For industrial application lies the difference in reliability and performance of materials. Among the multitude of standards that lead the way to manufacturing and application of materials, ASTM A182 has remained a cardinal. This standard lace industries such as petrochemical, power generation, and aerospace to ensure that materials utilized under high-pressure and high-temperature conditions meet strict standards of quality. However, what exactly does ASTM A182 stand for, and why is it so important? This article will fathom deeply into why it carries such importance, going through its purpose, specifications, and industries dependent on it, thus able to foster some appreciation as to its significance in engineering and manufacturing.

Introduction to ASTM A182

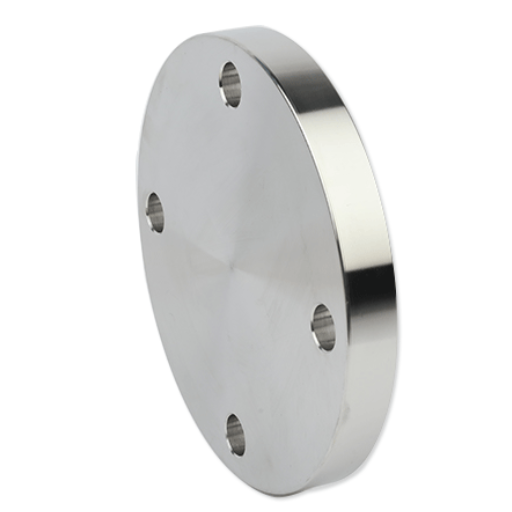

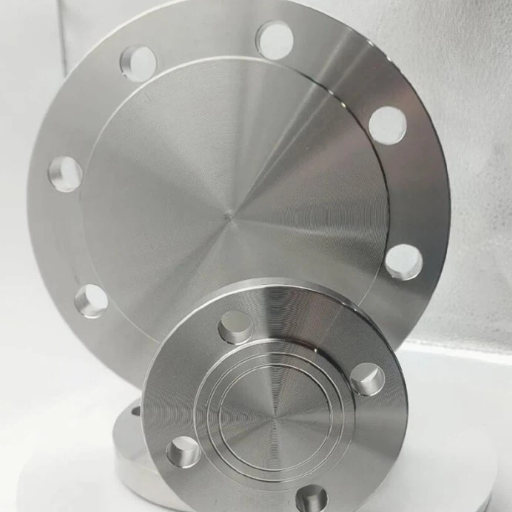

ASTM A182 is a standard specification prepared by ASTM International for forged or rolled alloy and stainless steel flanges for pipes, forged fittings, and valves, designed to be used under high-pressure conditions. Because the specification guarantees that materials satisfy the most stringent mechanical and chemical characteristics, these components are highly durable, reliable, and safe for tough working conditions. ASTM A182 covers a wide range of applications in the petrochemical, power generation, and aerospace industries and helps to standardize the quality of materials supplied, thus ensuring performance and trust in materials intended for critical use.

What is ASTM A182?

ASTM A182 is a standard specification set up by ASTM International covering forged or rolled alloy and stainless steel pipe flanges, forged fittings, valves, and parts for high-temperature service. It deals with the requirements relating to materials, including chemical composition and mechanical properties essential list to ensure strength, endurance, corrosion resistance, and pressure tolerance.

This specification includes numerous steel grades depending on the alloying elements. Commonly referred to are F304, F316, F22, and F91, which are designed to correspond with differing environmental or operational applications. For example, F304 and F316 are preferable for corrosion-resisting uses owing to the chromium and nickel they contain; F22 and F91 in contrast, due to the presence of molybdenum and chromium as alloying elements, find usage under high-temperature and high-stress conditions in power plants.

The ASTM A182 materials are characterized by a tensile strength ranging between 485 and 655 MPa as minimum and a minimum yield strength of 205 MPa for lower grades and higher for the specialized grades. This property makes ASTM A182 a widely sought-after standard in oil, gas, and chemical industries, including power generation, where the component needs to sustain extreme conditions without failure.

The specification includes testing such as ultrasonic, tension, and hardness testing for ensuring all materials are free from defects. This level of inspection gives ASTM A182 manufactured products an excellent standing as components in critical applications, limiting industrial operation risks and downtimes. Its flexibility and clearly established quality parameters have made ASTM A182 a choice-worthy standard for high-performance steel components worldwide.

