Galvanized steel angle is one of the most important, versatile, and durable materials that meet the requirements of a huge range of construction and manufacturing applications. Its strength, great resistance to corrosion, and adaptability put it on the top list of materials for use both by professionals and amateurs. But, the availability of high-quality galvanized steel angle that meets your needs precisely does not necessarily imply a complicated process. This article discusses the advantages of buying galvanized steel angles over the internet, the comfort of ordering custom cuts to sizes, and the main factors to consider to make sure you are selecting the right material for your project. Whether you need precision, efficiency, or simplicity, we will take you through the process step by step, thus enabling you to save time and maximize your purchase.

Introduction to Galvanized Steel Angles

Galvanized steel angles are a stronghold in the construction and fabrication industry owing to their very high strength, long-lasting life, and resistance to corrosion. The process of galvanization comprises coating the steel with a protective layer of zinc that protects the steel from rust and weather-related damages. This makes them a wise decision for the indoor and outdoor applications of structural supports, braces, and framing, etc. Their versatility, low cost, and long lifespan make galvanized steel angles one of the best reliable materials for projects requiring dependable materials.

What is Galvanized Steel?

Galvanized steel is basically steel which has applied a protective zinc coating on it, thus preventing corrosion and rust. The zinc layer which provides protection is normally applied through hot-dip galvanization, during which the steel gets dipped in molten zinc. The outcome is a strong, long-lasting, and rust-proof material that finds extensive application in construction, manufacturing, and industries. Its positive traits such as strength, low cost, and long life make it the best selection for different types of indoor and outdoor applications.

Understanding Steel Angles

Steel angles, which are also referred to as angle bars, are considered among the most important structural components in the building and engineering projects due to their versatility and strength. They are L-shaped pieces made from either galvanized or non-galvanized steel and are used for support, stability, and reinforcement in the frameworks, shelves, or bracing systems. Their design provides for easy installation and adaptability, thus allowing them to be used in a wide range of applications.

Importance of Size in Projects

Steel angle sizes are crucial factors in deciding their load-bearing capacity and possible applications. The major ones give more strength and stability, thus they can be used in heavy-duty areas, and in contrast, the minor ones can be in light structures only. Choosing the right size guarantees that the structure will be fit for its purpose and also that it will work at its best, according to the project specifications.

Benefits of Using Galvanized Steel Angles

Key Advantages at a Glance

- Corrosion Resistance: The application of zinc coating acts as a shield for the steel, preventing rust from forming even when exposed to very terrible weather and thus safeguarding the steel’s longevity while at the same time cutting down on the upkeep expenses.

- Longevity: Galvanized steel angles are able to live longer than the non-galvanized ones because they will not easily be defeated by Mother Nature’s wear and tear over time.

- Versatility: They can find a place in almost every application possible like construction, industry, and outdoor structures, thereby being a pretty flexible selection for various kinds of projects.

- Cost-Effective: Steel that has been galvanized is not only durable but also requires very little maintenance, which makes it a money-saving choice in the long term.

- Environmental Resistance: Such steel angles are still in full operation despite the harshest conditions of high or low temperature and moisture, thus they are still standing with their strength and ability in a very large spectrum of environments.

Corrosion Resistance

The protective zinc coating on galvanized steel angles provides a great degree of resistance to corrosion. This coating serves as a shield, obstructing the entrance of water and air to the steel under it which, in turn, greatly minimizes the chances of rust and deterioration. Moreover, the property of zinc being sacrificial means that the scratched coating still does not give way to rust in the area of exposure. Thus, they are the trustworthy option for the extreme conditions of the environment over a long period.

Durability and Longevity

The durability and longevity of galvanized steel angles are majorly attributed to their strong or robust zinc coating that protects the angles from wear, rust, and environmental stresses these factors won’t even be able to do any damage to the angles’ structural integrity, thus making them a perfect investment for projects that are reliable and require less maintenance or no maintenance at all.

Cost-Effectiveness

Galvanized steel angles provide a cost-efficient option because of their low maintenance and long-lasting properties. The zinc layer minimizes the need for regular upkeep or replacements, which results in reduced total expenses for the project. Besides, their strength guarantees that the material will be valuable for a long time, thus, it is a making-wide application, and even more so, an economical choice for all applications.

Applications of Galvanized Steel Angles

Galvanized steel angles are among the most flexible and common metal products, favored by different industries. The following are their main applications:

🏗️ Construction

The metal is very strong and not susceptible to rusting, making it a frequent choice for building and bridge frameworks, supports, and reinforcements.

