Steel pipes are the fundamental building blocks for many industries, with ASTM A53 considered as one of the most trusted and widely used standards. Customarily manufactured for all kinds of needs, the famed A53 pipes are known for very high service life, flexibility, and conforming to very strict quality standards. These pipes are utilized in construction works, plumbing, and other industrial operations. This blog post aims to dive deeper into the ASTM A53 steel pipe specification, covering its traits, grades, and classifications. Most importantly, it reveals some of the common applications and reasons that make it remain liked in different industries. Read on and get a complete overview of the reasons why A53 pipes continue to be a go-to brand for both structural and pressure needs.

Introduction to A53 Pipe

ASTM A53 Pipe is a standard specification for steel pipes for structural and pressure applications. Mechanical and plumbing systems make use of these pipes; they can support both low and high-pressure environments. Coming in three types: Type F, furnace-welded; Type E, electric-resistance welded; and Type S, seamless; A53 pipes are well suited for these conditions in giving strength, ruggedness, and flexibility.

What is A53 Pipe?

A53 pipe is a widely recognized and utilized specification under ASTM International standards, specifically designed for steel pipes supporting various mechanical and structural applications. These pipes are suitable for use in both above-ground and subterranean systems. A53 pipes serve industries such as construction, energy, and manufacturing, given their impressive performance in conveying fluids like water, gas, steam, or oil in low- and high-pressure environments.

The specification covers three types of pipes categorized by their manufacturing processes:

- Type F (Furnace-Welded): Produced through a furnace-welding process, these pipes are typically used in low-pressure applications.

- Type E (Electric-Resistance Welded): By using electric-resistance welding, Type E pipes provide enhanced mechanical properties suitable for moderate to high-pressure applications.

- Type S (Seamless): Seamless pipes are manufactured without any welded joints, ensuring superior strength and reliability for high-pressure and critical applications.

A53 pipes are offered in two grades, Grade A and Grade B, with Grade B being the most commonly used due to its higher tensile strength and durability. For example, Grade A has a minimum tensile strength of 330 MPa (48,000 psi) and a minimum yield strength of 205 MPa (30,000 psi), while Grade B exhibits a minimum tensile strength of 415 MPa (60,000 psi) and a minimum yield strength of 240 MPa (35,000 psi). This allows Grade B pipes to withstand harsher operating conditions.

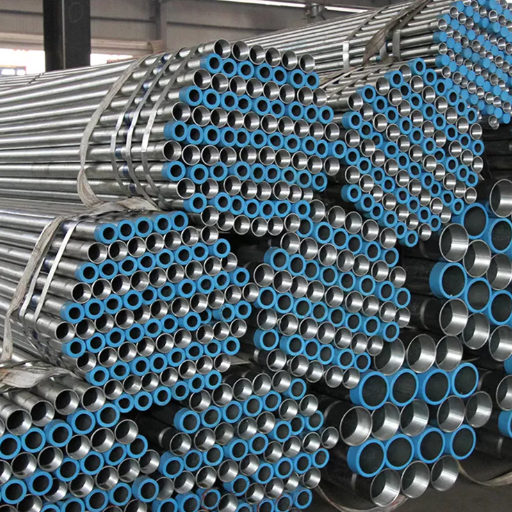

The pipes can be coated in black or hot-dip galvanized finishes, with diameters ranging between 1/8 inch and 26 inches. They conform to specific dimensional tolerances, chemical composition requirements, and mechanical properties outlined in the ASTM A53 specification for reliable performance across applications.

History and Development of ASTM A53

The ASTM A53 standard has its origins in the changing needs of the industrial revolution through the late 19th and early 20th centuries. During the rapid growth of industries such as construction, energy, and manufacturing, the demand for trustworthy, standardized steel piping solutions to fulfill ever-varying application needs had grown. ASTM International, formerly called the American Society for Testing and Materials, was prototypically formed in 1898 to develop specifications such as A53 to maintain uniformity and ensure safety in material performance.