Importance of ASTM Standards

ASTM standards play a crucial role in maintaining consistency, quality, and safety in various fields across the globe. They act as universal codes, enabling manufacturers, engineers, and organizations to create materials and products subject to stringent quality requirements. Industry data report that close to 12,000 ASTM standards are put to use in industries ranging from construction and aerospace to energy and healthcare. Their wide adoption highlights the pressing relevance of these standards for international trade and interoperability.

Studies have proven that incorporating ASTM standards into industries results in a decrease in production defects of up to 30%, thereby improving operational efficiency through clear-cut material specifications and testing procedures. In the oil and gas industries, ASTM standards become especially critical for pipeline materials to ensure that they can bear high pressures and corrosive environments and thereby reduce the incidence of failures set against stringent safety codes.

Additionally, ASTM continually updates standards to encompass new discoveries in terms of technology and also keep pace with advances in manufacturing methods and sustainability practices. From an innovation perspective, this approach supports businesses to stay competitive. In fact, through ASTM standards, an organization can portray compliance thereby lifting its image and gaining global acceptance from stakeholders.

Overview of ASTM A182 Specification

The ASTM A182 specification distinguishes standards for forged or rolled alloy and stainless steel pipe flanges, forged fittings, and valves generally for high-temperature service. These components find applications in petrochemical industries, power generation, and oil and gas sectors due to their capability of withstanding acute pressure and temperature.

Materials are organized into several classes under the specifications, where each class is defined by the chemical composition and mechanical properties of the materials to suit a particular application. Thus, ASTM A182 includes grades such as F304, F316, and F22, with each grade having a distinct resistance to corrosion, heat, and mechanical stress. The components manufactured to this specification are marketed for demanding applications and hence tested rigorously through tensile, hardness, and impact testing to ascertain their suitability for severe service.

Key dimensions such as pipe flange sizes and pressure ratings follow widely accepted standards like ASME B16.5. The standard A182 further defines quality requirements for surface finish, marking, and heat treatment to ensure anything manufactured to the standards will meet durability and functional requirements. This holistic approach makes sure that these products fit the modern industry’s aging, efficiency, and safety demand.

This standard provided by ASTM A182 allows manufacturers and end-users to have materials that meet internationally agreed-upon requirements, thus assuring a consistent performance in a wide range of critical applications.

Applications of ASTM A182 in Various Industries

ASTM A182 is widely used in industries like petrochemical, automotive, chemical, and power generation for high-temperature and high-pressure components.

|

Industry |

Applications |

Material Used |

Key Benefit |

Environmental Benefits |

|---|---|---|---|---|

|

Petrochemical |

Pipelines, valves |

F347, F51 |

High strength |

Reduces leaks, efficient |

|

Automotive |

Exhaust systems |

F304 |

Corrosion resistance |

Long-lasting, reduces waste |

|

Chemical |

Heat exchangers |

F51 |

High durability |

Minimizes replacements |

|

Power Gen. |

Boilers, turbines |

F91 |

High temp. tolerance |

Energy-efficient, durable |

|

Oil & Gas |

Pressure vessels |

F22, F11 |

High pressure |

Reduces material consumption |

Use in High-Temperature Service

ASTM A182 materials are generally accepted as performing well in high-temperature environments, hence their use in power generation, petrochemical, and oil and gas industries. These materials, typically forged stainless steels and alloy steels, undergo processing to ensure that they resist the severe thermal conditions and maintain normal structural properties over an extended period.

ASTM A182 F22, an alloy steel, is often favored in high-temperature applications for its resistance to scaling and ability to retain its mechanical strength even at 1,050 F (565 C). Also, ASTM A182 F316, a stainless steel grade, has excellent corrosion resistance coupled with oxidation resistance that are important in high-temperature service. Alongside, tests have demonstrated that these materials are exceptionally creep-resistant, which brings in reliability to pressure-retaining parts such as flanges, fittings, and valves.

