Drilling oil wells demands precision and stability, which are the key factors of success. Conductor pipe, which is commonly known as the foundation for well casing systems, is the most important accessory in this whole process. But what are the exact functions of conductor pipes, and what makes them so crucial? This article will discuss the conductor pipe’s function, purpose, and impact on the oil well’s overall integrity through construction. If you are a veteran industry player or a novice in the drilling universe, this guide is going to clarify how conductor pipes lay the groundwork for smooth and secure oil extraction for you.

Understanding the Conductor Pipe

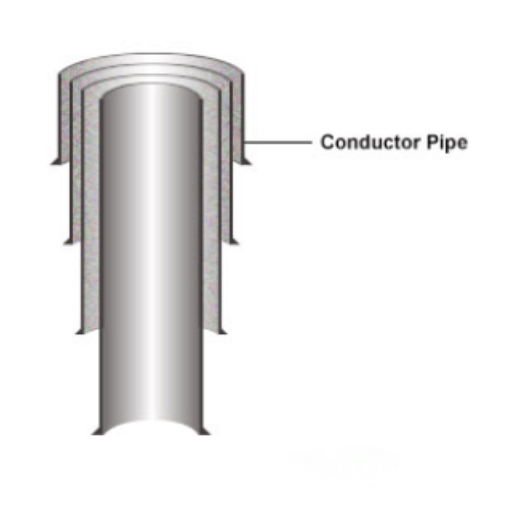

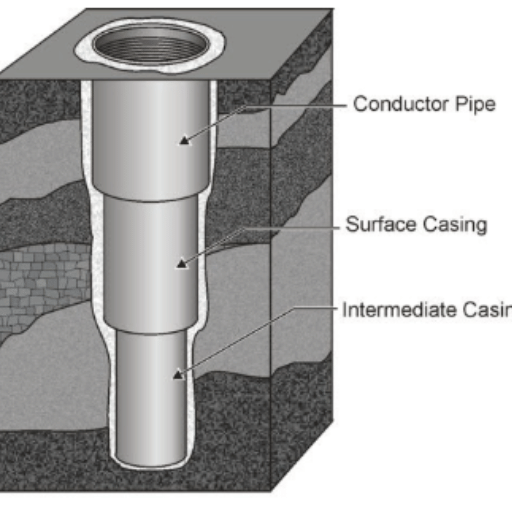

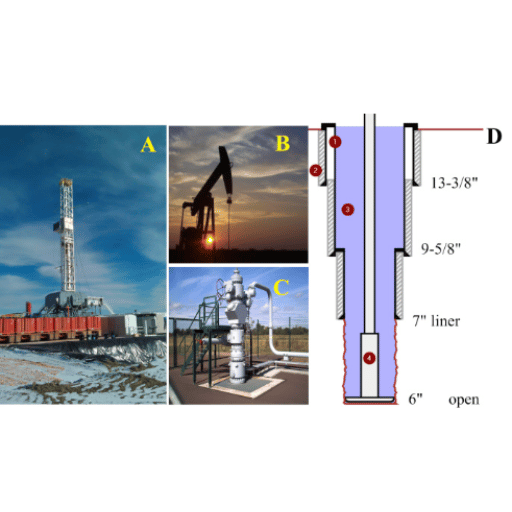

The conductor pipe is the first and the largest casing in an oil well, and it provides the initial structural support and stability for the drilling operation. It mainly prevents the loose surface soil from falling into the well and also facilitates the return of the drilling fluids to the surface. Normally, the conductor pipe is set up at shallow depths, and it also acts as a barrier to shallow water zones, thus ensuring environmental and operational safety. The conductor pipe, by providing this basic support, guarantees that the following drilling and casing activities will be carried out without problems and safely.

Definition and Purpose of Conductor Pipe

The conductor pipe is a pipe with a large diameter that is installed in the first stage of drilling to maintain structural integrity and avoid the collapse of surface layers into the well. It takes the drilling fluids back to the surface and separates the shallow water areas, thus ensuring safety and operational efficiency.

Role in Well Construction

The conductor pipe serves a very important function in the construction of a well by giving initial structural reliability to the well. It eliminates the possibility of near-surface rock layers falling in, it helps to carry out the casing process and it also transports the drilling muds safely to the surface. Moreover, it segregates the shallow water or gas intervals thus giving the rock and the environment the protection and safety they need during the drilling process.

