Steel channels play a significant role in various constructions and industries, and the reason is their togetherness in versatility and reliability. Whether you’re looking for mild steel channels to be used in general fabrication or structural steel channels for heavy-duty applications, making a good decision here will be very important for safety, stability, and long-lasting performance. This guide will lead you to the major types of steel channels that are available, their distinct advantages, and how to pick the right one for your specific project. Eventually, you will have enough information to make wise choices, quicken your buying process, and get the best results for your constructions.

Understanding Mild Steel Channels

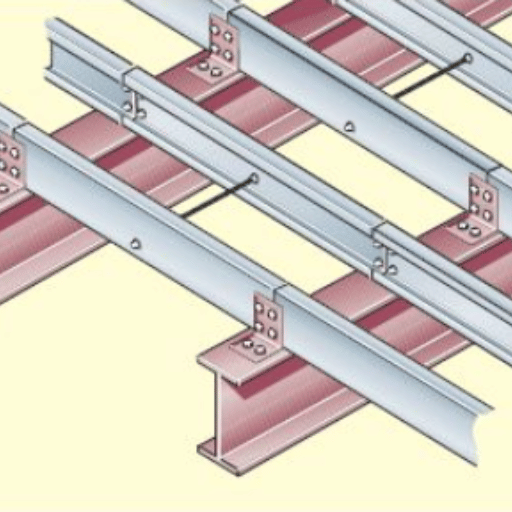

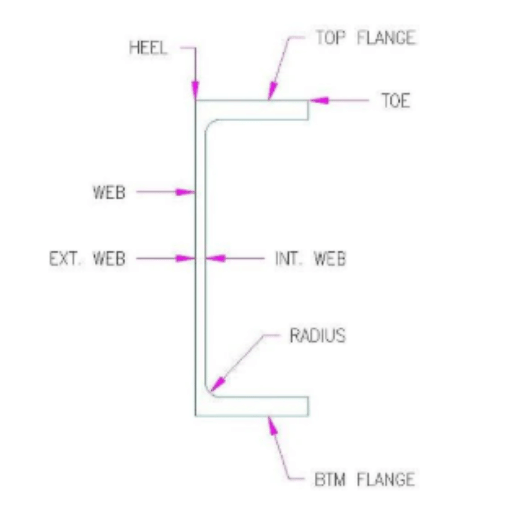

Mild steel channels are structural elements fabricated from low-carbon steel, and they are most commonly recognized for their durability, flexibility, and economical nature. They have U-shaped cross-section, which allows for using them in various applications such as construction frameworks, support structures, and load-bearing systems. The ability to bend and weld mild steel makes these channels easy to handle and their long-lasting nature assures that they are effective even under very high loads over a long time period. All these qualities make mild steel channels a good option for a project where reliable and adaptable structural solutions are needed.

What is Mild Steel?

Mild steel, referred to as low-carbon steel, is a steel that has a small percentage of carbon, generally between 0.05% and 0.25%. This specific proportion imparts to it a blend of strength, ductility, and malleability, thus making it easy to weld, shape, and handle. Mild steel’s characteristics like the low price and the ability to adapt for various applications make it hugely utilized in the construction, automotive, and manufacturing industries.

Properties of Mild Steel Channels

Mild steel channels have various important properties that lead to their great functioning and versatility. Among the features are:

- ✓ Excellent tensile strength for enduring heavy loads

- ✓ Good weldability for easy fabrication and joining

- ✓ High ductility enabling bending without breaking

- ✓ Corrosion resistance when properly treated

- ✓ Low weight with high strength ratio perfect for construction solutions

Comparison with Structural Steel Channels

Applications of Steel Channels

Steel channels are found to be extremely versatile in the industries and provide strength wherever applied. Some of the best applications include:

🏗️ Construction

Common as building framework, support beams, and structural reinforcements.

🚛 Transportation

Vehicle frame, trailer, and shipping container support fabrication.

⚙️ Industrial Equipment

Machine construction, rack, and heavy equipment support systems.

🌉 Infrastructure

Bridges, highways, and other large-scale infrastructure developments.

🏠 Residential Use

Used in window frame supports, roof, and simple architectural elements.

Common Uses in Construction

Steel channels are widely used in construction as structural supports, frames, and reinforcements for frameworks. Their versatility makes them suitable for myriad applications, such as forming beams, columns, roof supports, and load-bearing structures. In contrast, they have their share of uses in flooring systems, stairs, and bridge components to impart strength and cast durability on residential and commercial assignments.

Industrial Applications of Mild Steel Channels

Due to strength, versatility, and its cheap price, mild steel channels find extensive applications in the industries. These act as sturdy supports in machinery, conveyors, factory equipment, and storage racks. In addition to channels, they also constitute heavy-duty flooring of shed structures, warehouses, and machinery, capable of withstanding rough service.

Advantages of Using Steel Channels in Various Industries

- 1

Strength and Durability: Steel channels are heavy-duty structural supports that find uses under heavy-duty heavy loads and once-a-while type services by being subjected to harsh environmental conditions. - 2

Versatility: Due to their design, they can be used for an assortment of applications ranging from machine frames to warehouse trusses. - 3

Cost-Effectiveness: Due to the long life cycle and the low maintenance costs, steel channels pose less of an investment concern throughout their joint operation costs. - 4

Ease of Fabrication: They can easily be cut, fabricated, and installed for rapid assembly and customized implementation based upon project requirements. - 5

Sustainability: Steel is a recyclable material, hence, industries supporting sustainable developments consider this to be an environmental option.

Specifications for Steel Channels

Steel channels come in diverse sizes and weights to meet a broad range of construction and industrial requirements. Some key parameters that are often specified include:

Note: These specifications ensure their compatibility for various structural and manufacturing applications and further impart longevity and usability across industries.