🛤️ Infrastructure

The angles are very durable and therefore very suitable for utility poles, guardrails, and railway tracks.

⚙️ Manufacturing

The angles are structurally very dependable and are therefore used for shelves, frames, and equipment.

🌳 Outdoor Projects

The angles are very suitable for fencing, gates, and other sunny places as they can resist harsh weather conditions.

⚓ Marine & Coastal

Their resistance to corrosion makes them a good choice for docks, piers, and other structures that come into contact with water.

The applications above point out the role of galvanized steel angles in construction areas where only tough and economical materials are required.

Construction and Structural Uses

Galvanized steel angles are a popular choice in construction and structural applications, mainly because of their toughness, low price, and ability to withstand rust. They are responsible for giving support in frames, reinforcing concrete constructions, and they can be frequently seen in bridges, buildings, and factories. These multi-purpose elements are long-lasting, hence their usage in load-bearing and architectural projects is quite common.

Industrial Applications

The use of galvanized steel angles is a must in the industrial sphere because of their superior strength and resistance to corrosion. Such angles are widely used in the production of equipment, support systems, storage solutions, and even in the frameworks of machines. The combination of versatility and durability makes steel angles a perfect option for hard industrial conditions.

Home Improvement Projects

Galvanized steel angles because of their strength and adaptability are very popular in the home improvement world. They are mostly used for shelving, brackets, and structure reinforcement, besides framing and general DIY projects. Their resistance to corrosion makes them trustworthy for both indoor and outdoor uses, thus guaranteeing a long-lasting life.

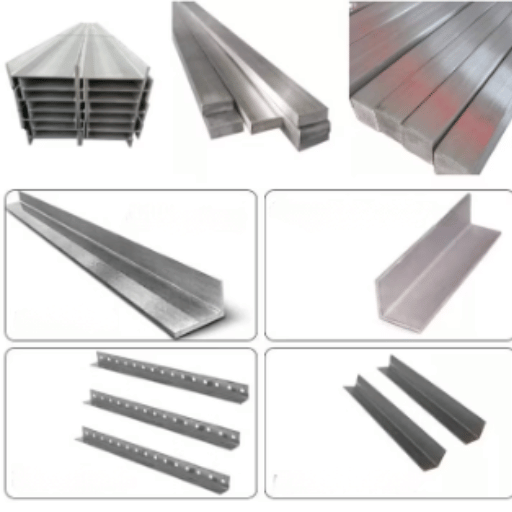

Types of Galvanized Steel Angles Available

Thus the different types leave a wide open door to all sorts of constructions, industries, and DIY projects, giving an exact solution for the project needs.

Different Grades of Steel Angle

There are different grades of steel angles, and each grade has its specific characteristics which are based on strength, resistance to corrosion, and suitability for certain places. The grades that are mostly used include Grade A36, which is a typical option for structural applications in general, Grade A588, which is a type of steel that can withstand the weather, and Grade 304 or 316 Stainless Steel, which is the best option for projects where the material has to be resistant to corrosion. Aspects like load capacity, exposure to weather, and longevity determine the grade selection for the project.

Common Sizes and Measurements

Steel products usually come in different standard sizes which are convenient for different purposes. Typical structural steel profiles are beams, angles, channels, and sheets, with sizes defined through different measurements such as width, height, thickness, and length. To illustrate, structural beams are frequently referred to in terms of their depth (for instance, W8x10, where “W” refers to a wide flange and “8×10” indicates the dimensions in inches and weight per foot). Plates and sheets are generally defined by their thickness (for instance, 1/4 inch or 6mm) and area. Proper measuring is very important for the success of a project in terms of both compatibility and performance. Checking the project specifications is always a good practice to choose the right dimensions.

Custom Cut Options

Custom cut options give the possibility to adjust the raw materials in such a way that their dimensions and shapes correspond closely to the requirements of the specific project. It is a technique that not only reduces the amount of waste but also makes the material more appropriate for the particular design and the whole process of assembling the pieces becomes easier. The usual service includes a variety of cutting options, which could be cutting steel, aluminum, and other materials into specified lengths, widths, or making custom profiles with the help of technologies such as laser cutting, water jet cutting, or plasma cutting. Properly discuss project specifications and get in touch with suppliers to obtain the best possible outcome.

Key Considerations When Selecting Steel Angles

📋 Essential Selection Checklist

1. Material Grade

Pick a steel grade that suits the specific requirements of your project. For instance, if it is a structural application, then the higher-grade steel will be a must for strength; whereas if it is a decorative project, the light grades can be allowed.