These parts find vital applications in steam turbines, reactors, and heat exchangers, with operating temperatures going beyond 800 F (427 C). The low-temperature expansion and stress rupture resistance of ASTM A182 allow it to maintain the safety and operational yield efficiency of these materials in such harsh conditions. ASTM A182 materials provide excellent corrosion resistance with base thermal stability, allowing them to stand as the core foundation for performance enhancement and reduced downtime in heavy industrial applications.

Applications in Oil and Gas Industry

ASTM A182 materials play a pivotal role in the oil and gas industry, where harsh environmental conditions and high-pressure situations call for components of utmost reliability and resilience. These materials find their way into the crucial equipment such as flanges, valves, fittings, and pressure vessels that encounter extreme temperature variations, corrosive agents, and mechanical stresses.

Downstream operations involve refining and petrochemical production where the ASTM A182 finds its importance. Equipment in these plants, such as heat exchangers and reactors, are regularly exposed to temperatures well over 1,000°F (538°C) and aggressive chemical media. It is the enhanced resistance of ASTM A182 towards oxidation and thermal fatigue which assures the efficiency and safety of the processes.

Upstream operations also find their relevance in ASTM A182 materials. It sees use within the drilling and extraction activities, with ASTM A182 components in high-pressure piping systems. In sour gas environments, these materials are an imperative to resist the very corrosive nature of substances such as hydrogen sulfide and carbon dioxide, hence minimizing the chances of material failures and leakages.

Midstream activities also utilize ASTM A182 materials. These high-strength flanges and fittings allow for the safe transportation of oil and gas through pipelines. Operating pressures in many pipeline systems range from 1,000 to over 2,000 psi, and the superior mechanical properties of ASTM A182 materials guarantee long service life with minimal maintenance.

Due to the great suitability of this alloy in the oil and gas industry, it attributes anything from increasing the life span of equipment, reducing operating costs, to ensuring safety. Their multifunctional nature and proven success have thus made them the basis of the industry’s stringent criteria of performance and environmental requirements.

Role in Power Generation

ASTM A182 materials have been the core of contemporary power generation where high-quality components are a must to deliver a level of guarantee for operation reliability. They are also used in utmost critical environments such as steam turbines, gas turbines, and pressure vessels since high strength is an essential consideration; resistance to thermal fatigue and extremely high temperature and pressure.

In steam turbines, ASTM A182 forged steel is used for rotor shafts and casings, where high durability against oxidation to high-pressure steam is required. This material is generally accepted for use at temperatures beyond 1100 F (593 °C) under the most demanding condition where structural strength is needed. Its resistance to corrosion factors ensures the longevity of the equipment, while amongst others, the least downtimes and maintenance costs. As industrial energy systems research has proved, in power generation, alloys such as ASTM A182 can raise energy efficiency by up to a margin of 15%.

With the global impetus toward renewable energy sources, these materials have started to enter advanced geothermal and concentrated solar power systems. They need durability against fluctuating temperature and high-pressure conditions to allow systems, such as heat exchangers, to perform reliably. This edge helps to optimize energy generation while lowering environmental impact, which goes hand in hand with the current demand for sustainable energy solutions.

Such exceptional features not only make ASTM A182 a necessity in conventional power generation but also present an enabling platform for fostering cleaner and efficient energy technologies.

Chemical Composition and Mechanical Properties

Depending on the grade, ASTM A182 consists of high-quality alloy steels made with carbon, manganese, phosphorus, sulfur, silicon, chromium, molybdenum, and vanadium. These elements are in such a balance to provide great strength, corrosion resistance, and durability.

ASTM A182 has the ability to stand high pressure and extremely high heat, due to its great tensile strength, ductility, and toughness. Specific details like the yield strength and elongation value differ according to the grades but have been laid down as standards by ASTM for quality assurance. These chemical and mechanical features make ASTM A182 a choice to rely on for the most demanding applications in the energy sector.

Overview of Chemical Composition

ASTM A182 is carefully engineered with a balanced chemical composition to ensure exceptional performance across industrial applications. The primary elements typically include iron, carbon, manganese, phosphorus, sulfur, silicon, chromium, molybdenum, and nickel, although the exact proportions depend on the specific grade. For example:

- Carbon (C): Typically kept below 0.35% to maintain optimal strength and facilitate weldability.