Dimensions and Length Options

Steel construction beams have an assortment of dimensions and lengths for meeting an array of application requirements. Usually, they range from about 20 to 40 feet in length. All other unusual configurations can be requested with the intent of meeting the needs of a peculiar need of a project. The standards may also change as per the structural needs of load capacity to provide the various fields with some flexibility.

ASTM A36 Standards for Mild Steel Channels

ASTM A36 stands as a prevalent ASTM specification for a mild steel channel used across construction and fabrication. It sets forth all mechanical and chemical property requirements of carbon steel at structural grade to assure durability and reliability. ASTM A36 mild steel channels support moderate loads and find applications in building frames, machinery fabrication, and general structural support.

Key Standard Features:

- Minimum yield strength of 36,000 psi

- Excellent weldability characteristics

- Optimal balance of strength and versatility

- Suitable for diverse range of projects

Hot Rolled vs. Other Manufacturing Processes

🔥 Hot Rolled Steel

- Shaped at high temperatures (above recrystallization temperature)

- Easy to form and work with

- Characteristic scaled surface finish

- Excellent for large structural applications

- Less concern for precision and finish

❄️ Cold Rolled Steel

- Processed after hot rolling at room temperature

- Tighter dimensional tolerances

- Enhanced surface quality and smoothness

- Increased strength characteristics

- Ideal where close tolerances are required

Maintenance Tips for Steel Channels

Proper upkeep of steel channels will guarantee their survival and original performance. Here are some vital tips to consider in this regard:

🧹 Cleaning Regularly

Wash channels from time to time to remove dust, debris, and grime, which would cause corrosion. Use mild detergents and water; avoid using harsh chemicals that might damage the protective coatings.

🔍 Inspection for Damage

Perform inspections regularly to identify signs of wear with the risk of cracks, bending, and rust, and treat damages immediately to avoid further deterioration.

🛡️ Applying Protective Coatings

Applying protective coatings, such as, primers, paints, and galvanization add protection powder or coverlayer against rust and corrosion, especially in areas exposed to moisture or chemicals.

🌡️ Keep an Eye on Environmental Situations

Whenever possible, carry out storage and use of steel channels in dry-controlled conditions. Keep the channels out of the way from being wet and from undue extremes in temperature, which might trigger corrosion.

⚙️ Lubrication of Moving Parts (if applicable)

Where the channels are in mechanical-service applications, any moving parts should be lubricated regularly to reduce friction and wear.

💡 Pro Tip: Following in these simple steps, you should be able to maintain the life and structural integrity of the steel channels.

Best Practices for Longevity

Periodic inspection is required to avert the early signs of wear, corrosion, or structural damage with the steel channels. At the earliest time such imperfection occurs, rectify it so that it will not snowball into greater damages. Thorough cleaning and drying are done after use, while storage minimizes atmospheres-induced attack. Regular maintenance to include an occasional coat of protective varnish and grease on any moving part will keep its life going while functioning and maintaining structural integrity.

Common Issues and Solutions

1. Corrosion

Issue: Presence of moisture and corrosive environment causes rust and degradation.

Solution: Paint anti-corrosive paints on it, and store it in dry and ventilated conditions. Regular inspection is necessary to detect signs of rust and immediately rectify them.

2. Structural Damage

Issue: Bending, warping, or fracture may take place due to overloading or incorrect handling.

Solution: Comply with the load limits and do not circumvent the use of handling equipment. Inspection has to be carried out periodically to cure possible damage at the earliest.

3. Wear and Tear

Issue: Continued use in high-stress environmental conditions weakens the material.

Solution: Carry out maintenance from time to time and replace worn-out parts in due course to keep it functioning at its optimum level.

Protective Coatings and Treatments

Protective coatings and treatments increase durability and resistance against environmental factors. An application of the suitable coating, whether that be anti-corrosion or heat-resistant, protects materials from harm by moisture, chemicals, or extreme temperature situations. In treated surfaces, galvanizing and anodizing act as additional protection methods that increase equipment lifespan. These coatings must be re-applied at regular intervals and kept under constant inspection in orderRetryClaude does not have the ability to run the code it generates yet.Lto guarantee their continued performance and to reduce on the time-loss of repairs.

Reference Sources

- Future Market Report – Mild Steel Channel Market: Illustrates the growth of the mild steel channel market due to demand generated by construction, infrastructure, automotive, and manufacturing sectors.

- Infra-Metals – Structural Steel Channels: States that steel channels find application in residential and commercial construction, industrial applications, and transportation by reason of their strength and versatility.

- Metalbook – Key Uses and Applications of MS Channels: Explain the prime importance of mild steel channels in construction and industrial projects in view of their strength, flexibility, and longevity.

Frequently Asked Questions (FAQs)

What is a mild steel channel?

A mild steel channel comprises a mild steel structural member shaped into a pattern of “C” or “U” and used in construction and industrial applications.

What are advantages of mild steel channels?

They are said to possess high strength, durability, flexibility, and cost-effectiveness while making them suitable for various structural and industrial applications.

What are some common uses for mild steel channels?

These channels are useful in construction (for beams, columns, and frames), in automotive (for chassis and frames), and for industrial machinery.

How are these channels made?

Typically, in hot rolling and cold rolling.

Are mild steel channels corrosion-resistant?

Mild steel being prone to rust, it is often coated with protective coatings like galvanization or paint.

Ready to Choose the Right Steel Channel?

Armed with this comprehensive knowledge about mild and structural steel channels, you’re now equipped to make informed decisions for your construction and industrial projects. Remember to consider your specific requirements, load-bearing needs, environmental conditions, and budget constraints when selecting the appropriate steel channel type.