The creation of ASTM A53, formalizing the dimensions, pressure ratings, and methods of manufacture of carbon steel pipes, was an important evolution toward industrial standardization. Over subsequent years, the A53 standard has evolved with changes in metallurgy and welding technologies. On the one hand, electric-resistance welded (Type E) pipes came about with innovations in welding methods; on the other hand, the seamless (Type S) process grew out of developments in material integrity and pressure resistance.

Nowadays, ASTM A53 remains an important standard for many industries. It is reviewed and updated regularly to keep up with technological advancements and improvements in quality. For example, tighter tolerances and better guidance for material sourcing and testing have been integrated, whenever sustainability and efficiency became vital concerns. This makes it robust enough to meet environmental and international quality standards. The use of A53 pipes is vast and extends to oil and gas pipeline systems, waterworks, and structural works, making its application more relevant than ever for industries.

Importance of A53 Specification in Construction

With an all-around nature, very strict standards, and almost universal applications, the A53 specification is something essential to the construction industry. Steel pipes provided under this specification are famous for their durability and imperviousness to corrosion and capacity to endure high pressure that makes them an essential factor in erecting buildings, bridges, and infrastructure projects. They are available in black and galvanized finishes, which are utilized for a whole range of purposes-from structural steel work to various systems for conveying fluids.

Recently, there have been some manufacturing process improvements that further improve the steel pipe characteristics of A53 pipe. For example, ASTM standards ensure that quality standards are strictly adhered to, requiring tensile strengths on the order of about 60000 psi and yield strengths of at least 35000 psi for Grade B pipes, so that these pipes will withstand the typical stresses encountered in the contemporary periods of construction.

Another ecological advantage of A53 steel pipe is its longevity, which helps reduce frequent replacements, and steel is recyclable, thereby contributing to green construction. Further, modern technological advancements in material testing and raw material sourcing guarantee that A53 pipes are almost devoid of impurities, making them at par with efficiency and reliability in critical applications.

The real importance of the A53 specification lies in its historical and continued relevance as a specification used to combat structural as well as environmental issues in modern construction. Worldwide, projects engineered according to these specifications are safe and long-lasting.

Types of A53 Pipe

A53 pipes are categorized into three types: Type F (Furnace-butt-welded), Type E (Electric-resistance-welded), and Type S (Seamless), each available in Grades A and B.

| Key Point | Type F | Type E | Type S |

|---|---|---|---|

|

Welding |

Furnace Welded |

Electric Welded |

Seamless |

|

Grades |

A, B |

A, B |

A, B |

|

Usage |

Low Pressure |

General Use |

High Pressure |

|

Coiling |

Not Suitable |

Suitable |

Suitable |

|

Manufacture |

Furnace Process |

Electric Process |

Hot Working |

A53 Type S – Seamless Pipe

The ASTM A53 Type S pipes, also called seamless pipes, are manufactured without a weld joint, making them suitable for applications where strength and uniformity are key requirements. Continuous extrusion of steel into a cylindrical shape grants these seamless pipes great reliability even under extreme conditions. A53 Type S pipes are chosen by industries such as oil and gas, energy, chemical processing, and mass production depending on variances in pressure and temperature.

The major specifications with regard to A53 Type S pipes include their availability in either black or hot-dip galvanized finishes for corrosion resistance. Then, there are two grades, Grade A and Grade B, with Grade B being more prevalent due to its strength attributes. Grade A pipe has typically 330 MPa tensile strength and 205 MPa yield strength, while Grade B pipe has 415 MPa tensile strength and 240 MPa yield strength, best for stiff applications.

Seamless pipes, being ASTM A53 types by dimension and tolerance, are made according to sizes starting from 1/8 to 26 nominal inches of diameter. Their wall thickness varies depending upon schedular and industrial-specific requirements. In addition, such pipes are subjected to tests such as hydrostatic testing and several nondestructive examinations to ascertain their strength and absence of internal defects.