- Chromium (Cr): Present in amounts ranging from 12% to 20%, contributing significantly to corrosion resistance.

- Molybdenum (Mo): Between 0.2% and 1%, enhancing resistance to pitting and crevice corrosion, especially in chloride-containing environments.

- Nickel (Ni): Varies from 0% to 10%, depending on the grade, improving toughness and resistance to high temperatures.

- Silicon (Si) and Manganese (Mn): Both work to improve the material’s strength and hardness, with Si typically around 0.5% and Mn between 0.4% and 1.5%.

The composition is precisely controlled to comply with rigorous ASTM standards, ensuring consistent quality and performance. These elements act synergistically to provide the alloy with its heat resistance, durability, and mechanical reliability, making ASTM A182 ideal for critical components in petrochemical, power generation, and other energy-intensive industries.

Mechanical Properties of ASTM A182 Materials

The ASTM A182 materials possess superior mechanical properties and hence are employed in applications that require very high performance. These properties include tensile strength, yield strength, and hardness values; for instance, ASTM A182 F22, being quite common in the power generation and petrochemical industries, exhibits tensile strengths about 415 MPa to 585 MPa and yield strengths not less than 205 MPa. Usually, this grade in the annealed condition registers a hardness value around 170 HBW (Brinell Hardness).

The modulus of elasticity, yet another indispensable characteristic, is considered to be near 200 GPa. This enables these materials to sustain their structural integrity even under heavy loads, resisting much distortion. ASTM A182 materials are also extremely tough and have high impact strength so that these could withstand severe thermal and mechanical shocks in extreme environments.

Many ASTM A182 grades like F304 or F316 exhibit excellent resistance to creep and fatigue, which is very much useful in long exposure to high temperature and pressure. A well-balanced ASTM A182 makes an excellent choice for flanges, fittings, and valve parts in scenarios that demand never-failing support over longer spans.

Comparison of Different Grades

ASTM A182 comprises various grades specifically tailored to meet distinct industrial requirements, with each grade offering unique mechanical properties, corrosion resistance, and temperature tolerance. Below is a detailed comparison of some commonly used grades:

1. ASTM A182 F304

- Composition: Contains 18-20% Chromium and 8-10.5% Nickel, with low amounts of Carbon (<0.08%).

- Strength:

- Yield Strength (min): 205 MPa

- Tensile Strength (min): 515 MPa

- Temperature Resistance: Performs well up to 870°C (depending on specific alloy adjustments).

- Corrosion Resistance: Exceptional resistance to oxidation and general corrosion, making it ideal for environments involving mild acids or atmospheric conditions.

- Applications: Commonly used in flanges, chemical processing equipment, and piping components due to its versatility.

2. ASTM A182 F316

- Composition: Enriched with 16-18% Chromium, 10-14% Nickel, and 2-3% Molybdenum for enhanced performance.

- Strength:

- Yield Strength (min): 205 MPa

- Tensile Strength (min): 515 MPa

- Temperature Resistance: Maintains stability and efficiency at elevated temperatures up to 925°C, depending on operating conditions.

- Corrosion Resistance:

- Superior pitting resistance compared to F304 due to the presence of Molybdenum.

- Highly resistant to chloride environments, making it a popular grade in marine and coastal applications.

- Applications:

- Oil and gas industries for handling corrosive fluids.

- Heat exchangers and pressure vessels requiring higher durability against aggressive environments.

3. ASTM A182 F22

- Composition: A low-alloy steel containing Chromium (2.0-2.5%) and Molybdenum (0.9-1.1%).

- Strength:

- Yield Strength (min): 275 MPa

- Tensile Strength (min): 485 MPa

- Temperature Resistance:

- Offers excellent creep strength at elevated temperatures, withstanding temperatures up to 600°C.

- Corrosion Resistance:

- Moderate resistance to oxidation and corrosion, suitable for less aggressive environments compared to stainless steel grades.

- Applications:

- Widely used in high-pressure systems, boilers, and power plants where strength and thermal stability are critical.

