Steel plays a major role in construction and manufacturing activities, but all steels are not created equal. Of the many grades, A588 steel sets itself apart through a special combination of strength, durability, and atmospheric corrosion resistance. This blog post attempts to become the most informative resource on A588 steel, reviewing its main characteristics and application opportunities while touching comparisons with the highly renowned weathering steel. In smoothing the passage for structural engineers, architects, or anyone interested in working with high-tech construction materials, the article will offer insights on why A588 steel has earned preference over many projects.

Introduction to A588 Steel

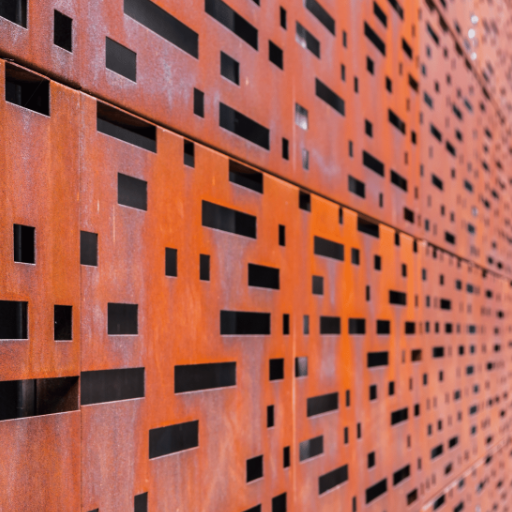

A588 steel is also known as weathering steel; it is a high-strength low-alloy steel engineered to resist atmospheric corrosion. In its composition are copper, chromium, and nickel amongst other elements, all of which combine when exposed to environmental conditions to form a thin surface oxide layer. This protective waxy layer discourages rust, so the steel hardly ever needs to be painted, or perhaps some other protective coating. A588 steel, by its very nature, finds applications in infrastructure such as bridges, buildings, and outdoor sculptures, all of which depend on its durability, looks, and cheapness. With a strong design, it offers resistance-longevity in an outdoor setting, providing a mature and dependable choice for any projects that involve exposure to corrosive elements.

What is A588 Steel?

A588 steel is high-strength, low-alloy structural steel designed to resist atmospheric corrosion. Its properties are endowed because of elements such as chromium, copper, nickel, and phosphorus, all of which resist rusting and other destructive weather conditions. The steel forms a stable patina with exposure to air and moisture, further resisting corrosion. Hence, it is highly suitable for outdoor applications.

This steel is largely used in civil engineering and architecture, coming with a tensile strength in the neighborhood of 70,000 psi (pounds per square inch) and a yield strength of about 50,000 psi, suitable for heavy-duty structural engineering. It is employed in building bridges, retaining walls, and facades, with an application in art installations and decorative work as well due to its rustic appearance.

Also, the steel is considered an economical material. A588 steel minimizes upkeep costs since it does not need to be painted or repaired frequently and has a service life of several decades with little intervention. There is also another significant advantage in favor of this type of solution: it is environmentally friendly as the steel composition normally consists of a very high percentage of recycled material.

Overview of ASTM A588 Specifications

ASTM A588 steel is a high-strength, low-alloy structural steel designed to exhibit enhanced atmospheric corrosion resistance, making it ideal for use in environments exposed to weather. It is commonly used in bridges, building structures, and other outdoor applications where durability and longevity are critical. Below is a detailed breakdown of its specifications:

- Chemical Composition: A588 steel includes elements such as carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, vanadium, and chromium, all contributing to its strength and corrosion-resistant properties. For example:

-

- Carbon (C): 0.19% maximum

- Manganese (Mn): 0.80% to 1.25%

- Phosphorus (P): 0.04% maximum

- Copper (Cu): 0.25% minimum for corrosion resistance

- Chromium (Cr): 0.40% to 0.70%

- Mechanical Properties:

-

- Tensile Strength: A588 structural steel demonstrates a minimum tensile strength of 70,000 psi (485 MPa) for plates up to 4 inches thick, ensuring exceptional resistance to stress and pressure.

- Yield Strength: The material showcases a minimum yield strength of 50,000 psi (345 MPa) for most thicknesses, making it suitable for load-bearing components.

- Elongation: Elongation in 8 inches is typically 21%, which reflects the steel’s ability to stretch under stress before breaking.

