Hence, these steels remain non-magnet and are weakly magnetic at best.

Q: Can 304 stainless steel become magnetic?

A: 304 stainless steel can become magnetic by undergoing processes like cold working. Such processes alter the structure and crystal lattice of materials, which tend to make them magnets.

Q: What is a ferromagnetic metal?

A: Ferromagnetic metals are those materials that encompass strong magnetization and may serve as permanent magnets. These metals consist of unpaired electrons with their spins aligned in a parallel manner and thus create a strong magnetic field.

Q: In what ways do nickel and chromium impact the magnetism of steel?

A: Nickel and chromium impact steel’s crystal structure. Nickel stabilizes the austenitic structure, which is generally non-magnetic. Chromium aids in resisting corrosion but doesn’t assist with magnetism in steel.

Q: What about unpaired electrons contributing to magnetization?

A: The presence of unpaired electrons is important for magnetization. They can spin in a way that joins e at a domain to change the material to one with magnetism. This occurs in metallic elements like iron, as they are able to align and become ferromagnetic.

Q: Is steel classified as containing iron?

A: Steel will always contain iron, as iron is its primary material, and its strength and magnetism are determined. The presence of iron allows the steel to be magnetized under some conditions.

Q: What is nonmagnetic steel?

A: The primary difference is the arrangement of some alloying components of the crystal structure. Sometimes referred to as ferromagnetic steel, magnetic steel comprises alloys that properly structure and allow for the superposition of moments. Non-magnetic stainless austenitic steels do not permit stacking due to the lattice.

Q: What is the impact of cold working on the magnetism of steel?

A: Cold working can increase steel’s magnetic properties because it can change the steel’s crystal structure from austenitic to martensitic or ferritic. This increase is due to a lower energy state (higher stability) of the magnetic moments within the steel, permitting better alignment.

Q: What other non-magnetic metals, like aluminum?

A: There are non-magnetic metals such as aluminum, copper, and zinc because these metals do not have unpaired electrons, providing a source for generating the magnetic field. Thus, these metals are termed non-magnetic substances.

Reference Sources

1. Stress and Temperature Associated Vector Magnetic Properties of Electrical Steel Sheet (Zhang et al., 2022, pp. 980-990)

- Key Findings:

- The proposed measurement method is verified by assessing the VMPs of non-grain and grain-oriented electrical steel sheets (ESS) at various temperatures and applied stress levels.

- The model proposes a method of measurement that includes the interaction of temperature and stress.

- Methodology:

- In the specimen’s measurement region, the horizontal bed of the vertical-type orthogonal double-U yoke is equipped with two opposite-opening rectangular magnets, which create a uniform magnetic field distribution.

- Vector magnetic flux density B and magnetic field intensity H are acquired using the B-probe and double compound H-coil techniques.

- Using a linear actuator, tensile or compressive stress is applied along the specimen’s rolling and transverse axes.

- The temperature controller facilitates variable temperature measurement conditions in conjunction with ceramic heating pads.

2. Study and Use of Ultra Thin Grain Oriented Silicon Steel Sheets Magnetic Properties Under Multi-Physical Field Coupling (Li et al., 2022)

- Key findings:

- In grain-oriented silicon steel, the magnetic properties are best for the selected region within a 30 30-degree magnetization deviation angle compared to non-grain-oriented silicon steel.

- Grain-oriented silicon steel will lose its magnetic properties as the non-uniform external heat temperature rises, unlike non-uniformly grain-oriented silicon steel, which behaves differently.

- Grain-oriented silicon steel has a relatively optimal magnetic property under 30 MPa stress.

- The use of grain-oriented silicon steel in the interior parts of electric vehicles (IPM) boosts the magnetic flux density of the stator teeth by 2.2%, increases motor torque by 2.18%, and peak efficiency by 1%, increasing gravimetric power at rest.

- Methodology:

- Grain-oriented silicon steel magnetic traits were examined under varying conditions using an Epstein frame and self-constructed multi-physical field devices.

- The model guided the exploration of using grain-oriented silicon steel in IPM for electric vehicles with a precision-oriented silicon steel motor model.

3. Multistep Cross Rolling of UNS S32101 Steel: Microstructure, Texture, and Magnetic Properties (Dandekar et al., 2021, pp. 2916–2929)

- Key Findings:

- UNS S32101 steel shows improved magnetic properties via multistep cross-rolling due to the refinement of microstructure and texture.

- Magnetic properties are not as favorable due to the characteristics of the cutting methods employed and the material.

- Wire cutting has little impact on magnetic performance, but laser cutting reduces relative magnetic permeability at greater depths within the steel strips.

- Methodology:

- After multistep cross-rolling, we characterized and measured the microstructure, texture, and magnetic properties of UNS S32101 steel samples.

- Magnetic measurements near cutting edges were done using a mobile B–H sensing framework.