Importance in Drilling Operations

The conductor pipe is a key element to any drilling operation as it provides stability to the well’s foundation and at the same time prevents surface-level collapses and guarantees safe fluid circulation. Isolating shallow layers and confining the danger, it offers a safe area for deep drilling with the minimum of safety and environmental impacts.

Materials and Specifications

Conductor pipes are generally constructed using high-strength steel for their durability against the physical stresses and extreme environmental conditions associated with drilling operations. The steel material is also subjected to treatments, coatings, or both to inhibit rusting through coming in contact with soil and water. Standard sizes are usually from 16 to 48 inches in diameter, which are determined by well design and geological requirements. Wall thickness is one of the factors used to provide additional strength in line with API (American Petroleum Institute) guidelines, which is the industry standard. Load-bearing capacity, soil stability, and environmental safety requirements are among the criteria that influence the choice of material and size.

Common Materials Used for Conductor Pipes

Conductor pipes, as a rule, are created with tough materials such as carbon steel and stainless steel. In most cases, carbon steel is the material of choice because of its great strength and low price, while stainless steel is used for its resistance to corrosion in very moist or salty environments. The choice of material is made based on the needs of the operation, the geological conditions, and the environmental factors to guarantee reliability and life span.

Steel Grades Comparison

Durability and Performance Under Extreme Conditions

OCTG items are designed to consistently perform even in the most difficult situations, such as under high pressure and at high temperatures. The robustness of these products is a direct result of the combination of modern manufacturing methods, careful selection of materials and thorough testing. Properties such as resistance to corrosion, very high tensile strength and superior quality in threading give the assurance that these substances will not only resist the adverse conditions but also keep their physical properties and function over a long time.

Installation Processes

Conductor pipes’ installation consists of a few essential procedures that guarantee the construction’s durability and the safe operation:

Installation Steps

- Site Preparation: The location for the installation is made ready and examined for the strength of the soil and the presence of any obstructions. The placement and the orientation of the pipes will thus be much more favourable than the original ones.

- Drilling the Hole: A hole of considerable diameter is bored by means of special equipment that will not only clear the way for the conductor pipe but also make its positioning very accurate.

- Pipe Installation: The conductor pipe goes down the hole while the positioning is monitored very closely. In this phase often the pipe is either driven or vibrated down to get the required depth.

- Cementing: The cement is injected into the space between the outer pipe and the ground to both lock and to give support to the pipe. This activity boosts the pipe’s load-bearing ability and forbids its movement.

- Inspection and Quality Check: The whole process is double-checked for right alignment, depth and stability, thus achieving the required industry standard.

All the phases are followed very strictly in order to benefit from the safety and engineering factors while reducing the risks in the operations that will come after.

Tools and Technologies for Installation

In order for the installation to be successful, the employment of exact tools and cutting-edge technologies is necessary for the realization of efficiency and accuracy. The main tools consist of trenching machinery, laser levels for perfect alignment, vibratory compactors for the refilling process, and pipe cutters for tailor-made modifications. By using GPS-guided systems and 3D modeling software, the execution and planning of installation can be done with much better precision. The use of these tools and technologies not only increases the amount of work done but also makes sure that safety and industry standards are not violated.

Challenges Faced During Installation

While putting in underground utilities, there can be many issues that lead to the decrease of precision and productivity. Such problems are caused by some unexpected conditions under the ground, for example, the presence of rocks or unstable soil and these can make trenching and excavation very complicated. Heavy rain and similar weather conditions can, on one hand, delay the work and, on the other, pose a safety risk. Urban or congested areas could also place restrictions on the access to the installation site, thus operating the equipment might be very difficult. Moreover, the communication with different parties and the adherence to government regulations can further complicate things. Good pre-planning and adoption of modern technologies are the best ways to clear these hurdles.

Best Practices for Choosing Conductor Pipes

Key Selection Criteria

- Understand Site Requirements:

To specify the right pipe size, material, and specifications, assess the geological conditions and environmental factors at the installation site. - Consider Material Durability:

For instance, steel or reinforced composites can be used as some of the long-lasting materials that resist corrosion, pressure, and environmental stress. - Prioritize Structural Integrity:

The pipes should be strong and thick enough to handle the applied load without experiencing any failure like buckling or collapse during operations. - Compliance with Standards:

It is mandatory that the pipes have obtained the proper industry standards and certifications so as to be assured of their safety and performance. - Account for Future Needs:

Selecting pipe dimensions and material capabilities must include possible expansions or rising operational demands.

