The selection of materials in oil and gas exploration is very important for efficiency, durability, and safety. One of the most outstanding materials among the many options is API 5CT N80 steel pipes which are versatile and reliable. The pipes can be used in casing, tubing, and seamless applications and can even provide the required strength and robustness to endure harsh underground operations. In this comprehensive guide, we will discuss the main characteristics, applications, and advantages of API 5CT N80 steel pipes, hence, giving a detailed comprehension of their being a preferred choice in the energy sector. The guide will be of great help in extracting well integrity or streamlining drilling processes, as it will provide the user with the necessary insights to make informed decisions.

Introduction to N80 Tubing

N80 tubing is a type of steel pipe that is particularly tailored for the oil and gas industry and is able to provide good strength and durability under high-pressure applications. This tubing is mainly for moderate depth and heat conditions, thus it is a trustworthy choice for a variety of drilling and production operations. The mechanical properties of N80 tubing are very strong and it performs consistently that even enhances the well integrity, and lowers the risk of failure, while at the same time making the whole process very efficient in challenging applications.

What is N80 Tubing?

N80 tubing is a kind of casing used in oil and gas wells that is produced to withstand moderate depths and temperatures. The tubing comes with a lot of benefits, such as high strength, durability and resistance to pressure which makes it possible to use it for the well integrity assurance and the lowering of operational risks in many drilling and production situations.

Importance of N80 in Various Industries

N80 tubing is a very important and necessary material in various fields, one of which is the oil and gas industry. Its high strength and durability make it the only solution for maintaining well integrity in conditions of moderate depths and high-pressure. Furthermore, by minimizing the risk of equipment failure and optimizing operational efficiency, N80 tubing guarantees safe and consistent performance in drilling, extraction, and production processes. Thus, they are supporting industry standards and reducing costly disruptions.

Overview of API 5CT Standards

The API 5CT standardization, set up by the American Petroleum Institute, lays down the specifications for the use of casing and tubing in oil and gas activities. These regulations guarantee that the materials’ quality, strength, and performance will be adequate for the very demanding subsurface environments. The standardization includes material grades, testing protocols, manufacturing procedures, and marking requirements, thus ensuring that the oilfields worldwide will be operating with the same reliability and uniformity. Meeting the API 5CT standards is essential for safety assurance, production enhancement, and risk minimization in operations.

N80 Tubing Applications

N80 tubing, because of its durability and versatility, is used extensively in oil and gas exploration and production. Its main applications are as follows:

- Oil and Gas Wells: Best for fluids transport in moderate depth and temperature conditions, thus guaranteeing performance stability under pressure.

- Well Completion Operations: Serves to strengthen the well structure and preserve its integrity during and after drilling.

- Production Tubing: Allows for the quick and low-resistance movement of oil, gas, or other substances from the reservoir to the surface.

Such uses prove N80 tubing’s trustworthiness in keeping wells safe and in maximizing the effectiveness of the operations.

Utilization in Oil and Gas Industry

N80 tubes are extensively used in the oil and gas sector owing to their excellent mechanical properties and low cost. They are generally applied in drilling and production of wells to withstand pressure and temperature fluctuations while maintaining their integrity. Their application in tubing for production allows hydrocarbons to be easily moved from the underground reservoirs to the surface, thus improving safety and dependability of operations. These characteristics of N80 tubing make it an indispensable part of the overall production process optimization and the well life extension.

Applications in Construction and Infrastructure

N80 tubing is crucial in construction and building, offering sturdy and trustworthy support for structural frameworks. Its tensile strength and deformation resistance under stress make it perfect for heavy-duty applications like bridges, building reinforcements, and foundations. Also, the fact that it can resist changing environmental conditions gives it longevity and stability in tough projects. All these properties together make the whole infrastructure development process safer and less consuming of time and resources.

Role in Transportation of Fluids

The steel industry greatly depends on the fluid transportation sector because of its robust and long-lasting characteristics, as well as its resistance to corrosion. It is the main material for moving water, oil, gas, and others through pipelines, tanks, and processing units even under high pressure and over great distances. Steel’s capacity to hold its form during very high temperatures and pressures translates into the efficiency and trustworthiness of the whole transport system for fluids.

Advantages of N80 Casing and Tubing

- High Strength and Durability:

N80 casing and tubing provide superior tensile strength and fatigue resistance and can thus be used in high-pressure areas. - Cost-Effectiveness:

N80 is a choice that is both trustworthy and economical, offering the same performance as the more expensive options without very high costs. - Versatility:

Suitable for a vast array of applications, like drilling, production, and the transport of fluids. - Corrosion Resistance:

Designed to survive in the most corrosive environments, thus ensuring a longer life cycle with less maintenance done. - Ease of Deployment:

Being light in weight and easy to manage, it makes the installation and running of the processes less complex.