Being free from welding processes, these pipes do not carry any inherent weak points at the weld seam and are best for applications under extreme pressure or intense mechanical stress. These qualities, combined with precision manufacturing and their robustness, make A53 Type S pipes an efficient and reliable solution for any modern engineering project.

A53 Type E – ERW Pipe

A53 Type E pipes, also referred to as Electric Resistance Welded (ERW) pipes, are produced through a procedure in which the steel edges are heated and brought together by electrical resistance, with the joint subsequently heat-treated to ensure strength and uniformity. Providing for high dimensional precision and quality, Type E pipes find application in almost everything.

The ERW pipes come in various sizes and wall thicknesses, geared toward different project requirements. Generally, these pipes are furnished with NPS varying between 1/8 and 26 inches, with wall thickness per Schedule 40 and Schedule 80 standard classifications. These A53 Type E pipes also conform to very strict industry specifications, enhancing their reliability and safety in all applications relating to the transportation of fluids, structuring, and tubing machinery.

The main benefits of A53 Type E pipes are a smooth inner surface providing for fluid flow and the ability to withstand moderate pressure levels. To this, these pipes are mostly used in industries like construction, agriculture, and oil and gas, where efficiency and durability matter most. In addition, they are generally zinc-coated or treated with other protective materials for corrosion resistance, particularly when used outdoors or for underground applications.

Rigorous tests such as hydrostatic one, bend one, and flattening one ensure quality for ASTM A53 Type E pipes, meeting or exceeding ASTM criteria for integration with other materials and components in engineering settings.

A53 Type F – Welded Pipe

A53 Type F welded pipes are, by and large, considered as carbon steel pipes manufactured by the furnace butt-welding process. These pipes are best suited for low-pressure conveyance work, such as in water, gas, or steam distribution systems. Due to the manner of their manufacture, Type F pipes are mostly used in non-critical applications where tolerance for high pressures is not essential.

Standard sizes for A53 Type F pipes include nominal diameter ranging from ⅛ inch to 26 inches, and wall thickness according to ASTM specifications. They are usually manufactured in standard lengths of 21 feet and 40 feet, but custom lengths may be available upon request.

A53 Type F pipes follow ASTM A53 / A53M specifications; however, they cannot be used for bending, coiling, or flanging. The pipes are produced in Grades A and B with Grade A normally more common for this type because of its lower tensile strength criteria. Given low-pressure needs in most applications, Grade A pipes having a minimum yield strength of 30,000 psi and a minimum tensile strength of 48,000 psi suffice.

Quality methods such as visual check for defects and standard pressure testing would have been applied to ensure the long life of the A53 Type F pipes and thereby assure safety against minimum reliability requirements for its intended use. While their application scope is more limited compared to other types like A53 Type E or S, Type F pipes remain a cost-effective and reliable choice for a specific low-pressure distribution assignment.

A53 Pipe Specifications

A53 pipes are governed by ASTM standards and are available in three types based on their manufacturing processes:

- Type F – Furnace-butt welded, designed primarily for low-pressure applications.

- Type E – Electric-resistance welded, suitable for higher pressure systems and general uses.

- Type S – Seamless, offering superior strength and uniformity for high-pressure or critical operations.

Each type is available in two grades:

- Grade A: Lower tensile strength, used for moderate or less demanding conditions.

- Grade B: Higher tensile strength, suitable for more rigorous applications.

The pipes are produced in standard nominal pipe sizes with walls of varying thickness, categorized under Schedule 40, 80, or other specific schedules as required. Material composition includes carbon steel, meeting minimum strength and durability criteria, ensuring reliability across various industrial and structural uses.

ASTM A53 Grade B Overview

ASTM A53 Grade B is a highly versatile carbon steel pipe specification widely used across industries for structural and pressure applications. This grade offers a blend of strength, durability, and weldability, making it suitable for various demanding environments. The pipes are generally manufactured using two methods—seamless or welded—with both types meeting stringent quality standards.