- Corrosion Resistance: A588 steel forms a stable oxide layer on its surface when exposed to atmospheric conditions, effectively protecting it from further corrosion. This weathering characteristic minimizes the need for protective coatings or treatments in many applications.

- Product Forms:

-

- Plates, sheets, angles, bars, and beams are the most common product forms manufactured to ASTM A588 standards, allowing wide applicability in structural engineering and construction.

- Applications:

-

- Bridges and overpasses

- High-rise buildings

- Industrial framework and towers

- Railway cars and shipbuilding components

- Artistic sculptures and aesthetic architecture

The superior strength and resistance properties of ASTM A588 steel, paired with its sustainable and cost-effective attributes, make it a preferred choice for modern infrastructure projects aiming for durability while reducing environmental impact.

Importance of Weathering Steel

Weathering steel, also known as Corten steel, is mainly deemed into modern construction for its noted durability, appearance, and ecological considerations. Most notably, this steel, once exposed to the atmosphere, obtains a rust layer that serves as its protection, and which would otherwise require painting or maintenance on a recurring basis. This unique attribute does, therefore, considerably diminish the costs incurred over long periods in infrastructure projects.

At a structural level, weathering steel has a tensile strength that is either equal to or above that for conventional carbon steels, so it is ideally suited to load-bearing usages. According to recent industry information, weathering steel-based structures can offer good service for over 100 years under favorable conditions with very little intervention. Moreover, in terms of corrosion under varying climatic conditions, the material stands out as valuable, especially where frequent wet-dry cycles take place.

Sustainability is indeed another aspect to consider. Weathering steel is highly recyclable, with recycling rates exceeding 80%, while the production processes are comparatively low in carbon emissions when pitted against conventional steel manufacturing. Its application in the bulk protection of infrastructures-heads and bridges, railways, and buildings-reduces the use of coatings which generally include chemicals harmful to the environment.

Architecturally, weathering steel is thus favored for its particular character. The rich, earthy hues fit adequately within city and nature settings, often seemingly merging with the environment. This perfect marriage of utility, longevity, and adaptable aesthetics is perhaps a convincing case on why designers, engineers, and environmentalists alike endorse weathering steel.

Mechanical Properties of A588 Steel

The steel grade A588 is known for a bunch of awesome mechanical qualities, worth the versatility offered to and reliability among metallurgists. It has a yield strength of at least 50 ksi (345 MPa) and tensile strength of at least 70 ksi (485 MPa), allowing easy application of tough loads. As far as low temperatures are concerned, the material is tough and durable. It welds very well and has great resistance to atmospheric corrosion. For this reason, it is commonly used in engineering applications where strength and service life are considered paramount.

Tensile Strength and Yield Strength

Considering A588 steel’s mechanical properties, the tensile strength ranges mostly from about 70 to 100 ksi (485 to 690 MPa), depending on the thickness of the steel. Similarly, the yield strength starts at a minimum level of 50 ksi (345 MPa), meaning it can resist deformation when put under considerable stress.

thicker-plate A588 steels, tensile strength may tend to lie toward the lower end of the scale but remain well within limits for most of the severe applications being encountered. The yield-to-tensile strength ratios suggest a good compromise between ductility and strength. For this reason, A588 steel makes for an efficient design in bridge works, building frames, and other heavy load-carrying structures that require guaranteed performance over a long service life.

Impact Resistance and Toughness

A588 steel is meant to enhance impact resistance and toughness, especially when kept in a harsh environment from the outside. Thus, I can say that while design for durability is concerned, it indeed can resist sudden forces and perform well under stress. It contains a composition that stays intact with structural integrity, thus ensuring performance in difficult situations.

Comparison with A36 and A572 Steel

A588 steel offers superior corrosion resistance, A36 is cost-effective and easy to shape, while A572 provides higher strength and durability.

| Key Point | Details |

|---|---|

|

A588 |

Best for corrosion resistance |

|

A36 |

Cost-effective, easy to reshape |

|

A572 |

High strength and durability |

|

Applications |

A588 for weathering, A36 for general, A572 for heavy loads |

|

Cost |

A36 is the cheapest option |

Chemical Composition of A588 Steel

A588 steel is primarily composed of iron, with small but significant additions of other elements to enhance its mechanical and weather-resistant properties. The key chemical components are:

- Carbon (C): 0.19% max

- Manganese (Mn): 0.80% – 1.35%

- Phosphorus (P): 0.04% max

- Sulfur (S): 0.05% max

- Copper (Cu): 0.20% – 0.40%

- Chromium (Cr): 0.40% – 0.65%

- Nickel (Ni): 0.40% max

- Vanadium (V): 0.01% – 0.10%

These elements create a strong and durable alloy with exceptional resistance to atmospheric corrosion, making A588 steel highly effective for structural applications exposed to harsh environmental conditions.