4. ASTM A182 F91

- Composition: High-strength low-alloy steel with enhanced Chromium (8-9.5%) and Molybdenum (0.85-1.05%) for superior performance.

- Strength:

- Yield Strength (min): 415 MPa

- Tensile Strength (min): 585 MPa

- Temperature Resistance:

- Remarkable thermal stability, supporting applications up to 650°C while maintaining mechanical integrity.

- Corrosion Resistance:

- High resistance to thermal oxidation and creep, ideal for extreme operating conditions.

- Applications:

- Primarily utilized in power plants, steam turbines, and high-pressure steam piping systems.

Grades and Classes of ASTM A182

ASTM A182 covers various grades, typically based on specific steel alloys, to address diverse industrial requirements. Common grades include:

- F304/F304L: Austenitic stainless steels known for their corrosion resistance and suitability in moderate temperature environments. F304L features lower carbon content, reducing susceptibility to sensitization.

- F316/F316L: Similar to F304 but with added molybdenum for enhanced resistance to pitting and crevice corrosion. F316L provides extra benefits due to its lower carbon composition.

- F22: A low-alloy steel grade designed for high-temperature service, often used in power generation and petrochemical applications.

- F91: A ferritic alloy steel primarily utilized in high-pressure, high-temperature conditions due to its superior strength and creep resistance.

Each grade is divided into classes that signify different conditions, such as annealed, normalized, or quenched and tempered, ensuring the material’s properties align with the application’s demands. These distinctions allow for precise material selection based on performance and operating conditions.

Overview of Different Grades

ASTM A182 includes grades like F5, F9, F11, F22, F304, and F316, covering ferritic, martensitic, austenitic, and duplex stainless steels for high-temperature and pressure applications.

|

Grade |

Material Type |

Applications |

Strength |

Corrosion Resist. |

Environmental Benefits |

|---|---|---|---|---|---|

|

F5 |

Ferritic Alloy |

High-temp piping |

High |

Moderate |

Durable, reduces replacements |

|

F9 |

Ferritic Alloy |

Pressure systems |

High |

Moderate |

Long-lasting, efficient use |

|

F11 |

Low Alloy Steel |

Boilers, pressure |

High |

Moderate |

Reduces waste, durable |

|

F22 |

Low Alloy Steel |

High-pressure vessels |

High |

Moderate |

Fewer replacements, efficient |

|

F304 |

Austenitic Stainless |

Corrosive environments |

Moderate |

High |

Corrosion-resistant, long life |

|

F316 |

Austenitic Stainless |

Marine, chemical |

Moderate |

High |

Reduces environmental impact |

ASTM A182 F316 and its Applications

ASTM A182 F316 is a widely used grade of stainless steel, primarily selected for its outstanding corrosion resistance, durability, and ability to withstand high-temperature environments. This grade is an austenitic stainless steel that includes molybdenum, which significantly enhances its resistance to pitting and crevice corrosion, particularly in chloride-rich environments like marine or chemical processing industries.

Chemical Composition and Properties

The chemical composition of ASTM A182 F316 typically includes approximately 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, delivering excellent chemical resistance. It has a tensile strength of around 515 MPa (minimum) and yield strength of approximately 205 MPa. The high chromium and molybdenum content ensure unparalleled resilience against oxidizing and reducing agents.

Applications Across Industries

Thanks to its unique properties, ASTM A182 F316 is utilized in a variety of demanding applications, including:

- Chemical Processing: Its resistance to acids and solvents makes it ideal for equipment such as reactors, heat exchangers, and storage tanks.

- Marine Industry: High tolerance for saline environments ensures its widespread use in seawater piping, pumps, valves, and structural components of marine vessels.

- Food and Beverage Industry: The hygienic properties, along with resistance to corrosion from acidic and alkaline substances, support its use in food processing equipment.

- Pharmaceutical Manufacturing: Its non-reactive surface and ability to endure cleaning agents and sterilization processes make it a favored material for pharmaceutical devices.

- Oil and Gas Sector: Frequently used in pipelines, flanges, and valves due to its performance in high-pressure, high-temperature, and corrosive subsea environments.

