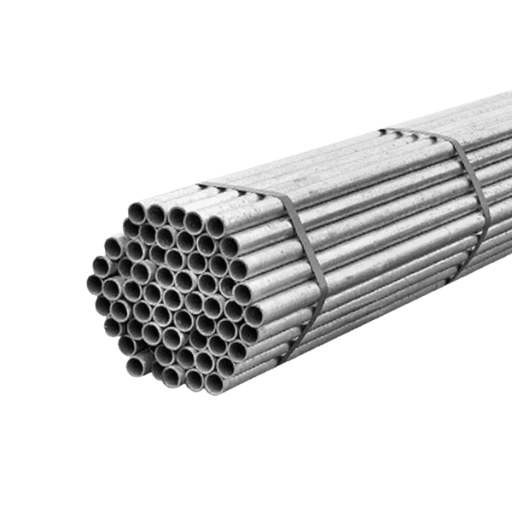

Galvanized Iron Pipes represent a vital concept in modern infrastructure and construction activities. GI Pipes are considered one of the most durable and corrosion-resistant products, thereby proving to be key in many major fields, including construction and the oil and gas industry. The galvanizing process, which involves coating these steel pipes with zinc, offers a lifespan far longer than that of typical steel pipes, thereby rendering them an essential ingredient in several projects worldwide.

Introduction to GI Pipes

Importance of GI Pipes in Various Applications

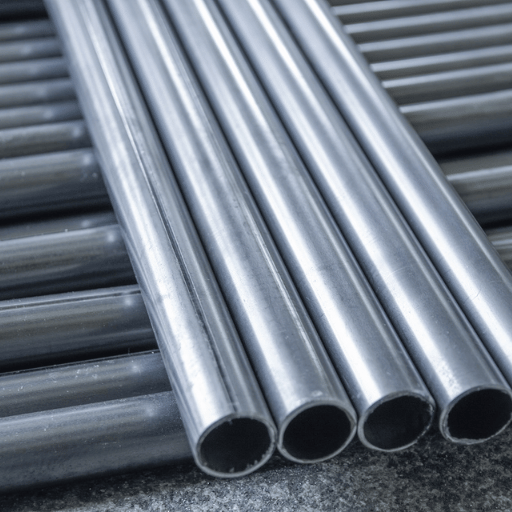

GI pipes are indispensable conduits in various applications due to their robustness and versatility. These are the pipes extensively used for water supply, sewage lines, and protection conduits for electrical wiring. Since galvanized steel pipes were corrosion-resistant, they could withstand any hard environmental condition, making them an unparalleled choice for exterior and underground settings. With the transport of oil and gas, the safety and reliability of these pipes become of utmost concern.

Overview of Galvanized Steel Pipe Manufacturing

Several steps are taken to ensure the manufacture of galvanized pipes is meticulous, resulting in top-quality, durable products. The production process begins with the selection of high-quality raw materials, such as mild steel or carbon steel, which are then welded internally using the ERW method or other techniques. Then, they are galvanized with a coating of zinc in the crucial step of hot-dip galvanizing, which provides corrosion resistance to the welded steel pipe and thereby extends its lifespan. This holistic procedure ensures that pipes offer an elevated grade in tandem with industry standards.

Benefits of Using GI Pipes

GI pipes offer multiple benefits that make them a preferred choice for projects. While GI pipes are durable and withstand weathering in storms, they are also affordable and require minimal maintenance in terms of cost. The zinc coating protects these pipes from corrosion, thereby increasing the pipe’s lifespan; hence, the maintenance cost decreases over time. Whereas GI pipes are versatile and find application in every kind of setup, they are used in both small setups, such as residential plumbing, and large setups, including industrial, revenue yards, and commercial plumbing.

Criteria for Selecting Top GI Pipe Manufacturers

Quality Assurance and Standards

When analyzing GI pipe manufacturers, quality assurance and adherence to industry standards are essential. Leading manufacturers implement rigorous quality control procedures in the production of their goods to ensure that proper specifications are met. Pipes are tested periodically for durability, corrosion resistance, and structural integrity. Pipes adhering to international standards can be trusted for use in critical applications, with safety considerations and performance measurements at the forefront.

Range of Products Offered

An extensive range of products caters to the multifaceted demands that customers may set. Obscure suppliers of GI pipes offer a broad range of pipe types, including galvanized iron pipe, welded steel pipe, and other industrial-grade pipes such as mild steel pipes and carbon steel pipes. By this means, clients can be offered specific solutions tailored to their particular needs in the construction, industrial, and fluid and gas transportation sectors.

Customer Service and Support

Customer service and support are of utmost importance when evaluating the best GI pipe manufacturers. The trustworthy suppliers prioritize customer service by offering support services such as consultation, technical support, after-sales service, and timely product delivery. Communication is made effective, and suppliers remain responsive to client concerns throughout the project, thereby encouraging a long-term client relationship rather than lapsing from inception through execution.

