Being the backbone of myriad industries-from construction to manufacturing, automotive to agriculture-galvanized square steel tubing is a very versatile and durable material. Its great strength, combined with its corrosion-rust resistance, plus the adaptability of application, these features have rendered it one of the vital choices for any project’s needs in reliability and life span. A complete guide through all aspects of 2 square galvanized steel tube features, pros, general-purpose application, and factors to take into account in making the right choice for your own needs. Whether a contractor, an engineer, or a DIY person, this article should give you some insights into making educated decisions that will be instrumental in getting the best performance from this product.

Introduction to Galvanized Steel Tubing

Galvanized steel tubing is the type of steel tubing that has a protective layer of zinc to avert corrosion and ensure durability. The protection given by the zinc coating renders the tubing highly resistant to rust and suitable for various environments, including outdoor and industrial situations. Hence, it finds a large array of applications, including construction, infrastructure, and manufacturing, due to its eminence in strength, versatility, and longevity. Galvanized steel tubing requires lower maintenance and is an economical alternative, thus finding use in various applications for its structural and utilitarian purposes.

What is Galvanized Steel?

Essentially, galvanized steel refers to steel that has been coated with a zinc layer to offer corrosion resistance and durability. Generally, the steel is dipped into molten zinc during the galvanization process; this is why it is denoted as hot-dip galvanization. This creates a metallurgical bond between the steel and zinc coating that is adequate enough to resist any barraging of moisture and other environmental elements.

Such galvanized steel finds use in industries that require an element of corrosion resistance. It spans the construction, automotive, agriculture, and utility sectors. The enduring nature of galvanized steel, combined with low maintenance needs, makes it the cost-effective option for the erection of frameworks, fencing, roofing, and other structural and utility-related purposes.

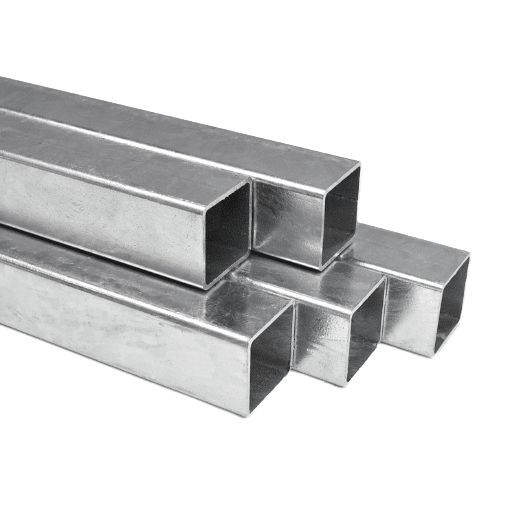

Overview of Square Tubing

The square-shaped hollow section offers square tubing the value of a structural material. Materials commonly used in fabrication for the tubing are steel, aluminum, and stainless steel-so that the applications remain fair in the weight given to the strength and perhaps longevity of the product. Because of its regular shape and uniform load-bearing qualities, square tubing lends itself well to the construction, manufacturing, and industrial spheres. The geometric design is leveraged in frames, furniture, supports, and fencing, and is appreciated for stability along with a clean, uniform appearance.

Benefits of Using 2 Square Galvanized Steel Tubes

- Corrosion Resistance: The finish offers a coating of zinc that imparts some rust and corrosion resistance and hence makes galvanized steel ideal for indoor and outdoor applications.

- Durability: The inherent strength of steel combined with the longevity of galvanization yields a tough solution for heavy-duty applications.

- Cost-Effectiveness: Galvanized steel, being low-maintenance and long-lasting, ensures cost-effectiveness over the non-galvanized kind.

- Enhanced Strength: Excellent load-carrying capacity provided by square tubing design with uniform weight distribution for structural support and reinforcement.

- Versatility: These tubes find applications in numerous fields, including construction, furniture-work/furniture making, fencing, and shelving, just to mention a few, owing to their uniformity and adaptability.

- Aesthetic Appeal: Clean-lined appearance of galvanized steel elevates the aesthetics of any structure it is applied to, thereby fulfilling its utilitarian purpose.