These benefits are the reason why N80 casing and tubing have found their way into the oil and gas industry and other sectors that require heavy-duty and fluid transport solutions with minimal risk and at a low cost.

Comparative Strength and Durability

N80 casing and tubing present remarkable strength and resistance even under the most difficult conditions when compared with other materials. They are made to last through extreme pressure and heat and thus, they own the best tensile strength and impact resistance, which makes them the top choice in the hard-to-drill and operational surrounding. Their sturdiness not only gives them the power to perform reliably for a long time but also it ultimately reduces the frequency of replacements and costs associated with them, thus, being the best option for fluid transport and industrial applications by providing a solid and secure one.

Corrosion Resistance Properties

The superiority of our raw materials lies in their excellent resistance to corrosion and therefore are best suited for harsh and chemically aggressive environments. By utilizing extreme coatings and alloys that resist corrosion, they are able to survive exposure to acids, salts, and other corrosive substances. This not only gives them a longer service life but also reduces the need for maintenance, and most importantly, it makes industrial operations safer and more reliable.

Cost-Effectiveness Compared to Other Options

Our materials represent a very high cost-benefit ratio since they are durable, require little maintenance, and last long. Their resistance to wear and corrosion is so good that it can even lead to non-replacement and non-repair scenarios, which are traditionally termed as repairs and replacements, thus ultimately resulting in lower total ownership costs. On top of that, their high performance in harsh conditions guarantees maximum efficiency and reliability, thus providing great value over time.

Technical Specifications of N80 Steel Pipe

Thus, the specifications make the N80 steel pipe a reliable choice for powerful applications that use high strength, endurance, and flexibility.

Chemical Composition and Mechanical Properties

N80 steel pipe is an alloy made primarily of carbon, manganese, silicon, phosphorus, and sulfur, all in perfect ratio for the best outcome. Generally, it has around 0.28-0.30% carbon and about 1.30-1.60% manganese, which together give it high strength and good wear resistance.

The mechanical properties of the N80 steel pipe include a minimum yield strength of 80,000 psi and a minimum tensile strength of 100,000 psi, thus providing excellent durability and flexibility even under high-pressure and high-temperature conditions. All these factors combined make N80 steel pipe the best choice for oil and gas drilling and production operations.

Dimensions and Weight Specifications

N80 steel pipes aren’t only in one size but rather in a variety of sizes to satisfy different operational needs. The outer diameters go from 2 3/8 inches up to 4 1/2 inches, while wall thicknesses change accordingly to support various pressure and load conditions. The weight per unit length of the pipe is a function of the size and wall thickness, hence ensuring it meets the requirements set for high-performance drilling and production usages.

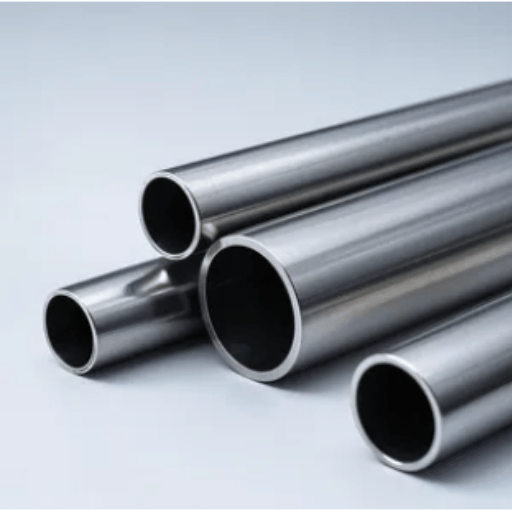

Differences Between Seamless and Welded Options

It is possible to customize both solutions according to particular project needs, considering factors like pressure, budget, and the intended application.

Frequently Asked Questions (FAQs)

Reference Sources

- Union Steels – N80 Tubing: Describes the specifications of API 5CT N80 petroleum pipe along with its mechanical and chemical requirements and applications in the drilling process to safeguard the wellbore.

- USI Steels – Specifications of API 5CT Grade N80Oil Casing: Defines the dimensions, durability, and resilience of N80 oil casing as well as the most common manufacturing processes such as quenching and tempering.

- CR4 – N80 Tubing and Burning Gas from Oil Production Wells: Reviews the chemical makeup and uses of N80 tubing in oil fields, pointing out its medium carbon steel characteristics.

Conclusion

API 5CT N80 steel pipes represent a cornerstone of modern oil and gas operations, delivering an optimal balance of strength, durability, and cost-effectiveness. From their versatile applications in casing and tubing to their exceptional performance in high-pressure environments, N80 pipes continue to set industry standards. Whether you’re managing well integrity, optimizing drilling processes, or planning infrastructure projects, understanding the comprehensive capabilities of N80 steel pipes empowers you to make informed decisions that enhance safety, efficiency, and long-term operational success. By adhering to API 5CT standards and leveraging the technical advantages of both seamless and welded options, industry professionals can ensure reliable performance across the most demanding applications.