Top 15 GI Pipe Manufacturers

1. Baling Steel

Year Founded: 1998

Introduction: Renowned for its high-quality galvanized iron pipes, Baling Steel is a global leader in the steel industry.

Main Products: GI pipes, steel coils, and structural steel

✓ Advantages: High durability, corrosion resistance, and adherence to international standards

✗ Disadvantages: Limited availability in some regions

Website: Baling Steel

2. Atkore International

Year Founded: 2010

Introduction: A leading manufacturer of galvanized rigid conduit (GRC) and intermediate metal conduit (IMC) for electrical systems.

Main Products: Galvanized steel IMC and GRC

✓ Advantages: Precision manufacturing and long-lasting value

✗ Disadvantages: Focused primarily on electrical applications

Website: Atkore International

3. Metal Supermarkets

Year Founded: 1985

Introduction: Offers a variety of metals, including galvanized steel pipes.

Main Products: Mild steel pipe, galvanized

✓ Advantages: High corrosion resistance and durability

✗ Disadvantages: Limited product range for specific industries

Website: Metal Supermarkets

4. St. Louis Pipe & Supply

Year Founded: 1987

Introduction: A reliable supplier of galvanized pipes with a comprehensive inventory.

Main Products: Carbon, alloy, and chrome pipes

✓ Advantages: Extensive inventory and reliable supply chain

✗ Disadvantages: Primarily a supplier rather than a manufacturer

Website: St. Louis Pipe & Supply

5. V&S Galvanizing

Year Founded: 1968

Introduction: Specializes in hot-dip galvanizing for enhanced corrosion protection.

Main Products: Galvanized steel and fasteners

✓ Advantages: Expertise in corrosion protection

✗ Disadvantages: Limited to galvanizing services

Website: V&S Galvanizing

6. Majestic Steel USA

Year Founded: 1979

Introduction: Offers galvanized steel sheets and coils for various industries.

Main Products: Galvanized steel sheets and coils

✓ Advantages: Custom sizes and high rust protection

✗ Disadvantages: Focused on sheet and coil products

Website: Majestic Steel USA

7. Texas Iron & Metal

Year Founded: 1939

Introduction: A prominent supplier of high-quality galvanized steel pipes.

Main Products: Seamless and welded galvanized steel pipes

✓ Advantages: Extensive inventory and value-added services

✗ Disadvantages: Limited to the U.S. market

Website: Texas Iron & Metal

8. American Cast Iron Pipe Company

Year Founded: 1905

Introduction: Specializes in ductile iron and spiral-welded steel pipes.

Main Products: Ductile iron and steel pipes

✓ Advantages: Advanced manufacturing technologies

✗ Disadvantages: Focused on waterworks and oil sectors

Website: American Cast Iron Pipe Company

9. Metalplate Galvanizing L.P.

Year Founded: 1975

Introduction: Offers hot-dip galvanizing services for corrosion protection.

Main Products: Galvanized steel pipes and services

✓ Advantages: Over 60 years of experience

✗ Disadvantages: Limited to galvanizing services

Website: Metalplate Galvanizing

10. McWane Ductile

Year Founded: 1921

Introduction: Manufactures ductile iron pipes for water distribution.

Main Products: Grooved ductile iron pipes

✓ Advantages: High strength and durability

✗ Disadvantages: Limited to ductile iron products

Website: McWane Ductile

11. APL Apollo Tubes Ltd.

Year Founded: 1986

Introduction: India’s largest producer of structural steel tubes with a significant market share.

Main Products: Structural steel tubes, GI pipes.

✓ Advantages: Advanced forming technology, extensive distribution network

✗ Disadvantages: Focused primarily on the Indian market

Website: APL Apollo Tubes

12. Jindal Pipes Ltd. (JPL)

Year Founded: 1970

Introduction: A leading manufacturer of GI pipes in India.

Main Products: Galvanized and black steel pipes

✓ Advantages: High-quality materials and rigorous testing

✗ Disadvantages: Primarily serves the Indian market

Website: Jindal Pipes Ltd.

13. TATA Steel

Year Founded: 1907

Introduction: A global leader in steel manufacturing, including GI pipes.

Main Products: GI pipes, steel sheets, and coils

✓ Advantages: Global presence and high-quality standards

✗ Disadvantages: Higher pricing compared to local competitors

Website: TATA Steel

14. Surya Roshni Ltd.

Year Founded: 1973

Introduction: Manufactures GI pipes and other steel products.

Main Products: GI pipes and structural steel

✓ Advantages: Wide product range

✗ Disadvantages: Limited international presence

Website: Surya Roshni Ltd.