- Eco-Friendly: Galvanized steel is recyclable, which makes it a sustainable building material and also helps cut down on waste.

- Fire Resistance: Being able to resist higher temperatures without losing its integrity, galvanized steel acts as an extra layer of safety in places exposed to fire hazards.

Applications of 2 Square Galvanized Steel Tubes

Common Uses in Construction Projects

Innovative Applications in Various Industries

Using Square Tubing for Fencing and Structures

Square tubing is a useful and durable material largely employed for fencing and other structural applications. With steel, aluminum, or stainless steel as materials, square tubing offers excellent strength against weight balance, hence being fit for applications that require both resilience and beauty. Its uniform shape ensures easy alignment, even load distribution, and stronger structural integrity.

Advantages of Square Tubing for Fencing

📊 Industry Data and Insights

- According to recent market analytics, steel is strong for load-bearing applications in fencing and structures, having tensile strength varying from 58,000 to above 80,000 PSI depending on the grade.

- The galvanized square tubes are said to last nearly 20 to 50 years in a non-salting environment because of the anti-corrosive property of zinc coating.

- To the contrary, aluminum square tubing is lighter but also has high strength, and wherever a decrease in weight is imperative, like aluminum rooftop structures or fencing in corrosive environments, it is employed.

🏗️ Applications in Fencing and Beyond

Square tubing is one of the most versatile design solutions one could think of. It falls between practical applications and design considerations for fencing and structural supports. When it comes to residential decoration or a fit for industrial duties, it truly stands to act as a measure of performance, cost, and solutions in the industry.y.

Corrosion Resistance and Durability

How Galvanization Enhances Corrosion Resistance

It is a corrosion resistance process in which the square tubing is coated with a layer of zinc. The zinc layer then prevents oxygen and moisture from reaching the steel underneath. It also has levels of sacrificial protection since zinc will corrode before steel if the surface is scratched or damaged. This process, therefore, greatly extends the life of the material and is suited for environments exposed to moisture, chemicals, or outdoor conditions.

Comparing Galvanized Steel to Other Materials

Industry Standards for Durability

A benchmark, according to industry standards, is set in terms of durability for materials to maintain their performance and integrity over a period when exposed to unfavorable conditions. For galvanized steel, the widely accepted standards promulgated by ASTM International include ASTM A123, specifying the requirements for zinc coatings on iron and steel products. It measures coating thickness, adhesion, and uniformity to provide long-lasting resistance to corrosion. Adherence to these standards will ensure that the galvanized steel meets the accepted performance levels required by various industries such as construction, manufacturing, and infrastructure.

Choosing the Right Square Steel Tubing

Factors to Consider When Selecting Tubing

🔍 Key Selection Factors

Understanding Wall Thickness and Sizes

Understanding wall thickness and sizes should always be specific to the application under consideration. The wall thickness determines the strength, toughness, and ability to contain internal pressure of the tubing, while its size must conform to the dimensional requirements of the project. Considering these parameters consciously will ensure that the tubing will offer the best performance, with safety and design criteria taken care of.