Chemical Composition and Mechanical Properties

ASTM A53 Grade B pipes demonstrate a balanced chemical composition that ensures optimal performance:

- Carbon (Max): 0.30%

- Manganese: 1.20%

- Phosphorus (Max): 0.05%

- Sulfur (Max): 0.045%

- Copper (Max): 0.40%

- Nickel (Max): 0.40%

- Chromium (Max): 0.40%

- Molybdenum (Max): 0.15%

These components contribute to the material’s strength, resistance to wear, and ability to undergo various fabrication processes.

- Tensile Strength: Minimum 60,000 psi (415 MPa)

- Yield Strength: Minimum 35,000 psi (240 MPa)

- Elongation: Varies depending on the thickness and diameter of the pipe, typically exceeding 20% in most cases.

Application and Testing Standards

ASTM A53 Grade B pipes are used in industries including construction, piping systems, gas and oil transmission, and steam conduction. The pipes undergo rigorous testing to ensure compliance, such as:

- Hydrostatic Testing: Confirms the pipe’s ability to withstand specified pressures.

- Nondestructive Electric Testing: Used for welded pipes to verify the integrity of the weld seam.

- Bend and Flattening Tests: Confirm the pipe’s flexibility and structural integrity under stress.

These evaluations ensure reliable performance in high-pressure and high-temperature environments, making ASTM A53 Grade B a trusted material for critical operations.

Mechanical Properties of A53 Grade B

ASTM A53 Grade B pipes are always favored in industrial applications owing to its strong mechanical specifications. Some of its major mechanical properties are:

- Tensile Strength: A53 Grade B has a minimum tensile strength of 60,000 psi (415 MPa) and is thus able to resist large tensile forces without failing.

- Yield Strength: The minimum yield strength is held to be at 35,000 psi (240 MPa), giving sufficient resistance to deformation under substantial heat loads.

- Elongation: The elongation percent is dependent on the kind and size of pipe being tested, with usual values between 20 and 30%. This measure gives an indication of the ductility of the material, the capacity to lengthen without breaking.

- Hardness: ASTM A53 Grade B lies in moderate hardness, offering good machinability and sound structural integrity.

- Temperature Tolerance: This steel grade is suitable for functioning under different high- pressure and high-temperature conditions, making it suitable for tough environments.

These properties are helpful to the structural behavior of A53 Grade B pipe, bearing on performance-related aspects of being durable, adaptable, and reliable over time in a lot of applications, like construction, conveyance of liquid and gas, and energy systems.

Wall Thickness and Pipe Schedule

A53 Grade B pipe wall thickness is crucial for determining strength and its suitability for certain applications. Generally, pipe wall thickness is defined by a standard known as the “Schedule,” which correlates the pipe’s ability to withstand internal pressure. Common pipe schedules for A53 Grade B could be Schedule 40 and Schedule 80. Schedule 40 pipes are considered standard and typically see use in general applications, while Schedule 80 pipes with higher wall thickness are meant for high-pressure or more demanding conditions.

For instance, a nominal 4-inch A53 Grade B Schedule 40 pipe has a wall thickness of 0.237 inches. Meanwhile, the same nominal size with Schedule 80 has 0.337 inches in wall thickness, thus being more durable and capable of handling more pressure. Which schedule to opt for will depend on the actual condition of the service, including pressure, flow rates, and environment.

Awareness of pipe schedule and wall thickness is vital to safety and efficiency in an engineered and construction project. Proper schedule selection will ensure that the structure is built to perform adequately and will meet industry standard requirements wherever in industries such as Oil & Gas, Water Distribution, and Industrial Systems.

Applications of A53 Pipe

Due to strength, durability, and versatility, this pipe enjoys wide usage. Primarily, it is put to the following uses:

- Construction and Structural Support: It is among those structural elements that serve as frameworks, columns, and beams for buildings and infrastructure.

- Water and Gas Transport: Water, steam, air, and gas are transported through low-pressure systems.