Classification of Forged Fittings

Forged fittings are classified according to numerous types based on their design, pressure holding capacity, and application areas with the object to ensure that an industry chooses the right fitting for its operational needs. The primary classifications are:

1. Socket Weld Fittings:

Socket weld fittings are made for the high-pressure service where they provide a leak-proof joint through welded construction. They are common in smaller-diameter pipelines, say below 2 inches. Among their merits are the low possibility of corrosion being present at joints and promoting free air or fluid flow. Stainless steels and alloy steels are probably the materials chosen for such fittings because of their good mechanical properties and resistance to harsh atmospheres.

2. Threaded Fittings:

Threaded fittings are provided with internal or external threads to screw into each other without welding. They are frequently employed in low-pressure applications or wherever welding can become inconvenient. Threaded fittings come into play whenever bills get into gases or non-corrosive substances; they come into a few different thread types to suit regional or functional requirements, including NPT and BSP.

3. Elbows and Bends:

These fittings make directional changes in the line. The common types are 45˚ and 90˚ elbows. Elbows are used for sharper turns, whereas bends are for long curvature requirements, thus reducing pressure loss.

4. Tees and Crosses:

These are capable of combining or splitting flow inside a piping system. Tees permit a single-speed connection, whereas crosses provide two-speed connections. They are commonly used in oil and gas industries or chemical treatment.

5. Coupling and Union:

Couplings are used to connect two pipes, and unions allow the disconnection and reconnection of pipes without any cutting. They are highly useful in areas where heavy maintenance activity is taking place or constant alterations.

6. Caps and Plugs:

Caps seal the open ends of piping, whereas plugs close the opening in fittings or pipes. Their sealing character makes them required wherever one tries to avoid leakage or environmental contamination for a closed system.

Advantages of Using ASTM A182 Products

1. Good Durability:

ASTM A182 products are manufactured to attain exceptionally high strength and long life for use in heavy industrial applications.

2. Corrosion:

The materials are highly resistant against rust and will withstand all operational conditions that include temperature extremes and chemical exposures.

3. Safety Requirements:

Being the highest quality steel products made to meet stringent requirements, any mechanical failure becomes less likely with ASTM A182 products.

4. Versatility:

Available in several grades and types, these are accepted for use in different industries such as oil and gas, petrochemical, and power generation.

5. Economical Benefits:

Given their durability and performance, they require little maintenance and hence present a long-term economic benefit.

Durability and Reliability

ASTM A182 products have always stood for strength and reliability, while putting them into difficult industrial applications. The majority of the award-winning components are made of alloy and stainless steel so that they may be exposed to harsh environmental conditions involving high pressure and temperature. For example, ASTM A182 F22, a widely known grade, safely works at around 1200°F (649°C), asserting its thermal resistance in critical systems.

The corrosion resistance offered by ASTM A182 materials imparts further reliability against dangers posed by harsher environments, such as offshore drilling operations or chemical processing plants. Research shows that an ASTM A182 manufacturing component has a much longer lifespan compared to ordinary counterparts, some in line with decades of working operation if maintained adequately. Fewer replacements are thus needed, reducing interruptions to operation and increasing overall system efficiency.

ASTM A182 flanges and fittings are thoroughly tested to withstand international quality standards, thus ensuring continual acceptability in opposition to various dynamic operational stresses. Their versatility and reliability combine to make them worthy of use in critical industry fields where any failure of the equipment may not be tolerated, such as in power generation and petrochemical processing.

Corrosion Resistance Features

ASTM A182 flanges and fittings exhibit an exceptionally high grade of corrosion resistance, offering an ideal option for use in settings exposed to harsh chemicals, moisture, and extreme temperatures. They have always been formed from high-grade alloys of stainless steel and alloy steel, both of which are excellent against oxidation and degradation through time. For instance, high chromium and molybdenum are present in stainless steel types 304 and 316. This acts as an extremely protective oxide layer on the surface and hence resists corrosion in conditions such as acid and saline environments.

Research shows that grade 316 L stainless steel fittings resist pitting or crevice corrosion after prolonged exposure to environments maintaining chloride concentration up to 1000 ppm. Considering this, these have enormous potential of being employed for use in marine environments, offshore platforms, and chemical processing plants, where corrosive nature takes birth. Moreover, because of the low-century content, these are hardly subjected to intergranular corrosion incident to welding and are capable of sustaining performance life even in highly demanding applications.