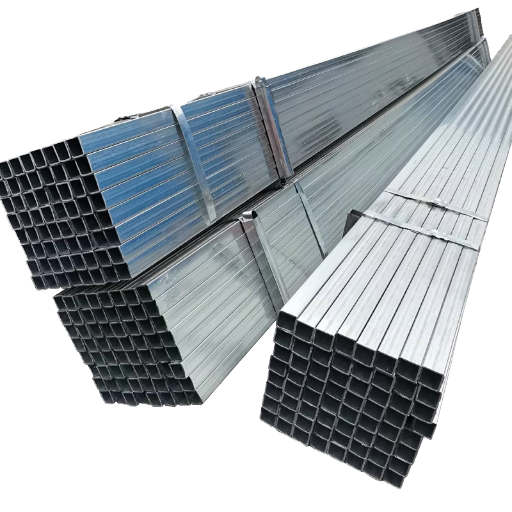

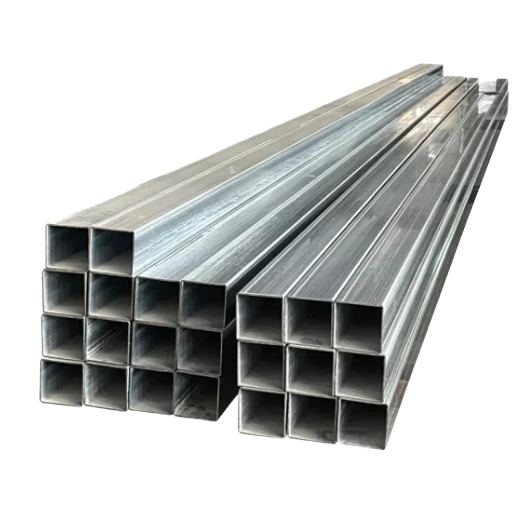

Inventory and Supply of Galvanized Square Steel Tubing

The quality inventory of galvanized square steel tubing comes in all sizes and wall thicknesses to suit varying requirements from projects. Ensuring that every piece conforms to industry standards guarantees quality and durability. Proper supply chain management ensures maintenance of stock levels and timely delivery to reduce project delays. For specific sizes or custom orders, suppliers cooperate with the clients to get to unique specifications while maintaining regulations concerning safety and performance.

Conclusion and Call to Action

Summary of Key Benefits

- ✅ Compliance with industry standards ensures high-quality and durable products.

- ✅ Efficient supply chain management reduces stock shortages and project delays, ensuring that you can buy materials like steel pipe when needed.

- ✅ Timely delivery maximizes project efficiency and minimizes downtime.

- ✅ Custom sizing and orders are available to meet unique client specifications.

- ✅ Dedicated support ensures adherence to safety and performance regulations.

Encouraging Further Exploration

For your specific needs concerning galvanized square steel tubing products and services, we would like you to connect with the expert suppliers. Once they comprehend your project requirements, they can offer solutions that best fit your goals.

To have detailed information or a consultation, visit supplier websites or contact them directly. The expert teams await your contact, ready to give you the best guidance and lead you with resources.

Frequently Asked Questions (FAQs)

Reference Sources

📚 Reference 1

1. The Ductility Capacity of an Outside Joint between a Square Steel Tube Column and an H-Shape Steel Beam

- Authors: Yongle Lin et al.

- Journal: Sustainability

- Publication Date: 20th February 2023

- Citation Token: (Lin et al., 2023)

Summary:

- This study developed a 1:2 scale model using T-shaped steel with one-sided bolts to connect a square steel tube column to an H-shaped steel beam.

- This test aimed to study the mechanical properties and seismic behavior of semi-rigid joints under quasi-static testing.

- The main results showed failure characteristics, hysteresis characteristics, and strain tendencies under cyclic loads.

- A numerical model for parametric analysis was established with the ABAQUS finite element software, and this analysis pointed out that the forces on both sides of the joint were not uniform, causing a negative influence on seismic behavior.

- It was found that the selection of a T-shape steel connector greatly affects the seismic capacity of beam-column joints, and increasing the size of the T-shape steel may improve the seismic capacity.

📚 Reference 2

2. Title of the Paper: Behavior of Concrete-Filled Steel Tube Having Granulated Blast Furnace Slag as Fine Aggregate in Normal Strength Concrete After Exposure to Elevated Temperature

- Authors: Pramod Kumar Gupta, Rakesh Kumar Patra

- Journal: Advances in Structural Engineering

- Published Date: 22-09-2023

- Citation Token: (Gupta & Patra, 2023, pp. 2814-2829)

Summary:

- This is a study about the behavior of concrete-filled steel tubes (CFST) using granulated blast furnace slag as fine aggregate, particularly after being exposed to elevated temperatures.

- The paper has tested more than 30 specimens with varying types of sections (square, circular, rectangular) in axial compression, after the specimens were subjected to temperatures of 200°C, 400°C, 600°C, and 800°C consecutively.

- From the study, with an increase in temperature, load-carrying capacity was observed to have decreased very considerably, with maximum reductions recorded at 800°C.

- The target failure modes included local buckling and bulging, which means that material properties must be given full consideration when designing for high temperatures.