- Industrial Works: It is used in various mechanical and machine-related applications such as conveyor belts and equipment supports.

- Plumbing and Piping Systems: Mostly for use in plumbing systems for residential, commercial, and industrial purposes.

These applications underline the adaptability of A53 pipe across a broad range of industries and environments.

Pressure Applications for A53 Steel

A53 steel pipes are found in many pressure applications because they provide durability, strength, and resistance to challenging conditions. These pipes are designed to take up low to medium-pressure duties from plants all over the industry. Being made of high-grade carbon steel, A53 pipes excel at the transportation of liquids and gases while retaining their structure under pressure.

Pipelines for A53 pipe applications in the oil and gas sector serve to transport substances such as crude oils, natural gas, and petroleum products. They also operate under great stress in systems subjected to pressures up to around 300 pounds per square inch (psi) (Class B and Class C types). Distribution of steam in factories also utilizes A53 steel pipes, which can withstand heat and pressure, other than safety, and efficiency.

These pipes also conform to ASTM standards for use in various pressure applications and may be supplied as seamless or welded depending on the requirement. Upon-required subjected to hydrostatic testing as demanded to achieve specific performance under specified pressure limitations. This makes them worth having if used in the Chemical Processing or Water Treatment Plants where pressure integrity is of utmost concern.

The versatility of A53 steel in pressure applications is at the very least an indication of well-engineered properties that allow the safe and efficient operation of many single systems in various industries.

Use of A53 Pipe in Various Industries

In all manner of industries, the A53 pipe is an essential component on account of its strength, great versatility, and long life. I consider its immense value to construction, where it is used for structural support, as well as to the energy sector for conveying oil, gas, and steam. Manufacturing processes for many products and water conveyance systems make good use of it, meaning it’s indispensable for routine applications as well as highly technical ones.

Galvanized A53 Pipe for Corrosion Resistance

Galvanized A53 pipe is specially treated for enhanced corrosion resistance, thereby lending itself ideally for use in harsh environments. The process of galvanization consists of coating a pipe with a layer of zinc by either hot-dip galvanizing or electro-galvanizing methods. Zinc provides that barrier momentarily against moisture, chemicals, and other corrosive factors that could so quickly reduce its lifespan.

The industry says galvanized pipes typically stay around for about 40-50 years in normal conditions, with durability significantly affected by factors such as saltwater presence or industrial contaminants. This long life makes it most favorite of pipes on constructions, transport, and industrial piping. The ability of these pipes to withstand friction and maintain their integrity in the absence of external air favors their use in construction and infrastructure development.

Galvanized A53 pipe maintains all the strength characteristics and versatility of the standard A53 pipe, thus simultaneously meeting the structural and functional requirements. When high-performance industries require a material with durability and cost-effectiveness, the galvanized A53 pipe is the best available material.

Comparison with Other Pipe Specifications

Having been compared with other pipe specifications, some specific considerations arise. Due to the zinc coating, galvanized A53 pipes are esteemed for corrosion resistance and thus find favor in all locations exposed to the outdoors or where a high degree of humidity exists. Black steel pipes usually do not have any protective coating; therefore, they were prone to rusting and degradation as time passed. On the other hand, the galvanized A53 pipes offer a cheaper route to a service life than stainless steel pipes but they do not offer the same amount of corrosion resistance to very corrosive environments as does stainless steel. In addition to contributing to such generally useful versatility, the A53 specification ensures assuredness in the structural and pressure-based application they are being tasked. Welded, the principal point for galvanized A53 pipe becomes performance balanced with cost, hence making this pipe ameliorative to many industries while strengthening the price rationale.

