ASTM A105 Flange Manufacturer

Balingsteel Is Your Professional Chinese A105 Flange Manufacturer. We Will Produce Your Carbon Steel Flanges According To ANSI B16.5, ASME B16.47, EN1092-1 and DIN standards. We Can Produce Flanges With The Following Specifications:

- Size: DN15 to DN2000

- Pressure Rating: PN6~PN100, 150#~2500#

- Leading Time:7~25 Days.

A105 Flange Specification

A105 Flange Material

BalingSteel Has Its Own Forging Factory, And We Have More Than 25 Years Of Experience In Forging A105 Raw Flanges.

The A105 Flanges We Produce Have Excellent Performance And Can Add 10 To 15 Years Of Service Life To Your Pipeline Project.

Please Contact Us For The Most Favorable A105 Flange Price.

A105 Galvanized Flange

In Addition To Producing A105 Flanges With Normal Surface Treatment, Baling Steel Can Also Customize The Production Of Flanges With Different Coatings For You To Choose From. We Can Produce Galvanized Flanges, Flanges With Anti-Corrosion Coatings, Flanges With Flame Retardant Coatings, Flanges With High Temperature Resistant Coatings, Flanges With Wear-Resistant Coatings, Flanges With Waterproof Coatings, Etc. Welcome To Contact Baling Steel To Purchase Flanges With Different Surface Treatments.