Elements and Their Effects

1. Carbon (C):

Carbon greatly enhances the strength and hardness of steels. At a maximum of 0.19%, the carbon content in A588 steel is kept low enough to maintain hardness but high enough to prevent excessive brittleness. Controlled carbon content is, thus, important for striking a good balance between toughness and weldability, both of which are important for structural application.

2. Manganese (Mn):

Manganese, in the range of 0.80% to 1.35%, acts as a deoxidizer and confers qualities such as ductility and toughness. It withstands abrasion and shock, allowing the alloy to withstand heavy load and stress.

3. Phosphorus (P):

Phosphorus, at a maximum of 0.04%, increases resistance to atmospheric corrosion in steel. High amounts, though, tend to induce brittleness, and so its amount is kept under strict control for consistent performance.

4. Sulphur (S):

Maxed at 0.05%, this element improves the machinability of the alloy allowing for smooth cutting and shaping during manufacturing processes. However, the presence of S must be kept to a minimum to keep adverse effects on toughness at bay.

5. Copper (Cu):

Cu at a concentration of 0.20% to 0.40% is the central component behind the extraordinary corrosion resistance of A588 steel. It promotes the growth of an oxide film, or patina, that protects the material in aggressive atmospheric exposure.

6. Chromium (Cr):

With its content maintained between 0.40 and 0.65%, it is responsible for increasing hardness and tensile strength. It assists copper in increasing corrosion resistance, which is vital for long-term structural integrity.

7. Nickel (Ni):

Restricted to a maximum of 0.40%, nickel affords a slight but important benefit in the fortification of A588 steel with toughness. It improves the performance of the material in low-temperature environments, thereby minimizing the risk of brittle fractures.

8. Vanadium (V):

Vanadium amounts to 0.01 to 0.10%, refining the grains in the steel for enhanced mechanical properties such as toughness and resistance to fatigue. It also aids in improving the hardness and wear resistance of the alloy.

The composition of A588 steel is accurately controlled so that each element contributes toward optimizing strength while providing it with an advantage of superior atmospheric corrosion resistance. The said properties have made this alloy an ideal one to be used for bridges and buildings and all forms of infrastructure laid under different environmental conditions. The complementary nature of all these elements allows the alloy to be utilized safely over the years in aggressive check environments.

Corrosion Resistance Features

The genesis of extraordinary steel corrosion resistance takes place through a purposeful set of alloying combinations accompanied by the precipitation of a patina over time. This patina, deriving its basis from controlled atmospheric oxidation, separates the steel from corrosive species to a large extent. Studies reveal that this corrosion layer can prevent corrosion rates even up to 75% as compared to normal carbon steels in certain atmospheres.

In harsh atmospheric conditions, A588 steel really shines. Copper and nickel, for instance, ensure resistance against moisture, salinity, and the presence of pollutants. This can be extrapolated by considering that under industrial conditions with large exposures of sulfur dioxide, A588 steel maintains its integrity structurally better than many traditional types of steel. Purely looking at marine atmospheres, either, and the alloy surprisingly holds well, and as it does so, it extends the service life as chloride resistance comes naturally to it.

Compound as it is, combining the best grade of materials with one that forms a self-healing patina through time, A588 yields a cost-effective and rugged solution for infrastructure that is subjected to harsh weather variations and environmental changes. Hence, these features make it not just a preferred choice but a sustainable one for long-term use.

Comparison with Corten and Other Weathering Steels

The comparison of the A588 steel with Cortens and other weathering steels brings out interesting differences in composition, performance, and application. Cortens, in particular the ASTM A242 and A606 grades, are considered weathering steels in the truest sense, as exposure to the weather produces a unique stable rust-like appearance. This feature tends to reduce the need to paint or coat, making it very popular for application in architecture in bridges, sculptures, and building facades.