A106 Steel Pipe vs A53 Pipe

A106 pipes are seamless and designed for high-temperature and high-pressure applications, while A53 pipes can be seamless or welded and are used for low to medium pressure applications.

|

Key Point |

A106 Pipe |

A53 Pipe |

|---|---|---|

|

Type |

Seamless only |

Seamless or welded |

|

Application |

High temperature/pressure |

Low-medium pressure |

|

Material |

Carbon steel |

Carbon steel |

|

Heat Resistance |

Higher (contains silicon) |

Lower |

|

Usage |

Power plants, refineries |

Water, steam, air transport |

ASTM A500 and Its Differences from ASTM A53

ASTM A500 is for structural tubing, while ASTM A53 is for pressure and mechanical applications.

|

Key Point |

ASTM A500 |

ASTM A53 |

|---|---|---|

|

Application |

Structural tubing |

Pressure/mechanical piping |

|

Material |

Carbon steel |

Carbon steel |

|

Shape |

Square, rectangular, round |

Round |

|

Welding |

Not for fluid transport |

Suitable for fluid transport |

|

Coating |

No galvanization required |

Often galvanized |

When to Use A53 vs. A106

Deciding between A53 and A106 steel pipes depends on several factors, including the specific application, temperature conditions, and the required mechanical properties. Both A53 and A106 pipes are produced to ASTM specifications, but they serve different purposes and perform optimally under distinct conditions.

1. Temperature and Pressure Tolerances

A106 pipes are specifically designed for high-temperature and high-pressure applications. They are seamless pipes, making them ideal for transferring fluids and gases under extreme conditions, such as in power plants, oil refineries, and chemical processing plants. On the other hand, A53 pipes, while capable of handling moderate pressure and temperature, are generally used for low to medium-pressure applications, such as plumbing, water distribution, and structural uses.

2. Manufacturing Process and Grades

ASTM A53 pipes are available in both seamless and welded forms, offering Grades A and B. Grade B is particularly common due to its superior strength. Comparatively, A106 pipes are exclusively seamless and available in Grades A, B, and C, with Grade C offering the highest tensile strength. The manufacturing focus of A106 on seamless pipes ensures a more uniform structure, making it a preferred choice for critical industries.

3. Chemical Composition and Mechanical Properties

The chemical composition of A106 allows for superior performance in extreme temperatures, as it includes higher concentrations of manganese and silicon. This provides better flexibility and durability compared to A53 pipes. A53 pipes, while versatile, do not have the same level of elemental refinement, which impacts their use in extreme conditions. Key mechanical properties such as tensile strength and yield strength are generally higher in A106 pipes, especially in Grade C.

4. Common Applications

- A53 Pipe: Great for structural purposes, low-pressure systems, and general transportation of water, air, or steam.

- A106 Pipe: Best suited for high-temperature fluid transfer, industrial boilers, and superheaters.

5. Cost Considerations

A53 pipes are often more cost-effective for general-purpose uses, while A106 pipes, designed for demanding applications, are priced higher due to their manufacturing complexity and material excellence.

Understanding the specific requirements of your project is essential in choosing between A53 and A106 pipes. While A53 fulfills a wide range of standard applications, A106 is the go-to option for performance under extreme operating conditions. This distinction ensures that each pipe type delivers optimal reliability and cost-efficiency in its intended use.

Reference Sources

- The effect of thermomechanical treatment on residual stress level of A53 steel pipe

- Authors: R. D. Ramdan et al.

- Publication Year: 2020

- Summary: This study investigates how thermomechanical treatment affects the residual stress levels in A53 steel pipes. The research highlights the importance of controlling residual stresses to enhance the mechanical properties and longevity of steel pipes used in various applications.

- Methodology: The authors employed experimental techniques to analyze the residual stress levels before and after the thermomechanical treatment, providing insights into the treatment’s effectiveness(Ramdan et al., 2020).

- Analysis of Temperature Variations, Types of Insulation and Coating on Corrosion Under Insulation on ASTM A53 Pipes

- Authors: Reza Putra et al.

- Publication Date: 2021-11-26

- Summary: This paper examines the impact of temperature variations and different types of insulation and coatings on the corrosion rates of ASTM A53 pipes, particularly in marine environments. The findings indicate that the type of insulation and temperature significantly influence corrosion rates, with specific coatings providing better protection.