Factors to Consider for Specific Applications

When choosing conductor pipes for certain applications, the following main factors should be taken into consideration:

- Environmental Conditions: Analyze the surrounding environment, which includes temperature, pressure, and soil or seabed characteristics, so that the pipe can handle the external stresses.

- Load Requirements: Find out the mechanical loads, for instance, the axial and lateral forces, to confidently assess the pipe’s structural integrity.

- Material Selection: Use materials that have good corrosion resistance, strength, and durability for the specific environment.

- Installation Logistics: Consider the transport, handling, and installation difficulties depending on the project site and the tools available.

Going through these considerations will make certain that the pipe will perform and last as long as it was intended.

Ensuring Optimal Performance and Longevity

For the purpose of keeping performance and life expectancy at their best, it would be advisable to concentrate on the use of first-class materials, the compliance with the prevailing industry standards, and the use of the right installation methods. Regular maintenance which includes inspections at intervals and repairs done on time is a must in order to avoid the deterioration of the equipment. Moreover, consider the environmental factors and the demands of operation to change the designs and strategies that will make the products last longer and be more reliable in the future.

Cost Implications and Budget Considerations

When dealing with the cost implications, it is very important to choose value rather than expense by choosing the materials and solutions which give long-term reliability and efficiency. Set aside the budget for regular maintenance and possible upgrades to keep the expensive failures at bay. Look at the lifecycle costs instead of the upfront costs, as this method usually cuts down the overall cost and gets you better performance. Mixing quality with price is the secret to getting sustainable results within the limits of your budget.

Safety and Efficiency in Well Operations

To accomplish security and efficiency in well operations, a proactive strategy regarding risk management and a strict adherence to the best practices of the industry are necessary. The major tactics include:

⚠️ Critical Safety Measures

- Regular Equipment Inspections: Carry out routine checks for the purpose of detecting and fixing wear, corrosion, or possible malfunctions, thus making sure that all equipment functions under the safest conditions possible.

- Proficient Training: All the workers should receive proper training that will make them handle the equipment, deal with emergencies and operating not to cause human error.

- Compliance with Standards: The company must implement the safety measures that are in accordance with the governing environmental regulations and guidelines.

- Use of Reliable Materials: Choose the materials that are strong, high-quality, and will last long for all the operational components so that the risk of failures during the processing can be minimized.

- Monitoring Systems: Set up high-tech monitoring systems that can give you the real-time information on pressure, temperature, and the other operational measures, thus allowing the quick react to the potential issues.

By giving priority to these measures, the well operations can be performed in a safe and environmentally friendly manner without compromising efficiency.

Minimizing Risks with Proper Conductor Pipe Installation

It is very important for the proper installation of the conductor pipe to minimize the risks involved in well operations. It is a seal that holds the well from blowing gas, and also it is a guarantee of perfect conditions for the drilling of other casings. The whole operation is based on good soil and subsurface conditions assessment, the right choice of pipe materials, and strict observance of installation standards. Regular inspections and pressure tests can offer extra protection to the process, thus assuring long-term safety and reliability of the operation.

Maintaining Well Stability

To keep the well stable, one has to plan and execute each operation meticulously. In addition to constant monitoring of pressure conditions, these activities encompass securing casing strings by proper cementing and applying advanced drilling fluids to equalize formation pressures. Inspections at regular intervals and plans for adaptive responses are imperative for the quick handling of any instability risks. By giving the utmost importance to structural integrity and operational safety, it is possible to maintain well stability effectively for a long time.

Improving Overall Project Outcomes

For the purpose of improving the overall outcome of a project, the first thing to do is to integrate advanced technologies, secondly, to promote cooperation among the teams and lastly to follow best practices in safety and efficiency. Use data-driven decision-making to forecast and prevent possible risks, and at the same time, make communication between the parties involved very smooth. When projects focus on continuous improvement, structural integrity, and process optimization they can achieve higher success rates and also effectively meet strategic objectives.

Reference Sources

- Wikipedia – Conductor Pipe

Conductor pipes are basics in offshore drilling, and they are indispensable for subsea wellhead stability. - ScienceDirect – Conductor Pipe Overview

Describes the role of conductor pipes in isolating surface freshwater zones and in giving stability during drilling operations. - TechSci Research – Oil and Gas Conductor Pipe Market

Covers the market size, applications, and the significance of conductor pipes in both onshore and offshore drilling.

Frequently Asked Questions (FAQs)

Ready to Learn More?

Understanding conductor pipes is essential for successful oil well operations. Whether you’re planning a new project or optimizing existing operations, proper conductor pipe selection and installation are critical to your success.