In contrast, A588 steels offer better mechanical properties than some Cortens. The tensile strength of A588 steel usually varies between 485 and 690 MPa as per thickness, making it suitable to be structurally applied where increased strength is needed. A comparison of yield strengths shows A588 as more advantageous from about 345 MPa upward, usually greater than Corten A or A606 in yield strength.

Another important factor that can be considered is the rate of atmospheric corrosion resistance. Researches showed the better performance of A588 steel if considering high moisture or pollutant concentration environments. Hence, such a better choice for industrial, coastal, or urban atmospheres containing accelerated corrosion risks. Furthermore, it is highly acclaimed for its weldability and machinability in engineering and infrastructure works.

While other weathering steels possess similar properties, a balanced combination of durability, strength-to-cost ratio makes A588 steel stand apart. The patina formation on it offers a service life that can often surpass Corten and plain carbon steels under similar conditions. It is for these considerations that A588 steel has been gaining increasing popularity in industries that require both aesthetic appeal and functional application.

A588 Steel Plate Applications

The plate A588 steel is used mostly in applications that need strength, durability, and freedom from atmospheric corrosion. These are among the common usages:

- Bridge Construction: Suitable for structural components that need longevity in exposure.

- Buildings and Infrastructure: Used to a great extent in architectural work for aesthetics and functions.

- Transportation Equipment: Used for manufacturing railcars, trucks, and other heavy machinery for which high-performance use is required.

- Marine Structures: Used for docks, piers, and other seaside installations since it resists weathering under coastal conditions.

- Industrial Equipment: Used in mining, power generation, and other heavy industries where heavy materials are required.

Due to the amalgamation of its properties, A588 steel can prove to be a very reliable material to be used under heavy-duty applications.

Use in Construction and Infrastructure

Due to superior strength characteristics and corrosion resistance property, the steel A588 has now become the primary choice in civil-structural works. The steel finds applications in bridges, where high tensile strength along with good resistance to atmospheric corrosion permits much longer life and harsher maintenance levels for these structures. Due to its strength, resistance to atmospheric corrosion, and breathtaking structural appeal, A588 steel was used in the New River Gorge Bridge in West Virginia, where it underwent a natural process to develop a rust-like patina, which protects it from further corrosion.

In the urban setup, A588 steel finds several applications in skyscrapers and architectural elements that value durability and cost-effectiveness. According to estimates, such life-cycle costs can be lowered by conventional steel by 30% with the use of weathering steel such as A588 because there won’t be any requirements for paint or coating.

The material, conversely, finds use in infrastructure exposed to brutal climatic circumstances, such as highway overpasses and rail bridges. From heavy downpours to the blazing sun, it gives infrastructural cover for the long run. In this way, A588 steel takes another step toward sustainable building, basically reducing the applications of protective coatings in favor of having eco-friendly material takes precedence in the industry’s forefront.

Applications in Manufacturing

Due to its superior toughness and resistance to corrosion, steel A588 has a broad spectrum of manufacturing applications. Its weathering properties are especially useful in the manufacturing of heavy machinery, industrial equipment, and storage containers exposed to nature. The uncoated steel develops a protective patina over time, which reduces maintenance requirements while increasing shipping container durability.

Recent advances in manufacturing have increased the possibilities for the use of steel A588. For instance, it welds well with modern welding methods, hence does not lose strength during fabrication into complex assemblies. Therefore, it also allows greener processes by cutting down the use of any coatings or paint that would otherwise be necessary.

Increasingly, industries are utilizing A588 steel in products such as railcars, cranes, and farm implements, where performance under varying mechanical stresses is paramount. It is reported that this material finds preference in manufacturing processes that result in as much as a 20% reduction in lifecycle costs over those associated with conventional carbon steel. Due to its versatility and environmental-friendliness, A588 steel continues to get accepted in worldwide manufacturing sectors.

Case Studies: Real-World Examples of A588 Usage

Infrastructure and Bridges

The use of steel A588 has somewhat become a standard in the construction of heavy-duty infrastructures, especially in bridges. For example, corrosion-resistant weathering steel with maintenance-negligible properties is used in the construction of the New River Gorge Bridge, West Virginia. Studies show that using A588 steel in bridge construction brings about up to 35% reduction in maintenance costs over the span of 50 years in comparison to bridges constructed of traditional carbon steel. This cost-effectiveness, coupled with aesthetic superiority-weathers to form a natural rusted finish blending with the environment, has preferably motivated bridge engineers to use the steel in their works worldwide.