Low corrosion brings along with it low maintenance and hence an extended life span from their service. Of course, A182 materials perform ideally, do not often demand replacement, and yet, hold good for another longer period. This particular property affirms operational efficiency along with being a little relieving toward the total cost of ownership over time for industries that hinge hugely on them such as oil and gas, petrochemical, and pharmaceutical processing.

Cost-Effectiveness in Long-Term Use

When considering the materials of ASTM A182, their benefits come from long-term considerations that make a convincing case for their cost-effectiveness. Studies show the durability almost negates expenses for replacement and repair or at least cuts them substantially, while minimizing downtime in high-demand applications. The grades of stainless steel offered under ASTM A182 have an estimated useful life of 20-30 years, depending on how they are operated, which means the high costs involved in maintenance are not felt by the industry on a recurring basis.

In addition, their resistance against oxidation or corrosion in environmental factors makes endothelial mechanisms appreciate uninterrupted functioning on their end. Consequently, applications using these materials showed industrial operators can save as much as 40% in maintenance costs when compared to those systems using weaker materials. On the decay side, it comes with greater capacities for heat and pressure reduction, suggesting less additional installation or installation of second parties becomes needed in operations that are critical. While combined, these factors greatly diminish total cost of ownership (TCO), granting ASTM A182 materials the status of one of the prime selections for the sustainable operational efficiency.

Comparison with Alternative Materials

For durability and performance at elevated temperatures and pressures, A182 materials always measure up better when put into a comparative perspective. ASTM A182 materials improve life and reduce replacement owing to better corrosion and wear resistance compared to carbon steels. These materials, being ASTM A182, far outrank most non-alloys in holding up structural integrity and reliability in critical situations. In this light, ASTM A182 becomes one of the most cost-effective and reliable materials for industries with the long-term operational efficiency requirement.

ASTM A182 vs. Other Alloy Steels

ASTM A182 stands out for its high strength, durability, and suitability for high-temperature and high-pressure applications compared to other alloy steels.

|

Parameter |

ASTM A182 |

Other Alloy Steels |

Environmental Benefits |

|---|---|---|---|

|

Material Type |

Alloy & Stainless |

Varies (e.g., carbon) |

Long-lasting, reduces waste |

|

Applications |

High-temp, pressure |

General-purpose |

Efficient resource utilization |

|

Strength |

High |

Moderate to high |

Durable, fewer replacements |

|

Durability |

Excellent |

Varies |

Reduces material consumption |

|

Corrosion Resist. |

High |

Moderate |

Minimizes environmental impact |

Benefits Over Carbon Steel

Alloy steel ASTM A182 finds advantages over its carbon steel counterpart in many dimensions, making the higher performance selection in those demanding industrial applications. Perhaps one of the most crucial advantages is its extreme corrosion and oxidation resistance. Whereas carbon steel often undergoes rapid deterioration when deployed in harsh environments, ASTM A182, thanks to its alloy composition, offers long durability even under conditions of extreme temperature and pressure.

The steel in ASTM A182 also boasts higher mechanical properties like superior tensile strength and higher toughness. ASTM A182 F22 is 90-125 ksi in tensile strength, while a proximal carbon steel like ASTM A105 is 60 to 85 ksi. This enhanced tensile strength permits the component design to be thinner from a structural stability standpoint, thereby making the components lighter and more efficient. The improved creep resistance is yet another advantage, and it makes it an excellent candidate for high-temperature environments such as in power generation or petrochemical establishments. There remain excellent machining and welding properties to these ASTM A182 materials reducing trouble during manufacturing and plugging potential downtime.

From the economic perspective, the ASTM A182 steels might be costlier in the first place compared to carbon steel, but they are cost-efficient with longer service life and little maintenance leading to a much lower total cost of ownership in the demanding application. By synthesizing these benefits, ASTM A182 molds itself into a strategic investment in industries demanding performance and longevity.