- A105 Flange Chemical Composition

- A105 Flange Mechanical Properties

- A105 Flange Pressure Rating

| Element | Percentage Range |

| Carbon (C) | 0.35% max |

| Manganese (Mn) | 0.60 – 1.05% |

| Phosphorus (P) | 0.035% max |

| Sulfur (S) | 0.040% max |

| Silicon (Si) | 0.10 – 0.35% |

| Copper (Cu) | 0.40% max (when specified) |

| Nickel (Ni) | 0.40% max (when specified) |

| Chromium (Cr) | 0.30% max (when specified) |

| Molybdenum (Mo) | 0.12% max (when specified) |

| Vanadium (V) | 0.08% max |

| Columbium (Nb) | 0.02% max |

| Property | Requirement |

| Tensile Strength | 70,000 psi (485 MPa) minimum |

| Yield Strength | 36,000 psi (250 MPa) minimum |

| Elongation in 2 inches (50 mm) | 20% minimum |

| Reduction of Area | 30% minimum |

| A105 flange hardness | |

| Test Type | Maximum Value |

| Brinell Hardness (HB) | 187 HB |

| Rockwell Hardness (HRB) | 90 HRB |

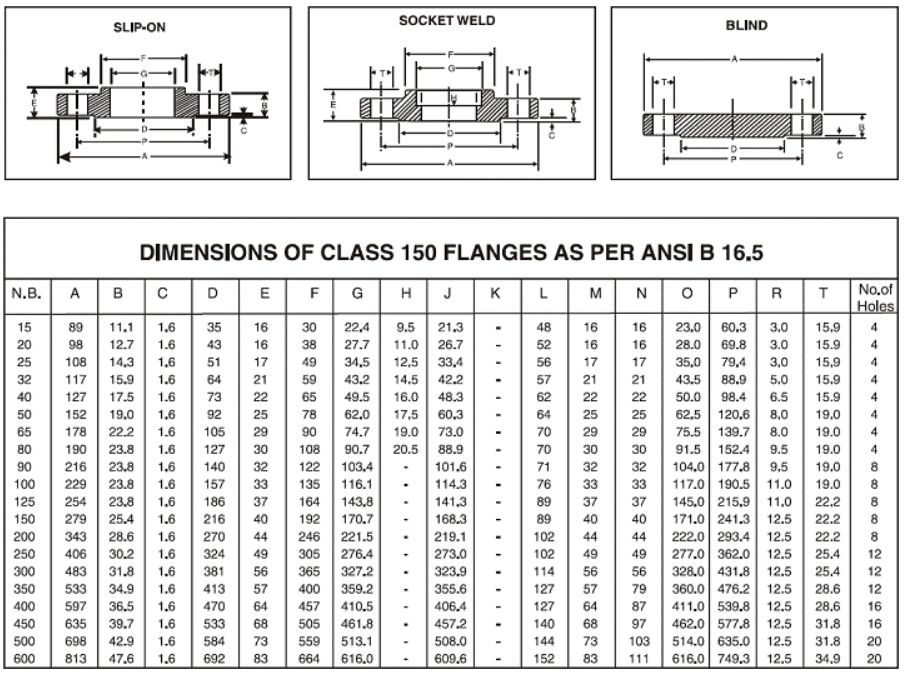

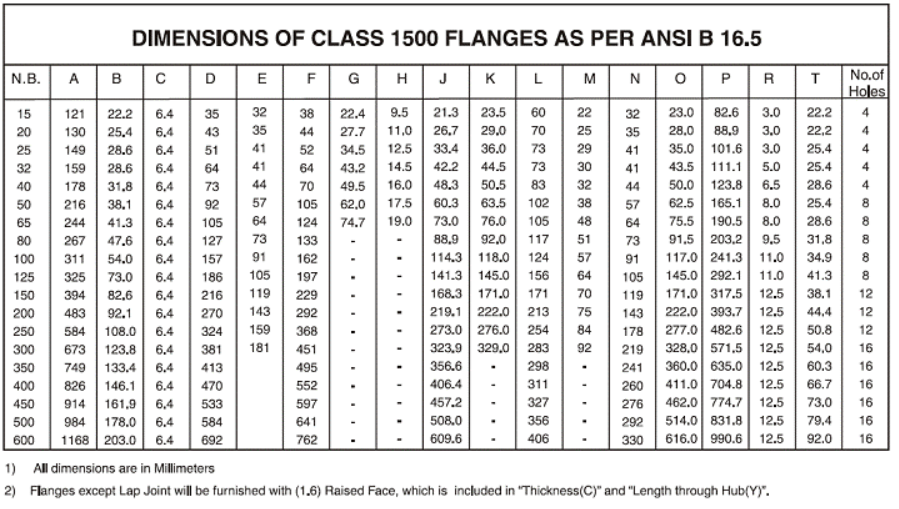

ASTM A105 Flange Dimensions

Dimensions Table

The Following Is A Comparison Table Of ASTM A105 Flange Dimensions

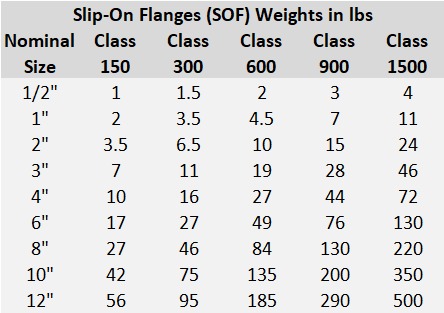

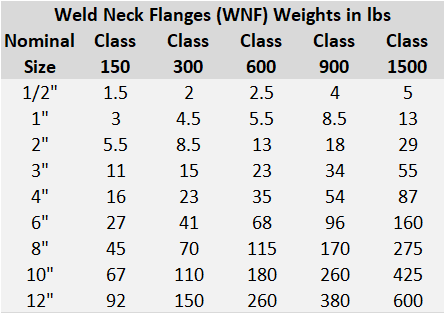

A105 Flange Weight Chart

A105 Slip-On Flange Weight Chart

A105 Weld Neck Flange Weight Chart

A105 Blind Flange Weight Chart

ASTM A105 is the forging specification for carbon steel pipe products. It is a common material for medium and low pressure pipe fittings.

ASTM A105 is a common material for carbon steel flanges and pipe fittings.

Yes, A105 is a killed carbon steel. Deoxidizers are added during the production process to make A105 more excellent.

A105 is a forged material specification, there is no seamless or welded.

No, A105 is a carbon steel.

A105 is a medium carbon steel with a carbon content of 0~0.35%.

A105 is the material of forged steel pipe fittings, mainly flange elbows and flange materials used in piping systems.

- A105 is a forged carbon steel specification for fittings.

- A106 is a seamless carbon steel pipe specification.

- A105 is for forged carbon steel components.

- A234 is forged carbon steel pipe fittings and alloy steel pipe fittings.

- A105 is a medium temperature carbon steel material standard.

- A105 LF2 is a low temperature carbon steel, which has more stringent requirements and requires impact testing.

The production processes of the two are different. A105 is forged carbon steel and WCB is cast carbon steel. Their other chemical compositions are similar.

A105N refers to A105 material after normalizing treatment. Usually, the performance and price of A105N material are better and higher than A105.

- A36 is the standard requirement for structural steel.

- A105 is the standard requirement for forged pipe fittings.

A350 is the material for low-temperature pipe fittings. It has strict low-temperature impact requirements and is relatively expensive.

| International equivalents | |||||

| A105 | P250GH | WCB | A106 | A36 | A234 |

No, they are made using different processes (one is forged and the other is cast), but usually, the two can be substituted for each other.

A105 material has different standard pressure levels such as European standard PN12, American standard 2500#, we need to determine the final pressure value based on your design.

The organizations that set the standard requirements are different. ASTM is the American Society for Testing and Materials, while ASME is the American Society of Mechanical Engineers.

They are two different types of flanges, RF is a raised face flange and RTJ is a ring face flange. RTJ flanges have grooves for installing gaskets, so they have higher sealing and can withstand higher pressures.