Architectural Landmarks

On the architectural side, projects have also benefitted from the utility of A588 steel, which merges function with visual appeal. The Barclays Center in Brooklyn, New York, is the best example having used weathering steel for its dramatic façade. The weathering ability of A588 ensures designers develop buildings that are both durable in exposure to city life and look great at the same time. Findings from Case studies showed that the use of A588 steel could extend the life expectancy of external walls by 20% on average, thereby lessening repair and refurbishment requirements greatly.

Transportation Equipment

A588 steel has turned into a prime material in heavy-duty vehicle manufacture due to its qualities of durability and resistance to stress. For improving structural strength-to-weight considerations, this material is used for the manufacture of railcars. It has been reported that railcars constructed with A588 steel suffer very little material fatigue which translates to a useful operational life extended by 10 to 15 years over standard ones. Further, the reduced weight due to the use of A588, results in fuel savings and lower emissions, thereby complementing the industry’s green agenda.

Renewable Energy Structures

A588 steel is becoming popular within the domain of renewable energy, chief among the wind power sector, for its ability to offer strong performances under quite hostile environments. Wind turbine towers, created with this steel, offer improved resistance to strong winds, salt spray, and all other corrosion-inducing agents. Research proves that the performance of wind energy schemes employing A588 steel is enhanced, thus cutting down about 30% of possible downtime and maintenance costs. That way, having those performance features will really help finish the green energy targets and guarantee the longevity of the installations.

These applications express numerous and far-reaching, showing A588 steel becoming a versatile, cost-effective, and eco-friendly alternative to a variety of industrial sectors. On-going innovative adaptations of this material are evidence of its synergy with both new-age engineering needs and environmental issues.

Benefits of Using A588 Weathering Steel

1. Exceptional Durability

A588 steel resists atmospheric corrosion, thereby lowering the requirement for any paint protection or regular maintenance. The advantage of durability enables the use in structures wherein they are exposed to harsh weather conditions.

2. Cost-Effective Maintenance

Through the development of a stable rust-like appearance naturally with time, A588 eliminates periodic maintenance painting or sealing, thereby reducing maintenance charges.

3. Environmental Sustainability

Meaning less coatings and maintenance imply less waste of materials and hence lesser environmental footprint, thereby contributing to green building initiatives.

4. High Strength and Versatility

Compared to conventional structural steels, A588 steel has higher tensile strength. Thus, it is used for heavy applications such as bridges, buildings, and outdoor installations. Its use across industries confirms its functionality.

A588 weathering steel, combining strength, sustainability, and cost-effectiveness, is undoubtedly a building block for today’s infrastructure.

Durability and Longevity

A588 weathering steel is resilient and makes it difficult for harsh environmental factors to cause deterioration. Unique in its formulation, it allows the formation of a protective oxide layer, called “patina,” on the surface when exposed to natural elements. Acting as a deterrent to moisture and pollutants and hence corrosion of the bare steel, this patina accordingly reduces the demand for maintenance and application of protective coatings.

Studies found weathering steel capable of cutting maintenance costs by 30% to 50%, over the life of a structure, in comparison with traditional steel. The performance of weathering steel has been well documented for many adverse climates, including those with high humidity or salt exposure. Such climates, being also prime cases for making bridges, railroads, and outdoor sculptures, would be an apt choice. The ability of this steel to sustain works such as the New River Gorge Bridge in West Virginia has been demonstrated with durability, ensuring a lifespan of decades even under adverse conditions. Weathering steel thus contributes to sustainable construction by minimizing repair frequencies, consequently reducing the environmental impact of construction in the long term.

Cost-Effectiveness Over Time

Cost-effectively, A588 weathering steel acts as a superior option over time. Its very low requirements for maintenance and, consequently, longevity make it the best among others. Conventional steels oblige frequent painting or coating on an almost regular basis to curb corrosion, while A588 develops a protective patina that shields the steel from precipitation. The elimination of expenditures recurring due to repairs or repainting goes a long way to afford huge savings over the long term in both infrastructure and construction projects.

According to recent figures from industry sources, the cost of upkeep for traditional steel structures can go as high as 5-10% of the initial capital outlay for construction on an annual basis. Conversely, from 5-10% on an annual basis for 50 years, A588 weathering steel contractors may cut maintenance costs by some 30% over their lifetime. Their durability further supports keeping downtime for the backbone infrastructure, i.e., bridges and railways, down, thereby fostering indirect savings through averted hindrance to transport and logistics networks.