Performance Comparison with Stainless Steel

When comparing ASTM A182 to stainless steel, several key performance metrics stand out, highlighting the suitability of each material for specific applications. ASTM A182, particularly in high-strength alloys such as F22 or F91, exhibits superior creep resistance and higher tensile strength, making it ideal for high-temperature and high-pressure environments, such as in petrochemical or power generation industries. Stainless steel, on the other hand, offers exceptional corrosion resistance, particularly in environments with high humidity, saline conditions, or exposure to harsh chemicals, which makes it a preferred choice for marine, food processing, and pharmaceutical applications.

Thermal performance is another critical area of distinction. Stainless steel generally retains its properties across a wide temperature range, offering stability and resistance to scaling at elevated temperatures. Yet, ASTM A182 grades engineered for heat resistance, like those containing chromium and molybdenum, often outperform standard stainless steel grades in maintaining structural integrity under sustained heat and stress.

Regarding cost-efficiency, stainless steel’s higher chromium and nickel content often translates to a higher upfront material cost, but it compensates with exceptional durability and lower maintenance in corrosive settings. Conversely, ASTM A182’s alloy variations can be tailored to meet thermal and mechanical demands without excessive reliance on pricier alloying elements, which can optimize costs for specific industrial operations.

Ultimately, both materials exhibit excellent performance characteristics tailored to different industrial needs. Choosing between ASTM A182 and stainless steel depends on factors such as operating environment, desired longevity, and budgetary considerations.

Reference Sources

-

Effect of Hydrogen on the Mechanical Properties of ASTM A182 F22 – Academia.edu

https://www.academia.edu/71953943/Effect_of_Hydrogen_on_the_Mechanical_Properties_of_ASTM_A182_F22_and_ASTM_A36_Steels_Welded_Joint_Using_Inconel_625_as_Filler_and_Buttering_Metal

Discusses the mechanical properties of ASTM A182 F22 steel. -

Stainless Steel Grade Chart – Stanford University

http://large.stanford.edu/courses/2020/ph240/barnett2/docs/atlas-nov00.pdf

Provides detailed information on stainless steel grades, including ASTM A182. -

Piping for Utility Distribution – Michigan State University

https://ipf.msu.edu/sites/default/files/2018-08/CS_TEC_2004_336012_PIPING_FOR_UTILITY_DISTRIBUTION.PDF

Covers the use of ASTM A182 in utility piping systems.

Frequently Asked Questions (FAQs)

What is ASTM A182?

ASTM A182 is a standard specification that covers forged or rolled alloy and stainless steel piping components for use in pressure systems. This specification includes several grades of low alloy steels and ferritic-austenitic stainless steels, ensuring that the products meet the required mechanical properties and chemical composition for various applications.

What types of materials are included in ASTM A182?

The specification covers forged low alloy and stainless steel, including martensitic stainless steel and ferritic steels. It provides requirements for products made to this specification, ensuring compliance with both chemical and mechanical standards.

What are the common applications of ASTM A182 products?

Products conforming to ASTM A182 are commonly used in pressure systems, including valves and parts for high-temperature service. The specification ensures that the steel piping components can withstand the demands of various industrial applications.

What are the requirements outlined in the ASTM A182 specification?

The specification outlines the requirements for chemical composition, mechanical properties, and dimensions or dimensional standards. It also refers to international standards to ensure the products meet global quality and safety benchmarks.

What grades of low alloy steels are available in ASTM A182?

ASTM A182 includes several grades of low alloy steels. These grades are designed to meet specific requirements for different applications, providing options for engineers and designers when selecting materials for a project.

How does ASTM A182 compare to other standards?

ASTM A182 is specifically focused on forged or rolled alloy and stainless steel components, while other standards may cover a wider range of materials or applications. The specification is developed in accordance with ASME specifications that are referenced for additional guidance on design and safety.

What supplementary requirements are provided in ASTM A182?

The specification includes supplementary requirements for testing or inspection, allowing manufacturers to ensure that their products meet the necessary standards. This is crucial for maintaining quality control in high-stakes applications such as pressure systems.

What are the testing or inspection requirements for ASTM A182 components?

Testing or inspection requirements are provided for use in ensuring that the products conform to the required chemical and mechanical properties. Nonconformance with the specification can lead to significant safety concerns, making these requirements essential.