2. Load-Bearing Requirements

Calculate the angle’s weight and the maximum stress it will be subjected to. Heavier loads imply thicker steel angles or reinforced ones to maintain the safety and durability standards.

3. Corrosion Resistance

For outdoor use or in areas with high humidity, choose shining steel with a protective coating or corrosion-resistant alloy like the galvanized or stainless steel, and thus ensure the long life of the material.

4. Size and Dimensions

Check if the angle’s dimensions correspond with the specific measurements of your project. You can find standard lengths in the most common sizes, but custom cuts can be ordered if exact dimensions are required.

5. Ease of Installation

Think about whether the installation process will be easier for your design needs with pre-drilled holes or lightweight options.

6. Budget Constraints

Try to strike a balance between quality and cost by looking for steel angles that fulfill your project’s needs without going beyond the budget. If possible, check for discounts or supplier deals for bulk purchases.

Living up to these factors means you will not only have the right steel angles for the structure but also the aesthetics of your project.

Understanding Mechanical Properties

In the performance assessment of steel angles under different conditions, mechanical properties turn out to be the most critical ones. The main characteristics are tensile strength, the measure of the force needed to snap the material when it is pulled, and yield strength, the stress a material can take without becoming permanently deformed. Other than that, ductility tells how much the steel angles can stretch before they break, while hardness is a measure of how resistant the steel angles are to being worn down and cut. The selection of the proper steel angles will be making sure that not only the structural aspects but also the safety standards are met.

Evaluating Project Requirements

In order to assess the requirements of the project correctly, it is convenient first to recognize the precise wants of the structure, as for example the ability to bear loads, environmental aspects and time of use. Take into account the mechanical properties needed, for instance, toughness for long-lasting or ductility for bending without breaking under the load. Besides, confirm fitting with safety norms and regulations applicable to the project. Furthermore, weigh-up cost-effectiveness and material supplies to make sure that the process is economically practicable and at the same time, the quality is not compromised. The use of this all-around processing is certain to the optimal alignment with the project objectives.

Choosing the Right Finish

Choosing the appropriate finish is a matter of weighing cosmetic factors, utility, and nature’s concern. Think about the wanted look, for instance, matte for subtle elegance or gloss for a bright, contemporary look. Assess the life-time needs considering the areas where the product will be exposed to abrasion, water, or sunlight. Go for the finishes that conform to the safety and eco-friendliness standards, and are accessible in terms of application and maintenance. At the end, the right finish is the one that enhances not only the material’s characteristics but also the project’s goals as well.

Reference Sources

- Data Insights Market – Understanding Growth Challenges in Galvanized Steel: The topic of usage of galvanized steel angles for structural framing and reinforcement in the construction industry is discussed.

- South Atlantic LLC – Galvanized Steel Angle Size Guide: The paper explains the use of steel angles in the framing, supporting, and bracing of architectural and industrial structures.

- Industrial Metal Supply – Steel Angle Fabrications: It points out the versatility and strength of galvanized steel angles for various applications.

- Heyan Steel Structure – Market Demand for Angle Steel: The issue of angle steel in office buildings, shopping malls, and industrial warehouses is covered.

- Bushwick Metals – Galvanized Steel Angles Sizes and Capabilities: The hot-dipped steel angles benefits especially for outdoor construction projects are discussed in detail.

Frequently Asked Questions (FAQs)

What is a galvanized steel angle?

A galvanized steel angle is a structural steel member covered with zinc to protect it from rust and corrosion.

What are the usual applications of galvanized steel angles?

They find their application in buildings for framework, bracing, and reinforcement as well as industrial, infrastructure projects and DIY projects.

What is the reason for the preference of galvanized steel angles over the normal ones?

The galvanized steel angles provide the best resistance to corrosion which makes them suitable for use in outdoor and high moisture areas.

What are the available sizes for galvanized steel angles?

They exist in a wide range of widths and thicknesses to meet the requirements of different construction and industrial applications.

What is the process of making galvanized steel angles?

The standard process involves dipping steel angles in molten zinc (hot-dip) to form a protective coating.

Ready to Get Started?

Whether you’re working on a construction project, industrial application, or home improvement task, galvanized steel angles offer the perfect combination of strength, durability, and cost-effectiveness. Take the time to evaluate your project requirements, choose the right specifications, and invest in quality materials that will stand the test of time.