Beyond this, another aspect is that A588 weathering steel reduces the demand for energy-intensive maintenance works within the framework of modern sustainable construction practices. In this regard, its existence prompts further reductions in carbon emissions and bolsters the adherence to eco-friendly standards for construction, thus enhancing its overall merit in any long-term establishment.

Environmental Considerations

The use of A588 weathering steel can have seizure ecological effects, especially in ensuring sustainable construction and environmentally friendly infrastructure development. The steel limits instances of repeated painting or coating application, thereby granting substantial emission of VOCs that would otherwise degrade air quality. Reduced maintenance translates to lower energy consumption during repair works, and greenhouse gases would therefore not be emitted during the course of a building’s life.

Also, the long life span and recyclability of A588 weathering steel make it one of the greatest contributions towards the circular economy. Studies show that the recycling degree of steel tops 80%, making it among the highly recycled materials worldwide. Its long durability ensures fewer replacements of materials over time, thereby reducing total resource consumption. Integrating such a type of steel into projects also contributes to reducing landfill waste, as upcycled steel can be easily reused for new construction projects without any compromise in quality.

On the other hand, with regard to preparation, advancements in the workings of steelmaking have made weathering steel grades even more eco-friendly. Modern steel mills use energy-efficient technologies such as electric arc furnaces, which drastically reduce energy consumption by 75% compared to the conventional method. These technological advancements, accompanied by increased use of renewable energy during its manufacturing process, place A588 weathering steel at the forefront of consciously chosen materials for environmentally friendly infrastructure and architectural projects.

Comparative Analysis of A588 and Other Steels

When compared to other types of steel, the differences are clear for A588 weathering steel. To begin with, A588 has been developed for atmospheric corrosion resistance to a greater degree, thus limiting the application of coatings or maintenance, something less achievable with traditional carbon steel or fine grades not specified for weathering. Compared to galvanized steels, the patina finish of A588 is more natural and blends into the environment, thus maintaining structural integrity over time. High tensile strength and durability make it a suitable candidate for heavy-duty applications where normal mild steels are least expected to perform or show longevity in harsh weather. This makes A588 an economical and green alternative for construction and architectural applications.

A36 vs. A588: Key Differences

A588 steel offers higher strength and corrosion resistance, while A36 is more cost-effective and easier to work with.

| Key Point | Details |

|---|---|

|

Strength |

A588 is stronger |

|

Corrosion |

A588 resists corrosion better |

|

Cost |

A36 is cheaper |

|

Composition |

A588 has alloying elements |

|

Workability |

A36 is easier to shape and weld |

A572 vs. A588: A Comparison of Properties

A588 steel excels in corrosion resistance and outdoor use, while A572 is stronger and suited for structural applications.

| Key Point | Details |

|---|---|

|

Strength |

A572 is stronger |

|

Corrosion |

A588 resists corrosion better |

|

Usage |

A588 for outdoor, A572 for structural |

|

Composition |

A588 has weathering elements |

|

Durability |

A588 lasts longer in harsh climates |

Weathering Steel: How A588 Stands Out

Being known for its excellent weathering properties, weathering steel A588 fares better than many traditional steel types. A588 forms a stable rust-like protective surface on being exposed to weather, and hence many outdoor exposures need not be painted or sealed. This makes it a natural fit for the construction of bridges, structural frames, or projects subject to environmental exposures.

The specs of A588 include the higher corrosion resistance. The steel can be said to exist eight times longer under the same environmental conditions in comparison with the ordinary carbon steel such as A36. The exact chemistry with increased amounts of chromium, nickel, and copper forms an oxide patina that impedes further corrosion feature that suffices to offer protection in coastal and industrial atmospheres.

The data also suggests that the A588 has superior mechanical properties. It provides a minimum yield strength of 50 ksi (kilopounds per square inch) and weldability characteristics that make it compete with other high-strength low-alloy steels such as A572 but with the added advantage of superior weather resistance. These qualities ensure that the structure stands over time, even in challenging environments.

In terms of sustainability, the natural weathering of this steel allows yet analysis reduction on the maintenance and material waste throughout its lifecycle, so this aligns well with modern construction that focuses on green, cost-effective solutions. The ability to weather naturally is not outgrown by its immediate function, and therefore, the practical use of the material for natural weathering should be pleasing to designers and architects alike.