- Methodology: The study utilized a series of experiments involving varying temperatures and insulation types, measuring corrosion rates using the ASTM G31-72 weight loss method(Putra et al., 2021).

- Effect of Flow Rate and Temperature on Erosion Corrosion Rate of Crude Palm Oil Against Elbow A53 Grade B Carbon Steel Material

- Authors: B. Prasojo et al.

- Publication Date: 2019-01-08

- Summary: This research focuses on how flow rate and temperature affect the erosion-corrosion rates of A53 Grade B carbon steel when transporting crude palm oil. The results show that higher flow rates and temperatures lead to increased erosion-corrosion rates, which is critical for pipeline integrity.

- Methodology: The authors conducted experiments with varying flow rates and temperatures, measuring the erosion-corrosion rates using established standards(Prasojo et al., 2019).

Frequently Asked Questions (FAQs)

What is an A53 Pipe?

An A53 pipe is a type of steel pipe that is commonly used in various industrial applications. It is manufactured according to the ASTM A53 specification, which covers both welded and seamless steel pipes. This specification outlines the requirements for the materials, design, and manufacturing processes to ensure the pipe meets the necessary mechanical properties and pressure applications.

What are the different types of A53 Pipes?

The A53 pipes are available in various types, including seamless and welded options. Seamless A53 steel pipes are produced without a seam, providing greater strength and durability, while welded A53 pipes are created by welding together steel plates. Both types are suitable for various applications, including mechanical and pressure uses.

What is the difference between ASTM A53 and ASTM A106 Pipes?

The primary difference between ASTM A53 and ASTM A106 pipes lies in their intended uses and chemical compositions. A53 pipe is primarily used for low-pressure applications, while A106 pipe is designed for higher temperature and pressure applications. Both have varying grades, including Grade B, which is common for both types, but A106 is typically made from carbon steel alloy, providing enhanced strength for demanding applications.

What is the nominal wall thickness of A53 Grade B Pipe?

The nominal wall thickness of A53 Grade B pipe varies depending on the pipe size and schedule. For instance, Schedule 40 and Schedule 80 A53 pipes have different wall thicknesses, with Schedule 80 offering a thicker wall for increased pressure resistance. It is essential to select the appropriate schedule based on the specific application requirements.

Is A53 Pipe suitable for welding?

Yes, A53 pipe is suitable for welding, especially the welded version that is manufactured to meet the ASTM A53 standard. The weld seams are designed to withstand pressure applications, making them ideal for construction and industrial projects where structural integrity is crucial.

What are the mechanical properties of A53 Steel Pipe?

The mechanical properties of A53 steel pipe include tensile strength, yield strength, and elongation, which vary based on the grade. For A53 Grade B, the minimum yield strength is 35,000 psi, while the minimum tensile strength is 60,000 psi. These properties ensure the pipe can handle various mechanical and pressure applications effectively.

How is A53 Pipe Galvanized?

A53 pipe can be hot-dipped galvanized to enhance its corrosion resistance. The process involves immersing the steel pipe in molten zinc, creating a protective coating that significantly extends the lifespan of the pipe, especially in outdoor and high-moisture environments. Hot-dipped galvanized A53 pipes are widely used in construction and plumbing.

What applications are suitable for A53 Seamless Steel Pipe?

A53 seamless steel pipe is suitable for various applications, including ordinary uses in steam, water, gas, and air. Its ability to withstand high pressure and mechanical stress makes it ideal for use in construction, manufacturing, and transportation industries. The seamless nature of the pipe also provides a consistent wall thickness, enhancing its overall strength.

What is the significance of the ASTM A53 Standard?

The ASTM A53 standard is crucial as it establishes the specifications for carbon steel pipes used in various applications. It outlines the manufacturing processes, chemical compositions, mechanical properties, and testing methods required to ensure the quality and reliability of A53 pipes. Adhering to this standard ensures that the pipes meet industry requirements and can be safely used in construction and industrial settings.