15. Hi-Tech Pipes Ltd.

Year Founded: 1987

Introduction: A tech-driven manufacturer focusing on critical infrastructure needs

Main Products: Steel pipes, GI pipes

✓ Advantages: Cutting-edge technology, EPC model expertise

✗ Disadvantages: Smaller scale compared to competitors

Website: Hi-Tech Pipes

Current Industry Trends Influencing GI Pipe Manufacturing

Sustainability Practices in Pipe Manufacturing

The sustainability movement has captured the attention of the GI pipe industry lately. More manufacturers are adopting greener avenues, including but not limited to recycling and minimizing waste during manufacture. The use of non-toxic materials, energy-efficient processes, and so forth, will help cast down the carbon footprint, Pays respect to sustainability travel goals worldwide, and serves consumers whose demand for green products is rising.

Innovation in Materials and Technology

With the industry emphasizing the development of materials and technologies in the manufacturing of GI pipes, first-rate materials and production technology have enabled innovations in this industry, such as high-strength alloys or improved galvanization techniques, resulting in better performance and longer pipe life. Furthermore, automated and digital production technologies have enhanced efficiency and precision, setting high standards for pipe manufacturing quality and consistency.

Market Demand and Price Trends

GI pipes market is truely a fluctuating market in terms of demand and price trends. The very factors of urbanization, infrastructure development, and industrial expansion are increasing the demand for good-quality pipes. However, pipe prices themselves are influenced by fluctuations in raw material costs and other geopolitical factors. Manufacturers are responding to this by streamlining their production processes and looking for new opportunities to price competitively.

Considerations for Choosing a GI Pipe Manufacturer

✓ Assessing Quality and Compliance

In selecting a GI pipe manufacturer, it is necessary to evaluate the quality and compliance status of their products. High-quality GI pipes are durable and corrosion-resistant, with these qualities being imparted through stringent quality controls and adherence to tested methods or industrial standards.

- Manufacturers should do regular testing to ensure the pipes are within specifications in terms of structural integrity and corrosion resistance

- International standards must be complied with so that for critical applications, these pipes find usage

- Focus on safety and reliability, especially where performance is critical, such as in hydrocarbon transport

✓ Evaluating Supplier Reliability

Supplier reliability ranks as a strong and foremost consideration in the purchase of GI pipes. A reliable supplier is one who consistently supplies good-quality products and maintains transparent communication with the customers.

- Look at the suppliers’ track record; go to customer reviews, and see what’s being said in the industry

- Ensuring that customers receive answers promptly and issues are resolved efficiently is where robust customer service should be emphasized

- Reliability must then be maintained in the project life cycle to keep the timeline on track

✓ Understanding Lead Times and Delivery Options

Understanding lead times and delivery options offered by a GI pipe manufacturer becomes vital during the planning and execution of any project.

- Manufacturers should be willing and able to offer production and delivery timelines that are realistic and well understood

- Considerations of lead times should factor into the complexity of the order and the availability of raw materials

- Ensure the manufacturer’s ability to accommodate rush orders and offer flexible delivery options

- Late deliveries and delays initiated may negatively affect big projects in terms of overall cost and schedule

Future Developments in the GI Pipe Industry

🚀 Emerging Technologies and Innovations

The GI pipe industry stands at the cusp of transformative changes due to emerging technologies and innovations. Materials science advancements have brought forth high-strength alloys and improved galvanization techniques and processes, resulting in enhanced performance and greater longevity of galvanized steel pipes. Increasingly, automation and digital technologies are being adopted in manufacturing, thereby providing significant efficiency and precision. These enhance the pipes with blessed beauty, enabling them to confront the ever-changing demands posed by modern infrastructure projects, thereby maintaining their competitiveness in a highly dynamic marketplace.

📋 Regulatory Changes Impacting Manufacturing

Regulatory changes entail significant impacts on the manufacturing practices of GI pipe producers. With governments worldwide tightening their environmental regulations, manufacturers are required to practice sustainability and reduce their carbon footprint as a result. Henceforth, adherence to the new rules, which include emissions, waste disposal, and the use of non-toxic materials, will determine their market competitiveness. These regulatory changes encourage manufacturers to innovate and invest in cleaner production technologies, making their products both legal and an acceptable green option in the eyes of consumers.

📈 Predictions for Market Growth and Demand

Market for GI pipes is expected to witness robust growth due to increased demand from infrastructure development and industrial sectors. Urbanization and the growth of the oil and gas industry are thereby driving this demand. As more countries channel investments into infrastructure improvement, demand for durable and dependable GI pipes will continue to rise. Additionally, geopolitical concerns and escalations in raw material prices will alter the market dynamics, prompting manufacturers to streamline their operations or develop new markets to ensure growth and address changing consumer requirements.

Final Thoughts

The GI pipe industry is ever-changing with his technological progress, sustainability initiatives, and changing demand in the market. An appropriate consideration must be given to quality standards, supplier reliability, and future trends of the industry in the selection of the manufacturer. As infrastructure development grows rapidly all over the world, high-quality galvanized iron pipes will be needed even more in construction, industrial, and utilities. With a clear picture of the industry and developments unfolded, choosing manufacturers of reliable innovativeness and quality will help businesses secure the most reliable and efficient piping solutions for their projects.