With such features, weathering steel A588 stands tall and proud for the construction of sturdy, long-lasting, and aesthetically appealing structures exposed to varying weather conditions.

Reference Sources

- Understanding geometrical size effect on fatigue life of A588 steel using a machine learning approach

- Authors: Wenkai Yang et al.

- Publication Date: April 1, 2023

- Summary: This study explores the geometrical size effect on the fatigue life of A588 steel using machine learning techniques. The authors developed a model to predict fatigue life based on various geometrical parameters, revealing that size significantly influences fatigue performance.

- Methodology: The research utilized machine learning algorithms to analyze experimental data, focusing on the relationship between specimen size and fatigue life, thus providing insights into design considerations for A588 steel applications(Yang et al., 2023).

- Biaxial tension-torsion fatigue properties of A588 steel weld joint for high-speed train bogie

- Authors: Jianzhi Chen et al.

- Publication Date: January 1, 2023

- Summary: This paper investigates the biaxial tension-torsion fatigue properties of welded joints made from A588 steel, specifically for high-speed train bogies. The findings indicate that the fatigue strength of the weld joints is influenced by the loading conditions and the geometry of the weld.

- Methodology: The authors conducted experimental fatigue tests under various loading conditions to assess the performance of the weld joints, providing valuable data for the design of high-speed train components(Chen et al., 2023).

- Effect of forging load and heat treatment process on the corrosion behavior of A588-1%NI for weathering steel application in a marine environment

- Authors: M. Rohmah et al.

- Publication Date: June 1, 2022

- Summary: This study examines how different forging loads and heat treatment processes affect the corrosion behavior of A588 steel modified with 1% nickel in marine environments. The results show that specific heat treatment conditions can significantly enhance corrosion resistance.

- Methodology: The research involved experimental setups to test various forging loads and heat treatment processes, followed by corrosion testing in a saline solution to evaluate the performance of the treated A588 steel(Rohmah et al., 2022).

Frequently Asked Questions (FAQs)

What is A588 Steel and its Applications?

A588 steel, also known as weathering steel, is a high-strength, low alloy steel primarily intended for use in welded bridges and buildings. It is designed for applications where savings in weight or added durability are important, particularly in outdoor structures that are exposed to the elements.

What are the Mechanical Properties of ASTM A588 Grade Steel?

ASTM A588 grade steel exhibits excellent mechanical properties, including high yield strength and good toughness. Its low carbon content enhances its weldability, making it suitable for use in welded applications such as construction equipment and transmission towers.

How Does A588 Weathering Steel Form a Protective Layer?

A588 weathering steel forms a protective layer of rust when exposed to the elements, which prevents further corrosion. This natural patina reduces maintenance costs and enhances the longevity of steel products used in unpainted applications.

What is the Difference Between A36 and A588 Steel?

A36 steel is a standard carbon steel while A588 steel is a low alloy, high-strength weathering steel. A588 is designed for structures where corrosion resistance is critical, making it an excellent choice for outdoor applications, unlike A36 which may require additional protective coatings.

Can A588 Corten Steel Be Used for Exposed Applications?

Yes, A588 corten steel is ideal for unpainted applications where it will be exposed to the elements. Its weather-resistant properties allow it to develop a protective layer that enhances its durability and aesthetic appeal over time.

What is the Chemical Composition of A588 Steel?

A588 steel has a unique chemical composition that includes copper, phosphorus, nickel, and chromium, contributing to its excellent corrosion resistance. This composition allows A588 to form a natural patina, making it suitable for outdoor structures.

How is A588 Gr Steel Used in Construction?

A588 gr steel is commonly used in general structural applications, including the construction of bridges and buildings where savings in weight and added durability are important. Its high-strength properties make it an excellent choice for demanding environments.

What Types of Steel Shapes are Made from A588 Steel?

A588 steel is available in various forms such as plates, bars, and structural shapes. These steel shapes are used extensively in construction equipment and outdoor structures, providing both strength and aesthetic appeal.

What are the Advantages of Using A588 Weathering Steel?

Using A588 weathering steel offers several advantages, including excellent corrosion resistance, low maintenance due to its natural patina, and the ability to save weight without sacrificing durability. This makes it a preferred choice for many structural applications.